A modern residential building is crammed with electrical equipment, panels and other devices connected to each other by wires of a single electrical network. Contact connection points become the most vulnerable places, the failure of which can lead to dire consequences. An important task is the selection and installation of such small mounting accessories as terminals, which are difficult to do without when connecting conductors or equipment.

The element base is constantly updated with advanced developments, excluding old samples from use. Therefore, this review will help you not to get lost in the wide range of these electrical products. For a home craftsman who independently installs electrical wiring in an apartment, it will be useful to learn how to choose the right models, what to look for, as well as what mistakes there are when choosing to avoid when purchasing.

Traditional switching devices

Terminal blocks, unlike terminals, which are an integral part of conductors, act as devices for switching wires:

- isolated;

- naked;

- with fixed terminals.

Material:

• ceramics – for installations with special temperature conditions or heating devices

• polypropylene – for lighting devices

• polyamide – in heavy-duty pads

• carbolite – for cars and devices with high vibration loads

• polyvinyl chloride – in low-current connections

• textolite and ebonite

To reduce contact resistance and reduce heating, conductive pastes are often used, applied to increase anti-corrosion properties.

Screw terminal blocks

Electrical (construction)

Made in the form of steel or brass sleeves, equipped with clamps with screws and mounted in a non-flammable polymer block. Permissible load of connected wires with a cross-section of up to 35 mm² up to 100 A. Permissible voltage up to 600 V. Mounted in the machine for installing fuses that protect the terminal block installation line and outgoing connections.

Advantages:

- ease of operation;

- reliability of contact;

- suitable for vehicles;

- minimum price.

Flaws:

- the possibility of crushing wires with a screw during installation due to the softness of aluminum or copper;

- high probability of overheating with subsequent loss of contact;

- the need to use brass lugs for stranded copper conductors;

- gradual weakening of the screw clamping force with the need to periodically check the fastening.

Barrier

Made in the form of copper or brass plates installed in a getinax body. The permissible current strength at an operating voltage of up to 1 kW is up to 200 A. The cable cross-section can reach 100 sq. mm. Typically used on powerful power plants.

Advantages:

- reliable connection contact;

- collapsible design;

- organizing conductors;

- mounting on the dashboard, DIN rail, printed circuit board;

- the presence of plexiglass for protection against short circuits or accidental contacts;

- visual monitoring of connection status.

Flaws:

- increased contact resistance;

- installation duration;

- the need to equip conductors with lugs for reliable contact.

Clamp terminal blocks

Self-clamping

The solid polymer case contains a brass-plated metal pressure plate that is activated when the conductor is inserted all the way. The bare core is then securely pressed against the tinned busbar.

Advantages:

- ease of installation;

- connection reliability;

- good ordering;

- low price;

- possibility of connecting copper-aluminum;

- with the function of improving contact when heating.

Flaws:

- used for fastening cables with a small cross-section of no more than 4 mm²;

- low permissible current value up to 25 A, limiting use on powerful networks;

- impossibility of using stranded wires due to low rigidity when pushing through the plates.

Spring

The polymer housing contains two contact plates made of brass. One is movable, and the second is rigidly fixed. After installing the conductor, the movable contact is lowered and snapped onto the latch. The installed spring is pressed, providing pressure and a reliable connection.

Advantages:

- easy installation and replacement;

- preventing accidental contact;

- permissibility of joining different materials - aluminum and copper;

- possibility of using multi-core wires;

- presence of a contact for remote grounding.

Flaws:

- the possibility of the spring pressure weakening over time or as a result of heating;

- suitable for wires with a small cross-section of no more than 2.5 mm²;

- Application for low currents up to 25 A.

How to choose the right terminal clamps

It is worth understanding that all work related to electricity is quite dangerous, so you need to select the right materials and devices for electrical installation work.

Experienced specialists highlight several recommendations on the correct choice of terminal clamps for wires.

Let's look at some of them:

- Select the correct terminal type, as they all differ in current carrying capacity and permissible wire size.

- For work with power buses or heating equipment, terminal blocks made of ceramic material are best suited, as they can withstand very high temperatures.

- When working with household lighting devices, select terminals made of polypropylene, as they are highly durable and not subject to deformation.

- For work with blocks that require increased loads, choose terminals made of polyamide, which can withstand any overload.

- To work with equipment that produces vibration, choose terminals made of carbolite, which is resistant to static loads.

- For work with low-current connections, a polyvinyl chloride terminal is suitable.

Foreign-made terminal blocks

The best manufacturers have developed convenient technologies and innovations that have made it possible to transform classic terminals into unique connection interfaces.

Pressing Push Wire

A one-piece product that uses rigidity properties for reliable fastening. Installation is performed by pushing the stripped end of the wire into the hole. Removal is carried out by unscrewing the wire.

Types of connectors:

- for a single wire;

- for wires with reduced rigidity.

It is almost impossible to pull out the installed wire without damage!

Power spring Power cage clamp

Universal terminal block for all types of electrical wires with a cross-section of up to 95 mm². Consists of a double cage equipped with a spring with a press and a metal tire.

The connection is made using a hexagon for pressing. After installation, the key turns and the lowered press reliably presses the conductor.

Stacked self-clamping Cage clamp

Exclusive technology, patented by WAGO, for conductors of any conductor cross-section up to 35 mm². The connection is made by lifting the spring clamp using a special lever. After installing the conductor, the clamp is lowered back.

terminal block WAGO

Self-clamping Cage clamp S

Use does not involve the use of electrician's tools. The connection is made by installing the bare end of the wire all the way.

Peculiarities

When carrying out a major renovation, a person changes everything in his house, including the wiring. A new junction box is installed where wiring needs to be done. To do this better, it is best to use terminal blocks. This is an excellent device that will provide tight fixation for the entire period of operation.

Today, new types of this product are being produced, which are many times superior to screw ones. To carry out installation and wiring, a person will need a minimum of time. This was largely made possible thanks to self-clamping terminals.

Criterias of choice

In the process of selecting the appropriate type of terminal block for electrical wiring, the following parameters are taken into account:

- installation method and method;

- brand and material of manufacture;

- operating voltage and permissible current;

- number of connected conductors;

- minimum section;

- the need to connect wires of different metals.

Section selection table

The selection of suitable terminals must be approached carefully. After all, you often have to connect different metals, which gradually heat up and deform. The result is a short circuit and complete loss of electrical circuit integrity.

Screw or spring terminal blocks are not suitable for connecting aluminum and copper wires!

Technical requirements for terminal clamps

Before selecting terminals, you need to pay attention to the requirements for these devices. They must have high safety, since the terminals involve working with electrical networks.

Let's look at the list of these requirements:

- The terminals must be made of high quality plastic that can withstand high temperatures. Typically, devices made from liquid crystal polymers are chosen.

- The plastic must have fire-resistant properties. Typically, plastic containing polyamide is chosen.

- The terminal clamp must be made of materials that can withstand high temperatures and do not corrode. Typically, clamps made of stainless materials are chosen.

Where can I buy

Before going to a specialized department of an electrical store to purchase the necessary accessories, it is advisable to read the best reviews and recommendations from customers, as well as find out the advice of a professional electrician.

Electrical goods stores offer a wide range of terminal blocks, so you need to choose budget products that are suitable for a specific installation. You can find out which company is better to buy in advance or directly from a consultant who has undergone special electrical training.

In addition, you can order terminals online from an online store of construction or electrical marketplaces. The Yandex.Market aggregator also offers to find out how much the required terminal block costs, read the description, compare functionality, select a store and order online.

Conclusions and useful video on the topic

The presented video material will expand your knowledge about the types of terminals and methods of their installation.

Electrical installation work is rarely complete without the use of the described accessories. It would seem that these are small details that are easy to discard, replacing the technological connection with the usual twisting of wires.

But the practice of electrical engineering is marked by a lot of cases where it is the banal twisting of conductors instead of a reliable terminal connection that leads to tragic consequences .

Do you have experience using terminals to connect wires? Or still have questions on the topic? Please share your opinion and leave comments. The communication block is located below.

Rating of quality terminals from the best manufacturers

The domestic electrical goods market is saturated with products from Russian, European and Chinese manufacturers. Many people do not pay much attention to the homeland of origin of the terminal blocks. However, if these small devices fail, they can significantly affect the safety of property. Therefore, we must take into account that inexpensive Chinese consumer goods at a budget price rarely meet the requirements of the standards.

Products from Russian enterprises are reliable, but, according to buyers, they are technologically and aesthetically inferior to goods from Europe, which are more expensive but of the highest quality.

STEKKER

The models of the German company are used for reliable installation of electrical circuits with a large number of wires of different conductors in a small limited volume, like in a junction box. Manufactured in a transparent case, allowing you to monitor the state of the contact. The installation speed is ensured by the rounded ends of the working levers.

STEKKER terminal

Characteristics:

| LD222-412 | LD222-413 | LD222-415 | LD222-418 | LD226-10A | |

| Current, A | 32 | 32 | 32 | 32 | 10 |

| Voltage, V | 250 | 250 | 250 | 250 | 250 |

| Section, sq.mm | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 4 |

| Number of contacts | 2 | 3 | 5 | 8 | 12 |

| Amount in a package | 1 | 50 | 40 | 5 | 10 |

| price, rub. | 87 | 900 | 1080 | 247 | 700 |

Advantages:

- no special tools or skills are needed for quick installation;

- convenient marking;

- long service life up to 10 years;

- high quality materials;

- good fire resistance;

- modern design.

Flaws:

- no obvious ones were identified.

Legrand

French manufacturer of electrical products known throughout the world. The most popular product in this segment are screw terminal blocks.

Nickel-plated brass products are highly resistant to sudden temperature changes. The popularity of the models is due to their durability and large range of sizes.

Legrand terminal

Characteristics:

| Block 2.5-4 sq.mm | Block up to 10 sq.mm | Block up to 16 sq.mm | Terminal block 4x1.5-16 sq. mm | Terminal block 1x6-25 sq. mm | |

| Current, A | 24 | 57 | 76 | 80 | 100 |

| Voltage, V | 250 | 250 | 250 | 400 | 400 |

| Number of clamps | 12 | 12 | 12 | 4 | 1 |

| Section, sq.mm | 2,5 — 4,0 | 10 | 16 | 16 | 25 |

| Average price, rub. | 167 | 310 | 579 | 262 | 649 |

Advantages:

- reliability;

- heat resistance;

- long service life;

- high build quality.

Flaws:

- no obvious ones were identified.

Legrand Viking 3 terminal blocks - in video review:

One of the leaders in the production of terminals from Germany. Products are manufactured at nine factories. Single-use or reusable products are characterized by high connection reliability and ease of operation.

Models in a durable ceramic case have good anti-vibration resistance and are used for automotive wiring. The conductive element is tinned copper, which provides low resistance to strong contact. Some popular models are filled with anti-corrosion gel.

WAGO terminal

Characteristics:

| 221-412 | 221-413 | 222-412 | 222-413 | 222-415 | 2273-203 | |

| Current, A | 32 | 32 | 32 | 32 | 32 | 24 |

| Voltage, V | 450 | 450 | 400 | 400 | 400 | 450 |

| Section, sq.mm | 0,14-4 | 0,14-4 | 0,08-4 | 0,08-4 | 0,08-4 | 0,5-2,5 |

| Number of contacts | 2 | 3 | 2 | 3 | 5 | 3 |

| Amount in a package | 20 | 20 | 5 | 20 | 5 | 20 |

| price, rub. | 508 | 570 | 88 | 443 | 164 | 186 |

Advantages:

- tight connection;

- high build quality;

- quick installation;

- stylish design.

Flaws:

- not suitable for use in power electrical circuits with a load power greater than 7 kW;

- requires regular maintenance, so it must be in the public domain without being covered with plaster;

- There are many Chinese fakes and similar analogues, but with different characteristics.

Video about WAGO terminals:

Wire connection options

Connections are made in several ways:

- mechanical twisting of wires

- switching conductors by soldering or welding

- terminal blocks for connecting wires

Any connection must satisfy a number of requirements to ensure its reliability and safety:

- availability for inspection and repair

- sufficient mechanical strength

- electrical resistance is not more than 1.2 times the electrical resistance of the entire conductor

- stability of properties throughout the entire service life

Twisting wires

This connection method is no longer provided for by the Electrical Installation Rules, but is still very widely found in practice, especially in the electrical wiring of old houses. Instead of this type, switching with insulating clamps (ICP) is used, represented by special caps with an internal steel spring. These caps are screwed onto a bundle of several conductors, forming their strong mechanical and electrical contact. Applicable only to conductors made of homogeneous materials.

Soldering or welding

This connection method is very labor-intensive and requires special equipment and training for the installer. As a rule, it is found during the installation of low-current electrical systems and is a type of permanent connection. It is also used for wires made of homogeneous materials.

Terminal blocks

This switching option satisfies all requirements and is the least labor-intensive to install, which has made it the most widely used in recent years, especially when the corresponding materials have become widely available in the retail chain. Switching conductors using a terminal block is also used for wires made of various materials.

Types of connectors presented on the electrical market

Terminal blocks for connecting cables can be of several types. You should choose those that will be more convenient to install in a given situation. The connection density will be at the proper level, regardless of which type is selected. Let's take a brief look at the general information.

Screw connectors and their features

The cheapest terminals are brass tubes in a plastic shell with a pair of screws. They allow the connection of copper and aluminum conductors, but are not very convenient when switching several wires is required.

Screw connection bars can also be considered terminal blocks

Wire clamps or spring terminals

Depending on the number of sockets, wire clamps allow you to connect from two to eight wires. But for industrial connections, terminal blocks for 16 cores are also produced. Can be disposable or reusable. But disposable is just a name; reuse is possible. The difficulty arises only in removing the cable core from the terminal. The advice to “slip in a thin screwdriver and squeeze out the paw” is absurd. It's impossible to do this. It's easier to do the following. Holding the connector with one hand, pull the wire towards you with the other, scrolling left and right. After two or three “twists” the core comes out of the socket and the terminal block is again ready for use.

Spring self-clamping terminal blocks are most convenient for installing electrical wiring

Features of fused connectors

These terminals are mounted on a DIN rail. They have special grooves where the fuse is installed. This provides additional protection against overloads or short circuits.

Features of using terminal blocks

These connectors are popular when installing lighting. The housing can withstand temperatures up to 105°C, and springs with copper plates tightly press the cable cores. It is possible to add graphite paste to eliminate the possibility of oxidation.

Terminal blocks for the lazy: knife connectors

A special feature of knife terminal blocks is that there is no need to clean the insulation before connecting. The special design automatically cuts it in the right place, ensuring tight contact.

For such terminals, preliminary stripping of insulation is not required.

Twisting of conductors

Due to the relocation of the electric stove in the kitchen, it is not always possible to lay a new power cable, so you have to extend the old one. Some plates can consume up to 7 kW of electricity, and here ordinary twisting is not enough, and soldering or welding conductors is labor-intensive. In this case, it is better to use a terminal block designed for a rated current of 60A to connect the conductors.

Distinctive features of Wago

They are a small plastic box with a reliable clamping mechanism inside. They are practical and simple.

- When using these products, each electrical wire has a separate terminal.

- The exposed wire is located inside the clamp, so there is no possibility of contact with it.

- Easy to install, even a beginner can handle it.

- During installation, the wires are not deformed due to the fact that the spring terminal adapts to the cross-sectional area of the cable and the appropriate compression force is applied.

- Durable and reliable, resistant to vibrations and shocks.

- Bare wires are protected from oxygen and moisture and do not oxidize.

- Compactness.

- Do not require constant monitoring and maintenance.

It is recommended to install the VAG connections in an accessible location.

What materials does it consist of?

Wago clamps consist of a plastic housing and terminals. The terminals are made of specially tinning electrolytic copper, chromium and nickel steel for springs and dielectrics for transporting conductive elements. Plastic materials made on the basis of linear high-molecular synthetic compounds and thermoplastics act as dielectrics.

| Technical indicators | ||

| Passing current (A) | Cable cross-sectional area (mm²) | Voltage (V) |

| From 6 to 232 | From 0.08 to 95 | From 100 to 1000 |

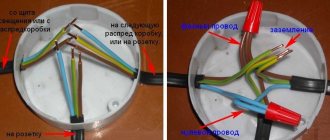

Connecting various electrical receivers in the junction box

Now you can directly examine the connection of the wires in the distribution box. After all, it largely depends on the type of device being connected, as well as on the number of these devices. Sometimes it is advisable to create two or even three distribution boxes for one room rather than trying to fit all the connections into one.

Connecting group wires

First of all, we need to determine whether we have an end or pass-through junction box. Ideally, each junction box should be an end box.

A terminal box is a junction box that does not have wires connecting it to other junction boxes. A pass-through is a box that has such a connection.

The photo shows a walk-through junction box with an outlet connection

So:

The end distribution box contains three cores of the power cable or wire from which the end consumers are powered.

- The feed-through junction box has three supply wires, which are usually connected to the terminal block. The next distribution box is powered from the same terminal block. As a result, we get two wires connected to each other.

- Another possible option is if for one group the box is an end box, and for another group it is a pass-through box. Moreover, usually the wire for which the box is a feedthrough does not have any connections in it. It just runs along the box.

Connecting sockets

First of all, let's look at the connection of wires in the junction box at home when connecting an outlet. After all, this is one of the simplest connections.

Connecting a socket in a distribution box

- So, in the junction box we have three strands of the supply wire. As we have already said, this is phase, zero and ground, indicated by the corresponding colors.

- To connect the socket, we need to connect the wire going directly to the socket to the corresponding cores of the power cable. In this case, color coding should be observed.

Switch connection

The wiring diagram in the junction box for connecting the switch is somewhat more complicated, but also quite simple and understandable. And even a two or three-key switch should not cause you problems.

Connecting a two-gang switch

So:

- First of all, we connect the switch. To do this, it is necessary to connect the wire leading to the switch input to the phase of the supply cable. We lead the wire from the switch output into the distribution box.

- Now we connect the lamp. First of all, we connect it to the neutral and protective power cable, the wires going to the lamp. After this, we connect the phase wire of the lamp to the wire coming from the switch terminal.

- As for two-, three-, or even four-key switches, the same principle applies. The only difference is the connection of the phase wire from the switch terminal.

- If this is a chandelier with two operating modes, then it has two phase wires. We connect our outputs from the switch to them.

- If different lamps will be connected from the switch, then our instructions advise first of all to connect their neutral and phase wires. Then one phase wire from the switch terminals to each lamp.

Connecting the lamp and socket

But to connect an outlet with a switch there will be a more complex circuit. The connection of the wires in the junction box is a little more confusing in this case. But if you analyze the diagram completely, then there is nothing complicated in it.

Connection diagram for switch from socket

- First of all, using the method described above, we connect the outlet.

- Now we connect the neutral and protective wires of the lamp. This is done in the same way as with a normal connection.

- As for the phase wire for the switch, there can be two options. You can purchase a single product, a switch with a socket in which the connection has already been made. Or you can purchase a separate switch and a separate socket. In this case, you will make the connection between them yourself.

- To avoid wastage of wires, in this case it is advisable to connect the switch directly from the phase contact of the socket. We connect this wire to the switch input.

- The wire from the switch output, as with a normal connection, is brought out into the junction box. Here we connect it to the phase wire of the lamp.