If a decision has been made to install a heated floor system in the house, then it is not enough to simply buy the required materials - you also need to know how much of them will be needed. And these calculations are not easy, considering that you want not to buy too much and at the same time make sure that the purchased materials will be enough to achieve the required temperature level in the rooms. How to calculate a heated floor? Let's try to figure it out.

How to calculate a heated floor

Classification of heated floors

What can affect heat transfer?

To begin with, I would like to dwell on what a correct and high-quality heated floor should be, regardless of what coolant - electricity or water - it will work on. So, such a heating system will work differently depending on the thickness of the base or the quality of the heat insulator , which means that all these points must be taken into account. It is believed that the thickness of the thermal insulation material should not be more than 3 cm, and it is better to purchase the material with a reflective layer - this will make it easier to retain heat indoors.

Advice! It is recommended to purchase polystyrene foam with a density of about 35 kg/m3 as a heat insulator.

Do-it-yourself warm floor

The thickness of the concrete screed should be about 4-10 cm, especially if we are talking about laying a cable or water floor. Inside, it is reinforced with a reinforcing mesh, onto which, by the way, coolants can be attached. Due to this, heat will be redistributed better. If you plan to install a water floor, it is recommended to purchase pipes made of metal-plastic or cross-linked polyethylene with a diameter of 16-20 mm - with them it is easiest to provide the system with optimal power sufficient to warm up the rooms.

Scheme of a heated floor under a screed

Pipe for heated floor

We evaluate the quality of the product

Choose only quality options

When purchasing a set of heated floors of any kind, do not forget about the main criteria - the appearance of the product and the accompanying documentation. Reputable manufacturers provide warranties for the equipment and include installation and operating instructions. If such documents are not included in the kit, it is better to refuse to purchase such a system, despite the reasonable price. There is a high probability of purchasing a fake that does not meet safety requirements and technical specifications.

Don’t be shy to check that the equipment specified by the manufacturer matches what the seller offers.

You should pay attention that upon detailed inspection there are no visible damages - scratches on the film or broken rods, damaged insulation on wires and other defects.

You should immediately select sets of additional materials for installing the system specified in the manufacturer’s instructions. You can often find recommendations to use branded thermal insulation, protective film, and more. If there are any, you should not neglect them. As a rule, components from the same manufacturer are ideally suited and then the heated floor system will serve the owner for the maximum possible time.

What factors should you consider?

In order to make all the necessary calculations that will help determine the amount of materials for a heated floor, you should consider the following:

- the total area of the room where floor heating will be installed . The number of circuits in the system will depend on this figure;

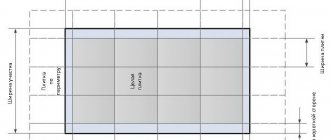

How to calculate the area of a room

Important! One heating circuit effectively heats a maximum of 40 m2. Moreover, its length should not be more than 100 m. And the step between laid pipes should not be more than 30 cm.

- number of collectors . It is important to remember that each heating circuit can only be connected to one manifold;

- layout of rooms where heating is installed;

Options for heating cable laying schemes

- the sizes of windows and other places where heat will be lost . Type of glazing. Types of doors;

- can also affect the power indicator ;

- indoor air humidity;

- arrangement of furniture and other interior items in the room . Under them, a heated floor is not installed if it is electric, since ventilation will be insufficient and the system may be damaged. And excessive heating can also have a negative effect on the safety of furniture and equipment;

- purpose of the room where installation will be carried out . Depending on this, the heating power is selected;

- other heat sources and their power.

When calculating a heated floor, many points need to be taken into account

The temperature regime in the region and the need to heat a specific room and regulate the temperature in it may be important. The type of floor finish can also have a significant impact on the power of the floor - some materials easily transmit thermal energy, others - worse.

Installation diagram of electric universal heating mats for heated floors

Advice! The easiest way to calculate underfloor heating is to use online calculators.

Recommendations from experts

For more accurate calculations, you need to seek advice from experienced specialists.

Let's look at the most basic tips:

- To make calculations easier and more accurate, special online calculators will help you.

- You should not install water systems in dilapidated and old buildings.

- Calculate all indicators with high accuracy, because the effectiveness of the entire system will depend on this.

- Observe safety precautions during installation.

Determining the desired temperature in the rooms

The final floor temperature depends on the purpose for which the room is used. For example:

- +29-30 degrees – halls, hallways;

- +27-29 – offices, living rooms;

- +30-35 – floors near windows, on verandas;

- +32 – bathrooms, toilets;

- +17-19 – gyms.

Installation of water heated floor

In this case, the coolant temperature should not be less than +40 degrees or exceed +60. The heating system should be such that the difference between the temperature indicators of the forward and return pipes in the case of water floors does not exceed 15 degrees. Otherwise, the base will be heated completely unevenly.

The balance of thermal/hydraulic loads for a water floor must also be optimal and adjusted. Therefore, the heating circuits must have a certain length in accordance with the diameter. The optimal pipe option is 18 mm, since even with a small amount of water such a pipeline will work correctly and heat the base.

Installation methods

The heating cable must ultimately be covered on all sides with mortar/tile adhesive; this can be achieved in three ways:

Fill

. The most correct way in my opinion. It consists of pouring a 1-2 cm mini-screed over the mounted cable. The resulting screed will be suitable for any floor covering. To implement this option, when pouring the main screed, you should provide a couple of centimeters of height in places where there will be a warm floor. For work, mixtures are used that allow such thin layers to be poured. If the screed is initially poured at one level and raising the floor level is unacceptable, then this method is not suitable.

Glue layer

. When the tiles are laid, and in addition to everything else, it is permissible to raise the level of the subfloor by 1-2 cm (do not forget, the tiles themselves will add at least 1 cm), the tiles are placed on top of the cable on a thick layer of glue. This option should be considered last, because there will be a significant difference at the border of the warm zone.

Grilling

. The most difficult and tedious method, however, when raising the screed level is unacceptable, is the most correct. First you need to mark the lines where the heating cable will go. You also need to take into account the groove for the corrugation with a temperature sensor and the coupling with the cold connecting cable. After marking, you need to attach some kind of thread/rope to the lines to check the length of the grooves. You need to be sure that the entire cable will fit into the future groove, otherwise you need to change the markings.

After gating, the dust is carefully removed and the surface is primed. The wire is laid in a groove; the depth of the groove should allow 3-5 mm of caulking solution to be applied over the cable.

The temperature sensor in the corrugation is also mounted in the groove; the corrugation must be plugged at the end (wrap it with electrical tape). The end of the corrugation should be placed between the heating conductors, not far from the edge of the heating zone (but not on the edge). The optimal distance of the temperature sensor is 30-50 cm from the edge, deep into the warm area.

When the wire is laid, the grooves are sealed with tile adhesive or a self-leveling floor mixture. If you plan to lay linoleum, it would be a good idea to apply a finishing layer of 1-2 mm of self-leveling floor.

Floors should be checked or used no earlier than a month after completion of all wet processes with the floor (pouring, laying tiles). Switching on earlier will not damage the cable itself, but may cause the solution/adhesive to crack.

Conclusion

- Heating cable is recommended for use with heated floors. The most preferred method of application is a direct heating system or "thin floor".

- Among all the variety of heating cables, it is best in terms of price-quality ratio to use a two-core resistive cable.

- The selection of the required cable with the required power density, its length and laying pitch are obtained as a result of calculations.

- Changing the length of a resistive cable section (except for a zonal cable) is unacceptable.

Calculation of heat losses

Typically, underfloor heating systems do not act as the only source of space heating, but some plan to heat the house this way. But before making this engineering decision, it is important to make sure whether a particular room can be heated only in this way.

Electric heated floor

If during the period of use of the system, heat loss does not exceed 100 W/m2, then the floor heating system will be quite sufficient to warm up the room. However, it is quite difficult to make calculations on your own to obtain the necessary data, since complex formulas are used. So it is recommended to use an online calculator for calculating the heat loss of a room. If heat loss exceeds 100 W/m2, then the thermal insulation of the room must be improved or an additional heating system must be installed.

Calculation of UNIMAT rod mat

The UNIMAT infrared rod mat has a self-regulating function, so it is not afraid of being blocked by furniture and the area of the set should be equal to the area of the room.

For convenient control and economical use of heated floors (up to 35%), a thermostat is designed. There are mechanical (manually controlled) and programmable thermostats with functions of saving settings, modes to reduce energy costs, etc.

Our stores offer a wide selection of multifunctional thermostats for heating systems from European manufacturers, the most popular among them are:

- TI 200 and TI 950, THERMO;

- 320 and UTH-130, CALEO;

- from DEVI – Devireg Touch.

Calculation for different types of premises

Each room, depending on its characteristics, requires different floor heating power. It should be greatest in cool rooms, as well as on a loggia or balcony. In such a room, the power cannot be less than 180 W/m2. In a bathroom or toilet - at least 140 W/m2 due to high humidity levels.

On a note! The power of the floor heating system cannot be low if there are unheated rooms under the room being equipped.

As for the electric floor, in this case the minimum power should be 120 W/m2.

Electric heated floor under tiles

Table. The power of the floor heating system when used as an additional heat source.

| Room | Power, W/m2 |

| Balcony and loggia | 180 |

| Bathroom, toilet | 140-150 |

| Living rooms and kitchen located on the 2nd and higher floors | 120-130 |

| Living rooms and kitchen located on the 1st floor | 140-150 |

What is needed for the calculation

In order for the house to be warm, the heating system must compensate for all heat losses through the building envelope, windows and doors, and the ventilation system. Therefore, the main parameters that will be required for calculations are:

- house dimensions;

- wall and ceiling materials;

- sizes, number and designs of windows and doors;

- ventilation power (volume of air exchange), etc.

You also need to take into account the climate in the region (minimum winter temperature) and the desired air temperature in each room.

These data will allow you to calculate the required thermal power of the system, which is the main parameter for determining the pump power, coolant temperature, length and cross-section of pipes, etc.

A calculator located on the websites of many construction companies that provide installation services will help you perform a thermal calculation of a pipe for a heated floor.

Screenshot from the calculator program page Source www.apostroy.ru

Note! If a water heated floor is used as an additional, rather than the main source of heat, the resulting power values are reduced to a certain proportion.

How to calculate electric floor heating

In general, a floor heating system consists of several elements. This is a thermostat that helps control the level of heating of the floors, a temperature sensor that monitors how hot the floors are, a heating element, as well as a power cable for connecting all this equipment to the electrical network.

The thermostat is usually installed on the wall, all wires are connected to it. The heated floor itself, as well as the temperature sensor, are installed under the floor covering (in the screed or on its surface, depending on the type of system - heating mat, IR film or heating cable).

Touch programmable thermostat

On a note! The easiest way is to install infrared floors or heating mats. They can be laid simply under the floor covering. But the electrical cable will have to be covered with a screed. Yes, and the pitch between the wires in this case will have to be calculated independently.

To install cable heating, a single or two-core cable is used. The first is the simplest, but at the same time difficult to work with, although cheap. It will be quite difficult to calculate all the parameters for it, since both ends of the cable need to be brought out to one place. And an extensive electromagnetic field is formed from it.

Two-core cable for heated floors

It’s easier to buy a two-core cable, which, although it costs a little more, is still easy to install and operate due to the special arrangement of the wires.

Calculation formulas for electric floors

It is easy to determine the power of a warm electric floor system. To do this, it is enough to multiply the power of 1 m2 of the selected system by the area that it will heat. By the way, in the purchased kit the amount of cable used is already measured and marked. The distance between the turns of the wires should be 5-20 cm. It can be calculated accurately using the formula h = Sх100/L , where h is the desired value of the step width, L is the length of the cable, and S is the area of the room.

Calculating electric heated floors

We take into account the stages of repair

The sooner you decide, the more options you have to choose from.

When selecting a heated floor, the degree of preparation of the surface for installation is important. There can be two of them:

- the screed has not yet been poured;

- the screed is already filled.

In the first case, any type will do. The cable floor and heating mats are mounted directly into the screed. The cable is poured with concrete to a depth of 3 - 5 cm. The mats and the IR rod floor are laid in a self-leveling self-leveling floor to a depth of 0.5 - 1.5 cm. It is most convenient to lay the IR film or rod floor or heating mats on the already poured screed. In this case, the choice depends solely on the finishing coating.

How to calculate a warm water floor

Let's see how many materials are needed to install a water heating system in the room. In this case, the calculation of the number of pipes per 1 m2 is done as follows: you need to find out how much heat loss in the room will be. The easiest way to determine them is with the help of an online calculator, which includes data about the building itself, as well as weather conditions outside. Let them be equal to 80 W/m2. Let’s take the area of the apartment where the heated floor system will be installed to be 80 m2. As a result, the total heat loss can be found by multiplying two values 80x80 = 6400 W. It is this value that will have to be compensated using all heating systems with a power reserve of up to 20%.

Water heated floor

Table. Pipe calculation depending on the loop pitch.

| Step, cm | Consumption, m./1 sq. m. |

| 10 | 10 |

| 15 | 6,7 |

| 20 | 5 |

| 25 | 4 |

| 30 | 3,4 |

Typically, the distance between water lines is maintained at about 15 cm with a pipe cross-section of 16 mm. Then the power of 1 m2 of floor will be about 100 W. Dividing the total area of the room by the step size, we get: 80/0.15 = 533 m. This is exactly how many meters of pipe will be required to install a water heating system in this apartment. The length of each contour is calculated in approximately the same way.

Attention! Near the walls of the room adjacent to the street, the step will be slightly smaller (10 cm). Taking this into account, the footage of the water pipeline is calculated.

In construction stores, pipes of a certain length are available for sale - from 50 to 240 m. They are wound into coils. And to connect the entire system to the collector, you will have to buy larger diameter water pipes.

Heated floor pipe circuit length calculator

Go to calculations

Link to source.

Pipe and power calculations

The data obtained as a result of measurements is the basis for calculating the power of equipment such as a heating heat pump, gas or electric boiler, and also allows you to determine the distance between pipes when performing installation work.

Fastening pipes to reinforcement mesh

In order to correctly calculate the length of pipes required for installation, you should determine the type and features of these elements:

- stainless steel corrugated pipes are characterized by efficiency and high-quality heat transfer;

- copper pipes are characterized by a high level of heat transfer and impressive cost;

- cross-linked polyethylene pipes;

- metal-plastic version of pipes with an ideal ratio of quality and cost;

- foam propylene pipes with low thermal conductivity and affordable price.

Corrugated pipe for underfloor heating is one of the best options for water floor heating

The use of special computer programs can significantly simplify calculations and make them as accurate as possible. All calculations must be carried out taking into account the installation method and the distance between the pipes.

The main indicators characterizing the system are:

- required length of the heating circuit;

- uniform distribution of released thermal energy;

- the value of the permissible limits of active thermal load.

It should be taken into account that if the area of the heated room is large, it is possible to increase the laying step while simultaneously increasing the temperature of the coolant. The possible range of steps when laying is from five to sixty centimeters.

The most common ratios of distances and thermal loads:

- a distance of 15 centimeters corresponds to a coolant of 800 W per 10 m²;

- a distance of 20 centimeters corresponds to a coolant from 500 to 800 W per 10 m²;

- a distance of 30 centimeters corresponds to a coolant of up to 500 W per 10 m².

To know for sure whether it is enough to use the system as the only source of heating or whether “warm floors” can serve solely as an addition to the main heating, it is necessary to perform a rough, preliminary calculation.

Connection diagram for a water heated floor to a boiler

Rough calculations of the thermal circuit

To determine the density of the effective heat flux given off by m² of heated floors, you must use the formula:

g (W/m²) = Q (W) / F (m²)

Where:

- g is the heat flux density indicator;

- Q is the total indicator of heat loss in the room;

- F is the floor area expected to be installed.

To calculate the Q value, the area of all windows, the average height of ceilings in the room, and the thermal insulation characteristics of floors, walls and roofs are taken into account. When performing underfloor heating as an additional option, it is advisable to determine the total volume of heat loss in the form of a percentage.

When calculating the value of F, only the area of the floor involved in the process of heating the room must be taken into account. In areas where interior items and furniture are located, free zones about 50 centimeters wide should be left.

To determine the average temperature of the coolant under the conditions of the heating circuit, the formula is used:

ΔT (°C) = (TR + TO) / 2

Where:

- TR is the temperature indicator at the entrance to the heating circuit;

- TO - temperature indicator at the exit from the heating circuit.

The recommended temperature parameters in °C at the inlet and outlet for a standard coolant are: 55-45, 50-40, 45-35, 40-30. It should be taken into account that the supply temperature cannot be higher than 55 °C, with the condition of the return temperature being a difference of 5 °C.

In accordance with the obtained values of g and ΔT, the diameter and pitch for pipe installation are selected. It is convenient to use a special table.

Tables for calculating heat flow for heated floors depending on the flooring material

Tables for calculating heat flow for heated floors depending on the flooring material

Tables for calculating heat flow for heated floors depending on the flooring material

Tables for calculating heat flow for heated floors depending on the flooring material

At the next stage, the approximate length of the pipes involved in the system is calculated. For this purpose, it is necessary to divide the area of the heated floor in m² by the distance between the laid pipes in meters. To the obtained indicator, you should add the length reserve for making bends and the connection length is added to the length for pipe bends and the length for connecting to the collector system.

With a known length and diameter of the pipes, the volume and speed of the coolant can be easily calculated, the optimal value of which is 0.15-1 meter per second. At higher travel speeds, the diameter of the pipes used should be increased.

The correct choice of pump used in the heating circuit is based on the coolant flow rate with a margin of twenty percent. This increase in the indicator corresponds to the parameters of hydraulic resistance in the pipe system. The selection of sediment for the circulation of several heating systems consists in matching the power indicators of this equipment with the total flow rate of all heating circuits used.

Calculation of the cost of heated floors

Additional calculations

Let's consider how the hydraulic calculation occurs. It is necessary to determine the power of the purchased pump. Losses for a straight pipe with a length of 10 m, a diameter of 16 mm and a wall thickness of 2 mm will be 1600 Pa. Rotations of 180 degrees – 40 Pa each. Then, for a room with an area of 18 m2 with a length and width of walls of 5.6 and 3 m, respectively, when installing a water floor system with a snake, the hydraulic losses will be 18,680 Pa. The figure was obtained by the following calculations: the value of the width of the room 3 is divided by increments of 0.15 . This results in 20 straight sections of pipe. Losses of all straight sections: 20x5.6x160 = 17,920 Pa. At turns, the GP will be 19x40 = 760 Pa. Thus, adding 760 and 17,920 Pa, we get the value 18,680 Pa.

Manifold with installed pump

This means that for the system to work correctly, it will be necessary for at least 2.4 l/hour of coolant to pass through 1 m of its length. You can accurately calculate the performance as follows: coolant flow RTH = 0.86xMK/RT, where MK is the circuit power in kW, RT is the temperature difference in the supply and receiving sections of the pipe . Based on the above calculations, a pump that can pump 0.172 m3/hour (0.86x2/10) will be useful for that room.

Video - What calculations are needed for heated floors

Prices for heated floors Caleo

warm floor caleo

Calculating the circulation pump

To make the system economical, you need to select a circulation pump that provides the required pressure and optimal water flow in the circuits. Pump passports usually indicate the pressure in the circuit of the longest length and the total coolant flow in all loops.

The pressure is influenced by hydraulic losses:

∆ h = L*Q²/k1 , where

- L —contour length;

- Q - water consumption l/sec;

- k1 is a coefficient characterizing losses in the system; the indicator can be taken from hydraulic reference tables or from the equipment passport.

Knowing the pressure value, calculate the flow rate in the system:

Q = k*√H , where

k is the flow coefficient. Professionals assume the flow rate for every 10 m² of a house is within 0.3-0.4 l/s.

Among the components of a warm water floor, a special role is given to the circulation pump. Only a unit whose power is 20% higher than the actual coolant flow will be able to overcome the resistance in the pipes

The figures regarding pressure and flow rates indicated in the passport cannot be taken literally - this is the maximum, but in fact they are influenced by the length and geometry of the network. If the pressure is too high, reduce the length of the circuit or increase the diameter of the pipes.

Example of approximate calculation

Let's look at a simple example of how to calculate the heated area and power of an electric floor in a kitchen, which is located on the ground floor. The floor will be used as an additional heat source. The area of the room is 10 m2. From it you need to subtract the area occupied by the refrigerator and furniture - 0.36 m2 and 2.4 m2. When laying the contour, you should step back from the walls by about 5-10 cm - this will be about 0.5 m2. Thus, we get 10 – 0.36 – 2.4 – 0.5 = 6.7 m2. This value is equal to the floor area under which electric heating will be installed. For a kitchen located on the ground floor (that is, there is a cold basement below the room), subject to additional heating, a floor power of 140 W/m2 will be sufficient. Now you need to multiply the heated floor area of 6.7 m2 by 140 W/m2. It turns out that the power of the heating system should be 930 W.

Do-it-yourself calculation of a heated floor

About film heaters

Calculating the amount of infrared film is much simpler and comes down to selecting a heating material based on size and specific heat transfer:

- Calculate the room's need for thermal energy (section one of this publication).

- Sketch the layout of a room with stationary furniture. Calculate the size and square footage of the free area.

- Film heated floors are laid out at a distance of 15-20 cm from the walls. Draw these stripes on the sketch and subtract their dimensions from the free area.

- The last task is to place an infrared film of the required total power on the remaining area. Select rolls of the desired width and heat transfer from the manufacturer’s catalog.

Keep in mind that thermal film can only be cut across, guided by special lines (interval - 250 mm). Adjacent canvases can be laid end to end or with a calculated interval, but not overlapping. For the bedroom from our example, the amount of film is calculated as follows:

- The required heat transfer of the floor circuit is 1.08 kW. If you take a product with a heat output of 130 W/m², you will need 1080 / 130 = 8.3 m² of film heater. Taking into account the reserve - 9 m².

- The roll width is 0.5 m. To collect 9 squares, you need to take a film 18 m long.

- Since there is 15 m² of free space in the bedroom, this type of heater is quite suitable.

Rules for laying IR heated floors

You need to follow a few simple rules for installing infrared heated floors:

- The first line of film should be located at a distance of at least 100 mm to the wall and no further than 400 mm.

- The pitch of the film cutting line is 250 mm; the film cannot be cut in other places.

- The distance between adjacent film strips should be 10 mm or higher.

- The permissible length of the floor strip is 8 m.

Under laminate

When laying film heated floors under laminate, follow the rules:

- To prevent infrared film from overheating, it must be distributed in areas where there is no furniture.

- In order for the room to be heated with maximum efficiency, the film floor must cover at least 70% of the area.

Installation diagram of IR heated floors for various types of finishing floor coverings

Next you need to draw a plan for the location of the heating elements. On paper, reflect the locations of the furniture and heating film.

Laying is done on a surface that has been leveled beforehand.

The concrete screed should not have any differences. To prevent heat from escaping from the thermal film through the floor slabs into neighboring apartments, a thermal insulating substrate (polypropylene) must be laid on the floor, the thickness of which is 3-4 mm and covered with foil on one side.

Thermal insulation strips are secured with thermal insulation tape, and they also need to be carefully trimmed around the perimeter of the room.

The heating film can only be cut in the places marked on it. They are highlighted with a dotted line and a scissors symbol.

If you cut the film diagonally, you will simply ruin it.

The distance of the film from the wall should be 10 cm.

The heating film strips are laid on the substrate one next to the other with a gap of at least 5 mm, but not more than 1 cm.

You cannot bend the heating element at an angle of 90 degrees or more, as it will stop functioning.

Connection diagram for IR heated floor

In places where the thermal film is cut and the conductive busbars are cut, it is necessary to install bitumen insulation, which is included in the heated floor kit. The contact must be installed in the center of the end of the conductive busbar and pressed well with pliers. Using a sharp knife, it is necessary to strip the current-carrying wires by 5-8 mm and clamp them with pliers in the contact terminal, then the entire contact is insulated with bitumen insulation. The infrared heated floor is connected in parallel with copper stranded wires with a cross-section of at least 1.5 mm². It is also recommended to install a temperature sensor so that the automatic floor heating works correctly.

At a distance of 20-25 cm from the wall on which you will install the thermostat, use a hammer drill to perform a groove. Place the temperature sensor into the hole formed under the heating film.

In order for the sensor to show the correct temperature, it must be placed on a heat-insulating substrate.

After all the above manipulations, the thermostat is connected.

Upon completion of installation, check the functioning of the IR heated floor. All thermal films should heat up when turned on. Only after making sure can you lay the laminate on heating elements.

Under linoleum

Laying under linoleum is similar, but has its own characteristics:

- At the first stage, prepare the base, because... The floor can only be installed on a flat and stable surface.

- The mats can be cut into 25 cm pieces. The edge is insulated with a special tape. The gap to the heating system pipes should be 30 cm.

- The film must be laid with the copper bars facing up; overlapping joints is strictly prohibited. The remaining steps are carried out in accordance with the instructions. A prerequisite for high-quality heating is the connection of a thermostat.

- Then linoleum is laid. In small rooms, the coating is laid and left for a couple of days, after which the edges are pressed against the baseboards.

There are different ways to install linoleum

When carrying out work, take into account the fact whether it will be necessary to disassemble and move the system in the future, and also pay attention to the technical characteristics of heated floors

As you can see, infrared film heated floors are an excellent option for a heating system, and its installation is not that complicated. Therefore, everything can be done with your own hands.