Determining the thickness of the tile adhesive when laying on the floor or walls is one of the main tasks when planning the finish. In this case, it is important to take into account many factors: the type of material, for example, porcelain stoneware or ordinary tiles, its size, surface quality, etc. Let's figure out what thickness of the solution is considered optimal in a particular case.

The thickness of the adhesive is important when laying tiles

Individual choice of tile adhesive thickness

There is no generally accepted advice regarding the required amount of glue, since facing work in each specific case has its own specifics. The required thickness of the glue may well be just two or three millimeters or a whole centimeter.

The smaller the area of each individual tile square, the thinner the layer of adhesive applied to it should be. It is also important to consider the type of decorative tiles.

For example, when decorating a wall with porcelain tiles, less mortar will be needed than with regular tiles.

Comb tooth size

Before laying tiles, the surface is pre-prepared. Prime so as to straighten the bumps, distortions, and cracks. The tile will lie better, a flat floor or wall will take less adhesive. The layer of bonding agent also depends on the height of the spatula teeth.

The thickness of the adhesive when laying tiles is half the height of the teeth. If you choose a tooth size of 6 mm, the layer will lie at 3 mm.

The depth of the pattern on the inside of the tile should be taken into account. When applying glue, the spatula will also go into the recesses. It is better to choose the longest tooth length depending on the size of the lines.

For synthetic solutions, you will need a spatula with a small tooth height. This way it is possible to apply a thin layer. Mortars with cement are bulky and applied in greater thickness. It is more convenient to use a tool with high teeth.

Purchasing spatulas with different teeth will be useful if you need to apply the adhesive composition unevenly.

For wall cladding, the height of the teeth will be sufficient at 5-6 mm. Small tiles are laid with a spatula with 4 mm notches. For large format tiles you need a high comb - 10-20 mm.

How to avoid interior thresholds

When calculating the thickness of tile adhesive, you need to focus on how exactly other types of decor are laid in other rooms of the apartment.

This will prevent the formation of unplanned thresholds at the junctions of floor tiles with:

- Insulated linoleum;

- Layer of laminate;

- Highly laid parquet.

Ultra-thin porcelain tiles

This type of product belongs to a special type of finishing materials, the thickness of which is no more than 4 mm. Many consumers, as well as manufacturers, note a number of undeniable advantages of products in this category:

- Low own weight of products - products with dimensions of 400x400 mm or 500x500 mm weigh no more than 2 kg.

Ultra-thin material

- Reasonable retail price due to the small amount of raw materials used.

- The tiles are ideal for wall cladding in rooms with high humidity.

- When covering walls in rooms with a small area, for example, when performing finishing work in separate bathrooms, the product “eats up” minimal space.

Wall covering

- Can be mounted on thin partitions with low load-bearing capacity.

At the same time, this porcelain tile has a number of disadvantages, which is why not every owner of an apartment or private house gives it preference:

- Increased fragility of the structure - the material breaks even with minor impacts.

- Difficulty during installation - installing products on the wall requires the involvement of highly qualified labor.

- Increased requirements for careful operation, in the case of installation as a floor covering.

Crack on porcelain stoneware

Thus, this finishing element should be installed exclusively on walls, subject to the involvement of a proven installation team.

Features of laying ultra-thin porcelain tiles

When laying ultra-thin porcelain tiles, the master must take into account the following nuances:

- Taking into account the increased fragility, it is prohibited to apply strong pressure when fixing the element with adhesives.

Tile adhesive

- Installation is carried out only on plastic adhesive materials that do not contain solid inclusions of coarse sand.

- When laying, you need to use a spatula with a large tooth.

- The glue must be applied to a pre-leveled surface.

- The thickness of the adhesive composition should not exceed the thickness of the tile.

Applying glue with a notched trowel

- Considering the fast setting period of the tile adhesive, all work should be carried out with increased intensity and in the shortest possible time, which requires additional qualifications from the master.

- In some cases, experts recommend laying ultra-thin porcelain tiles over old tile material.

- When cutting material, the use of manual tile cutters and other tools whose operation involves exerting increased pressure on the element is not allowed.

Cutting with a diamond blade

- During installation, special attention should be paid to the absence of voids in the adhesive composition, since the presence of these defects can cause destruction of the material during careless use, which is especially important for flooring.

- Regardless of the area of the surface to be finished, professionals recommend carrying out installation work without interruption, which reduces the risk of cracking of the material due to shrinkage of the adhesive composition.

Construction of an extended wall

Thus, given the large number of complexities, ultra-thin porcelain tiles enjoy minimal popularity among consumers. While saving on material, the owner of the premises has to overpay for the work, and the end result is worse than when installing standard porcelain stoneware.

Types of tile adhesive

When calculating the amount of glue needed and the thickness of its layer, you must also take into account the type of adhesive solution used. These indicators largely depend on the chemical compounds used in the manufacture of the adhesive substance. For example, the cement mixture can be applied in a higher layer.

Minimum and maximum values

With the correct layer thickness, good adhesion of the adhesive mixture to the base occurs. Insufficient and excessive volume of the mixture leads to a number of problems when facing: the layer may not dry well, crack or delaminate. It happens that after some time the facing material completely moves away from the base.

The maximum thickness of the adhesive when finishing the floor is 1.5 cm. It is recommended to apply no more than 1 cm to the walls. A thicker application can lead to an unpredictable result and defects over the entire area of the cladding.

The maximum cannot be exceeded due to a decrease in the degree of adhesion of the solution. This is due to the increase in his weight. With a large layer thickness, severe shrinkage occurs. Because of this, the tile may burst.

The minimum adhesive layer for small tiles is about 1.5-2 mm, and for large-format tiles - 4-5 mm. It is not recommended to apply a smaller volume of solution, because there will be no adhesion of the tiles to the base.

The calculation of the required amount of composition should be made based on its layer. To do this, the consumption per 1 mm is multiplied by the thickness of the solution. And all the necessary information on applying the glue can be found on its packaging.

Small tiles and mosaic tiles

The dimensions of the fragments of the decorative coating are essential for the correct selection of the height of the adhesive layer. When using small format tiles with sides of about 10 cm, the thickness of the mortar should be no more than two millimeters.

If the tile used turns out to be even smaller in size, for example, with a square side of 5-7 cm, then the layer of mortar after pressing the cladding should not exceed one and a half millimeters.

What affects the thickness of the adhesive layer

There are difficulties in identifying general recommendations, because cladding is not a standard job. They even take into account the height of the coverings characteristic of other rooms. For example, laminate will differ from other options.

They even take into account the height of the coverings characteristic of other rooms.

Type and size of tiles

The calculation requires reliance on the dimensions of the cladding materials. 2 mm is enough for small-sized varieties. For small sides of square parts up to 5-7 cm, 1.1-1.3 millimeters is enough.

Medium and large format components require increased thickness for the adhesive. The 30 cm side of the square requires 2.5-3.5 mm.

Dimensions are also related to the types of materials used in the cladding. The increased water absorption of tiles is due to their pore structure. Laying such materials requires more solutions. Porcelain stoneware structures have their own differences. This base practically does not absorb moisture, which reduces glue consumption.

The thickness of the tiles used directly affects the thickness of the adhesive for porcelain tiles on the floor. In the case of heavy weights, increased requirements for high-quality fixation lead to higher costs. Of the total mass of materials, adhesive layers make up 40-50%.

Moisture is practically not absorbed by porcelain stoneware, which reduces glue consumption.

Finishing base

Different types of bases require the production of different types of glue. The areas of application are indicated separately on the packaging by the manufacturers themselves. Here, too, there are some nuances that cannot be ignored:

- In the case of drywall, good adhesion is ensured with a thickness of 5 millimeters;

- 3-4 mm will be a layer with the same base, but if the tile itself is medium format;

- The next stages are leveling;

- Concrete and surfaces with plaster require increased thickness. This is a separate substrate.

Different types of bases require the production of different types of glue.

Before tiling begins, the walls and floor are carefully examined. The quality of the foundation is one of the factors influencing further work. The consumption of solutions becomes minimal if there are no differences with unevenness. Leveling adhesive is chosen if existing problems are known in advance. Some compositions allow application in a layer of up to 1.5 cm. For novice craftsmen, these compositions cannot be called suitable; they will not be able to organize heating properly.

Shrinkage of thick layers creates difficulties for those who lack experience. The presence of unevenness with a height of 3 cm or more suggests the abandonment of leveling materials. Then screeds and plasters are needed to increase the quality of the surface.

Volume is the main difference in tiles for wall and floor surfaces. The second case involves reducing the thickness of the wall tile adhesive.

The quality of the foundation is one of the factors influencing further work.

Composition of adhesive

The main classification involves division into thin- and thick-layer types. Plasterboard bases allow the use of materials based on resins. A thickness of 3-5 mm is sufficient for application, otherwise the drywall is more likely to be subject to defects.

Two-component mixtures are also not difficult to find on sale. They are created from a catalyst with the addition of a paste with different elements:

- Resins;

- Quartz filler;

- Various additives, according to GOST.

When such compositions dry, there is no shrinkage. This means that the thickness of the glue remains small and does not undergo significant changes. 2-5 millimeters is equal to a layer for mixtures with two components. If you follow the rules, laying the material will not be difficult.

2-5 millimeters is equal to a layer for mixtures with two components.

Thick-layer varieties of compounds help cope with various irregularities and defects. Sold dry, the main components for them are:

- Plasticizer part;

- Sand additives;

- Cement, which is also not as easy to lay as it seems at first glance.

Here the parameter of interest reaches 14 mm. Such options are combined with dimensional varieties of tiles, which are characterized by increased weight. 5-7 mm is enough for cladding ordinary walls. Half of these indicators are not used anywhere.

5-7 mm is enough for cladding ordinary walls.

Humidity and moisture absorption

The moisture content of the tile adhesive is controlled separately when doing repairs. If you simply apply a dry solution to the surface, adhesion between the materials at the proper level of quality cannot be guaranteed. Water absorption is also considered an important characteristic for this area. In the case of porous bases, it is one of the highest. Examples include certain types of concrete and sand-lime bricks. Sometimes they are placed in a room such as a toilet.

The thickness of tile adhesive with high water absorption will be greater. The use of primers helps to cope with problems, including when processing a hallway, the size of which does not matter.

The thickness of tile adhesive with high water absorption will be greater.

Spatula teeth size

Notched spatulas are a type of surface treatment tool that can also be performed with other devices. It makes it easier to obtain the appropriate thickness for the adhesive. The choice of device is based on the size of the materials used in practice. The formation of excess on the surface is the result of using spatulas with large teeth for small format tiles. A small comb is not compatible with large-sized cladding materials. This increases the height of the projections after processing.

Wall cladding allows spatulas with a height of 5-6 millimeters, in the case of mosaics it is 2-3 mm. The teeth become larger as the dimensions of the tile increase. Then the size of the comb will be 1-2 cm. Processing tiles for flooring is easier thanks to the comb. 4mm teeth are an excellent choice for small spatulas with square shapes. The 6 mm option is optimal for medium format tiles 20 by 20 cm. Chipboard sets different rules for processing.

A notched trowel makes it easier to obtain the appropriate thickness for the adhesive.

Additional calculation nuances

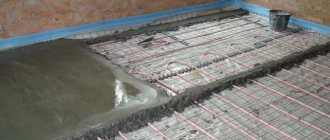

Laying materials for decorative purposes requires tiles with increased weight and dimensions. Therefore, the main difference from normal conditions is the consumption is 1.5 times higher. Working with “warm water floor” systems deserves a separate discussion.

- The size of the cables is taken into account when laying mats with electricity. At least 5-6 mm is placed on top of the adhesive mass;

- 30 mm for infrared panels will be the distance between the edge of the segments for decoration on top and the surface of the bases. The thickness of the tile will become the basis for calculating the consumption of fastening materials in such circumstances. Height is determined separately.

Laying materials for decorative purposes requires tiles with increased weight and dimensions.

Before finishing work begins, experts recommend leveling all surfaces and priming them if possible. After all, it is not always possible to use only simple types of connecting compounds to correct defects. With an integrated approach, there are fewer problems in achieving the desired result and securing it for at least several years. Rubber mallets are used to adjust all the unevenness of the tiles and expel excess air from the materials. This also improves the overall quality of work.

Medium and large tile sizes

For tiling with medium and large sized tiles, the adhesive will need to be applied in a thicker layer. If the side of the tile square has a length of 20-30 cm, then the layer after pressing should be at a level of 2.5 to 3.5 mm.

To use the solution more economically, the tiler needs to experiment with the angle at which he tilts the trowel.

- Large ceramic decor with a square side of 30-50 cm should be placed on a layer of glue 3-4 mm high.

- To accurately determine the height of the adhesive layer when fixing rectangular tiles, you must take into account the area of each element.

A guideline for this can be the indicator calculated for tiles measuring 20 x 25 cm laid in the bathroom. It is exactly three millimeters.

What is taken during the drying time of the adhesive composition?

Glue dries differently at different stages of work. You need to understand what is meant by the drying time of the mixture.

Installation condition

Time to use the finished composition is limited. After diluting the dry mixture with water, the solution must be used quickly. It hardens in a bucket more slowly, within 5 hours. Meanwhile, after laying on the wall it dries in 30-45 minutes. A little time to adjust the laid coating.

On the surface, the adhesive composition transfers part of the liquid to the wall or floor, as well as to the facing material. Therefore it dries several times faster.

Primary setting

The time when the mixture has already hardened, but has not become strong, is called primary setting. At least 12 hours, or preferably a day, must pass for the composition to acquire sufficient strength. Only then is application possible.

Experienced craftsmen advise: at least 3-4 days must pass from the moment of cladding for the adhesive mixture to completely harden. Otherwise, if you start walking on the laid tiles, the material may crack.

Final hardening

Complete hardening occurs within a week. Until this time, the material should not be subjected to stress. Only after this time can you seal the seams and arrange the furniture. For full use of the ceramic surface, at least three weeks must pass.

Porosity and water-repellent properties of tiles

The tiler must take into account the type of cladding used in his calculations. For example, tiles are characterized by increased porosity, which means that they will intensively absorb water and its evaporation.

Accordingly, for cladding it is necessary to take more solution, otherwise the damp atmosphere will separate a number of squares from the base plane.

As for porcelain stoneware, its structural features prevent the same active absorption of water. This means that there is no need to ensure the strength of the fixation by increasing the thickness of the glue. In this case, you can take much less.

- One should not lose attention to such a feature of the tile as its thickness.

- It determines the mass of the square fragment and accordingly affects the height of the adhesive substance.

- It is not difficult to guess that thick and heavy ceramic decor must be glued to a higher layer of mortar.

- To firmly fix porcelain stoneware, the adhesive layer must be at least half the thickness of the tile.

Main characteristics of porcelain stoneware

There are no strict requirements for porcelain stoneware at the federal level, but at the same time, each manufacturer issues a quality passport for its products. This document describes the following product characteristics and features:

- Product thickness. As a rule, to ensure strength, the minimum permissible tile thickness is taken from 8.0 – 8.5 mm or more, without taking into account the existence of a special series of ultra-thin tiles with a limited scope.

- The hardness of products is on an international scale from 1 to 10; porcelain stoneware is assessed based on test results at 7–8 points.

- The wear resistance of the tile depends on the material of the front surface and the processing method. There are 5 categories of strength of this material - from PEI I (at least 150 reference roller passes on the surface, without the formation of visible defects) to PEI V (from 12 thousand or more roller passes).

Product with wear resistance index PEI V

- The friction coefficient is one of the most important characteristics on which the possibility of using products on the floor surface and the safety of its operation depend. The most commonly used method for determining this parameter is called DIN 51097, according to which the tiles are assigned classes A (slippery), B (moderate), C (high level of safety).

Material class C, according to classification, DIN 51097

- Water absorption of the structure of the stone material, this parameter depends on the density and porosity of the material. Most often, the manufacturer focuses on achieving a water absorption index of no more than 0.01% - 0.05%.

- Chemical Resistance – Each plant strives to produce products that are resistant to all types of known chlorine, acid and alkaline components.

- Durability - an indicator characterized by the ability of a product to maintain its original appearance and surface quality over time, subject to exposure to ultraviolet radiation and other aggressive environmental factors. This parameter is calculated based on international standards DIN 51094, according to which there are 5 types of changes in the appearance of products (AA, A, B, C, D). AA is the most reliable porcelain stoneware, and class D indicates a rapid loss of appearance.

- Resistance to contamination - the manufacturer tries to develop and implement its own technologies that simultaneously meet the safety requirements of operation and ease of surface cleaning.

AA class products

The most important parameter on which the strength of the screed, the level of the finished floor and other important indicators depends, is the thickness of the porcelain tiles. Below are detailed descriptions, as well as the advantages and disadvantages of all existing product parameters according to this criterion.

Type of base used

Each type of tile adhesive is designed for specific types of substrates. To accurately find out the area of use of a particular solution and the rate of its consumption, you should carefully study the operating instructions.

- If it is necessary to cover plasterboard with facing tiles, the layer of adhesive substance should be no more than five millimeters thick.

- If medium format tiles are placed on such a base, then the glue should have a thickness of 3 to 4 mm.

- If the master is dealing with concrete, plaster or screed, then more glue can be applied.

It is worth keeping in mind that for cladding walls and floors it is necessary to spend different amounts of the mixture. For the floor, use less glue, otherwise the tile will quickly separate from the base surface.

Rules for applying the solution

In the process of applying the adhesive, an area equal to 2-3 elements is captured. Otherwise, the composition will dry out quickly and the tiles will not adhere well. The mixture is distributed evenly, it should fill all the recesses.

A smooth spatula is required for mixing and applying the solution. The toothed ones spread the glue over the surface. The composition is prepared according to the instructions for use.

Pro tip: dilute the solution to a thicker consistency. Then later you can dilute it with water if necessary. The composition must infuse for 12 minutes, then they begin to use it.

How to apply glue:

- Use a smooth spatula to scoop out part of the composition;

- half is applied to the tile, the other to the surface;

- smooth with a notched spatula;

- the layer should fill all voids;

- The thickness is adjusted according to requests.

Thick and thin layer adhesives

Cladding tiles can be laid using different types of adhesive solutions.

They are divided into forming

- Thick layer;

- Thin layer.

Glue made using resinous substances is applied to the plasterboard base planes. The layer of such a reagent should have a thickness ranging from 3 to 5 mm.

Humidity and moisture absorption

Two more estimates are worth making when deciding how much solution to apply. This is the humidity of the solution and the moisture absorption of the base. When laying ceramics on a wall, you should not use a semi-dry solution; moreover, the wall must be primed, if necessary several times, until the strong absorption of the surface stops.

With high absorbency, you have to increase the thickness of the glue so that the tile simply does not fall off when it dries. Pouring water will not help much, especially if the base consists of ordinary cement-sand plaster with a low cement content.

When laying ceramics on the floor, a drier solution is allowed than on the wall, but only if the moisture absorption of the floor is low. Therefore, the floor base should also be primed.

Some builders pour water excessively on the walls, on the floor, on everything around, thinking that it will be better, but no, due to excess moisture, the glue loses its properties. You need everything in moderation, as they say.

Ingredients of two-component formulations

It is easy to find two-component mixtures in construction and hardware supermarkets and specialized online stores.

They include

- Catalyst;

- Resinous filler;

- Quartz component;

- Functional additives.

This kind of mixture is good because it practically does not settle when it dries. Thus, the master can find out exactly what the height of the adhesive layer will be even when applying the adhesive liquid. Most often, this type of composition is applied in layers ranging from two to five millimeters thick.

General dependencies

It is worth considering that the characteristic varies depending on many factors; when laying tiles, the layer is smaller, when laying porcelain stoneware the layer is thicker. There are also differences between the location of the work: a wall or a floor. So, when gluing facing material to a wall, the glue should not be too thick, but when gluing floor tiles, it is quite possible to increase the thickness of the adhesive mortar.

Of course, the base of the surface to which the tile is glued has a special influence on the thickness of the layer. The best option is when the base is in perfect condition. Clearly level, without pits or bulges, even small ones, completely free of dust and mortar residues, high-quality coated with a special deep-penetrating primer (which one can find out and buy at any hardware store). Only in this case can we talk about truly high-quality laying of tiles or porcelain stoneware.

An important rule for high-quality work with ceramics is a perfectly level, measured and prepared base!

When tiling a floor, a situation often arises when porcelain tiles have a fairly large distortion; it turns out that it is either convex or concave. In such a situation, the layer under the lowest points of porcelain stoneware should not be more than 10 mm.

The surface of the back side of the tile must be covered with a continuous layer of adhesive at least 80%

Advantageous features of cement mortar

If you have to veneer a rather old and crooked wall, generously covered with potholes and chips, then the best choice in this case would be cement mortar. It falls into the category of thick-layer adhesives.

Cement tile fixative is sold in dry form. Its components are:

- Sand;

- Cement;

- Plasticizers.

The height of the layer in this case is quite capable of reaching one and a half centimeters. Such a thick layer is used to cover the massive and large tiles used to cover the floors.

If cement is used to cover walls with tiles, then it will be possible to limit it to a layer with a height of five to seven millimeters.

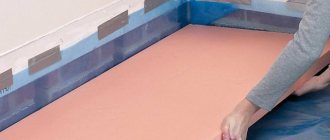

Laying tiles on walls

Before installation, the base must be leveled. Then you should wait until the surface dries. The location of the tiles is planned on paper and marked vertically and horizontally on the wall. First, the lowest point of the wall is selected. Then the height of one element is noted.

Draw a horizontal line, which will become a guide for the masonry. There should be no sections in the visible part of the wall. The elements are laid out whole.

Photo of perfect tile installation

Types of floor tiles

Conventionally, two main categories of this type of material can be distinguished:

- Ceramic - the most common when used in residential areas.

- Porcelain tiles are more often used in industrial premises.

Ceramic products are not intended for use under heavy loads, therefore, where there is a lot of traffic, this option should not be used. This tile is more suitable for home use.

Porcelain tiles are characterized by high levels of resistance to mechanical stress. This allows the use of porcelain stoneware even in industrial premises, where a large load is placed on it.

REFERENCE. When purchasing tiles for laying on the floor indoors, it is recommended to choose packs from the same batch, since the color and size may vary slightly in different batches, but in the end this will be noticeable.

Surface type and its meaning

Each adhesive is intended for individual substrates, which can be found out from the information on the packaging. There you can also see the approximate consumption and the required layer.

Type of surface and required thickness of the adhesive mixture:

- For drywall, the layer is no more than 5 mm.

- Concrete requires a larger layer of up to 1 cm.

- For porcelain stoneware you need about 2-4 mm.

Reference! The condition of the floor also matters. If there are defects or unevenness, a greater thickness of the composition is required to fill the voids.

In the absence of visible flaws and cracks, the consumption of the product is insignificant. To work with uneven surfaces, you should choose a special leveling compound. There are products that can be applied in a layer of up to 1.5 cm. Beginners should not work with them.

It is difficult to work with leveling compounds due to shrinkage. When there are defects larger than 3 cm, it is better to close them by plastering.

Reference! When laying floor and wall cladding, a different thickness is required. In the first case, the layer is larger.

Recommendations for choosing tiles for a specific site

Many experts use the following aspect ratios and thicknesses of porcelain stoneware as a guideline: 300/8, 450*9, 600/10 mm. Accordingly, with increasing size and load, the height of the tile should increase. Let's get acquainted with the parameters that experts recommend considering in relation to a particular work site.

Example of a porcelain stoneware façade Source pinimg.com

Floor

The choice of porcelain tile sizes for the floor is determined mainly by the design load, including localized load from furniture or household appliances. So, if the load is small, then the thickness can be 8 mm. For rooms such as a kitchen, hallway, hall, the lower limit should be 10 mm. These tiles can handle heavy traffic and impact loads from most falling objects. If floors in a commercial space are to be covered, then a lining height of 12-14 mm will be required; for a garage the minimum is 16 mm.

Walls

Since vertical structures are rarely subjected to mechanical loads, porcelain tiles are manufactured in comparison with floor collections with a smaller thickness. In this case, the dimensions of the sides can be increased. As a rule, collections with average parameters are considered so that one tiler can cope with the cladding without the use of lifting equipment.

Wall cladding with porcelain tiles Source vannyekomnaty37.ru

Wood effect tiles

The latest word in construction fashion has become tiles that imitate parquet planks in their shape. It is the length of these strips that is the weak point of this product, therefore, in order to neutralize this drawback, such tiles are produced exclusively from high-quality and well-fired porcelain stoneware. Such a “board” can reach one and a half meters in length. The thickness of such tiles varies from 7 to 11 mm.

But in addition to tiles, another very important parameter is tile adhesive.

The appearance of the tiles imitates wood

Comparative analysis of products from different brands

If you adhere to the tile installation technology and also choose really high-quality tiles, then finishing it yourself will not cause any difficulties. And the repair itself will delight you with its beauty and durability. As practice shows, thicker tiles last much longer without cracking or chipping. But the following rule is also true: the thicker the tile, the larger its size. But the use of large tiles is not always relevant.

Porcelain tiles come in different sizes and thicknesses

Therefore, before starting repairs, study the manufacturers’ proposals regarding these two parameters. Then it will be much easier for you to choose the best option based on external aesthetics and operational parameters. Please note that there are no generally accepted standards regarding the thickness of ceramic tiles. Each manufacturing company manufactures its products with those parameters that they consider to be in demand among buyers.

Let's compare options from different countries and in size variations below. (Ukraine) offers customers options from 7.5 to 9.5 mm in thickness. Note that many stores practice rounding this parameter and you can find Atem products with a parameter of 10 mm.

Table - Russian tile manufacturers produce such options.

| Manufacturer's name | Thickness of ceramic products |

| Azori | 9 mm in sizes 333x333 and 505x201 mm |

| Altacera | 8 mm in size 418x418 mm |

| Kerama Marazzi | 7.8 mm in size 302x302 and 8.3 mm in size 402x402 mm |

CEDIR, a manufacturer from Italy, offers its customers tiles measuring 333x333 with a thickness of 9 mm, and the Italian company Settecento - 478x478 mm with a thickness of 10 mm. The quality of such tiles is beyond doubt, as confirmed by numerous reviews from satisfied customers.

Brief characteristics of ceramic tiles

An excellent option for the floors and walls of the bathroom, kitchen or dining room is the use of ceramic tiles. This cladding has high aesthetics and practicality. It demonstrates excellent moisture resistance, satisfactory strength and excellent resistance to mechanical damage. Qualified construction specialists argue that flooring repairs should be carried out immediately after installing (replacing) communication systems. And only after that the ceiling and walls are finished.

Installation of a tile covering is not particularly difficult, but such floors and walls will serve flawlessly for several decades in a row. The main thing is that the technology for working with tiles is followed.

Calculation of material quantity

To determine the required amount of mixture, you need to have all the data on the material, glue and area of the working area. The calculation is carried out in several steps.

How to determine the required amount of funds:

- Determine the dimensions of the tiles, based on which, calculate the required thickness.

- Look on the packaging to see the mixture consumption per meter with a layer of 1 mm.

- Multiply these values to obtain the required amount of glue.

- Calculate the area for cladding.

- Multiply the first value by meters.

- Multiply the result by 1.1 for the margin.

On video: Laying porcelain tiles. We calculate the thickness of the glue.

Dimensions of porcelain tiles for floors

Popular sizes of floor tiles range from 10 cm to 60 cm. In some rooms it is appropriate to install large-format models. For example, when finishing large industrial or retail premises.

Dimensions of porcelain floor tiles that can most often be found on the market:

- square - 60x60, 45x45, 30x30;

- rectangular dies - 120x30 and 120x60.

Thickness - 8 mm.

Among the options for a 100x100x5 mm floor slab, the rarest and most ineffective is a thin and narrow strip that requires a lot of time to install. That is, if it does not have decorative content, there is no point in using it.

Forms of porcelain stoneware cladding

Two types of floor coverings are used - ceramic tiles and porcelain stoneware. In the manufacture of the latter, pressing and subsequent very strong heating are used, or, to be more precise, baking. This allows you to create elements that can withstand significant loads.

The standard for the production of porcelain stoneware slabs is provided not only for the process itself, but also for their shape and size. They can have a square shape, be produced in the form of a pentahedron, hexagon, or octahedron. In addition, modules may differ in parameters (side length).

What is porcelain tile

First, we need to explain the difference between ordinary ceramics and porcelain stoneware.

All about porcelain tiles - a fascinating video

Ceramic tiles, which are popularly called tiles, have been popular and in great demand for many years. But porcelain stoneware appeared relatively recently. What is the difference?

No special components are used to create porcelain tiles. But the tiles are produced at high temperatures up to 1200C, as well as under high pressure.

As a result, porcelain stoneware has the following advantages:

- Low porosity. The material is very dense, which also causes almost zero water absorption.

- This results in high frost resistance, so the material can be used for exterior work, for façade cladding or floor coverings in unheated rooms.

- At the same time, porcelain stoneware is a durable and wear-resistant material, so that with a thickness less than the thickness of the tile, it can withstand heavy loads and mechanical stress.