Aerated concrete is a lightweight and fragile material that can be easily processed even with hand tools, and power tools can handle it much faster and even more so. When laying aerated concrete blocks, you will have to saw them, grind them, drill them, make grooves and holes. In this article we will talk about all kinds of tools that are useful for processing aerated concrete.

You can cut aerated concrete with hand saws for wood and aerated concrete, but it is better to give preference to a specialized saw, as it will last much longer and will save you money on buying a new blade. And a power tool, such as a reciprocating saw or an alligator saw, will greatly speed up sawing and save you effort, which would be better spent on laying the blocks themselves.

Special hacksaw for aerated concrete

A hand saw for aerated concrete is very similar to a saw for wood, the differences are in the teeth, which have a different shape, size, and wear-resistant coating. A hacksaw for a gas block is very justified on private construction sites, where the volume of work is small and the number of cuts is small.

With the help of such a tool, additional blocks are cut, holes are made in the wall, and window and door openings are adjusted.

Note that for smoother and more convenient cutting and fitting, auxiliary tools will be useful, such as a special corner and aerated concrete grater.

Cutting Notches

To install jumpers or fill an armored belt, you need special U-blocks with a recess-trough into which reinforcement is installed and concrete is poured. It is better to buy them ready-made. But it happens that it was not available or there was not enough, and you have to think about how to cut the gas block to obtain such a complex shape.

All of the tools listed can be used, but with their help it is difficult to achieve the same depth of the slots and an even line of their “bottom”. In such cases, I recommend a circular or circular saw, the blade of which can be set to the desired height. If you have a wall chaser, even better.

How to make a block with a recess yourself, watch the video:

Reciprocating saw

An electric reciprocating saw is an excellent assistant for cutting aerated concrete, which saves effort and time. The cost of such a saw is reasonable, and for private construction its purchase is completely justified, especially since it can also cut wood.

The principle of operation of a reciprocating saw is in a replaceable blade, which very quickly makes rotational and translational movements. The length of the blade can be different, and for more convenient work we recommend blades longer than the thickness of the block.

Advantages of a reciprocating saw: good speed, cutting accuracy, minimal groove width, reasonable price.

How to cut aerated concrete at home?

Step-by-step algorithm of actions:

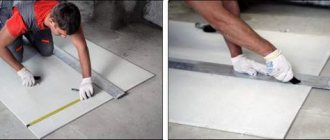

- Before you begin, you need to mark the lines along which the cut will be made. To apply markings, use a pencil, square, tape measure and ruler.

To cut the block lengthwise along the lines, make cuts to a depth of up to 3 cm. This will avoid the formation of chips. These notches will act as guides.- The cut starts from any side. Do not put too much pressure on the saw. It is positioned relative to the block at an angle of 45 degrees. Work continues until the block is cut.

It is possible that you will not be able to cope with the task the first time, so you need to take care of the availability of additional blocks.

Manual wall chaser

The most common tool for cutting aerated concrete is a regular wall chaser, which is a tube with a handle. The principle of operation is to press hard on the aerated concrete and pull in the desired direction, while selecting pieces of aerated concrete. For a more even cut, it is worth using a guide block made of wood, which is temporarily secured with nails or self-tapping screws. Among the important advantages, we note the absence of dust and noise during operation.

Alligator

The alligator-type saw is particularly durable and wear-resistant. The teeth of such a saw have special coatings made of pobedite, which makes the teeth more durable. This tool is used in the construction of large objects (apartment buildings, large offices).

The advantage of this tool is that it does not need to be constantly sharpened or blades changed, as, for example, in an electric jigsaw.

When purchasing such a saw, it is better to choose an option with a thick-walled blade, since only cutting with such a blade will give an even cut without chips or roughness.

It is often written that before starting to work with such a saw, you need to lubricate the surface with a special lubricant, but practice says otherwise. The lubricant mixes with dust, causing the saw to stop working.

Although the instructions for most tools of this type specify the use of lubricant. The absence of lubricant increases productivity significantly.

Grinder and electric wall chaser

There are special attachments for the grinder, which are two metal disks that leave behind two even grooves.

There are also specialized grinders, the so-called electric wall chasers, in which you can adjust the width and depth of the groove. After cutting, the aerated concrete itself must be selected using a chisel and hammer. Among the advantages, we note the high speed and evenness of the cut, and among the disadvantages, there is a large amount of dust, which will require connecting a vacuum cleaner.

How to cut aerated concrete blocks: 5 suitable tools

Alligator saw

This professional power tool is equipped with two cutting edges arranged in parallel.

When the motor is turned on, they move in opposite directions, which increases cutting speed and accuracy. The alligator chews its food in a similar way. This similarity explains the unusual name of the electric saw. Porous aerated concrete is sawn through very quickly and easily in this way. The worker does not have to put in almost any effort. The advantages of Alligator cutting include speed and high cutting accuracy. Operating this power tool is safe and quite simple. When the teeth become clogged, the locking mechanism is activated and it stops. Impact-free cutting does not leave chips on the surface.

There are also disadvantages. One of them is limited application. Blind holes, for example, cannot be cut with such a device. Like any professional equipment, the Alligator is expensive. It is not advisable to buy it for one-time work.

Instagram vovcka_dewalt

Instagram vovcka_dewalt

4. Chainsaw

It is considered a universal power tool, although it was originally used for sawing wood. The design of the equipment is quite complex. The cutting chain is closed in a loop. It moves through two sprockets along a guide rail. Another sprocket secures this system to the drive shaft, through which the movement of the electric motor is transmitted. The degree of chain tension is adjustable, this ensures normal operation of the equipment.

The advantages of working with chain power tools are high speed and maximum cutting accuracy. Professionals choose it for making U-shaped notches and complex shaped cuts. The electrical equipment is optimally balanced and is comfortable to work in any position, including sawing overhead and at any angle. You can change the length of the guide bar, which allows you to work with blocks of different sizes.

Disadvantages: the chain gets dull quickly. Therefore, it is best to choose a chain with pobedit tips for working with aerated concrete, but it will also have to be sharpened from time to time. Another disadvantage is the stretching of the chain circuit during continuous sawing, the chain heats up and stretches. Therefore, it is advisable to take cooling breaks and keep the power tool away from dust.

This tool is not designed to work with gas blocks. Therefore it gets very hot. The sprockets quickly wear down and fail. This is not a problem, since replacing them is a simple and inexpensive procedure. It is much worse if dust clogs the electric motor and it breaks. It will be impossible to restore it. Novice builders are interested in whether it is possible to cut aerated concrete with a chainsaw. This is a gasoline analogue of an electric chain saw. It also cuts blocks well, and can also fail due to dust and overloads. Considering that its price is much higher than that of the electric modification, it is better not to risk it.

When might cutting or sawing be required?

Concrete blocks come in standard sizes and the building materials market rarely focuses on selling anything non-standard.

During the construction process, the master understands that he needs to find a block that could complete the masonry in a certain place, and standard material will not work here. In such a situation, you have to resort to cutting the block concrete material.

If concrete blocks of non-standard size are needed in large quantities, then it is better to cast them yourself using homemade molds. You can also order non-standard blocks from the manufacturer, but this will cost more.

Often, a builder may need half or a quarter of a whole concrete block. Then you need to make a cut.

Similar situations often occur when pouring a strip foundation, when all the blocks must be the same size, and when completing its arrangement, several elements are missing. The same situation can arise when constructing a building according to an established design, when the thickness of the walls is already clearly defined and it is impossible to deviate from the values.

Often, when laying corners, it is not possible to fit the concrete block correctly and gaps remain between the stones. Many builders fill them with fragments of material, which is also not entirely true. In this case, it is recommended to pay attention to the tools and methods by which you can quickly and easily cut concrete block material.

Additional accessories for cutting aerated concrete

Miter box for cutting aerated concrete

For certain types of work use:

- A special plane is a grater with an iron sole and handle. Allows precise alignment of sawn blocks, making them easier to lay.

- A manual wall chaser is a bent iron pipe with a handle, which allows you to make rounded grooves on the surface of the blocks for laying fittings, pipes, etc. in them. (after the construction of the building).

- An electric wall chaser is similar in appearance to a circular saw, but it uses two discs. Due to the precise mechanism for adjusting the depth of the saw, it is possible to make the necessary slots for the grooves. They can also be cut with a grinder.

- Crowns - it is advisable to buy ones for concrete, with a durable pobedit cutting tip. Allows you to make holes in ceilings and walls for laying ventilation ducts, installing sockets, etc.

- Angle – allows you to control the cutting process.

To ensure accurate cutting of aerated concrete, it is better to make a miter box yourself - a wooden rectangular structure in the shape of two letters P, fixed to the platform with corners. The block should fit inside these letters without any problems. There must be a normal gap between them to make the cut. The gap should allow the saw to move freely, but it should not move to the sides. It should be larger in the plane of the platform than on the sides. This will allow waste to fall in as you work.

Safety precautions when sawing aerated concrete require the use of certain technologies taking into account the tool used, as well as special clothing (suit, boots, gloves or mittens) and personal protective equipment (respirators, masks or goggles).

What you need to know about cutting foam concrete?

A guarantee that the cutting of foam concrete will be of high quality is not only the correct selection of cutting tools, but also well-made markings on the block itself. In addition, you just need to be able to use the tool you are using and, of course, do not forget about safety precautions, especially if you are using an automated saw.

To do this, each device, as a rule, has instructions with a photo, which shows the main components and the correct position of the tool when used.

Note! Stability, quality and accuracy of cutting are ensured by strong fastening of the foam block and the correct direction of the cutting part of the tool. The saw blade must be directed perpendicular to the plane of its surface into which it cuts, and in accordance with the markings. For accurate and precise cutting, a special tool is used - a corner for foam blocks.

The video in this article shows how to properly hold the tool and the foam block itself when cutting it.

Other tools

To lay blocks on glue, use a hacksaw for aerated concrete, a special trowel-bucket, a grater, and a wall chaser. You will also need the following auxiliary devices:

- To make the work easier, you will need to press the saw against the aerated concrete surface, so you will need to purchase a limiter for the blade stroke. This method will increase quality, accuracy and speed. In this case, it is possible to shift the stop, which will provide the desired step width when cutting blocks.

- The pendulum system will increase the speed of work and remove waste from the working surface, thus extending the service life of the blade and reducing the load on the hand. Not every model has this feature.

- A drill cutter for aerated concrete is suitable for making grooves for reinforcement.