Many people try to expand the usable space in their apartment by adding a balcony. In warm regions, they even remove the door, combining the loggia with the living space.

However, simple insulation is not enough to ensure a comfortable temperature, so it is recommended to install a warm floor on the loggia. It will allow you to maintain an optimal microclimate and use additional space to create a recreation area, dining room or office.

In the article, we will look at the types of heating systems that can be laid on the balcony, their pros and cons, as well as how to install them yourself. Methods for preserving heat in a loggia by insulating walls, ceilings or floors are described.

Which heated floor is best to use on the balcony?

What type of warm floor heating is best to use for a balcony or loggia? This question is asked by many owners of these premises. There are different types of underfloor heating - water, cable, infrared film:

- Water is the most expensive device, consisting of pipes; it is often mounted in a screed.

- Electric cable - in it the cable acts as a heating element. The “pie” is also filled with concrete mortar.

- Infrared film - heating is produced by carbon plates; they emit ultraviolet waves.

A balcony is a protruding slab that cannot withstand heavy loads, so a heavy water structure is not suitable here. It is also not recommended to install an electric heated floor on the balcony under the screed. Infrared film is considered the most suitable; it weighs little and is easy to install.

In loggias, a water or electric model for screeding can be considered if the given loads on the slab are acceptable in a particular case. To do this, it is necessary to calculate the load level in advance.

Electric TP on the wall? It is possible or not, which type to choose and install.

To determine which heated floor is best to choose, we will consider each model in detail.

Heating mats

Such a system consists of many special heating cables, which are comprehensively fixed to a mesh that serves as a base. Fastening is done in the form of a snake around the entire perimeter.

Heating mats, whose power reaches only up to ten W/m, are best used as auxiliary heating.

The system has the following advantages:

- High degree of safety, absolutely not harmful to human health.

- Using such a laminate heating system, the floor level will rise by no more than half a centimeter.

To heat rooms of non-standard shape, you can cut the base without damaging the warm cable itself, and lay it on the floor with your own hands.

A heated floor system using a mat system is considered a ready-made structure that just needs to be laid and connected to the network to start working. It does not need to be secured, but when used with laminate, it is better to secure it a little.

The installation process consists of the following points:

- Even a concrete surface can serve as a base. For better adhesion, it is advised to completely remove dust and thoroughly coat the concrete with a primer.

- Check functionality using an ohmmeter. Do this before installation.

- Consider the installation location of the control device. Decide which option is better for installing the wiring, walls or floors, and make the necessary grooves.

- We install a sensor for adjusting the power level of the circuit.

- We roll out the laminate heating system and connect it to the network.

Water floor - its characteristics

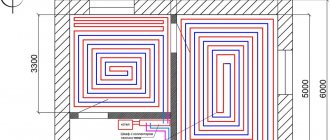

A water floor is one of the types of heating systems. It is a structure made of pipes with a circulating coolant inside. It could be antifreeze or water. Heating elements are laid in a “snake” or “snail” pattern.

The floor “pie” consists of a base, a layer of hydro and thermal insulation, pipes, concrete screed, and a finishing coating.

Advantages and disadvantages

Despite the significant installation costs during operation, such a floor is the most economical, perfectly warms the room and does not take up useful space.

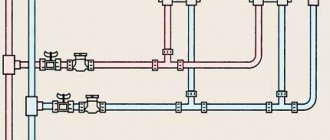

It is connected to the central heating (but this requires permission, which is time and money), or connected to an independent source.

But since during construction the hydrofloor is often filled with screed, it is not recommended to install it on the balcony due to its heavy weight. Also, it is difficult to adjust the entire system in such a room.

And due to pressure surges in the pipeline, installation of a pump is required - this is quite difficult. Another disadvantage of water structures is the risk of leakage, since it is difficult to find the cause and also eliminate it in such conditions.

The disadvantage of the system, if it is connected to a common riser, is the inability to turn it on when it gets cold. You will have to wait until the general heating of the house starts working or use a cold room.

Installation

Despite the fact that it is not recommended to install a water floor on the balcony, its installation on the loggia is possible. Indeed, unlike a balcony, a loggia is equipped with two supports at the bottom, so the structure can withstand a large load.

Watch the video on how to connect to central heating

Balcony features water heated floor from central heating

Before work, you need to stock up on materials, tools, and also develop a layout diagram for the heating elements.

The reinforced concrete slab must be flat, without holes or protrusions. If there are irregularities, the installation process should begin with it.

Step by step, do-it-yourself water heating installation looks like this:

- A thin leveling screed is poured.

- A layer of waterproofing (technical polyethylene) is laid; it must be laid extending onto the walls.

- Thermal insulation is installed - extruded polystyrene foam boards 30 - 50 mm.

- Damper tape is glued around the perimeter of the loggia - it will compensate for the thermal expansion of the screed.

- The pipes are placed according to the planned pattern, but for loggias a “snake” is more suitable; the standard pipe diameter is 20 mm. The pipeline is attached to the grooves of the plates, or with special fasteners. Seamless metal-plastic pipes are a must. They should be placed at a distance of 50 mm from the walls, in increments of 100 - 150 mm.

- Connection is made to the heating system or an independent source.

- A concrete screed is poured.

- The finishing coating is installed (only after the concrete has completely hardened) - a material with high heat transfer; you can cover the floor with linoleum, laminate, or tiles.

Before pouring concrete into the structure, you need to test the system.

You can lay water-heated floors on logs, which will be much faster and easier.

The logs are placed at a distance of 30 - 40 cm from each other. Waterproofing is laid under them, and thermal insulation material is placed between them. The pipes are placed in the grooves made, and sheets of plywood are laid on top of the logs. The finishing coating is laid on it.

DIY cable floor installation

Installation of cable heated floors

- The first step is to remove the previous floor and remove all small debris.

- Then lay the “bottom” floor - a leveling base for the future screed. Lay a layer of thermal insulation between the balcony slab and the “bottom” floor so that all the heat remains inside the room and does not go to the neighbors. The base is lined with a waterproofing material (for example, polyethylene) so that the heat insulator is not saturated with condensate moisture, which reduces the effectiveness of its functions.

- Wooden beams are laid across the balcony at intervals of about half a meter and attached to the concrete base with anchors. Longitudinal logs are placed on these transverse boards and secured with self-tapping screws. As a rule, three logs are enough for a standard balcony. The base for leveling should be the highest point of one of the outer lags. The rest of the boards are leveled to the level of the base using mounting wedges. All voids between wooden beams and joists are filled with heat-insulating material (for example, mineral wool).

- Chipboard sheets are laid on the logs. This material should not be replaced with plywood or anything else; it is ideal for a balcony - it is resistant to fluctuations in humidity and temperature. The seams between the sheets are filled with polyurethane foam.

- The heat cable is fixed to the chipboard. It is mounted with a “snake”, the distance between the turns is called the laying pitch. For a standard balcony it is 10 cm. This value must be taken responsibly, because if the step is too large, the floor will partially warm up. The cable is fixed to a special mounting tape, which is fixed in advance to the chipboard. Now you can connect the thermostat (for the balcony it is installed externally) and check the heating system to eliminate any shortcomings.

- The final layer is filled with screed - the thickness is about 5 cm. It is not recommended to use reinforcing mesh and make the screed layer thicker, so as not to burden the balcony structure.

- After five days, when the concrete has completely dried, the flooring can be laid.

Installation video instructions

It is much easier to install another type of electric heated floor with your own hands - heating mats.

Installation of heating mats

First you need to decide on the location of the heaters themselves.

Then everything follows the same scheme: thermal insulation, “bottom” floor, heating mats according to a given scheme, connection to the power supply system and the mandatory test. The advantage is that a concrete screed is not needed; the floor covering is laid directly on the heating elements. This version of a warm floor is well suited for tiles, which are mounted with special glue. After the glue has dried (usually 20 days), you can begin to operate the heating system.

Heating mats and their types

A heating mat is essentially the same as an electric cable floor, but the wire is already fixed to a fiberglass mesh. The length of the mat is from 50 cm to 3 meters, the width is usually 50 cm. These heated floors operate on 220 W electricity. The device uses a cable with a diameter of 2.5 and 4.5 mm.

Electric mats use two types of wire:

- Single-core - both ends are connected to the thermostat, so it is more difficult to install heating with such a cable. The downside of the wire is that it emits an electromagnetic field; it is not recommended for installation in rooms where people spend a lot of time. Plus - the cost is not high.

- Twin-core - a more advanced look, suitable for a balcony. When placing it, it is not necessary to bring both ends to the regulator. Such a cable emits a minimum of electromagnetic waves, so it is not dangerous for people.

Electrical mats with any of these types of wires can last for more than one year.

A single-core cable is thinner than a two-core cable, has more power, and therefore warms up faster.

Advantages and disadvantages

The main advantages of electric heating mats:

- do not take away the height of the room, since the thickness of the “pie” is only about 2 cm;

- economical - electricity consumption is not significant;

- easy to install.

But the cost of mats is higher than the price of a regular cable floor.

The mats are recommended for heating for a short period of time; they are not intended for continuous operation. The product cannot be shortened. Therefore, having chosen a warm floor in the form of mats, you first need to measure the area of the balcony.

Installation

Apartment renovation in a new building. Do-it-yourself floor insulation on a loggia

Electrical mats must be installed carefully so as not to damage the cable.

The process consists of:

- drawing up a project - it reflects the wire laying diagram, the location of the temperature sensor and regulator;

- preparing the rough base - leveling and sealing uneven areas, clearing debris.

- laying thermal insulation - this is necessary to eliminate heat loss;

- pouring the screed - the concrete layer will serve as the base;

- placement of mats according to the pattern;

- installation of a thermostat and connection of the system;

- applying tile adhesive 2 - 3 mm and fixing the tiles - the adhesive must be applied evenly so that air voids do not form.

If you plan to lay a wooden covering on a balcony or loggia, then polystyrene foam is laid on top of the mats, on which the boards are laid.

Principle of calculation of floor systems

Before choosing any floor system, it is important to calculate the power of the heater and determine its required length.

To do this, you need to calculate the heat loss of the loggia. A lot of thermal energy comes out through window openings, so ensuring a temperature of +20-+23°C is quite problematic, especially in the winter season. Therefore, it is recommended to install heating equipment in heating mode.

You can calculate the heat loss of a balcony using an online calculator.

Before installing a heated floor system on a loggia, it is important to first insulate the room

The recommended temperature of heating mats, cable or IR film is +26°C. This mode is suitable for heat-insulating parquet floors. If tile, marble or other heat-conducting coating is used as a coating, then the recommended cable temperature is +28-+31°C.

Typically, loggias require 160-180 W per m2 for heating and 200-220 W per m2 for heating mode. Taking these recommendations into account, you can calculate the required cable length, laying pitch, and system power.

For example, a loggia has an area of 2 m2. The flooring is tiles, no screed is planned. Let's take the heating mode, which requires 200 W per m2. Next, we determine the heating area.

It is calculated using the formula:

Sgr=Stot-Spr, where

- Spr - the area occupied by cabinets and other furniture;

- Stotal - total area of the room.

Let's say the area occupied by furniture is 0.5 m2. Then Sgr=2-0.5=1.5. The heating mode is selected for the loggia, so the required cable power is 200 W per m2.

Then the recommended system power is 1.5 * 200 = 300 W per m2.

If a screed is not planned, choose a thin cable system that can be completely embedded in a layer of tile adhesive.

You can select a system with the required characteristics using tables describing the characteristics of the equipment.

Using the technical characteristics of the mats, you can determine the optimal model based on individual requirements (+)

Based on the table, we determine the thickness of the mat, its dimensions and length based on its area. In our example, the power of the mat is 0.25 kW, and the length is 17 m.

Next we look for the installation step. We calculate it using the formula:

h=(Sgr*100)/Lcab , where

- h —laying step;

- Lcable - cable length in meters.

We substitute the values into the formula and get: h=1.5*100\17=8.8 cm.

When laying mats or cables, remember that the distance from the walls should be 10 cm.

Heating electric cable

The heating element in the electric cable floor is a two-core 5 mm shielded cable, and the system is controlled via a regulator. The device operates at a voltage of 220 W, it heats the surface from +25 to +32 degrees.

The wire is placed in a concrete solution or tile adhesive mixture, although dry installation is possible.

Advantages of a heating cable:

- the size of the electromagnetic field emanating from the system is small and not dangerous to humans;

- since the design uses low-power cores, the service life is significantly increased;

- The presence of a screened film ensures electrical and fire safety and protects against damage.

A good choice for placement on a loggia or balcony would be electric heated floors with a tile finish.

The disadvantage of a cable device filled with a concrete mortar screed is the heaviness of the structure and the duration of installation.

Installation

Warm floor on the balcony

The principle of arranging an electric cable floor on a balcony is similar to the process of laying cable mats:

- you need to start with preparing the rough surface - cleaning and leveling;

- then you need to make thermal insulation - lay extruded foil polystyrene foam 20 - 30 mm thick;

- pour a concrete screed on top of the thermal insulation with a thickness of 10 - 15 mm - there will be no contact of the material with the insulation, and the risk of overheating will be minimized;

- lay down the mounting tape and spread the cable according to the planned layout - the wire is fixed with tape;

- install a thermostat and a temperature sensor - grooves must be made for the wires running from the floor to the control unit;

- Lay down the finishing coat only after the screed has dried.

The cable should be installed on a well-insulated loggia, otherwise you will simply heat the street. Before pouring the concrete mixture, you should check the system for functionality.

Heating system with cables

Today, the most popular and most affordable system used to create warm laminate flooring is the cable heating system. With its help you can easily heat even the smallest and most compact balcony. The complex is installed under the final coating, in the very top leveling layer of the screed, connected to the control relay, on which the degree of heating is set.

Has the following key advantages:

- Low power consumption.

- It has high quality and degree of protection. It does not oxidize and is completely protected from damage by the cement screed.

- The degree of heating is easily adjusted.

Stages of fixing mounting tapes

Installation of such a device is somewhat more complicated than that of the above systems. We give you recommendations that will help you install it correctly and do it yourself:

- It is necessary to apply a layer of waterproofing and insulate the balcony well.

- The thickness of the screed that is applied to such a system is four to five centimeters.

- The cable is laid in a serpentine shape.

- The interval between the lines should be maintained about ten centimeters.

- You can install laminate flooring on a warm floor after the screed has completely dried in about three weeks.

Infrared heated floor

Infrared electric floor is a popular model, especially for installation on a balcony. The design is two layers of polyester film with carbon plates inside.

The work of IR flooring is the generation of long-wave infrared rays. The film comes in different types, differing in power, heating temperature, thickness and area of application.

When choosing the power of a strip floor for a loggia, you should take into account the characteristics of the finishing material. At high power, it is recommended to lay ceramics.

Advantages and disadvantages

The main advantages of the film:

- environmental friendliness and safety for humans;

- the device does not worsen air quality, as it heats objects, not air;

- does not emit electromagnetic waves;

- does not affect the height of the room - the film thickness is only 0.3 mm;

- if one area is damaged, the entire film continues to function;

- durability, practicality, no repair required.

Due to the flexibility of the canvas, it is easy to install in a room of any shape and is easy to dismantle. The installation process is simple and not lengthy, since there is no need for a screed. Suitable for heating open spaces such as balconies, even in winter.

The main disadvantage of infrared floors is energy costs, but since most often balconies have a small area, they are not significant. The inability to place heavy furniture on the film is also one of the disadvantages of the model.

Installation

Insulation of the loggia Warm floor and electrics (PART 2) WE BUILD FOR OURSELVES

The film floor is installed on the loggia in several stages:

- the base is being prepared - it is important that it is level;

- insulation with a reflective layer (foil insulation) is laid, the joints between the sheets are glued with tape;

- openings are cut into the insulation for the contacts and sensor so that there are no protrusions;

- the infrared film is mounted, if necessary, it is cut strictly along special lines;

- contacts are connected and insulated with bitumen tape;

- a regulator and temperature sensor are installed;

- spread polyethylene over the film with a slight overlap;

- flooring is being laid.

This heating can be used immediately after installation.

Is underfloor heating compatible with laminate?

A balcony is usually a place of high humidity and temperature fluctuations, so you need to wisely choose a high-quality moisture-resistant laminate (not lower than class 33). It is imperative to take care of the waterproofing of the room itself. Therefore, if you plan to dry clothes on the balcony or set up a winter garden, it is advisable to choose a different finishing method.

Laminate flooring is suitable for a glazed balcony. Before covering it, it is necessary to insulate it so that the temperature does not drop below +5°C. Laminate flooring on the balcony looks stylish. This capricious material does not like sudden changes, so it is advisable to keep it indoors before installation.

For finishing, you just need a material that conducts heat well. When purchasing, you need to pay attention to the labeling. It should indicate that the specific type of laminate is recommended to be laid on a heated floor.

It is important to remember that temperatures above 26 °C cause the material to release unwanted fumes.

Temperature sensor installation

To regulate the temperature in a room heated by electric floors, you cannot do without a temperature regulator and sensor. The method of connecting devices is simple, it is the same for all systems, the main thing is to follow the instructions.

To install this device, you must:

- make a recess in the wall for the box;

- cut grooves for the wire in the wall from the floor to the location where the regulator is installed;

- install the device in the prepared opening;

- insert the sensor into the corrugated pipe and place it between the heating elements;

- connect the sensor and cable from the floor to the regulator.

The regulator should be placed close to the wiring - this will save on wires.

How to install a heating structure

The installation technology for each type of “warm floor” heating system is individual. Let's take a closer look at them.

Installation of a water system

At the preparatory stage, a waterproofing layer is applied under the water structure with the applied material applied to the walls (slightly above the floor finishing level). The perimeter of the workroom is glued with damping material, which will help compensate for the linear expansion of the screed during temperature fluctuations.

Next, the pipes are laid according to a pre-designed scheme (any intersection of pipes is excluded) with their obligatory fastening to the slab. The heating circuit should be at least 50 mm away from the walls, the recommended pitch of the “snake” bends is 100-150 mm. The installation is completed by connecting the finished circuit to an autonomous boiler or a general heating system.

A screed made from a self-leveling mixture or cement-sand mortar is poured. After it has completely dried and the concrete has hardened, the finishing flooring material, which has high heat transfer, is installed.

Warm water floor pipe laying diagram

Cable system installation

The purchase of a cable for a heated floor is preceded by a mandatory power calculation. Based on the results obtained, the brand of the required conductor and its length for a specific area of the balcony (loggia) are determined, the electrical connection diagram is selected and a heat cable laying diagram is drawn up.

- Forming a hole in the wall (150 mm from the floor) for placing the thermostat; from it you need to make a groove (to the floor) for the wiring.

- Lay the reinforcing mesh and secure the mounting tape that will secure the heating cable.

- Installation of the temperature sensor, according to the plan, in a small recess in the insulation, prepared in advance. The sensor is located in a corrugated tube. One end of it, which will be in the screed, is closed tightly, and the second is brought out onto the wall above the future level of the screed. The temperature sensor should be easily removed from the concreted tube for possible easy replacement if damaged.

- According to the diagram, a “hot” cable is laid and secured with tendrils of a previously installed mounting strip.

- Using a tester, the parameters of the conductor are checked after installation. The deviation from the values declared by the manufacturer should not exceed 10%.

- Wall mounted thermostat. Connecting the power supply, heating cable and temperature sensor to it.

- Filling the screed.

- Finishing.

Electric floor connection

If heating mats are used, then ceramic tiles are laid on top of them without screeding on a layer of adhesive.

Installation of infrared system

After calculating the power, purchase a system kit for infrared heating or all the necessary components separately.

Installation procedure:

- Installing a distribution box with a thermostat and connecting power to it.

- Thermal insulation with the top foil side is laid on a perfectly flat surface. The connecting seams of the fabric (if any) are glued, the foil is grounded.

- Cut off a strip of IR film and lay it with the copper strip down. The exposed silver contacts at the edges are covered with bitumen insulating tape.

- A terminal is attached to the conductive strip through a technological cut in the film, to which the current-carrying wires are brought and crimped. Open terminal areas are insulated.

- For terminals, wiring and for installing a temperature sensor, recesses are made in the insulation layer. During installation, the temperature sensor is secured to the back of the IR film with bitumen tape.

- To avoid displacement, the laid film is fixed around the perimeter to the thermal insulation material with tape.

- Connection to thermostat.

- Carrying out a performance test of the heated floor.

- The film is covered with polyethylene and the finishing is installed.

The organization of heating on glazed loggias and balconies transforms these premises into the category of full-fledged residential “squares”. And the technology for installing heated floors is not so complicated that you need to seek the help of construction specialists. The entire complex of preparatory and basic activities can be carried out independently.

Insulation of balcony floors

When a heated floor operates, a lot of heat is lost through the base slab. And if the neighbors below have an unheated balcony, then these losses will increase significantly. Therefore, the insulation of balcony floor slabs must be approached responsibly.

The technology and material for thermal insulation are selected taking into account the characteristics of the balcony and ceiling height. In private houses, where the ceilings are high and the loggias below are supported by columns, there are many options; any method will do.

In apartments, when choosing a material, you have to take into account the design features, even if this affects the quality of heating.

Insulation with expanded clay

To get the effect of insulating a balcony slab with expanded clay, its layer should be at least 5 cm, and preferably 20 cm.

Expanded clay is a hygroscopic material; when wet, its thermal insulation properties are lost, and it takes a long time to dry. There are several types, depending on the size of the fractions (from 5 to 20 mm) - sand or gravel. It has been used as a material for thermal insulation for a long time, since it is not expensive, and its characteristics are practically not inferior to modern insulation materials.

The larger the fractions, the higher the thermal properties of expanded clay, but the degree of shrinkage is greater.

Styrofoam

Polystyrene foam is an artificial material made from polymers; it is not afraid of moisture and is not destroyed by external factors.

But since it has a lower density, its thermal insulation qualities are lower. Foam plastic is less durable, so it is not recommended for floors, although it is often installed due to its low price.

Extruded polystyrene foam

Extruded polystyrene foam is a solid sheet insulator, standard thickness is 3 - 5 cm. The boards are durable and can withstand the weight of a person. This material makes it easy to install beacons and install a heating element.

Penoplex practically does not reduce the height of ceilings, but it costs significantly more than expanded clay and polystyrene foam. But since the average balcony area is 3 sq.m., the costs will not be significant, so it is better to use it.

The process of insulating a balcony slab with polystyrene foam is not complicated, it is similar to laying any heat insulator, so this work is easy to do yourself:

- the slab is leveled - large bulges are cut off, and depressions larger than 3 mm are filled with cement mortar;

- polyethylene is spread as waterproofing;

- damper tape is glued around the perimeter of the balcony, its width is 10 cm - it compensates for temperature expansion;

- sheets of expanded polystyrene are laid;

- a reinforcing concrete screed is poured in a layer of 5 cm, and a plastic mesh is used for reinforcement.

After the screed has dried, you can proceed directly to installing the heated floor.

How to install a heating structure

The process of installing a water floor is more complicated than others, since it will require checking the pipes before laying them and covering them with screed. The other options are simpler in this regard, but they heat up less than a water floor.

Installation of a water system

Purely technically, installation is carried out according to the same scheme as for electric floors. Installation is carried out on a concrete screed or between wooden joists. Concrete is considered stronger, plus it serves as an excellent heat conductor and retains it for a long time.

Water heated floor

The floor on which work will be carried out must be perfectly level.

It is important to take this nuance into account, since during construction, external structures are made at a slight slope so that water does not linger on the roof, but flows calmly down. A water-based structure requires an additional layer of waterproofing

The material that provides protection from water should extend beyond the floor and be slightly higher than the final coating.

For the flooring itself, a flexible metal-plastic pipe is used. It is fixed to the thermal insulation with small clamps. A rubber corrugation is installed at the place where the clamp covers the pipe. This protects the folds from sudden refraction.

The pipe is laid in coils or snails. The distance between the pipes is 10-15 cm. They should be no closer than 5 cm to the wall. Intersections are not allowed.

A polyethylene tape is laid along the perimeter of the wall so that there is a damping gap when the screed shrinks. The screed is made from a self-leveling material or from a mixture of cement and sand using beacons. Afterwards, wait for the composition to dry completely (7 days) and lay the final cladding (after 1 month).

Dry installation is done on wooden logs. It is not necessary to level the surface for them; just insert the wedges. Logs are placed every 30 cm. The height of the structure is about 7 cm (the width of the insulation and pipe is taken into account).

Polyethylene is placed on the thermal insulation, and lathing is placed on it. The insulation is laid between the joists, securing the free space with polyurethane foam. In order for the pipe to pass through all the joists, grooves must be made at the joints. A layer of plywood is laid before the facing covering.

Cable system installation

The method of laying the cable is the same as for the water pipe. For convenience and ease of installation, you can use special electric mats. This is a thin cable that is supported by fiberglass film. They are easier to attach to thermal insulation.

Connection diagram for cable heated floor

A layer of metal reinforcing mesh is laid in front of the mats. There is no need to secure the mats. The tile covering can be laid directly on them using special glue.

The cable is installed similarly to a water pipe. At the bend points it is intercepted with clamps, which are fixed into thermal protection. A screed is poured on top and tiles are laid.

Installation of infrared system

The simplest option takes several hours. Before applying the film, the thermal protection is covered with an insulating layer of foamed polymer fabric. It is covered with foil. The joints are sealed with special tape.

Sensors and contacts must be flush with the floor; holes are made under them in insulation. The film is laid on top of the isolon. The contacts are pressed off and insulated.

A protective layer of polyethylene is laid on top. Next, you can lay any floor covering. Any material can be used for this type of heating deck. No screed is needed after applying the film.

Installation of infrared film floor

Such a heated floor system can heat not only the facing covering, but also the walls next to it, which is a particular advantage for lovers of house plants. Heating will help them survive the winter on the balcony.

It is difficult to dismantle decks filled with concrete screed; the help of specialists will be required. Wooden logs are easily removed, as is the film system.

Installing a system on a balcony can be a very troublesome task, but making a heated floor on a balcony with your own hands is possible. After installing the final screed, the walls of the room are finished. Flooring renovations are being completed

It is important to choose the right heating for the type of room. Prepare a flat surface, hydro and thermal insulation

Pipes or cables must be fixed; there should be no air left in the space between the thermal insulation and the screed.

A heated floor system will be useful for those who dry clothes on the balcony or want to create a quiet corner for practicing hobbies. The glass in such a room will not freeze; warm air from the flooring rises and prevents it from becoming covered with frost.

Opening the windows on the loggia where the structure is installed is completely safe; the temperature difference will not affect its safety in any way.

Insulation of walls and ceilings

To maintain comfortable conditions in the loggia, without wasting heat, it is imperative to insulate the walls and ceiling.

To do this, you can use various thermal insulation materials: mineral or polymer, sheet or roll, hard or soft.

Mineral wool

Mineral wool is made from basalt rocks. Pros: low thermal conductivity, fire resistance and affordable price.

However, it is hygroscopic and requires additional protection, so it is not recommended for insulating walls and ceilings on the balcony.

Styrofoam

Polystyrene foam is produced by foaming synthetic masses, resulting in a light and porous product.

It has a low level of thermal conductivity, does not rot and is easy to install.

Expanded polystyrene

Expanded polystyrene is a type of polystyrene foam, but a more modern and improved model. It is an excellent heat insulator, easy to install, lightweight and inexpensive.

Today, polystyrene is one of the most commonly used thermal materials, so let’s consider the process of insulating walls and ceilings on a balcony or loggia from it.

The method of attaching the insulation to the walls depends on their finish:

- on PVA glue or other composition that contains an aggressive solvent;

- using special wedging fungi;

- on wooden slats or metal profiles.

The following finishing is possible on top of the insulating material:

- installation of reinforcing mesh, with puttying, painting or wallpaper;

- cladding with plastic panels or siding.

As a specialist comment

Choosing a heated floor system is a matter of economics and consumer taste. The installation of a heated floor on a balcony is fundamentally no different from the installation of a heated floor on a loggia.

Without considering the water heated floor system as not being widely used due to legal restrictions, of the other two systems, both electric heated floors and infrared have no restrictions.

The choice of finished floor covering affects the choice of underfloor heating system:

- Tiles are good for any system

- Laminate and other wood materials, linoleum, carpet - the best choice is film heated flooring.

When using laminate and other wood materials, linoleum, carpet, make sure that precipitation does not fall on the floors - the balcony or loggia must be glazed. It is better to consider the installation of a heated floor on a balcony or loggia as part of a comprehensive insulation system; use the same materials for insulation.

Installing a heated floor on a loggia or balcony with your own hands is an interesting and useful process that does not cause any special problems for the skillful owner of the premises. Anyone who takes the process seriously can do all the work with their own hands.

Features of operation

There are several points that need to be taken into account when installing heated floors on the balcony in order to extend the life of the system and its efficiency:

- do not install heated floors on an uninsulated balcony, insulate the floor tiles, walls and ceiling - this will allow you to avoid wasting heat;

- use lightweight thermal insulation material, install from inside the room;

- use a moisture-resistant topcoat.

To summarize, it can be noted that the most suitable models for electric balconies are infrared film or cable mats. Although under certain conditions other types have the right to exist.

Currently, in order to increase the usable area and increase the functionality of the balcony, it is not only glazed, but also insulated, and heating is installed - warm floors. With a well-chosen heating system, you can use the balcony room at any time of the year.

Making a choice

There are several types of heated floors. Having examined each separately, you will be able to understand which of them is most suitable for use on the balcony.

Cable

Cable heated floor in section

The heating element is an electric cable placed in a concrete screed and powered from the mains. Concrete heated by a cable releases heat into the air. This type of heated floor can be used under tiles, linoleum and laminate. To save energy, you will have to purchase a thermostat. It maintains the temperature at a given level and automatically turns off the power when it reaches the desired value.

Water

Layout of water heated floor elements during installation

As in radiators, the role of the heating element in this type of heated floor is played by water, which comes from the central water supply system, passes through a gas boiler, and then, in a heated state, is supplied through pipes installed in the screed or joists in the wooden floor. This type of heated floor is ideal for private homes. But in houses connected to centralized heating, the removal of pipes to the balcony is strictly prohibited (due to a decrease in water pressure and, accordingly, heat from neighbors) and is punishable by law.

Film (infrared)

Infrared floor is a thin film with heating elements

A good option for a balcony. It consists of layers of thin polyester film into which carbon paste is sealed. The latter is a source of infrared radiation, operating on the principle of solar heating. This type of heated floor is easy to install and does not require a concrete screed. Installs directly under the floor covering.

Varieties

You shouldn’t think that there is a universal solution for your balcony; you need to select everything individually. Let's look at the most popular varieties:

- Electrical coating, which is carried out using cable and film

- Water floor with special circuit system

- Infrared floor

Water floor

The water floor provides uniform heat; the floor warms up over the entire area of the balcony. You will spend money for installation once and forget about spending. More economical than electric floors. Does not require additional batteries near the walls.

Among the main disadvantages, they immediately note the difficulty of installation, decreasing pressure that needs to be adjusted, the likelihood of leakage and difficulty in adjusting the temperature.

Therefore, a water floor is installed on balconies and loggias of private houses, where there is no risk of flooding neighbors and it is easier to carry out this circuit.

Electric floor

An electric floor warms up the entire balcony, but not as evenly as a water floor. But this variety is easy to control the temperature and costs much less (due to the fact that a water floor on a balcony is more difficult to install).

If any breakdowns or malfunctions suddenly appear, they are eliminated very quickly, making it easier to diagnose the wiring. This warm floor is suitable for any loggias and balconies, so you will not cause inconvenience to your neighbors due to leaks.

The obvious disadvantages are increased electricity costs, some are still highly susceptible to electromagnetic radiation.

An electric floor is more typical for modern interiors than a water floor. The ease of installation and savings on professional services are more attractive than the additional energy consumption.

Among electric floors, there are also several categories that are worth paying attention to. Perhaps one of them will suit you better.

Cable system

Cable is the most common; cables are laid on the floor as a circuit. They are placed between special heating sheets. Be sure to provide waterproofing and insulation; it is better to use a cement screed with a thickness of at least 4 cm. The cable itself runs at a depth of 3 cm. You should choose a good finishing coating for it that can conduct and retain heat. For example, ceramic tiles, concrete, porcelain stoneware. One of the disadvantages is that it cannot be used immediately. It will take a month before the floor is completely dry and can be connected to electricity.

Heating mats

Heating mats also perfectly heat the room; they reduce the risk of pressure on the balcony, perfectly replacing cement screed. The mats can be laid even on old floors or concrete; they can also be turned on faster than cables: as soon as the glue has dried. The topcoat must also conduct heat. The main disadvantage is the high risk of damage and the fairly high price.

Infrared floor

Creating a heated floor using the infrared method helps to warm up the room quickly, without taking up much space. Installation is very simple - such coatings come with instructions so that anyone can install what they want. But infrared radiation is not capable of completely warming up a cold floor in winter. Therefore, try to combine it with carpets, carpet or linoleum.