Canopies for gates and gates are quite compact structures that can be made independently in just a few hours. At the same time, even the simplest canopy will provide a significant extension of the service life of the gate, so it is worth spending the time and effort to build such a structure.

We will tell you how to do this below.

The canopy over the gate will protect the canvas, lock and hinges from rain

Application of internal loops

Despite some controversy among users regarding hidden garage fittings, internal hinges offer the following advantages:

- A higher level of security and burglary resistance, which is especially important if you store very expensive and valuable property in your garage.

- Long service life, which in practice is estimated at many decades.

- High resistance to loads, thanks to which doors weighing up to 400-500 kg each can be hung on hidden hinges without any significant consequences for the overall design.

If you value the security of your property, hidden hinges are a great investment and will give you peace of mind over your property.

Internal hinges for garage

Advantages of polycarbonate

- Light weight. Reduces pressure on the supporting frame and greatly facilitates the construction of a canopy with your own hands;

- High rigidity. The polycarbonate structure is resistant to impacts, snow and wind loads;

- Flexibility. The sheets bend perfectly even in a cold state, allowing the construction of geometrically complex structures in the form of arches and tents;

- Transparency. A high degree of light transmission, more than 80%, the canopy does not obscure the area, it is externally weightless and attractive. Harmful ultraviolet radiation is thus delayed;

- Easy installation. The material is easy to process, and its installation can be easily done with your own hands;

- Practicality. Polycarbonate does not require maintenance: debris and dirt are easily removed with water and detergents, except for abrasive ones and those containing ammonia;

- Safety. The sheet of material does not shatter into dangerous fragments like glass;

- Resistance to external environmental factors.

The material can withstand a wide temperature range, from −40 to +120 degrees. The sheets are resistant to chemicals and are not afraid of rain and snow; - Wear resistance. Many manufacturers provide a warranty period of 10 years;

- Aesthetic appearance and a large selection of colors.

Return to contents

Welded hinges

Iron gates, and every other one, in an iron frame are attached to the supports with special welded hinge hinges.

Kinds

Welded door hinges for gates differ from each other primarily in size and material of manufacture. In addition, there are differences in shape, design and ability to carry a certain load.

They are in form:

- Cylindrical;

- Hexagonal;

- Drop-shaped.

By design:

- Simple - with a removable or non-removable “finger”;

- Ball-type - with an iron ball, which ensures easy opening of the gate by reducing the friction force in the hinges;

- Bearing - with a bearing between the two halves of the product.

By load:

- Uncomplicated;

- Reinforced - with welded plates, allowing the load on the loop to be distributed more evenly. This increases the reliability of fastening the gate and increases the service life of the canopies.

Required number of loops

The overall dimensions of the welded hinges, as well as their number, are selected in accordance with the weight of the gate. The heavier it is, the more there should be. Or they themselves should be more wonderful.

The recommended quantity is shown in the table:

| Loop brand and height, mm | 610-4 (100) | 610-5 (125) | 613-4 (100) | 613-5 (125) | 500-4 (100) | 500-5 (125) | 401-4 (100) | 700-4 (100) | 700-5 (125) |

| Web weight, kg | |||||||||

| 30 | 2 | ||||||||

| 40 | 3 | 2 | 2 | ||||||

| 50 | 3 | 3 | 2 | ||||||

| 60 | 3 | 2 | |||||||

| 70 | 3 | 2 | |||||||

| 80 | 3 | 2 | 2 | ||||||

| 90 | 3 | 3 | 2 | ||||||

| 100 | 3 |

Installation of gates on welded hinges

It’s worth emphasizing right away that it’s very difficult to do this work on your own, and it’s simply unrealistic if you don’t have experience. Welding is a complex, labor-intensive process, scary for a beginner. Based on this, it is possible to undertake installation only if this is not the first time you have seen and held a welding machine in your hands.

In addition to this, do not forget to stock up on electrodes, a mask and personal protective equipment. And the necessary tools:

- An iron brush for cleaning work surfaces from dirt, rust, and old paint;

- Grinder for cleaning welds;

- Tape measure or ruler, pencil;

- Construction level;

- Clamps or other devices for fixing parts.

Then, it is necessary to make markings on the door leaf, depending on the number of hinges. The top and bottom should be placed no further than 15-20 cm from the edge.

It is much more ergonomic to weld them while the gate and frame are in a horizontal position.

A detailed description of the process is shown in the table:

| Image | Description |

| Lay the gate or its frame and support post on a horizontal plane so that there is a gap of 3-4 mm between the pipes to which the hinges will be welded. To do this, place spacers between them made from pieces of metal or used circles from an angle grinder, and clamp them with clamps. | |

| Along the welding line, draw a line parallel to the edge on the support pipe and fix an even block or piece of pipe along it. It is possible to clamp it with clamps, or to grab it with spot welding. Having placed the loop touching the block, place matches or pieces of wire under it to provide a gap. | |

| While holding the cylinder pressed against the block, tack its upper half in two places to the frame pipe. | |

| After this, grab the bottom part and remove/cut off the temporary block. | |

| Remove the clamps holding the gate and the box together and make sure that the leaf moves securely. If everything is fine, replace the spacers and clamps again in order to thoroughly weld the hinges. | |

| Full weld both seams. | |

| Clean the seams with a grinder so that no sagging remains. | |

| Open the gate and weld the seams on the back side. Clear them out. | |

| To give the structure a finished aesthetic look, prime and paint it. |

If the gate posts are already in place, installation is carried out using a different technology. The instructions recommend that you first accurately mark and weld the upper parts of the hinges to the gate leaf.

After this, as in the case of overhead awnings and a wooden gate, the sash is installed in the opening and fixed in it using pads and wedges. The verticality of the installation, and being in the same plane with the box, is checked by the building level.

After this, the lower part is inserted into the upper part of the loop, and its position is marked on the support post with chalk or a construction pencil. Or it is immediately tacked in two places by spot welding.

Having grabbed all the hinges, you need to remove the wedges and pads and check the movement of the gate. Only then is it possible to make vertical continuous seams.

And then everything is the same: the internal seams are boiled, they are cleaned, after which the entire structure is painted in the chosen color.

Manufacturing cost

Estimated price - from 2500 rubles. per sq. m. Depending on the decoration features, the cost of the product will vary, so for all pricing questions it is better to contact our consultants by phone. Along with purchasing a product, you can also order its installation! We carry out installation in Moscow and the Moscow region within 1-3 days.

You think that the visor is an optional element of decor over the gate, and this is just a whim or a way for their owners to stand out from the crowd. Then you should learn about three good reasons that in some cases this is a necessary attribute. You will probably be convinced of its necessity and decide to build a canopy for the gate of your own fence with your own hands.

Several distinctive features of welding hinges to corrugated sheets

Quite often, profiled sheets are used as a material for creating gates or fences. If a person needs to weld hinges to this material, then some factors should be taken into account. It is required to make lintels that must be parallel to the vertical part of the sash.

An important step in working on swing iron gates is welding the hinges

It is necessary to secure the jumpers in those places where the hinges are welded. They must divide the sash into 3 identical elements. Hinges must be welded to the jumpers. To cover the welding area and jumper, small pieces of corrugated sheeting can be screwed on top. It is better to give preference to thicker loops with a length of more than 1 m.

Welding without unpleasant consequences

To ensure successful welding of hinges to gates, follow these recommendations:

- do not work with a faulty welding machine;

- you can cook only after the paint has completely dried;

- clothing should not contain traces of grease, gasoline, oil or any other flammable liquids;

- Do not cook parts under pressure;

- Do not hang rags soaked in flammable liquids on the welding machine cylinder. This often caused a fire.

Basic truths

The process of installing hinges can be considered using the example of a metal gate. In order for it to properly perform its main functions, a number of conditions must be met when welding hinges:

- Provide a gap between the support post and the gate frame, which should be 3-5 mm.

- Provide a gap of several millimeters between the hinge and the gate frame by welding plates - metal plates of the required thickness - to the hinge. In total, for each loop you need two strips, the length of each of them is 2 mm less than the length of half.

- The optimal distance from the edge of the gate to the loop is 15-20 cm. If you need a middle loop, then it is located exactly in the middle between the outer loops.

First, the lower part of the fastener (with the pin) is welded to the post, then the upper part (with the groove) is welded to the sash.

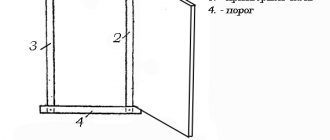

A properly assembled structure should have the following parts:

- a loop;

- plate; wicket frame;

- support pillar;

- lower part (with pin);

- upper part (with groove).

This design consists of several elements.

All loops must be coaxial, that is, their centers must be on the same straight line. The alignment requirement is extremely important. It is on its compliance that it depends on how evenly the weight of the gate will be distributed on the fastenings and, accordingly, how long they will last.

To work, the master will need:

- welding machine;

- metal plate for making plates;

- Bulgarian;

- hammer;

- plumb line;

- oil for lubricating hinges;

- protective equipment - mask, gloves, overalls.

At the preparatory stage, you should mark the gate frame and sash, determining the places where the hinges will be welded. Clean them from dust, dirt, and rust. To do this, you can use a wire brush and solvents. Next, a similar treatment is performed on the surface of the hinges, and lubricant is applied to their inner part.

The traditional welding method involves the installation of plates at this stage, for which it is recommended:

- Take 2 identical plates of the required thickness and length. Place them so that there is a gap of 2-3 mm between them.

- Place the bottom part of the loop on them.

- Weld the loop to one of the plates (in this case, to the right one).

- Do the same for the top of the hinge and weld it to the left plate.

- Then you need to install the shutters in the working position and fix them.

- The plates with the lower part of each hinge are spot welded to the post, then the upper hinge elements are inserted into the lower parts and spot welded to the sash. After checking the alignment of the hinges and the operation of the gate, final welding is carried out along the contour of the plates.

Where to buy or order

Currently, forged awnings are used quite widely . They are installed above swimming pools, above cars, above porches. And in the countryside, they perfectly protect firewood for barbecues, etc. from getting wet. The high demand for metal structures gives rise to a wide range of solutions offered by manufacturers.

Employees of the companies that are collected in the section “Where to buy or order forged awnings” provide customers with a wide range of products to choose from. Tags: wrought iron entrances, wrought iron carports, wrought iron canopies over the porch

Purpose of the product

Hinges, or awnings, are devices with which gates are opened. The mechanism consists of several elements. They rotate around their axis and ensure the operation of the gate. The principle of free rotation underlies all types of locking mechanisms. This quality makes them an indispensable part of the gate.

After installation

To choose the right gate awnings, you need to take into account the following:

It is better to purchase loops in a specialized store. Only large retail outlets have all the necessary documents: a quality certificate, a guarantee from the manufacturer and a hinge installation diagram. This does not always guarantee the quality of the product 100%, but if you are not satisfied with the product, it can be returned or exchanged. You should buy a mechanism taking into account the weight of the swing gates. Each type of canopy is designed for a specific load that it will withstand. It is advisable to choose with a margin of safety. For example, for a sash weighing 200 kg, take a device designed for 300 kg. Take into account the location of the house for safe operation of the gate. Some types of hidden swing mechanisms prevent the gate from opening completely. This is inconvenient when leaving the yard, since open doors interfere with street traffic.

You need to use gate canopies with the correct connection method

Hinges are welded onto metal sashes, and screwed onto wooden sashes with bolts or self-tapping screws. Therefore, it is important to know what material the sashes are made of. It is worth paying attention to the material from which the canopy is made. This affects the service life. Products made of plastic or thin metal will not last long on heavy sashes

Over time, they will begin to warp and jam. If you select such loops, then this must be taken into account.

Installation option

Classification of products according to GOST

Manufacturers produce hinges in a wide range. To select a product, they use GOST, namely a table that shows the technical parameters of the product. GOST (state standard) is the main document by which the dimensions, weight, load, shape for each type are determined.

Cylindrical version

According to GOST they are divided into the following types:

- cylindrical;

- cylindrical reinforced;

- end-to-end;

- secret;

- three-section overhead;

- invoices.

Uniform weld seam

Cylindrical with bearing

The canopy is shaped like a cylinder, which has been divided in two. One part of the gate hinges has a hole, called “mother”, the other with a pin is called “father”. The two halves connect to each other and rotate in a circle.

Materials and tools

To do the job well, you will need professional tools

In addition to the welding machine, you will need the following tools and consumables:

- welder's protective mask;

- measuring instrument: ruler, tape measure, building level;

- lubricant for hinges - grease or a composition similar in properties to it;

- An angle grinder will be needed to clean up welding seams and dismantle an incorrectly installed hinge group.

Support pillars are best made from a profile pipe of square or rectangular cross-section. This will ensure the reliability of the structure and facilitate the installation process of the canvas.

How to make a canopy over a gate with your own hands: a canopy made of corrugated sheets

You can make and install a canopy over the gate with your own hands without much effort. It will decorate the appearance of the outer part of the fence and protect the entrance leaf from negative environmental factors. The process of installing a visor involves following certain rules. The planning for creating a hanging element over the gate includes the selection of the optimally suitable material and the necessary tools. More details about everything below.

Selection of loops and their quantity

If you decide to use welded hinges to install the gate, you can choose from several types:

- the simplest and most inexpensive option is a split cylinder with a rotating axis in one part and a cavity-cap in the other. Such hinges require periodic lubrication, without which they quickly begin to creak;

- The most popular are hinges of the same design, but improved with a ball or bearing on which the axis rests. They can be either two- or three-section;

Welded hinges with a ball Source dekoriko.ru

Another option - the same hinges with metal plates welded to each part.

However, it is not enough to know how to weld hinges to the gate - first you need to calculate the load on them and decide on the quantity. This is not difficult to do if you know the weight of the sashes.

Hinges without plates can withstand a maximum of 400 kg depending on their diameter and the length and thickness of the metal. And hinges with plates that take on part of the load are designed for a more impressive weight - they can withstand up to 600 kg.

Knowing the design load on the hinges and the weight of the structure, you can determine the required number of hinges. Of course, there will not be less than two of them per sash. And in the case of heavy gates, the number of canopies is increased to 3 or 4. An additional hinge is installed just below the top one, which bears the main load.

3 hinges are often installed on massive insulated garage doors. Source dekoriko.ru

By the way, you can strengthen ordinary hinges yourself by welding to them plates cut from thick metal of a suitable size. The weld must be continuous.

Shapes of visors

Having decided on the material, you can decide on the design. Without experience, you need to realistically assess your strengths and fantasies so as not to spoil the external perception of the entire house. Here are some simple ideas:

- Single-pitch structure over a gate. Elementary installation, but if there is a lot of snow in the region, it is worth maintaining the angle of inclination.

- Gable canopy - has the advantage of protecting the gate during periods of precipitation at any angle.

- The arch is in demand because it looks beautiful and is easy to create, even without experience.

- Dome - you will have to think about it here, since several different parts are made, and then assembled into a single whole. But the protective functions are maximum.

- Direct canopy - a more durable material is chosen for it. The frame is carefully thought out.

Variety of shapes

- The most acceptable option is a slide-shaped device. Its installation is quick and easy.

- Model in the shape of a house. Its installation takes more time, but the structure is more durable.

- An arched canopy installed above the gate, made of sheet steel, perfectly emphasizes the exterior of the structure.

- Direct design, for the manufacture of which monolithic polycarbonate is used.

- Convex canopy, or awning. An original and beautiful device that gives the gate sophistication and uniqueness.

Choosing loops

The choice is made taking into account the size and weight of the valves. For example, a metal garage door will require stronger hinges with a support bearing than a gate. The stores offer a variety of types:

- Drop-shaped ones with support bearings are designed for weights up to 400 kg.

- Cylindrical, thanks to the amplifier, which works as a load distributor, and the support bearing, ensure ease of opening with a load of up to 600 kg.

- Through ones are chosen if it is impossible to weld the hinges or secure them with bolts. Fixation is carried out using a through hole in the rack. They are attached to the sash with nuts. Maximum load up to 200 kg.

- 3-section doors are difficult to break into and are used for hanging heavy sashes.

- Forged ones are functional and are used as decoration for wooden gates.

- Steel boom hinges are often installed on garage doors made of thick metal.

- Height-adjustable hinges are useful if the position of the support posts may change.

Hinge with support bearing ensures easy opening with loads up to 600 kg

Working sketch

A good canopy over a garage door is the optimal combination of reliability, cost of work and a shape that is pleasing to the eye. As a rule, if the canopy is small, then you can set it to a standard look. For outstanding structures, you will have to calculate the load on the load-bearing elements and, based on the data obtained, choose a shape.

Single-pitch canopy

The simplest, and therefore most common, option for installing a canopy over a garage door is a conventional lean-to structure. In this case, it is easiest to assemble and attach the frame to the wall. The slope itself is made with a slight slope from the wall.

Drawings of a single-pitch canopy are very common; they are easy to create yourself, taking into account the individual characteristics of the garage as accurately as possible.

Example of a standard visor

Gable

Classic gable visor

It is not much more difficult to install a gable canopy over the garage. In this case, it will be possible to reduce the load on load-bearing elements spaced from the wall. The canopy can withstand heavy loads.

Arched

Arched canopies over the garage are less common, but they are also quite easy to make. Most often, polycarbonate is used for them, which bends easily and takes on rounded shapes. If desired, you can make a canopy from metal sheets.

Approximate drawing of an arched structure

Domed

Dome-shaped canopies are perhaps the most impressive designs, but they are difficult to assemble. Their main quality is individuality, their own style, so it is very important to try to create something of their own, unique. In other words, it is better not to use standard projects, but only partially copy them, adding good finds and original moves.

An excellent solution for a dome canopy over a garage door

Wooden gate hinges

You can buy your favorite wooden gate inexpensively at any construction market.

An example of the design of forged hinges for a wooden gate

Many suppliers manufacture custom gates or wickets. For those who can boast of having even a little experience in construction work, it will not be difficult to make a simple structure with their own hands.

If you have a gate, all that remains is to select hinges that match it in terms of characteristics and dimensions. Correctly chosen fastening will provide the sash with an ideal “fit” and full-fledged long-term operation. For a small wooden gate, the most suitable way to fix the hinges is to install the door with self-tapping screws.

Installation of hinges with self-tapping screws

In principle, this method of attaching hinges is similar to installing interior doors. However, to install a wicket, the components must be wicket or gate components. When choosing this type of fixation, the hinges are attached to the end of the gate, providing the structure with additional stability and improving its external performance.

Stages of installing a wooden gate:

- Using wood screws, the wicket hinge should be attached to the facade of the sash in the marked places. For greater reliability, it is advisable to use at least 3 hinges for 1 gate.

Attaching hinges to the gate with self-tapping screws

The structure with attached hinges must be placed on a flat surface (on the ground) along with the posts. In this case, care must be taken to ensure that the fabric of the product is not damaged. It is best to place a lumber lining under the gate and posts, for example, a piece of plywood or chipboard. If necessary, places for hinges are prepared on the support post. For this purpose, cuts are made. It is convenient to do this work with a hammer and chisel. Piles with attachment points marked by markings are installed in holes prepared in advance for supports. The lower ends of each pillar should be treated with an antiseptic and wrapped in roofing material. The pillars must be fixed in a strict vertical line, which is verified by the building level.

An example of installed posts for a wooden gate

Using self-tapping screws, the gate is attached to reinforced piles.

For support pillars, a hole should be made at least 120 cm deep. At the bottom of the hole there must be a compacted sand cushion (15 cm in height). The pillars can be backfilled or concreted. This method of installing them will save the structure from shrinkage, which is fraught with transfer of loops.

Tips and tricks

Incorrect welding can lead to problems during further operation; to prevent this from happening, you should listen to the following recommendations:

- Before starting work, make and study a schematic drawing; if all the details are taken into account in advance, then the risk of redoing the finished structure will be much less;

- straight hinges are welded to the gate laid on a flat surface;

- You can open gates with newly welded hinges after the seams have completely cooled;

- on round posts the loop extends 5 mm outward, on rectangular posts it is welded flush;

- the welding seam should go from bottom to top.

Beginning of work

Before welding begins, you need to place the future gate leaves in the garage opening. This is done in order to achieve the correct position of the sashes and determine the scope of work. At this stage, be patient and, if possible, have an assistant. Only after you have achieved an even position of the valves can you proceed to the welding itself. The peculiarity is that it is extremely rare to carry out this type of work in a horizontal position. And making a vertical weld can be difficult even for experienced craftsmen. Taking this fact into account, welding should be carried out with special care, describing circular movements and, as it were, lifting the metal.

At first glance, this type of work seems complex and requires special skills. However, it is quite possible to perform it, following the rules and having a certain skill. The most important thing is to take your time when performing work and carry out actions in accordance with the plan.

You need to measure approximately 20-25 cm from the top and bottom of the canvas and mark it with a pencil or chalk. To prevent the hinges from baking, they need to be lubricated, for example with grease, or small pieces of wood the size of a match should be placed. This trick will help avoid jamming during operation and generally simplify the process. We weld the hinges to the gate. At the initial stage, you should not completely weld the hinges. You just need to lightly grab them by welding

It is important to remember that the lower half of the part is welded first. For those who use the welding machine for the first time, you need to remember that the loop is welded in the direction from the bottom to the top, and the movement of the electrode should be smooth and without breaks. After the first seam is completed, the gate needs to be opened and checked using a builder's level or laser level to see how well it opens and closes

You can finish the work if you are satisfied with the result. An ideally installed structure should open without effort or additional noise. Repeat all these manipulations for the remaining parts.

Places where welding was done must be carefully sanded using a grinder. The final stage is priming and painting the gate in the chosen color.

Safety precautions

Welding is a dangerous type of work. When performing this, you must follow safety rules.

- Do not keep flammable liquids or materials near the welding site. The area should be vacated.

- During work, children and pets must be excluded from the area.

- Welding is performed wearing a protective mask, goggles, gloves and an apron.

- It is necessary to strictly follow the instructions for handling the welding machine used.

- Cleaning and grinding of seams, as well as any other work - hanging sashes, for example, is carried out only after the joints have cooled to room temperature.

During work, keep a working fire extinguisher nearby.

Main types of garage hinges

The building materials market offers a wide variety of hinges for swing doors. Each variety has individual parameters and advantages of use. The first thing you need to do when choosing is to select an installation option. The following installation methods are available:

- welding - the hinges are fixed on the door leaf and frame;

- installation using bolts - used when working with wood material;

- fastening with self-tapping screws - suitable for structures made from profiled sheets.

Based on placement, clamps are divided into hidden and internal. Their main differences lie in the installation method and decorative characteristics. When choosing garage hinges, the weight of the door is of great importance. Incorrect calculation of the expected load provokes skew of the canvas and difficulties with opening. For dense sheet steel with a large mass, it is recommended to purchase reinforced clamps.

With support bearing

Hinges equipped with a support bearing are the basic type of cylindrical type fasteners. The support bearing and swivel joint are reliably protected from external influences by the main body made of metal alloys.

Models with support bearings are intended for lightweight swing structures. The maximum permissible load is 100 kg. The clamps with support bearings are attached to the sashes and frame using a welding machine.

Cylindrical with additional reinforcement

Reinforced clamps are equipped with additional plates, which helps distribute the load over a large surface of the sashes or pillar. It is recommended to use cylindrical hinges with improved plates for thin profile structures. The parts are fixed to the swing gate leaves and frame by welding or screw connection.

Depending on the side of location, cylindrical reinforced hinges are divided into right and left. The diameter of the element is 50 mm. The maximum total load reaches 600 kg.

End-to-end

If it is not possible to secure the hinges by welding or screwing to the frame, a through type is used. For installation in the gate frame, mounting columns are drilled along the entire length, into which part of the retainer is threaded. For final fastening, nuts of the appropriate size are used. Thanks to a special fastening scheme, through-type fasteners can withstand loads of up to 200 kg.

Three-section invoices

For massive swing gates, it is necessary to increase the number of latches and choose a type with increased wear resistance. The best option is three-section models that can withstand the load of a heavy structure. The main advantages of overhead three-section hinges are:

- smooth sliding when opening and closing the gate;

- no creaking;

- reliable protection against burglary;

- preventing the sash from warping and sagging.

Boom loops

Garage boom hinges are suitable for attaching large swing doors, gates and thin-profile structures. The main distinguishing feature is the increased area of the clamp, due to which it provides additional strength and prevents distortions.

At the connection points, the arrow loops are able to withstand increased stress. This is facilitated by uniform distribution along the entire length of the sash. The range of dimensions of the clamps varies up to 700 mm, which makes it possible to find the optimal option for any gate design. The fastening parts are made from durable sheet steel, which ensures a long service life.

Invoices

Despite the ease of installation, overhead types of hinges are highly reliable. The fasteners are made from durable materials, including steel alloys, brass and stainless steel, which significantly increases the variability of their use. Inside the housing there are 2-4 ball bearings necessary for smooth opening of the gate.

To fix the overhead hinges on the frame, you need to mark their exact location and secure it with self-tapping screws. The clamps are included in the universal category and are not divided into left- and right-handed ones. If after installation it becomes necessary to remove the canvas from the hinges, you will need to unscrew the screws.

Types of materials for visors

Taking into account the specifics of the structure of the canopy and the room, you can correctly determine the required type of product. It is also necessary to take into account the type of material from which the fence and gate are made. A device whose frame is made of wood is suitable for a wooden fence. Metal buildings will look great over a gate made of corrugated sheets. A forged canopy built over a gate will fit almost all types of canopies.

The canopy roof can be made using the following materials:

- metal tiles;

- polycarbonate;

- corrugated sheeting;

- slate.

A noteworthy material for making a canopy over a gate is polycarbonate. With this elastic and effective product, you can easily create the device yourself.

Canopy in the shape of a “house”

Variety of shapes

If previously a canopy was considered a small canopy with a slope, today there are many options for shapes. And your choice directly depends on taste and imagination. The principle of manufacturing any of the types is the same. If you decide to make a visor with your own hands, then you will have to tinker with more complex options, but the simplified version does not require special knowledge. The main thing is to decide on the material and be able to use the appropriate tool.

The most popular today are arched canopies, the frame of which is often metal, and the decor is forged elements. Polymer is often used to coat it. This material is unpretentious both in production and in operation. But, no matter what shape of the visor you choose, you need to prepare a sketch of it. The dimensions of the canopy depend on the size of the gate and the wishes of the owners.

Visors differ in shape and material, as well as in methods of installation and fastening with your own hands:

- arched, above the outside of the fence;

- arched, attached in the center, and shading both sides of the fence;

- corner products mounted on the outside;

- triangle shape, mounted in the center and others.

For all options, it is possible to use any material for the coating and frame.

When choosing what to make the canopy from, you should focus on the fence itself and the gate. One of the unique ones is forged, but the roof can be made of:

- polycarbonate;

- corrugated sheets;

- metal tiles;

- plexiglass;

- PVC sheets;

- galvanizing;

- slate, etc.

It is easy to install a canopy over the gate using polycarbonate with your own hands. This material is simple, beautiful, and inexpensive. Since there is a demand for it, manufacturers are trying to create it in different colors. The assortment includes unique visors of various shapes.

Step-by-step guide to installing corrugated sheet gates

- The first step is to mark the location for the gate.

- Next, holes for the pillars are dug at least one meter deep. Before digging in, the supports are treated with an anti-corrosion primer.

Post holes can be dug by hand or using an auger

The solution for strengthening the pillars must be compacted well.

To ensure that the gate stands level, before installation you need to position the gate and place a stone or brick under it

Locks, decorations, forged elements are installed on gates made of corrugated sheets last

The good thing about corrugated sheets is that they do not require painting. But you can purchase ready-made material, stylized as wood or stone. You can decorate the gate with forged elements or other decor - on top or along the door leaf. To decorate the gate, you can trim the top edge, but then it needs to be protected with a profile. If desired, the corrugated sheet can be painted with special paints that are resistant to external influences. You can only use the gate freely one month after installation.

What you need for a polycarbonate visor

You can make a canopy at the gate over the gate with your own hands by choosing the following materials as the frame:

- Wooden base - assembling such a device is not difficult. The product is attached to self-tapping screws, no complicated tools are required. Among the disadvantages, experts note the fragility and the need to use antiseptic compounds.

- Aluminum – has a variety of capabilities. It is possible to organize shaped and forged frame elements from aluminum.

- Metal profile - includes welded parts.

- Forging.

What should gate hinges be like?

Metal gates are most often installed on garages and fences that protect the perimeter of the area. First of all, they perform security and protective functions, and only then decorative ones. Products in this category can weigh from 200 to 1500 kg. Therefore, in order for the structure to serve well for many years, it is necessary to select only fittings that are suitable in terms of strength.

Drawing with dimensions of gate hinges

Poor quality hinges or hinges that do not fit the gate lead to the following problems:

- cannot withstand the applied load and become deformed;

- the gate begins to sag;

- The doors no longer open easily and close tightly.

Buying high-quality hinges that best fit the gate means:

- provide the gate with all conditions for long-term service;

- forget about creaking and grinding noises when operating the sashes;

- provide the entrance to the yard or garage with maximum protection against burglary.

Modern fittings for garage structures function perfectly in any weather. Permissible temperature range:

- from – 400;

- up to +1200.

Mechanism selection

Main types of garage hinges

The rapid technological process affects many aspects of our lives, and even hinges for wooden gates (as well as metal ones) are no exception. If previously the fittings for garage doors were very simple and monotonous, today you can find many types of different hinges that differ in their features and advantages.

The table shows the main types.

| Hinges. In the middle of the product, made of steel, there is a ball, thanks to which the loop moves. This type will be discussed in more detail below. |

| Cylindrical. This fittings are also called bearing hinges. It is attached to a special support by welding metals. Due to the design features and fastening on the gate, cylindrical hinges with a support bearing are well suited only for swing gates with a small mass - the total load should not be more than 400 kilograms for each hinge. Otherwise, there is a high risk of breakdown. |

| Cylindrical reinforced. These welded hinges are improved versions of the previously discussed hinges - they have a more advanced structure and optimal load distribution. The maximum weight that one such hinge can hold without any consequences is about 600 kilograms, so reinforced cylindrical hinges can be used for installing heavy gates. |

| Through. In the event that garage door hinges for certain reasons cannot be installed by welding or screwing to a surface, through-type hinges are used. To install such fittings in the gate structure, the entire length of the mounting columns is drilled into which part of the hinge is threaded. After this, it is firmly fixed using nuts of a suitable size. Due to this fastening scheme, through garage hinges are designed for a load of no more than 200 kilograms. |

| Invoices. These are the most popular gate hinges among garage owners, which have gained such popularity due to their high reliability, strength and wear resistance. Another advantage of overhead hinges is the complete absence of squeaking when opening and closing the doors. Such fittings completely take over the load from the door leaves and do not allow them to sag. Also, overhead hinges are also burglar-resistant. |

| Forged. This is an old type of garage hinge, which was born many centuries ago and was used to hold wooden gate leaves. Despite this, forged type hinges are often used today, including for creating design solutions. Some modern models of forged hinges are in no way inferior to others. |

Which gate hinges to choose from such a variety? If you are already overwhelmed by the wide range of modern stores, read on to find out the rules of choice.

Why hinge hinges are so good

It should be noted that hinged gate hinges are highly popular. It is largely due to the numerous advantages of such loops, which are listed below:

- Ease, smoothness and noiselessness of turning, subject to regular lubrication.

- Hinges for metal gates are highly resistant to burglary.

- Ability to withstand heavy loads, especially for hinges with a large hinge.

- No chance of spontaneous closing and opening (provided the garage door is installed correctly in a vertical plane).

The positive qualities mentioned above make it possible to install hinge hinges on gates made of corrugated sheets. Thus, the hinges that are installed inside the hinges are made of durable and reliable metals with decent performance characteristics. Thanks to this, not only the possible load on the hinges from heavy door leaves increases, but also their service life.

Cylindrical garage hinges in different sizes

It is important to select the correct number and parameters of hinges based on the weight of the gate door, for example:

- For a lightweight gate made of corrugated sheets, one hinge per hinge with a diameter of 25 mm is sufficient.

- For a standard gate door you will have to choose hinges with hinges with a diameter of 35 mm or more.

- If you plan to install a massive garage door, it is necessary to increase not only the diameter of the hinge, but also the number of such balls in one hinge (up to 2-3 pieces per leaf).

Why do you need a canopy over the entrance gate and gate?

Experts identify the following purposes for wicket and gate canopies:

- Extending the performance of wickets and gates. The canopy protects hinges, locks and foundations from the destructive effects of precipitation. If there is a video camera or intercom at the entrance opening in the fence, installation of a hanging element is required.

- Reduction of snow cover in winter. In winter, the canopy will not allow a large amount of snow to accumulate at the entrance.

- Decorative. A visor decorated with forged elements will add greater visual appeal to the overall look.

The idea of arranging a canopy over the sash

Taking into account the listed factors, it is worth thinking about creating a canopy at the stage of thinking through the design of the fence. It is important that the hanging element neatly complements the fence and does not look like a separate part of it.

Arranging a canopy begins with creating a strong frame. Wood or metal is used to make it. Wooden construction has a short service life. Therefore, the lumber used is additionally treated with antifungal agents.

Model of a metal product above the gate

The material for the canopy should be selected based on the fence itself, the gate door and the gate. The supporting part of the canopy comes in various designs. The following materials are used to cover the roof:

- polycarbonate;

- corrugated sheeting;

- metal tiles;

- plexiglass;

- PVC sheets;

- galvanizing;

- slate.

Variety of canopy shapes

A canopy over a gate made of corrugated sheets is one of the most popular canopy options. Profiled sheets are easily attached to the frame of a suspended structure and are inexpensive.

When purchasing, it is better to choose a material with a thickness of 0.5 mm or more made of aluminum, copper or chromium-nickel steel with an additional protective and decorative coating.

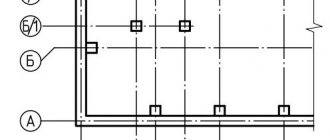

Frame diagram with main dimensions

Polycarbonate is the easiest material to install yourself. In addition to ease of use, it stands out for its beauty and low price. Given the great demand for it, manufacturers have expanded their range to include a variety of colors. Consequently, commercially available polycarbonate sheets have different textures and colors.

Sketch of a gable structure for a gate

Loop welding technology

Before we talk about how to weld hinges on gates, it is worth taking a closer look at the conditions necessary for their normal operation.

Even if the load is calculated correctly, the hinges may not be able to cope with it if their position deviates even slightly from the vertical. They will quickly fail. And the second point: there should be a small gap of 1-2 mm between the hinge body and the support post so that the metal parts of the post and the mating part of the canopy do not touch or rub against each other. The same gap should be left on the side of the sash.

Video description

To understand what we are talking about, watch the video

The nuances of installation on supports of different sections

The supporting posts on which the sashes are hung can be round, square or, less commonly, rectangular in cross-section. There is a difference between how to properly weld gate hinges to round posts or supports made of profile pipes.

If the profile pipe has smooth edges without bends or distortions, then it will be easy to cope with the task of how to properly weld gate hinges to square posts. They are installed on the outer plane of the support.

Canopy with plates on a square postSource distroy.ru

In the case of a round support, you must first decide in which direction the doors will open. Then they find the most protruding line (the middle of the pillar relative to the opening) and step back from it a few millimeters outward - in the direction of plowing. 5-6 mm is enough for the wicket or gate leaf to move smoothly and without jerking around the axis of the canopy. Since it is more difficult to weld hinges on gates to round posts than to square ones, here you need to be especially careful and attentive, maintaining the same indentation size for all hinges.

Installation and welding work

Experienced welders recommend first welding the canopies to the sashes, laying them on a flat horizontal surface. A half in the form of a hollow cylinder is welded to them, and a mating part with a pin (pin up) is subsequently welded to the supports. They retreat approximately 15 cm from the top and bottom edges.

Wicket frame with welded hingesSource www.chipmaker.ru

Then the sash with welded canopies is installed in the opening on stands that provide the required distance to the ground, and is rigidly fixed with clamps, pliers and other devices. They do this so that it stands strictly vertically, and there is a gap of 5 mm or so between it and the support. To do this, use a laser level or a plumb line, and spacers of the required thickness are inserted between the elements.

Other craftsmen prefer to first install the gate, and then weld the hinges to both it and the post. There is no big difference, everyone does what is convenient for them.

Another option is to make the upper and lower ribs of the frame whole when making the sashes and cut them after hanging them on the hinges. Source sqezo.ru

Now let’s talk about how to properly weld canopies on gates. The sequence of work looks like this:

- 1.5-2.5 mm thick wire is wrapped and twisted around the loops at the top and bottom to form a gap between it and the welding plane. You can place matches or other objects of suitable thickness, but they fall out, move or break, which is very inconvenient;

- The places where the canopies are attached are marked on the supports and an even long block or profile pipe is applied to them. Fix it level, ensuring a vertical position.

What not to do during welding

In order for welding work to proceed without incident, it is necessary to adhere to certain rules:

- Be sure to use protective equipment to avoid harm to your health. This kit includes a protective mask, gloves for welding, a thick jacket or shirt, and pants.

- Never touch a hot welding seam with oil-soaked rags, as they may catch fire.

- It is strictly forbidden to carry out work by eye, even if you are confident in your eye and skill, double-check everything with special tools, then the result is guaranteed to be of high quality and durable.

Now you know how to weld hinges yourself and you can share this information with your neighbors or friends who are still wondering how to weld hinges on their gates without any problems.

Watch the video: Tips and tricks

The goal of the gate is to lock securely, withstand force loads, and be functional. Another good gate is that it opens and closes comfortably. You not only need to know how to weld hinges on a gate or wicket, but also be able to use electric arc welding, then everything will be done efficiently and correctly. When the elements are welded correctly, the gate will open well. At the same time, there will be no gaps in the closed gate.