Convenient finishing of slopes with a starting profile

In most rooms, plastic windows are installed. When it comes to finishing, special nuances appear. For example, you can use P and F profiles for slopes .

Application of products

There are two types of slopes: one of them is located outside the building, the other is located on the inside. Both types require proper finishing. The slope is intended not only to give the windows an aesthetic appearance, it performs important protective functions.

Plastic windows are attached to the opening using mounting foam. It deteriorates under the influence of moisture and is gradually carried away by the wind, which is why it is important to install a slope profile that can protect the structure from adverse weather conditions. Otherwise, the foam may become deformed and damage the window frame.

Application of F-profile for finishing the external slope

Methods for finishing slopes

PVC and F-profiles for finishing external slopes

Slopes can be internal and external, and both of these types require proper finishing. Of course, their design is aesthetic in nature, because appearance plays a big role. However, this is necessary not only for beauty. The foam that fills the space between the window and the wall of the house must be protected from adverse conditions. Everyone knows that it is afraid of moisture and tends to absorb it, after which it swells and deforms the plastic window.

There are several ways to improve the appearance of the window space:

- Plastering is an old finishing method that takes a lot of time and effort. Unfortunately, it does not have the property of heat and sound insulation and over time may move away from the surface due to shrinkage of the house. Since the finishing work takes place in several stages and requires subsequent painting, I decided that I would not bother using this option.

- Plasterboard - this option is better than the first and if you insulate such slopes, they will last longer and will retain heat in the house. But one significant drawback made me refuse to use drywall - the fear of moisture. A prerequisite for long service life is a dry room with a low level of humidity. And the installation of such slopes is not far removed from plaster, and I already said that I wouldn’t want to bother.

- From PVC panels - a simple and affordable way that I immediately liked. Long service life and quick installation prompted me to choose plastic slopes, and most importantly, they are not afraid of moisture.

Important! The use of PVC panels is very appropriate for plastic windows; this combination will look quite harmonious, and besides, there are PVC profiles that will help complete and make the finishing process convenient and quick.

When I decided which method I would use, all that remained was to get acquainted with additional components for PVC and learn the installation technology.

Features of application

Finding out the desired profile is quite simple; it looks like the Latin letter “F”. The material is fixed using special plates that are fixed in its grooves. The starting profile for slopes has two important functions:

- Decorates the ends of windows, giving them a decorative look.

- Levels the surface without the use of complex structures and plaster.

Ready solution

The F-shaped profile for slopes is a convenient solution for cladding. It creates a perfectly flat surface, free of imperfections, protects the opening from moisture and sunlight, as well as wind, dust, and other mechanical influences.

The starting profile is attached to a plastic window without the use of glue. The design not only helps to make the slopes visually attractive, but is also perfect for places where different materials meet.

The starting profile is most often mounted in this way: one side of it touches the wall, the other touches the plastic structure.

If the size of the material does not correspond to the required parameter, it can be cut using a stationery knife; for the same purpose, a grinder or a metal file is sometimes used.

Advantages

The starting profile for PVC windows has several obvious advantages:

- Ability to resist ultraviolet radiation. The profile does not fade even for ten years.

- The material is durable, looks good, and can fit into any interior without standing out.

- Suitable for use both indoors and from the facade.

- Moisture resistant.

- There is minimal chalk in the composition.

- The semicircular end of the tail allows you to lay the profile on the most uneven wall.

- Hides wall imperfections, levels slopes without the use of other materials.

- The plank can be safely cut, no chips or cracks will appear on it.

- Installation is carried out independently; this does not require special skills.

- No glue is used.

PVC windows and slopes

The starting profile for a PVC window sill is ideal, but it can be used not only with it, but also if the walls are made of sandwich panels. The material will help protect the inside of the panel, easily attach to it and last a long time.

Do not put the profile on glue. This action will cause it to crack when exposed to low temperatures and begin to leak moisture.

PVC fabric that is too cheap may also be excessively soft. This will make it fragile. The soft fabric does not last long and is not suitable for outdoor use. It easily deforms from any touch.

You should not save on materials; once you save and purchase low-quality PVC panels, you risk not only spending extra money on replacing them, but also incurring more serious costs if the window frame is deformed.

What is required for finishing

The starting profile is the main component. If the window is standard, you will need 6 meters (the fact is that the panels are sold in lengths of 3 and 6 m). In addition, you will need a drill or screwdriver, as well as metal cuts.

The F-profile is attached using liquid nails. Before its installation, a starting profile is attached. This is easy if the windows are level. Pay attention to the joints: they must be cut to fit exactly together. You need to start work from the side slopes. Insulation can be placed between the wall and the profile.

Improved thermal insulation

It is impossible to properly insulate the seam at the junction of the window frame using polyurethane foam alone, so a support strip is needed.

For high-quality thermal insulation, it is recommended to choose a product with at least 2 air chambers and a wall thickness of 2 mm or more. For regions with cold winters, the best option is 3 cameras. A profile that is too narrow and thin will become the weakest point of the entire structure.

Practice shows that the stand itself, even with 3 chambers, does not provide adequate thermal insulation. Additional insulation and sealing are required, which will be discussed below.

Varieties

In addition to the starting one, there are other types of moldings. F-shaped is used when it is necessary to beautifully “close” the joining of the ends. For example, these could be corners where two sheets of PVC, windows or doors, or other slopes meet, or they could be joints of two different materials, for example, plastic panels and wallpaper. In other words, it is used when moving to another plane. Judging by the name, you can guess that this connecting profile is shaped like the letter F.

The next mounting molding - connecting - is selected in situations where two panels need to be connected to each other. For example, when it turns out that the height of the panel is much smaller than the walls, and you have to “grow” it. This profile resembles the letter H and is therefore also called H-shaped.

External corner, as the name suggests, hides the places where the panels form external right angles. The outer corner is considered to be the outer corner. The internal corner, in turn, masks the joining of sheets in the internal corners, which are always straight.

A general-purpose universal corner has approximately the same characteristics as a decorative corner. It is available on the market in several sizes: its sides can be from 10 to 50 millimeters. It is used to hide those places where the panels meet at right angles. This molding can serve both external and internal corners; thanks to its design, it bends in the desired direction.

Galtel, also known as ceiling plinth, is used at the joints of the ceiling and the upper edges of PVC panels. It masks this transition and adds completeness to the overall picture. This molding can be colored and thus fits perfectly into any interior. In addition to the fillets, you can also find profiles at the top called external corners. They are used when peculiar protrusions are created at the top, for example, columns or beams. Finally, interior corners on the ceiling are mounted where the walls form the interior corner.

If necessary, the ceiling plinth is supplemented with a connecting element. This detail secures two skirting boards together when one is simply not enough. It is worth noting that the length of a standard plinth is 3 meters, but in large rooms this may not be enough. Guide rails for sheathing, according to some experts, are also considered a type of profile. The purpose of this element is to simplify the installation of PVC panels. If the sheathing, like the sheets themselves, is made of plastic, then they are connected using special clips.

Finish molding, as again you can guess from the name, is used to secure the last panel. It “completes” the entire structure.

Useful recommendations from professionals

In order not to make a mistake when choosing one profile or another, you should contact a store where sellers will be able to offer you ready-made kits that are ideal for the corresponding PVC panel. Otherwise, you can buy constructs that will not fit with the coating or not buy something important. When purchasing, you should definitely take into account where such molding will be applied, and depending on this, buy certain types of initial profile. For example, if you need to decorate a part of the surface where there will be no window openings or corners, then only those profiles that form the sheathing are required. If you have to decorate the ceilings, then do not forget about the ceiling skirting boards. Almost all manufacturing companies produce moldings in white, which is ideal for any type of interior. but if there is a need for multi-colored models, then you should either look for them in specialized stores, or order them individually. When choosing plastic moldings, it would be good to find those that have increased strength characteristics. If we talk about technical parameters, then you should pay attention to the groove width that is intended for the panel. To learn how to install PVC panels, watch the video.

Material selection

Currently, the market offers profiles made of plastic and metal. Plastic moldings are cheap, but not of high quality. It would simply be unreasonable to use them for serious tasks, so most often they are chosen as a decorative addition.

In general, if we talk about how the PVC panel and the profile are connected, it turns out that the panel is partially “placed” in the profile itself and is fixed there. Therefore, to ensure reliable fastening, preference should be given to metal molding, which can be steel or aluminum.

As a rule, metal elements are also treated with a special compound that can prevent rust.

If we talk about sheathing slats, they can also be made of wood, however, this material is quite capricious. Despite the cost savings, this design will not please the owners for long - the wood may begin to rot, be exposed to fungus or become moldy. Therefore, the choice is still made in favor of other materials.

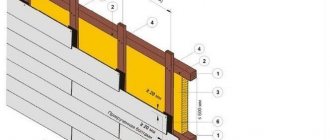

Fastening sandwich panels to special brackets for slopes

The difference between this method is that to fasten the panels, brackets are attached to the end of the window frame, which, instead of a “U” shaped profile, hold the base of the panel to the frame.

Installation of slopes made of sandwich panels with fastening to special brackets.

Positive features of this fastening method:

- The slopes look aesthetically pleasing and beautiful.

- Installation time is reduced.

A negative feature of this method is that if there is strong pressure on the base of the slope in a place where there is no bracket, the slope may come off the frame.

Despite this nuance, preference is given to mounting slopes on brackets, because the desire to improve the appearance exceeds the desire for reliability!

Dimensions

The dimensions of moldings for polyvinyl chloride panels depend primarily on the plastic sheets themselves, more precisely, their thickness. Usually there are four subtypes of profiles, the thickness of which corresponds to 3 mm, 5 mm, 8 mm and 10 mm. The usual profile length corresponds to 3 meters, and for a profile with a thickness of 3 millimeters - 2.5 meters.

Installation

Even before the installation of auxiliary components begins, it is necessary to calculate their required quantity. Both corners and other moldings are usually sold individually. They are selected in accordance with the color of the PVC, as well as taking into account their thickness. The planks must be attached to zinc-coated nails or regular self-tapping screws. When fastening is carried out, it is necessary to retreat at least 5 millimeters from the edge of the part. If the element is external, then it is glued to the slabs with a polymer-based composition. It is also worth mentioning that the profiles, if necessary, can be easily cut and brought to the required size. To ensure that they are aligned and placed parallel to each other, a regular thread is used.

Before installing the starting profile, it is important to clean the surfaces from dirt and, if necessary, level them; the quality of leveling can be assessed by using a level. In general, if a window opening is to be designed, the walls must be thoroughly cleaned of fasteners and other protruding parts.

It is also recommended to check window openings and frames for violations and deficiencies.

The starting profile must be secured to the sheathing with self-tapping screws. In general, regardless of the type of profile, they need to be installed so that a distance of 50 centimeters is maintained between them - this way it will be possible to mask all surface irregularities. Then a panel is installed in this profile, which is mounted on a rail. When the coating reaches the corner, it is time to use a corner profile, external or internal. Towards the end, the window and door slopes are covered with an F-profile, and the joints with the ceiling are covered with skirting boards. If necessary, connecting molding is also used. Installation occurs using staples, screws, nails or adhesive solutions. In the second case, however, it is worth remembering that the use of chemicals is possible only under specific temperature, humidity and other factors.

If the installation of PVC sheets takes place on the ceiling, then each sheet must be inserted into the profiles on three sides, so that its long side ends up in the initial molding. A screwdriver is used to correct errors. Again, speaking of the ceiling, the last panel is attached so that both sides are in the profiles.

In general, a certain sequence of fastening the moldings can be distinguished. First, elements are installed along the perimeter of the wall or ceiling, that is, the surface that is to be decorated. Opposite elements are mounted in such a way that they are in the same plane. Otherwise, curvature of the structure may occur, which will affect the joining of the panels themselves and, as a result, their appearance. The first profiles are attached either to brackets or to self-tapping screws.

Corners, both external and internal, are fixed according to the same principle.

Finally, the intermediate profiles are attached so as to connect the parts for which they are intended. Any process ends with the installation of skirting boards for the floor and ceiling and corners. They perfectly hide the joints and give the walls a finished look.

What it is?

F-shaped profiles are special metal trim strips equipped with a groove for the panel; they are designed for designing slopes. Some models are made from different types of plastic.

These structures have excellent resistance to ultraviolet radiation and can be installed independently without the help of specialists. Such profiles are quite elastic; the material can be easily bent if necessary, without breaking or crumbling.

F-shaped profiles are reusable. They can be quickly removed and installed in another place. In addition, such products have an aesthetic appearance. They allow you to give structures a finished look and fasten them securely and tightly.

Such decorative elements will not turn yellow and lose their original appearance for a long time. In addition, they are equipped with a special semicircular shank, which makes it possible to fix the element even on curved surfaces.

After cutting such planks, chips and cracks will not form on their surface. These parts can last as long as possible; if necessary, they can be easily replaced with new ones yourself.

Application area

F-profiles can be used in many areas of construction. But most often they are used for finishing cladding of window structures. At the same time, the products will ensure the tightest possible connection of the panels to the wall coverings.

These profiles are often used in the design of door structures. Moreover, their installation does not require the use of a special adhesive composition. With the help of such products it is easy to make even and neat joining of even different materials.

Sometimes these elements are taken as a starting profile. In this case, one of the sides will be pressed tightly against the wall, and the other - against the slope.

F-shaped models can be used when installing siding. In this case, they will cover the end if the surface on it is not finished with material. This makes for a much more beautiful and neat design.

Parts of this type may well be suitable for decking boards. This material is used in the construction of verandas and terraces in suburban areas. The profile will allow you to carefully hide all the imperfections and make the finished structure more beautiful.

Sometimes the parts are used for sandwich panels, which are a durable three-layer building material with an insulating layer, for the construction of structures made of plasterboard or gypsum vinyl, polycarbonate.

Metal F-shaped models can be purchased when designing the most winding staircases. After all, they are easy to bend, giving the necessary smooth shape, and they will not break. To give a wavy shape, a special metal bending machine is often used; it allows you to process the structure right at the installation site.

Why do you need a support profile for plastic windows?

The architectural features of modern and old buildings are such that in the area of the lower border of the window, air is pumped under the external tides. In Soviet times, they combated this by placing heating radiators directly under the windows. Now they are often trying to remove them from prominent places, so special attention should be paid to the window sill area and eliminate the possibility of cold bridges appearing there. To solve this problem, a stand profile is installed.

The presence of internal air chambers improves the thermal insulation of the window, and the design of the strip makes it easier to solve several issues at once.

Types and sizes

These types of building profiles can be classified into separate groups depending on the material from which they are made. Most often there are several types of models.

- Aluminum. Such metal products are particularly durable. They can last a long time without breakage or deformation. In addition, profiles made of aluminum are lightweight, making installation as easy as possible. They are resistant to fire; the aluminum structure is almost impossible to set on fire. It should be noted that the material is absolutely safe for humans. A special anodized coating is most often applied to the surface of aluminum parts, which also significantly extends their service life.

- Brass. These varieties have fairly high strength, resistance to corrosion, and flexibility. They are easy to install and are often fixed using silicone sealant. Brass products allow you to create the most accurate joining.

- Steel. As a rule, stainless steel is used in the manufacture of such parts. It boasts a high level of quality, durability and increased wear resistance. Products made from this metal are relatively lightweight; over time, a layer of corrosion will not form on their surface.

- Plastic. It is plastic profiles that are most often used in the design of window openings. They, as a rule, have a low thermal conductivity, good sound insulation, and resistance to various atmospheric influences. In addition, plastic models also boast durability and relatively low cost.

Such profiles can also be divided into separate groups depending on what design features they have.

- Finite. This type of profile is used for reliable and durable fixation of the slope to the wall, as well as simply for finishing window openings. Products can be painted in a variety of colors, but white and brown models are more common, and there are also black samples. Most often they are made from high quality plastic. These structures easily withstand exposure to ultraviolet radiation and sudden temperature changes. As a rule, they are attached using special screws.

- Laminated. This type is a standard F-shaped building profile, and its surface is covered with a special decorative coating. The outer film of such structures is highly durable and wear-resistant. It can be applied to the surface of products using powder dyes.

In construction stores, buyers can see a wide variety of such profiles. They all have different sizes. Mostly there are samples with the following values: 3000x10 mm, 2700x12 mm, 4000x30 mm.

The width of these decorative structures can vary significantly. You can often see such products with a value of 8 mm, 10 mm, 45 mm. Wider options are also available: 60 mm, 65 mm, 70 mm.

fprofile and scope of its application

Installing slopes on PVC windows

For complete cladding with PVC panels, various additional elements are used, which help to perform the installation efficiently and correctly. fprofile is one of

of these elements, which outwardly looks like a plank, the cut of which resembles the letter “F”. The ends of the plate are securely fixed in the grooves of the profile during installation. The F profile serves two functions:

- Decorative design of the ends of the trim

- Aligning the common plane

Preparatory work

Before installing slopes on windows, it is necessary to carry out preparatory work related to the preparation of walls. This work is not long, but it is necessary. After dismantling the old window, a lot of dust and dirt remains, which must be swept away with a broom, or better yet, removed with a vacuum cleaner. In some cases, it is necessary to knock down old plastered slopes, because they can interfere with the correct installation of new ones. It may be necessary to plaster the cracks between the bricks with a thin layer, because in old houses cold air from the street blows very strongly from these cracks! After this, the surface must be treated with a primer or plain water.

The most common methods of installing plastic sandwich panels for slopes is mounting on a U-shaped (starting) profile.

Photo of a “U” shaped (starting) plastic profile for installing slopes on windows.

And fastening to special brackets for slopes.

Photo of brackets for installing sandwich panels on plastic windows.

We install PVC panels and profiles

External slopes for PVC windows

To begin with, I will give advice that there is no need to save on PVC panels. This material will last for many years and therefore you should not spare money on a high-quality plastic sheet. Cheap PVC sheets are very soft and one careless movement can make a hole in them.

What do we need to finish the slopes:

- 6 meters of high-quality PVC fabric. If you are worried about the thought: why exactly 6 meters? – then the answer is simple. Panels are manufactured in lengths of 3 and 6 meters - a three-meter sheet may not be enough, but 6 meters is just enough.

- Start and f profile.

- Thermal insulation material for processing window openings, mineral wool is suitable.

- Self-tapping screws for metal - in the popular language “bugs”, “fleas”, “tex”. With their help, the starting profile is attached.

- Screwdriver and construction knife.

After the foam has dried, we attach the F-shaped profile to “liquid nails.”

First of all, we fix the starting profile. The process will not cause any inconvenience, because the windows are installed strictly according to the level - so it is not needed for the starting profile. Using the back side, use self-tapping screws to secure it along the edge of the window frame. The main thing is to trim the profile correctly so that there are no flaws in the corners at the joints. After this, we proceed to install the PVC sheet. First of all, we block the side slopes by inserting the eraser into the starting bar. Don't forget to add a layer of insulation! At this stage, the work also turns out to be simple and does not pose any difficulties.

The use of PVC panels and F-profiles for finishing the external slope

We are slowly approaching the completion of the “difficult” process and are launching our f profile. Carefully cut the strips to the required length and attach them to the plastic with grooves. Some people still resort to using liquid glue and firmly glue the f strips to the wall, but I did not consider this to be the necessary action and abandoned this advice. If you have small gaps somewhere, then white silicone will help with masking.

Installation methods

Let's consider the simplest method of fixing F-shaped profiles when finishing slopes. First you will need to secure the starting part. Installation is carried out from the back using special self-tapping screws. The element is attached to the edges of the frame.

The main thing is to trim the structure correctly. This should be done in such a way that there are no significant defects in the corners at the joints. After this, you can begin installing PVC panels. First, the side slopes are covered, and an eraser is inserted into the bar. At this stage, we must not forget about laying an additional insulating layer.

At the final stage, another profile is taken. It is trimmed a little, adjusting to the desired length. After this, the part is attached to the plastic part with grooves.

An installation method that uses special liquid glue is often used. If, as a result, cracks appear in the structure after installation, they can be removed using silicone sealant.

After installation, the part will look like a small and neat corner that hides the joints, while simultaneously ensuring a reliable connection of different or identical building materials.

Installation

There are 2 ways to install a window sill profile.

Method No. 1

With this option, the window sill strip is installed first, and then the frame.

- A piece of the required size is cut.

- It is placed in the opening and leveled using a building level.

- A preliminary fitting of the window frame is done. If there is a gap between it and the top of the opening, it can be eliminated by raising the support bar. To do this, you can place pieces of timber under it.

- The space between the bar and the opening is filled with polyurethane foam.

Mr. Build recommends that to prevent the “bare” bottom profile from becoming a weak point of the entire structure in terms of freezing, it must be additionally insulated. To do this, extruded polystyrene foam, cross-linked polyethylene or other insulation in the form of a bar is inserted into one of its chambers.

Method number 2

Experienced professionals do things differently:

- Detach the support strip from the frame.

- Insulation is placed in the profile chamber.

- Glue sealing tape to the bottom of the frame or apply mounting foam to the joint, as shown in the photo. You can use both at the same time.

Let’s assume an option using cross-linked polyethylene, which is located not in the chamber, but at the junction of the bar and the frame. But at least somewhere there must be insulation!

- The window block is installed together with the bottom profile.

Mr. Build recommends the second installation option: it is guaranteed to prevent freezing of the joint and the formation of cold bridges in the window sill area.

The window sill profile will ensure strong fastening of additional elements of the window block, and its high-quality installation will provide thermal insulation. The video below shows how to achieve 100% efficiency during its installation and not leave a single loophole for the cold, using EPS insulation, polyurethane foam and sealant.

(votes: 4 , average rating: 3.00 out of 5)

Window profile F-shaped, 2.5 m

Description

The profile is intended for decorative interior decoration during the assembly and installation of windows and installation of slopes. Used to close gaps or fastening elements. Size - 250 x 5 cm.

Characteristics

Product type Slope profile Manufacturer's article 10000477 Type F-shaped Material PVC Color white Length, cm 250 Width, cm 5 For panels thick, mm 10 Weight, g 150 Country of origin Russia Additional information The width of the product is composite - 50 mm (main part profile) + 10 mm (slope) Package dimensions (WxHxD), cm 8 x 250 x 5

Sources

- https://plastokonnik.com/napravlyayuschie-dlya-otkosov-plastikovyh-okon/

- https://delaydachu.ru/steny/f-profil-pvh-dlya-otkosov.html

- https://dekoriko.ru/paneli-pvh/startovyj-profil/

- https://stroy-podskazka.ru/stroitelnyj-profil/kakim-byvaet-f-obraznyj/

- https://LeroyMerlin.ru/product/profil-pvh-f-obraznyy-dlya-paneley-5-mm-18720743/

- https://www.Castorama.ru/profil-okonnyj-f-obraznyj