Typically, the operation of a gas water heater is accompanied by sounds associated with the burning of a flame and the flow of water inside the device. However, sometimes the user may hear whistling, popping, or other extraneous noise from the equipment. To understand why a water heater can whistle and make noise, you must first learn about the design of this type of water heater, as well as the operating features of gas water heaters.

If, when you turn on the column, you hear a pop, this is a sign of problems with the gas supply.

Each device has a working area in which gas accumulates when the equipment is turned on, as well as its gradual connection with air.

If the volume of accumulated gas and air corresponds to the manufacturer’s calculations, there will be no pops. If gas and air accumulate in excess, it causes a small volumetric explosion.

It not only causes a loud popping sound, but can also damage the chimney, so this situation should be corrected immediately.

The author of the following video offers his solution to this problem. After watching his video, you can independently get rid of the cotton when you turn on the gas water heater.

The cause of noise when heating water is insufficient draft. Therefore, in noisy equipment, it is the first thing to check.

A lit match or lighter is brought to the control holes or a special hatch in the upper part of the column. If the flame deviates towards the device, the draft is sufficient.

Otherwise, care should be taken to clean the chimney duct.

Also, noise can be caused by insufficient air flow into the room, for example, if plastic windows are installed in the kitchen. The seals in such windows interfere with the natural ventilation of the room. In this case, to eliminate noise, you should simply control the air flow.

Another reason the column is too noisy is that the pilot burner wick is dirty. And then to eliminate the noise, it is enough to clean the jets. A similar situation is possible if the jets in the main burner are clogged, then after cleaning it, the hum during operation of the column disappears.

In modern speakers that are turned on using electric ignition, the cause of noise during operation may be as follows:

- Discharged batteries. As a result, the gas-air mixture is difficult to ignite. In such a situation, the batteries need to be replaced.

- Damage to the sensor that controls the water supply. Often its malfunction is caused by oxidation of the contact group. Usually this sensor is not removable, so it is replaced.

- A spark plug malfunction prevents an electric spark from being produced. Most often, it shifts after many heating-cooling cycles. By returning the spark plug to its nominal position, you will restore the possibility of spark formation and eliminate extraneous noise.

- Problem with mechanical ignition retarder. Its presence can be determined after dismantling the assembly and shaking it - normally you should hear the noise of the ball moving inside the moderator. If there is no sound, this indicates that the ball is moving. You can return it to its place using a soft wire.

If a monotonous loud whistle is coming from your equipment, you should first determine where it is coming from. To do this, turn off the gas tap, and then open the hot water tap. Further actions depend on the resumption or absence of “trills”:

- If a whistle appears, its occurrence is associated with the water path. The most common reason for this sound is scale deposits in the heat exchanger or a foreign object getting inside the pipe. At the same time, the performance of the column decreases. In this case, to get rid of the whistling, you need to clean the heat exchanger from scale, and the reverse flow will help wash out the foreign object from the column.

- If there is no whistling sound, the cause of its occurrence was problems in the gas path. Most often they are associated with a defect in the valve that modulates the flame power. Then the whistle appears only at a certain power, and to eliminate it, you need to adjust the power in any direction. Another common cause is a clogged tract. Whistling sounds appear at any power. To identify the location of contamination, you will have to carry out extraordinary cleaning, which is best entrusted to a specialist who works with gas equipment.

After watching the following video, you will be able to clean the heat exchanger from scale yourself, without contacting a professional.

The speaker whistles

Typically, the operation of a gas water heater is accompanied by sounds associated with the burning of a flame and the flow of water inside the device.

However, sometimes the user may hear whistling, popping, or other extraneous noise from the equipment. To understand why a water heater can whistle and make noise, you must first learn about the design of this type of water heater, as well as the operating features of gas water heaters. If, when you turn on the column, you hear a pop, this is a sign of problems with the gas supply. Each device has a working area in which gas accumulates when the equipment is turned on, as well as its gradual connection with air. If the volume of accumulated gas and air corresponds to the manufacturer’s calculations, there will be no pops. If gas and air accumulate in excess, it causes a small volumetric explosion.

The author of the following video offers his solution to this problem. After watching his video, you can independently get rid of the cotton when you turn on the gas water heater.

The cause of noise when heating water is insufficient draft. Therefore, in noisy equipment, it is the first thing to check. A lit match or lighter is brought to the control holes or a special hatch in the upper part of the column. If the flame deviates towards the device, the draft is sufficient. Otherwise, care should be taken to clean the chimney duct.

Also, noise can be caused by insufficient air flow into the room, for example, if plastic windows are installed in the kitchen. The seals in such windows interfere with the natural ventilation of the room. In this case, to eliminate noise, you should simply control the air flow.

Another reason the column is too noisy is that the pilot burner wick is dirty. And then to eliminate the noise, it is enough to clean the jets. A similar situation is possible if the jets in the main burner are clogged, then after cleaning it, the hum during operation of the column disappears.

In modern speakers that are turned on using electric ignition, the cause of noise during operation may be as follows:

- Discharged batteries. As a result, the gas-air mixture is difficult to ignite. In such a situation, the batteries need to be replaced.

- Damage to the sensor that controls the water supply. Often its malfunction is caused by oxidation of the contact group. Usually this sensor is not removable, so it is replaced.

- A spark plug malfunction prevents an electric spark from being produced. Most often, it shifts after many heating-cooling cycles. By returning the spark plug to its nominal position, you will restore the possibility of spark formation and eliminate extraneous noise.

- Problem with mechanical ignition retarder. Its presence can be determined after dismantling the assembly and shaking it - normally you should hear the noise of the ball moving inside the moderator. If there is no sound, this indicates that the ball is moving. You can return it to its place using a soft wire.

If a monotonous loud whistle is coming from your equipment, you should first determine where it is coming from. To do this, turn off the gas tap, and then open the hot water tap. Further actions depend on the resumption or absence of “trills”:

- If a whistle appears, its occurrence is associated with the water path. The most common reason for this sound is scale deposits in the heat exchanger or a foreign object getting inside the pipe. At the same time, the performance of the column decreases. In this case, to get rid of the whistling, you need to clean the heat exchanger from scale, and the reverse flow will help wash out the foreign object from the column.

- If there is no whistling sound, the cause of its occurrence was problems in the gas path. Most often they are associated with a defect in the valve that modulates the flame power. Then the whistle appears only at a certain power, and to eliminate it, you need to adjust the power in any direction. Another common cause is a clogged tract. Whistling sounds appear at any power. To identify the location of contamination, you will have to carry out extraordinary cleaning, which is best entrusted to a specialist who works with gas equipment.

After watching the following video, you will be able to clean the heat exchanger from scale yourself, without contacting a professional.

Is the gas water heater noisy? It is necessary to find out the reasons: they depend on whether the equipment is new or has been in operation for several years. To find out why the speaker hums, hisses or buzzes, let’s look at its structure and operating features.

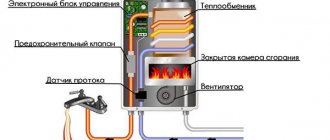

The column or flow heater, as it is called, is a metal box (casing). Two pipes are connected to it for supplying water and gas. The main design elements are:

- Radiator (water flows through it).

- Main and pilot burners (serve to heat the liquid in the radiator).

When the user opens the faucet, the valve opens and allows gas to flow into the burner. It lights up and the gas heats the heat exchanger. Combustion products are removed through the chimney and ventilation.

Hello, dear readers. Why does the gas water heater whistle? This question is very relevant for owners of this equipment. All such devices make certain noises. But when the whistling becomes strong and constant, you need to take action.

This article discusses the causes of whistling in geysers. The most common reasons are reflected, and those that are typical for models of certain brands, in particular “Neva” and “Bosch”. Methods for eliminating these problems are proposed.

The device can seriously whistle when you turn on hot water. When turned on in this way, the speaker may make noise with a gradual development of noise. Or he might immediately whistle very loudly and obnoxiously.

Why does the gas water heater whistle when you turn on the hot water? How to eliminate this complexity?

The gas is shut off. The hot water tap opens. The equipment should no longer whistle if this is a mild case. If the noise continues, inspect the plumbing. Potential causes also include:

- Blockages in the maintenance or water regulator.

- Rust on important components.

- Scale on the coil.

There may be a whistle in the column even after turning off the gas. Why is this happening? The answer is that some component of the gas control valve has broken down.

If the model is automatic, then in such a situation the whistle indicates scale in the maintenance system and a breakdown of the gas valve. The pipes should be cleaned.

If you hear a pop when you turn it on, this indicates a problem with the gas supply. Each device has a working area in which fuel accumulates when the equipment is turned on, as well as its connection to air. If the volume of accumulated gas coincides with the manufacturer’s calculations, then there will be no extraneous pops.

And if gas and air accumulate in excess, this leads to a small explosion accompanied by a loud bang. This action not only produces an unpleasant loud sound, but also increases the risk of damaging the chimney. You can solve the problem by calling a technician to your home or by yourself if you understand the design of the device. You can fix a geyser with your own hands like this:

- turn off water and gas;

- remove the body;

- inspect the gas pipeline approaching the burner;

- if necessary, clean parts from soot and soot;

- inspect the condition of the injectors; if there is contamination, clean the elements.

If the gas water heater is noisy, then most likely the reason is:

- poor traction;

- lack of ventilation;

- wick contamination.

The cause of noise when heating water is often a lack of draft. Therefore, if the gas water heater makes noise during operation, first of all check the presence of draft in the chimney. This can be easily determined by using a lit match or lighter, which is brought to the inspection hole of the chimney or its hatch:

- if the flame is drawn into the chimney, then there is draft;

- if the fire does not move, there is no draft.

READ MORE: Varieties of gas taps, main characteristics and features of choice

If there is no draft, the chimney should be cleaned. During operation, it becomes clogged with soot and debris.

The gas water heater is leaking - causes and ways to eliminate them

Read here Geyser does not work - what to do

Lack of air in the room can cause noise. Most often this happens if the owners replaced the old frames with plastic ones. Their seals interfere with natural ventilation in the room. In this case, to stop the noise, it is necessary to increase the air flow.

Another common cause of excessive noise is a clogged pilot wick. In this case, to eliminate the sounds, it is enough to simply clean the jets in the main burner device. Then the hum problem will be solved.

If a gas water heater whistles, you should immediately figure out which unit the noise is coming from. To check this, turn off the gas tap, and then unscrew the hot water tap. Subsequent actions depend on the nature of the noise:

- If after the above steps a whistle appears, then it is associated with the water path. The most common cause is scale deposits in the heat exchanger or a foreign object getting inside the pipe. As a result, the performance of the device decreases. In this case, cleaning or washing the object out of the pipes using reverse flow will help eliminate noise and increase the performance of the column.

- If the dispenser begins to operate quietly, it means that one of the gas supply units has failed. This is mainly due to a defect in the valve that regulates the power of the fire. A sign of problems with the valve will be a change in sound when adjusting the flame intensity. The problem may also be hidden in a clogged tract. The whistle is then audible in any case. It is recommended to call a specialist to identify the location of the blockage.

There are several reasons for the attenuation. To determine the malfunction, you need to pay attention to the duration and intensity of the flame. The following signs will help identify the cause of malfunctions:

- The column and wick light up and immediately go out - after repeated starts, the water heater does not start. Cause of failure: failed servomotor or solenoid valve. Cleaning the burner and jets will not help. The malfunction can only be eliminated by replacing broken components.

- The burner turns off after a few seconds of operation, when turned on again the flame burns longer, after 5-6 starts the column starts working normally - the reason: a malfunction of the ignition system, more precisely the flame ionization sensor or overheating relay. To eliminate the malfunction, change the module or move it closer to the flame.

What to do?

The first thing experts recommend doing is checking the presence and strength of draft in the chimney. Most instantaneous water heaters have a casing in which there are holes designed specifically for these purposes. If you are unable to find such holes, try checking the draft near the gap, which is located under the smoke hood. You can also feel the draft directly in the chimney at the cleaning hatch.

Traction is usually checked using a lit match. If the flame deviates well to the side, then the draft is normal, if it only trembles, it is weak. A stationary flame means a lack of draft - in this case, you should never operate a gas water heater.

New type of speakers with automatic ignition

Instantaneous gas water heaters equipped with an automatic ignition system are much more economical in terms of gas consumption. They operate under the control of an electronic module, which receives commands through microswitches located on the water and flame regulators. Such devices are considered very reliable, but they also have disadvantages, for example, expensive and complex repairs.

So, what should you do if you hear a pop of gas?

- Check the condition of the power supplies. A “bad” spark, resulting in the gas not igniting immediately, may be a consequence of a low battery charge level. This problem can be fixed very easily and does not require the intervention of a technician.

- Check the water pressure microregulator. This device is designed to inform the control module that water is being supplied and the gas needs to be ignited. The microregulator may break down and give incorrect signals if water gets on it. You can diagnose such a malfunction using a multimeter or ohmmeter. If the device readings do not meet the standards, it means that the microregulator is broken and should be replaced.

- Check the position of the spark plug. This part may become deformed when exposed to high temperatures or due to temperature changes. Correcting its position is quite simple since it is secured to a single screw. This screw needs to be loosened a little and the spark plug installed so that the spark gap is approximately 0.4-0.5 cm. In this case, ignition should occur on the first try.

- Check the condition of the ignition retarder. Gas can accumulate because the valve that slows down the flow of water is broken or poorly adjusted. The part in question is a small metal ball that partially covers the bypass channel in the water pressure regulator. In good condition, the ignition retarder should move freely (this can be checked by ear by shaking the cover). If this does not happen, you can try to set the ball in motion by hooking it with a flexible cable passed through a hole in the channel. If the moderator does not respond, you can try to remove it and clean the channel, but this is recommended only as a last resort.

- After any repair, all connections should be checked for leaks, and if necessary, seal them using rubber rings or special sealing compounds.

The cost of a micropressure regulator varies on average from 50 to 200 rubles.

Old type columns with ignition wick

Old-style instantaneous gas heaters “pop” quite often. This is due to the peculiarity of their design. They are considered less safe and convenient than new gas burners, but they are much easier (and cheaper) to repair.

The most common reason for the accumulation of gas in the cavities of water heaters of this type is the incorrect position of the wick for the igniter. In this case, the flame becomes too small to reach the edge of the main burner - most often this happens because there is not enough gas supplied to the wick. Gas supply may be difficult because the gas nozzle is clogged.

Variety of geysers used

The operating principle of speakers from different manufacturers does not differ significantly. Specifications vary.

By what indicators do the models differ:

- Performance;

- Type of burner;

- Degree of security;

- Ignition method;

- Flue gas removal method.

Classification by ignition type:

- Manual. Found on older models. Most modern manufacturers prefer not to use this type of ignition. To turn it on, you need to light the burner yourself with a match.

- Piezo ignition. To turn on the heater, just press a button. Within a few seconds the water from the tap will be hot.

- Electronic ignition. Allows you to save gas, as the automation turns off and turns on its supply.

Based on the type of burners installed, there are two types of heaters. At constant power, manual temperature adjustment is required. With a variable, automatic adjustment occurs. Modulating burners supply water at a uniform temperature.

Speaker power is one of the main selection criteria. Minimum value -16-19 kW. Maximum – 28-32 kW. A heater with low power will heat up to 10 liters of water per minute. This is not enough for a large family. You can only wash the dishes. Average indicators increase the volume to 20.

In order not to encounter the fact that there is no water pressure in the gas water heater, you should choose trusted manufacturers. The German and Italian companies have gained trust in the market. But there are domestic popular brands. The Neva geyser combines proven quality and an affordable price.

Why does the speaker go out after turning it on?

The automatic column works as follows:

- a gearbox is used as a trigger, internally divided into two parts by a membrane;

- the first section is connected to the hot water supply - after filling the block, water enters the coil located above the burner device;

- in the second part there is a rod that opens the gas supply;

- water entering the gearbox presses on the rubber gasket;

- the membrane presses on the rod and opens the flow of gas.

When switching to a shower, the pressure in the DHW decreases. When the water pressure is low, the column turns off. Installing a special pump that stabilizes the pressure in the water supply pipeline will help solve the problem. You can additionally check the condition of the mixer. The burner may turn off due to debris accumulation in the shower head.

Another common problem. The cause of the malfunction is the low quality of water entering the column and the resulting disturbances:

- The rod in the water unit (gearbox) gets stuck - the reason: the appearance of rust, as well as the weakening of the spring that returns the device to its original position after turning off the water. If the geyser does not go out after turning off the water, within just a few minutes the liquid will reach the boiling point and rupture the heat exchanger tubes.

- Damage to control valves - the water heater has a valve that opens the gas supply to the burner. The unit turns on and off simultaneously with the opening/closing of the water tap. After the valve fails, gas is supplied to the burner continuously. When the hot water tap is closed, the regulator does not operate. It is necessary to completely shut off the gas supply and call a technician.

If the gas water heater does not go out when the water is turned off, you should not try to repair it yourself. The breakdown requires a qualified technician to fix it.

If the gas water heater whistles after turning off the water, then this is a sign of a breakdown of the water controller.

A rod with legs is located inside the block. It is connected to the ignition mechanism. After turning off the water supply, a special spring should perform its function - it returns the working rod to its original position. If there is rust on the rod, it will jam. The ignition system does not turn off and generates a spark.

The operation of a gas water heater is always accompanied by certain sounds. Usually this is the sound of water running through pipes or the burning of a fire. But it happens that the device begins to make non-standard sounds: whistling, popping, clicking, etc. If this starts to happen, you need to quickly figure out why the gas water heater is making noise. The reasons may be different.

The freezer is noisy: is it a malfunction or normal?

Note that there is currently a trend towards reducing noise levels in household devices. Manufacturers are coming up with new technological solutions. Meanwhile, today there are no completely silent models. The noise level is indicated in decibels in the operating instructions.

If the equipment is noisy, but no additional signs are observed: water does not flow out, there is no burning smell, the display shows the operating temperature, no alarm signals or error codes are received, most likely, there is no need to worry!

All sounds are natural. Thus, crackling sounds are produced by elements of the cooling circuit.

Motor-compressors for refrigeration and freezer compartments

When the motor-compressor is turned on, the freezer starts and the thermostat clicks. A similar thing happens when you turn it off: a click and the motor stops humming.

Possible causes of low pressure

Due to the very principle of operation of the equipment, you can hear a slight noise, it crackles. Sounds may be amplified if the room is not well ventilated. There's nothing wrong with that.

Does the appliance make sounds when turning on hot water or heating? When drawing water, you may feel vibration because the flow passes through the pipes, turns, and passes through obstacles. To reduce the noise level, you can adjust the water handle. While scrolling it, listen: as soon as the sound vibrations decrease, leave it in this position.

Do you start the equipment and hear a pop? Does the device jerk and vibrate? This means there are problems with the gas supply. When starting, fuel accumulates in the working part: when the amount of air or gas corresponds to the norm, no popping noises should be heard.

Such problems can even lead to the failure of the chimney. Therefore, contact a service center or try to fix them yourself.

- Turn off the gas and water supplies.

- Remove the equipment casing: pull the handle towards you, unscrew the two screws.

- Inspect the fuel supply system and burner. Clean the parts from dirt. How to clean a gas water heater, read the previous article.

- Unscrew the two burner tongue screws.

- Inspect the condition of the nozzle. If it is clogged, clean it.

The main reason is poor traction. To test it, light a match and hold it near the hole. If the flame deviates to the side, as if from an air flow, the draft is fine. If not, the chimney channel is clogged with soot and carbon deposits, which are produced during the combustion process. Need to clean it up.

Poor ventilation also contributes to increased noise. This often happens after installing plastic windows. The bags are so sealed that natural ventilation becomes impossible.

What to do if the device cracks? This is possible when the burner nozzle (nozzle) is clogged. You need to disassemble them as described above and clean them.

READ MORE: Finding an answer to the question - what to do if the toilet cistern sweats?

If your column is turned on by electric ignition, the reasons may be:

- Such devices operate on batteries. When they are discharged, the fuel ignites poorly or does not ignite at all. Clicking sounds may be heard. In this case, replace the batteries.

- The flow control sensor is faulty. Most often, its contacts oxidize under the influence of moisture. You can try to clean the contacts, but it is better to replace the sensor.

- The spark does not ignite. The candle that is responsible for the fire has moved, so the process does not complete. Reinstall the spark plug and resume the process.

- The ignition retarder does not work. Remove the part and shake. In this case, you should hear the noise of the ball rolling in the housing. If you don't hear anything, the ball is stuck or dislodged. Put it back in place with wire.

Is the new equipment rattling? Perhaps the reason is not the boiler, but an installation error. To find out, inspect all connections to ensure they are connected correctly. It could also be:

- Depressurization of the air duct. Air enters not only through the main hole, but also through the hole. Therefore the noise increases.

- Incorrect burner placement. Perhaps it has shifted and cannot cope with burning the entire volume of gas. You need to install it in place.

If the product whistles and squeaks, you need to find out where the sound is coming from. What to do:

- Turn off the gas supply.

- Open the mixer in the “hot” position.

- Did the whistling intensify? This means that the problems lie in the water path. The main reason is scale deposits on the heat exchanger parts or pipes, or blockage. It is necessary to clean all the elements in order to restore the performance of the equipment and eliminate the cause of the whistling. Using a reverse flow of water can clear clogged pipes.

- If the whistling sound disappears when you open the tap, the problem is in the gas path. There is probably a defect in the valve that controls the flame intensity. Whistling may appear when the operating power is increased. Try turning the control until the sound goes away. Does not help? Then the problem is that the tract is clogged. The device needs to be disassembled and cleaned.

If you notice similar problems in your equipment, you can try to solve the problems yourself. But it is better to contact a service center, especially with a valid warranty card. Employees will repair or remove faulty equipment.

The causes of noise in a gas water heater equipped with electric ignition may be the following:

- The batteries are discharged - in this case, the ignition does not work well and the gas-air mixture is difficult to ignite. This problem can be easily solved by replacing the batteries.

- The sensor that controls the water supply is broken. Often problems are associated with the oxidation process of contacts. Basically, this sensor is not collapsible, so you have to replace the element with a new one.

- Problems with the mechanical ignition retarder. The presence of problems in this unit is determined by removing it and shaking it. During this procedure, the noise of the ball moving inside the retarder will be heard. If there is no sound, this indicates the ball has moved. You can fix the problem and return the ball to its place using a thin wire.

- A spark plug malfunction prevents an electric spark from appearing. It mainly moves after repeated heating and cooling processes. It is necessary to return the spark plug to its place, after which the possibility of a spark will be restored and the extraneous noise will go away.

Sometimes the cause of noise in a working geyser is not a breakdown, but loose communication connections or a poorly secured element. Therefore, if extraneous sounds appear, it is worth checking the tightness of the parts and pipeline connections. You can also see if anything has gotten into the device body. Perhaps after the last disassembly they forgot a bolt, electrical tape or other item.

When noise appears in a gas water heater, it is important to determine the cause and solve it as quickly as possible. A hum is the first sign of a problem with the device. If the problem is not corrected in time, it will gradually lead to more serious consequences. As a result, you will have to buy a new gas water heater instead of small repair costs.

To figure out why there is no pressure in the gas water heater, you should determine the main possible causes of the problem. And also the factors that influence it.

Factors:

- Speaker power. Without it, good pressure cannot be achieved. The problem occurs if the indicator is less than 8 kV. It must be from 10 kV.

- Blockages. If scale and other substances accumulate in the pipes, water does not flow. Therefore, filters should be checked.

- Scale formation. It can collect in the heat exchanger and go into tubes. If water with detached pieces gets into them, a blockage occurs.

- Past technical work and neglect of pollution prevention.

Causes:

- Weak pressure of hot water in the tap appears due to the fact that the filter is clogged. To solve the problem, remove it from the heat exchanger inlet and brush it with a brush under water pressure. If damaged, be sure to replace it.

- Scale has formed. You can use proven home remedies to get rid of dirt that will not damage the material. The most popular and effective is citric acid. If hot water flows poorly, it is not necessary to use aggressive special cleaning liquids.

- There is a blockage. Water does not flow well into the pipe. To eliminate this, a reverse flow of cold water is started.

- Problem with the mixer. Small debris can get in there. To solve it, it is recommended to check the filter and rubber hose. And then check how hot water flows from the tap.

| Problem | Possible solutions |

| The house (apartment) uses a low-power (low-performance) water heater | Buy a more powerful model |

| Use only one hot tap at a time | |

| Filter clogged | Remove the mesh located in front of the heat exchanger and rinse it with water to remove rust and lime deposits. |

| If damaged, replace the filter | |

| Presence of scale coming from the heat exchanger in the tubes | This problem can be solved by supplying cold water in the opposite direction or by replacing the clogged area |

| Scale on the walls of the heat exchanger is removed using citric acid dissolved in water | |

| Faucet problems | The mixer is disassembled and the blockage is removed, with replacement being a last resort |

Each of the problems is worth considering in more detail.

Filter clogged

The insides of the water heater gradually become dirty due to the operating principle of the device. Soot and deposits accumulate due to heating with gas. Due to poor water quality, the filter becomes clogged. It slows down the scale formation process by about 50-60%. However, it gradually becomes clogged, becomes unusable and even breaks.

How to return water pressure from a gas water heater if the problem is in the filter:

- Use a stiff brush to remove anything that has clogged the holes. These are salt deposits, small pipe debris.

- Rinse it with water under pressure. Then place in a separate small container.

- Fill with filter cleaner.

- Leave for half an hour. During this time, all deposits will move away from the walls.

- Rinse under running water to get water everywhere.

If the column is clogged, preventive measures should be reviewed.

If the pressure is very weak and the filter gets clogged often, you need to follow the rules:

- It is recommended to make the water soft.

- Regularly inspect the condition of the parts of the column and clean them, even if the pressure has not dropped.

Scale in the heat exchanger of a gas boiler should not be cleaned mechanically. There is a risk of damaging the surface of the coil from the inside. Because of this, a layer of plaque will appear again.

READ MORE: Why the gas pipe in the apartment vibrates and hums, causes of noise and ways to eliminate it

What products are used for processing:

- Household chemicals and substitute materials at hand. Citric acid is popular. A similar result can be obtained by using vinegar diluted to 7%. After cleaning, the pipes are washed with a soapy water solution.

- Calcium deposits will be removed by Silit and other similar products.

What to do to prevent scale from forming:

- Install a deep-cleaning main filter for the cold water supply and poor water pressure will not often bother you.

- Purchase a water filter to reduce water hardness. It changes the chemical composition of the liquid. Reduces the amount of scale by 40-60% and the cold water pressure does not decrease.

- Install a magnetic filter. It retains calcium salts.

Why is the circulation pump noisy in the heating system? Troubleshooting

Choosing the right circulation pump will help prevent annoying noises. The store offers units with two types of motors:

Dry. Devices of this type cope with high loads. The rotor remains dry. Cooling occurs using a fan, which will make noise.

Photo 1. Circulation pump for heating systems from the manufacturer Wilo. There is a fan at the back to cool the device.

Wet. The pump is located directly in the water. The unit is protected from overheating by a virtually silent coolant.

Attention! Dry type devices will create discomfort due to the sounds of the operating fan. For domestic needs, wet pumps are used. They are installed directly indoors

They are installed directly indoors.

Extraneous hum, noise or grinding of the device can be associated with some system malfunctions. The most common problems:

- Unstable voltage.

- Poor quality installation.

- Air lock in the system.

- Power and parameters mismatch.

- Equipment malfunction.

Unstable voltage

When voltage drops, the pump operates unevenly. Lack of synchronization leads to intermittent circulation of water in the system, and extraneous sounds occur inside radiators or pipes.

To determine the cause of the noise, diagnostics are carried out to identify malfunctions of the device. This procedure requires the involvement of a specialist with additional equipment.

Noise due to installation error

The rustling sound occurs due to increased cavitation loads. The problem can be avoided by installing a hydraulic compensator: a membrane tank that helps regulate static pressure when heating. This device draws excess moisture from the system and prevents water hammer. A correctly installed hydraulic compensator will significantly extend the life of the pump.

The pump whistles due to air locks

Whistling sounds that occur when heating is started are often caused by air pockets. Air enters the system when pipes and radiators are filled with water.

What to do if the pump suddenly starts whistling? To eliminate the problem, the design includes Mayevsky taps - special holes, closed with a screw plug, located in the upper parts of the radiator.

Photo 2. Mayevsky tap on a heating radiator. Allows you to bleed excess air from the heating system.

Open the device with the pump turned off using a screwdriver or wrench.

Reference. Installing automatic air vents will help eliminate air jams in a timely manner.

Mismatch between parameters and power

Noise when the heating is turned on is sometimes caused by the installation of an unreasonably powerful pump. The technical characteristics of the unit specified in the instructions must necessarily correspond to the design parameters of the entire system. The pump becomes one of the final acquisitions when the length of the pipes and the number of radiators are precisely known. The overall performance of the device at maximum load is calculated relative to low outdoor temperatures in the winter.

The device hums and crackles due to equipment failure

Common problems with a circular pump include a defective rotor or impeller. In addition to constant noise, this problem leads to deterioration in system productivity.

The hum is a consequence of technological gaps that have increased over time and shaft vibration. Repairing and replacing the shims will solve the problem.

Burnt motor windings can crack. It is better to entrust the correction of this defect to a specialist.

Water doesn't heat up

Weak pressure of hot water from a gas water heater is not the only problem that water heater owners face. The device may not heat up at all, resulting in cold liquid.

Why is there no hot water coming from the gas water heater:

- Dirty deposits have accumulated on the outside of the heat exchanger.

- The flame is not strong enough to heat. The problem of insufficient gas pressure will have to be corrected. Perhaps clean the parts.

- The heat exchanger is overheating. This violation leads to the appearance of a layer of scale. The normal operation of the device is disrupted. Cold liquid flows.

- The pressure level in gas pipes is low. This is a reason to contact the gas service.

- Lack of constant maintenance and pollution prevention. It leads not only to heating failure, but also to poor water pressure from the water heater.

What to do if cold water flows:

- Turn the regulator all the way to the right. Close the tap halfway. This will slow down the water movement and improve heating.

- Check gas pressure. Only a specialist can do this.

- See how the mixer works. It can add cold water to heated water.

- Determine if the filter or faucet is clogged.

Responsibility for unauthorized replacement

It should be remembered that replacing a boiler, water heater and other gas appliances in an apartment in a multi-storey building or in the private sector should only be carried out by qualified employees who have official permission to perform work with gas and gas equipment. You can also contact specialists from the state gas service. Self-repair or connection of equipment is not prohibited by law, but it is necessary to understand the full responsibility of such actions.

If you independently interfere with the gas supply system and tap into it without permission from the gas service, you will bear full responsibility in accordance with Federal Law No. 229-FZ adopted in 2021 “On amendments to Article 215.3 of the Criminal Procedure Code of the Russian Federation and Articles 150 and 151 of the Code of Criminal Procedure of the Russian Federation” .

There is a fine for such violations of up to 80 thousand rubles. Also, the violator may be punished by performing correctional labor for up to 360 hours. The offender can also be sent to correctional labor for up to one year.

In addition, they may be sentenced to restriction of freedom or complete deprivation of freedom for 2 years. In the event that after an independent intervention in the gas system, an accident occurs, as a result of which people were injured. Then the violator will be punished with the same fine, correctional labor for up to five years, and even imprisonment for up to 8 years.

To replace gas equipment, you must have a special permit. If an accident occurs and people are injured, the culprit will suffer administrative punishment upon initial prosecution, in accordance with Article 7.19 of the Code of Administrative Offenses of the Russian Federation in the form of a fine.

If a violation is detected again by the same person, the violator will be prosecuted in accordance with the adopted Federal Law No. 229-FZ “On Amendments to Article 215.3 of the Criminal Code of the Russian Federation (CC RF) and Articles 150 and 151 of the Criminal Procedure Code of the Russian Federation (CCP RF)".

How to choose a column

In order for the geyser to serve for a long time, you should choose a device from a trusted manufacturer. Decide on the selection criteria. Then the question of why the water pressure is weak will less often arise.

By type, heaters are either flow-through or storage. The first includes columns. It heats the water instantly. This is the main advantage over water storage devices.

First of all, you need to decide on the volume of water that is required. The heaters also differ in the method of removing combustion products. The safest option is to vent carbon monoxide through a chimney to the street. The diameter of the pipe depends on the power of the device. However, speakers without a tap are available for sale. They are dangerous to health. If the apartment does not have good ventilation, you should not install such models.

The devices also differ in the number of water supply points. There may be two or one. Good speakers are equipped with a gas leak protection function. But among them there are options costing less than 20,000 rubles. The Neva gas water heater is a representative of the domestic market. Even with a small budget, you can choose a safe flow-through heater from the manufacturer’s line.

Pollution prevention

If the water heater produces weak water pressure, it is worth not only removing the blockage, but also taking care of prevention.

What to do for normal operation of the gas water heater:

- Prevent the appearance of scale and salts. Clean parts of the device periodically. But the number of procedures can be reduced by choosing the optimal temperature regime.

- The heating temperature should not exceed 50 degrees. Therefore, it is worth choosing one indicator and making sure that there are no sharp jumps.

- Install a water filter that will retain salts and prevent them from damaging the surface of the pipes. Replace it with a new one in a timely manner.

- Install an electric softener to reduce the risk of scale formation.

- Clean the column correctly. Contact a specialist to check the quality of work. He will appreciate how hot water is supplied.

Problems and their solutions will not disturb speaker users if they prevent contamination and properly care for the device. It is important that the water is soft and clean. If the pressure decreases, you should immediately check for contamination and clean it with gentle means.

Types of filters

They will protect the boiler from the ingress of finely dispersed impurities, scale, and, as a result, the occurrence of noise effects.

The following types of filters are installed on water heaters and the inlet group of the water supply system:

- Rough cleaning. Captures mechanically suspended particles (up to 1 µm).

- Fine cleaning. Ion filters additionally remove small particles of impurities, including metals. Membrane (osmosis method) additionally neutralize chemical impurities.

- Cleaning systems using various adsorbents (physico-chemical method).

The most effective are combined types of filters with multi-stage cleaning.

Filters for water

Basic steps

What to do if the gas water heater whistles? The first step is to calculate the source of the sound. Turn off the gas. Open the mixer in the hot water position. If the problem is not serious, the gas unit immediately stops whistling.

If the whistling gets worse, pay special attention to the water path. Study its components: pipes and maintenance, and its components. They could get clogged. A particularly common situation is the accumulation of scale on them.

And scale often accumulates if the set water temperature parameters constantly exceed 60 degrees.

Back pressure should only be applied after turning off the gas and water. You also need to unscrew the liner at the inlet section.

The easiest way to carry out this operation is to use a faucet in the bathroom. The shower switch must be set to the neutral position. The taps should be opened slightly.

To remove lime deposits, use a descaling agent. You can also work with folk remedies: acetic or citric acid. They are diluted in the correct proportions. The resulting composition is poured slowly into the water path. It is added according to the degree of sound attenuation. Then repeat this procedure three more times.

And when you open the tap and there is no whistle, the problem could be hidden in the gas path. This means that there is possible damage to the valve for adjusting the flame power.

This is the most common answer why the unit does not stop whistling. The problem is especially pronounced when achieving the optimal ratio of gas flow dynamics and valve clearance width. This ratio may have different values in different columns.

If the gas water heater whistles when operating in high power mode, you need to adjust the regulator until the annoying sound disappears completely. Turn it smoothly, now in one direction, then in the other. The dynamics of the gas flow will decrease. It is not enough to produce sound. If it is increased, the valve clearance will expand, and the unit may start whistling again.

If these measures do not give the desired effect, it means that the gas path is clogged. The device will whistle even louder. It urgently needs to be disassembled, the problem area identified and thoroughly cleaned.

If your geyser is still under warranty, contact service immediately. You will have to contact them if the warranty period has expired and you cannot solve the problem on your own.

Solving the dilemma on your own is possible when you have the necessary knowledge and skills. The task comes down to cleaning this tract. Scale or winding elements could be stuck in it. If this is the case, the speaker will begin to whistle very powerfully.

Malfunctions and what to do

Extraneous noise emanating from equipment in some cases indicates failure of parts or malfunctions. To understand why the refrigerator clicks, you will need to consider additional factors. They will help you identify problems and find a way to fix them. At the same time, repairs are not always expensive; replacement of some parts does not exceed 3,000 rubles.

The start protection relay is broken

When clicks are heard periodically, but the engine does not start, it is dark in the refrigerator compartment, this indicates a failure of the relay. The mechanism cannot be repaired; replacement is required.

It is difficult to carry out repairs on your own. It's better to entrust it to a professional. When the master installs a new part, the extraneous noise will disappear. A similar problem most often occurs in Hotpoint and Samsung equipment equipped with the No Frost system. However, the cost of repairs is low: it reaches 1,500 - 3,000 rubles. depending on the model.

When the refrigerator clicks during operation, but the engine starts, the start-up relay has nothing to do with it. Equipment often reacts this way to temperature changes. You need to close the door more tightly and not keep it open unless necessary.

Users also experience a crackling sound when loading recently purchased products. Due to different temperatures, the unit makes noise. After 1-2 hours they disappear.

Thermostat is faulty

If the refrigerator clicks while operating and does not freeze, the problem is a faulty thermostat. You will need to make a replacement by calling a technician. The equipment should be turned off before he arrives, otherwise there is a risk of engine failure.

It is important to remember that the thermostat is always running, making a clicking sound. If they are observed when turned on, and the unit is freezing, there is no water under it, there is no need to worry

The system works properly and there is no need for repairs.

Broken motor-compressor

If the Indesit, Bosch or Samsung refrigerator creaks and crackles from behind when turned on, and the engine hums at the beginning of operation, and there is a burning smell in the air, then most likely the motor-compressor has failed. At the same time, the start-up relay may make unpleasant sounds.

You need to turn off the unit and call a technician. He will conduct an examination and replace the motor-compressor. The cost of repairs is up to 6,000 rubles. It is difficult to make a replacement yourself, because... knowledge is required.

The following may indicate engine malfunction:

- loud sounds before shutting down;

- a clicking relay that prevents the engine from starting;

- lack of cold in the chamber when the compressor is turned on.

If the compressor does not start, you need to urgently turn off the unit and call a technician. The motor will likely need to be replaced, especially when it turns on but won't turn on.

Loose compressor mounts

If the refrigerator clicks loudly before the motor stops, but there is light in the chamber, the equipment is producing cold, this indicates loose motor mounts. When the motor stops, it comes into contact with the housing, hence the reason for the grinding noise.

There is no need to call a technician to fix the problem. You need to slightly tilt the equipment or adjust the springs responsible for supporting the compressor. After this, the clicking will stop.

Owners of new refrigerators from Samsung, Hotpoint, and Deu most often encounter a similar problem. Ariston and Bosch rarely have such a crash, because they have better assembly and parts.

Low voltage in the network

If the refrigerator is cracking, the motor turns on, but after turning off it does not start for a long time, the problem may be low voltage in the network or surges. It is recommended to check it several times throughout the day.

To avoid breakdowns, experts advise purchasing a stabilizer. The device will protect the engine from burning out and save money. The cost of stabilizers is low, but thanks to them the equipment will function without failures. The purchase of the device is recommended for owners of Bosch models. German units may not turn on if there is no stable voltage in the network.

The average person does not understand the reason why the refrigerator cracks during operation. In most cases there is no need to worry. This sound is typical for many models. If the equipment produces cold and does not display errors on the control panel, you should observe it for 2-3 days. If the noise increases or water appears under the unit, you should call a technician for diagnosis and repair.