Brick is considered one of the most popular materials in modern residential construction - an environmentally friendly material that does not require insulation. The first stage of construction is planning and purchasing materials.

Transportation will be cheaper if you purchase the entire volume of building material in one go.

To do this, you have to decide what type of material to build from, as well as how to correctly calculate the bricks for the house. Correctly made calculations will eliminate the need to buy what is missing or overpay for excess.

What you need to know to carry out calculations

You can find out how many bricks you need for a new house by using an online calculator that will help you calculate the exact amount of stone for any building, be it a house, a bathhouse, a change house, etc. It is suitable for calculating both building and facing materials.

Without much difficulty, you can calculate the bricks for a house manually. But first, a few words about what kind of bricks are on sale. It can be solid, hollow and porous. Due to the existing voids in the material, its weight is reduced. And a room made of such building material will retain heat longer, since the air remaining in the voids is a poor conductor of heat. The most popular brick size is 250x120x65 mm.

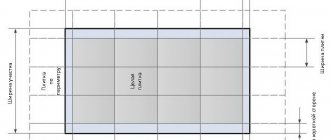

To show how easy it is to calculate the amount of building material needed, let’s take for example a square house, the size of which is 10x10 m with a height of two floors.

If we know the total area of the house, then it is necessary to carry out additional calculations, namely:

- find out what the perimeter of the building is;

- calculate the area of the walls taking into account their height;

- determine the thickness of the walls (external and internal).

Each of these parameters affects how many bricks are needed to build a cottage according to the given parameters.

Although the facing brick differs in texture, its dimensions are standard Source sv.decorexpro.com

See also: Catalog of projects of brick houses presented at the exhibition “Low-Rise Country”.

Types and sizes

How much and what kind of bricks are required to build a house can be determined by a specific display of product types:

- ceramic (hollow) - the material is universal in the construction of premises for any purpose. Gaps in the surface increase its insulating ability. High durability and decorative characteristics. Its diversity makes it possible to use it at all stages of construction, namely: the construction of the house frame and interior partitions, facade cladding, stove and fireplace finishing, interior decorative finishing;

- solid - the material is intended to fill a number of load-bearing structures from the inside. Perfect for anchoring furniture (for example, kitchen);

- silicate (facing) - a particularly decorative stone, has a soundproofing function. Consists of quartz sand (90%) and lime with additives (10%), has the best frost resistance and minimal moisture absorption compared to ceramic. This type is used both for the outer row of load-bearing walls and for interior partitions.

The next step is choosing the size of the brick. The most common sizes: Modern technologies offer double brick (double stone) as an economical option.

The correct choice of the size of stone required for construction will help the customer reduce their costs, and the builders will save time and labor costs.

In addition to the dimensions, the brand of brick plays a huge role (M100, M125, M150, M200). Here the number after the letter “M” determines the strength of the stone and the entire structure as a whole. Thus, the level of the indicator affects the implementation of a specific task (foundation, load-bearing structures or interior partitions, decor).

The influence of the environment is determined by two indicators: frost resistance (the ability to withstand freezing and thawing) and moisture absorption (should be limited to 6%-16%).

The higher the frost resistance and the lower the level of moisture absorption, the better the quality of the material.

Types of bricks included in the calculator

If the perimeter of the external walls is: 10 x 4 = 40 m, then in order to calculate the area of the walls, the sum of the perimeter should be multiplied by their height. Let it be equal to 3 m. From this it follows that the height of the two floors is 2 x 3 = 6 m. From this it turns out that the area of the external walls is: 40 x 6 = 240 m2.

To find out how many bricks are needed for a 10x10 house without a calculator, you need to take into account the thickness of the masonry and select the type and size of the stone from which it will be made. Dimensions of masonry material can be of three types:

- Single - 250x120x65 mm

- One-and-a-half - 250x120x88 mm

- Double - 250x120x138 mm.

How many bricks are needed to build a house can be found out by referring to the consumption table of the required material per 1 m2 of masonry:

Number of bricks depending on the laying method Source line-home.ru

On a note! A building built from double brick looks less elegant than one built from single brick. But this can be easily corrected using any facing material (granite panels, siding, plaster or brick of standard sizes).

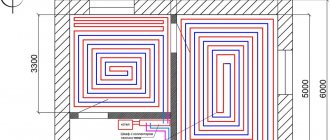

Masonry methods

To understand construction terminology, we provide a clear example of a description of the parties.

Solid masonry comes in two types:

- Single-row (or chain) ligation of walls.

- Multi-row dressing of walls.

- Masonry with a wall thickness of 1 stone (250 mm)

The figure on the left shows a single-row dressing, and on the right - a multi-row.

- Masonry with a wall thickness of 1.5 stones (380 mm)

- Masonry with a wall thickness of 2 stones (510mm)

An example of calculating a house with an area of 100 square meters. m

Now let’s calculate how many bricks are needed for a house of 100 sq. m. As in the previous example, to do this, you first need to find out what the perimeter of the walls is. Let’s say each wall of the house is 10 m, and there are four of them in total: 10 x 4 = 40 m;

- To find out the area of the external walls, you need to multiply the perimeter by the height, which in our case is 3 meters: 40 x 3 = 120 m2;

- It is not difficult to calculate how many bricks are needed for such a house. For example, if the masonry is made with a thickness of 2 bricks, and a single brick is chosen as the building material, then for each square meter of masonry you will need 204 bricks (including seams).

- We subtract the total size of all openings: 120 m2 – 12 m2 = 108 m2.

- The final calculation will look like this: 108 x 204 = 22,032.

Result: to build a house with an area of 100 m2, you will need to buy 22,032 single bricks, plus about 5% reserve in case of battle.

To get a good result, any construction must be preceded by careful calculations Source superdom.ua

Brick dimensions when calculating

An important value in the calculation is the dimensions of the brick itself. Factories produce several types of bricks: single, one-and-a-half and double bricks.

Wherein:

- dimensions of one-and-a-half bricks – 250*120*88 mm;

- double brick dimensions – 250*120*138 mm;

- dimensions of a single brick – 250*120*65 mm.

It is necessary to remember the thickness of the seams between the rows:

- vertical seam – 10 mm;

- horizontal – 12 mm.

Popular publications:

How much does white sand-lime brick weigh?

Choosing which brick is better: silicate or ceramic?

An example of calculating a house with an area of 200 square meters. m

By analogy, a brick calculator will help you calculate how many bricks you need for a house of 200 sq m:

- Perimeter: 20 x 4 = 80 m

- Area: 80 x 3 = 240 m2

- If the walls are laid with two and a half bricks, and a single stone is chosen as the material, then, in accordance with the table, it turns out that at least 255 pieces will be needed per 1 m2.

- Subtract the area of the openings: 240 m2 – 18 m2 = 222 m2.

- The final calculation is as follows: 222 x 255 = 17,316.

Bottom line: to build a house of 200 m2 you will need 56,610 pieces. bricks.

On a note! Approximate parameters were used in the calculations, including window and door openings. Each house has individual dimensions. To find out a more accurate number of bricks required for a cottage, you need to subtract the area of all existing openings inside the room from the total area of the external walls.

For the construction of houses located in areas with a temperate and cold climate, it is preferable to choose a load-bearing wall thickness of at least 2-2.5 bricks.

Typically, in every building, the interior space is divided by walls. It is also necessary to allocate a separate place for the ventilation system. For their construction, similar building materials may be needed.

You can find out how many bricks are needed for the interior decoration of a house by multiplying the total area of the internal walls by the number of bricks per 1 m2 of masonry.

Internal partitions are often made one brick thick - this must be taken into account when making calculations Source strojbum.ru

Thus, the calculator will calculate how many bricks are needed for a house of 150 sq. m (and any other size). But it is worth remembering that to the obtained result you need to add another 5-10% of building material as a spare. During transportation, storage and laying, it often breaks.

The block calculator for walls works in approximately the same way, only it takes into account the size of the blocks; they are usually larger than bricks, and accordingly fewer of them are needed for construction.

Masonry mesh: what it is and what it is used for (+ technology and laying rules)

Types and sizes of masonry mesh according to GOST. Classification by materials, areas of their application. Technology and installation rules in accordance with regulatory documents.

Features of masonry mesh: design, purpose and materials

According to GOST 6727-80, masonry mesh is made from wire with a diameter of 3-6 mm. Its main purpose is to reinforce brickwork. This is a special technological technique that makes it possible to provide walls with strength and resistance to destruction, and prevent excessive shrinkage and deformation. As a result, it is possible to increase the service life of the building and go longer without repairs.

Important: the mesh retains the masonry mortar, preventing it from penetrating into the voids of the building material. This is very important to ensure the required level of thermal insulation.

Laying mesh on brickwork

In what cases is it necessary to use masonry mesh:

- Construction of high-rise or capital buildings with walls of 2 or more bricks.

- Simultaneous construction of two brick or stone walls, different in shrinkage, creep and other characteristics.

- Construction of a building from lightweight blocks with a large number of voids into which concrete mortar can penetrate.

- Construction of an object in conditions of low temperatures, which slow down the setting process of concrete.

- Construction of large-format blocks with simultaneous brick cladding.

- Screeding of the subfloor to give it greater strength and stability.

- Applying plaster to the walls in a very thick layer (here, without a mesh, the solution simply will not stick to a vertical surface).

Please note : the mechanical strength of aerated concrete is not enough, therefore, in the absence of a mesh, there is a very high probability of cracks appearing in the masonry.

Percentage of brickwork reinforcement

In what places should masonry mesh be used:

- at the intersection of load-bearing walls;

- above the lintel and other openings;

- below under the last row;

- in the corners;

- under the floor slabs (depending on the design of the plinth - under the slab or directly on the foundation blocks).

The masonry mesh for the blind area is used for the same purposes - to give strength and durability to the structure. The material also allows you to extend the service life of the building’s foundation.

Vertical reinforcement of brick walls

What materials is it made from?

Externally, the material resembles the well-known chain-link mesh, which can often be found in adjacent areas in the form of fences and enclosures. In each case, to prevent the concrete solution from slipping off the masonry, a mesh with certain parameters is selected. The composition of concrete and the brand of brick are taken into account. The main difference between different masonry nets is the material from which they are made. Based on this criterion, the following grids are distinguished:

- of steel,

- basalt,

- fiberglass.

Steel mesh

It is based on cold-rolled low-alloy carbon steel St3Kp. The material has a fairly high cost, but it has high strength and reliability. To protect against corrosion, the mesh is galvanized or coated with a polymer composition.

Please note : the protective layer of zinc is applied to the surface using the galvanic method. The rolls are placed in a special drum, where electrolysis occurs, and the rods are coated with a layer of zinc of 8-9 microns.

Dimensions of steel masonry mesh

Other material features:

- It is manufactured using long-established technology, which reduces the risk of defects to zero.

- Depending on the thickness, they can provide the masonry with different strength and load-bearing capacity.

- They have increased strength, resistance to aggressive environments and temperature changes.

- Suitable even for capital construction, and not just for private construction.

For the best adhesion of the rods to the concrete solution during the production process, special notches are applied along their entire length. The basic technical requirements for steel mesh, as it relates to welded products, are given in GOST 23279-85. According to this document, for the production of steel mesh, wire of classes Bp-I and BI (classes according to GOST 6727) must be used.

Please note : the difference in the weight of the masonry mesh with the reference value should not exceed 5%. Otherwise, this will mean that wire of a smaller diameter was used in production or that the cell dimensions were not maintained.

All-metal expanded metal mesh (TSPVS)

It is made of cold-rolled sheet, produced in rolls, which, according to manufacturers, are even stronger than conventional steel mesh. The difference between CPVS is that it has diamond-shaped cells. In the production of masonry mesh in rolls, sheets of different thicknesses are used, which are fed in different ways. This allows you to achieve a certain level of rigidity and other necessary properties.

Advantages of TsPVS in comparison with other mesh options:

- Easier to cut and cut.

- It costs less than its analogue made of reinforcing steel.

- Light weight, which makes working with the material easier.

- Wide range of applications, including for thin masonry and with the use of adhesives.

Basalt mesh

Basalt masonry mesh has become the most popular in the construction industry . It is especially often used in creating brickwork. This is explained by the advantages and properties of basalt mesh:

- Provides a flexible connection between the wall and the cladding.

- During the cutting process, it does not injure the master’s hands, but is cut very easily using ordinary metal scissors.

- It is resistant to aggressive environments, including alkaline ones, which are formed in concrete mortar.

- Exhibits dielectric properties, eliminating the impact of electric current on the object.

- It goes well not only with brick, but with gas and foam silicate blocks, cellular concrete and stone.

- It has thermal conductivity, which is hundreds of times lower than that of metal.

What does a basalt mesh look like?

Another advantage of basalt mesh is its low cost - it is about 3 times lower than steel mesh with the same parameters. The raw material for the manufacture of such a mesh is continuous basalt fiber, which allows for reliable connection between rows of blocks.

Please note : for foam blocks it is better to give preference to basalt mesh, since the glue can quickly destroy the galvanization, causing the metal to begin to corrode.

Application of basalt mesh

Fiberglass mesh

In the production of fiberglass mesh, polyester epoxy materials, in particular fiberglass, are used. Compared to metal, it has several advantages:

- The weight is 8-9 times less, which reduces the load on the structure.

- Lower cost (compared to welded analogues).

- Good compatibility with masonry mortar and aerated concrete.

- Strength is approximately 2 times higher.

- Lower thermal conductivity.

- Absolute immunity to corrosion, which provides the material with a longer service life.

Fiberglass masonry mesh

Dimensions of masonry mesh

is based on cells of different sizes, the sides of which vary between 2.5-15 cm. Most often, cells of the following sizes are found: 3, 5, 9, 10 and 12 cm. In some cases, they can be not only square, but also rectangular.

When choosing a certain size of masonry mesh, it is necessary to use the instructions of the design working documentation. In general, the following principle applies here: the smaller the cell, the higher the strength of the material. Depending on the material, the mesh can have different sizes:

- TsPVS. It is characterized by dimensions of 1x2.5 and 2.5x6 cm. With such cells and a wire diameter of 2.5 mm, the mesh turns out to be stronger than a regular steel mesh 10x10 cm with a diameter of 3 mm.

- Basalt. Most often it is produced with cells of 2.5x2.5 cm, since these are the sizes that have proven themselves to be the most effective for laying facing bricks. This is due to the fact that this is how the material best demonstrates its natural flexibility.

- Fiberglass. The characteristic dimensions of the cells are 5x5 cm.

Dimensions of masonry mesh

The weight of the masonry mesh depends on the material from which it is made, the diameter of the rods, the size of the cells and the length of the web itself. According to clause 9.77 of SP 15.13330.2012, the distance between the transverse mesh rods is maximum 120 mm, minimum 30 mm.

Specifics of quantity calculation

To correctly calculate the costs of materials, you need to carry out the following steps. Decide on the thickness of the masonry. The formation of the walls is made in 0.5 bricks (120 millimeters), 1 length is 250 millimeters, 1.5 is 380 millimeters, 2,510, 640 millimeters, which is equivalent to 2.5 bricks.

The warmer the climate in the area where the structure is located, the thinner the walls are produced. The thickness of the walls is directly affected by the number of floors of the future structure and the depth of the base of the house (foundation). The larger the system, the greater the load the walls need to bear.

In this case, for buildings with a large number of floors, a masonry of at least two bricks is used.

Bricks are produced in single (250 × 120 × 65 mm), one-and-a-half (250 × 120 × 88 mm) and double (250 × 120 × 138 mm) configurations. The scale of the brick spoon and poke must be increased by approximately the thickness of the seam.

Most often, cement mortar GOST 28013 98 is applied to a horizontal surface, laying it in a ball of 10 millimeters, and on a vertical surface - 12 millimeters.

Since two building blocks are in contact with the seam, to take into account the thickness of the seam when calculating the number of bricks in 1 m² of wall, half of its indicator is taken, the length of the spoon is increased by 6 millimeters, and the height of the butt by 5 millimeters. Based on the information, the area of the spoon is calculated.

Next, 1 m² is divided into the area of the listed material: spoon. The result obtained is considered the approximate number of pieces of the finishing product that will be used to create any 1 m² wall with a thickness of 0.5 blocks.

We divide the thickness of the walls by the finished width of the butt and obtain an indicator by which the previously obtained number of bricks should be increased.

This gap is needed to cover defects or as a result of damage to the material that occurs during transportation or under other circumstances.

Average prices for material in the Russian Federation

For the construction of walls in Russia, three types of material are used - hollow, ordinary ordinary and facing. The first is used in the construction of private houses, where there is no heavy load on load-bearing walls. It retains heat better due to its internal cavities.

Solid brick is used for the construction of multi-story buildings where the strength of the material is required. The facing is used on the side of the facade of the house, it is placed as the outer layer during the construction of walls and does not require additional processing.

Average price in the Russian Federation:

| View | Brick type | Quantity in m3 without seams | Quantity per cubic meter m including seam | Cost per piece | Cost per cubic meter m in thousand rubles |

| single | hollow | 512 | 394 | 5-8 | 2,6-4,1 |

| private | 6-11 | 3,1-5,6 | |||

| one and a half | hollow | 378 | 302 | 8-10 | 3,0-3,8 |

| full-bodied | 12-15 | 4,5-5,7 | |||

| double | hollow | 242 | 200 | 11-13 | 2,7-3,1 |

| facing | single | 512 | 394 | 6-10 | 3,0-5,1 |

| one and a half | 378 | 302 | 8-20 | 3,0-7,6 |

Costs in Russian regions may vary . The price depends on the place of production, the quality of the raw materials used in production and the brand of material.

When purchasing bricks, you must request documents confirming quality in accordance with GOST standards.

Calculation of the cross-section of a round chimney

It’s more difficult with oval pipes; even employees of companies that manufacture chimney systems cannot answer about their area. The fact is that their products do not clearly correspond to an oval shape, but are more like a rectangle with rounded edges, and the radius of curvature may be different for different manufacturers. Therefore, to calculate their area, it is better to rely on the classic calculation formula, while the area will be a little larger, but you definitely won’t be mistaken, and the heating device will work correctly.

Prices in the estimate

The calculation documentation is drawn up by the contractor that will carry out the work. The estimate is drawn up based on the design of the building being constructed. If this is a large construction project, then the calculation is made in stages for each set of works, starting from the foundation and ending with interior finishing.

For the construction of a private house, calculations are made in one document , which reflects:

- Remuneration of workers, including external specialists who perform a specific function on a small scale.

Costs of necessary materials to complete the work. Additionally, delivery, loading and unloading are taken into account.- Payment for equipment used for construction. This could be hiring or reimbursing the contractor for the use of his machinery.

- Purchase of tools and equipment. This includes concrete mixers, trowels, buckets and consumables.

- Maintenance of workers. Travel allowances, if the object is located outside the locality of the construction organization, rental of residential premises and cabins for storing equipment and materials.

The estimate may also take into account unforeseen expenses as a percentage of the amount of costs for materials and tools that may arise during the work process and the contractor's profit.

When constructing a private house with a small number of floors, the estimate is drawn up in a simplified version , where the cost includes wages for workers, the price of materials and their delivery to the site. The final version of the settlement document is agreed upon with the customer.

How to calculate a pediment - how to calculate the area

To build a roof yourself, you need to have special skills. In addition, this process requires attention and precision. To create a reliable and durable roof, a correctly drawn up project is required, which describes the parameters of the structure being built. An important part of the roof is the gable, the construction process of which should be approached carefully. In addition, it is important to know how to calculate the gable area of a gable roof.

Cost of construction work

The cost of wall masonry work can vary significantly depending on the region of construction, the complexity of the surface topography and whether the contractor has a license.

To guarantee high-quality construction of load-bearing structures, it is necessary to contact qualified specialists who will ensure proper control over the construction workers.

Average cost of laying brick walls:

| Region | Rough masonry for cladding, thousand rubles. per cubic meter m | Complex masonry with cladding for jointing, thousand rubles. per m3 | Wall cladding with bricks, thousand rubles. per m2 |

| Moscow and Leningrad region | 2,5-3,0 | 2,8-3,6 | 0,8-1,3 |

| Sverdlovsk and Chelyabinsk regions | 1,0-2,8 | 1,5-2,5 | 0,75-1,5 |

| Krasnodar region, Sochi | 1,5-2,8 | 2,0-3,5 | 1,0-1,5 |

| Tyumen region | 1,0-2,5 | 1,5-3,0 | 0,7-0,9 |

The cost of masonry depends on the season, the qualifications of the workers and the deadlines set by the customer for the construction of the walls. The architectural features of the house project are assessed individually by the contractor depending on the complexity of the project.

What provides masonry strength?

Of course, only the brick itself. Its endurance, reliability and durability depend on the brand. If the masonry is made from low-grade material, it will not be able to withstand internal stresses. The load acceptable for a brick is indicated by a number. Thus, a product of the M75 brand will withstand 75 kg per 1 cm².

To create a brick wall, experienced craftsmen adhere to three rules:

- All loads are calculated with the condition that they will be strictly perpendicular to the masonry.

- For each brick row, horizontal and vertical lines must be strictly verified.

- When creating masonry, you need to ensure that the seams of two parallel rows do not overlap.

The last rule is especially important when creating a pier. The lowest layer of brick should be laid on a flat surface

It is prepared in advance, leveling it with a solution of cement and sand.

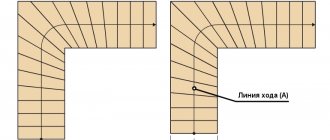

A characteristic feature of a brick wall laid with a “poke” is that the brick is positioned with the short side in relation to the wall line. If it is laid out with the long side, then it is a “spoon” laying.

We invite you to familiarize yourself with Quartz sand properties and applications

To calculate the load, it is not important how the wall is laid out

But it is extremely important to do dressings. There are two types of dressing: multi-row and single-row

When a wall is created using the single-row masonry method, the rows laid using the butt and spoon methods alternate and overlap each other. Then the load will be distributed evenly.

Choosing a brick

The calculations do not cause any particular difficulties; they consist of several simple mathematical operations. True, appropriate measurements should be taken, the accuracy of which determines the final result.

The accuracy of calculating the amount of brick depends on the correctness of the measurements.

First of all, the type of brick stone planned for construction work is determined. Let's look at the main types of bricks.

Made from unfired clay

In addition to the main component used for the manufacture of such bricks, fillers are used in the form of cut straw, reeds, shavings, etc. For production, an artisanal technique is used:

- clay is mixed with fillers;

- stones are formed from the resulting raw materials;

- The drying process is organized under sunlight.

The organic filler acts as reinforcement, preventing the stone from collapsing during construction work and throughout the entire operational period. The main advantage of this material used to build a house is its reasonable cost and availability of manufacturing, which can be organized directly on the construction site on your own. Unfortunately, due to an imperfect technological process, the brick strength indicator leaves much to be desired, and, in accordance with current SNiPs, is not used for the construction of large objects. This type of brick is not suitable for the construction of two-story or higher buildings, but it is quite suitable for outbuildings.

Refractory

For production, a special grade of clay of a yellow hue is used - fireclay. Often mineral components of large fractions are added to the brick, which gives the surface of the stone a grainy appearance. The material is able to withstand elevated temperatures for a long time, reaching one and a half thousand degrees Celsius, which allows it to be used for arranging stoves, chimney ducts, fireplaces, and thermal insulation screens. The cost of bricks made from refractory clay is high, which makes its use for the construction of walls economically unprofitable.

Silicate

The basis of such stone is lime and silicate components, which explains the poor tolerance of exposure to a humid environment. Stones of a light gray shade are formed by pressing, are not subjected to subsequent firing, and are not used for the construction of structures that require operation in conditions of high humidity.

Ceramic

A common type of solid brick material used in the construction of load-bearing walls. It is made from pressed clay and fired under a certain temperature.

Such bricks are divided into three groups:

- private. Solid stone used in the construction of facades, laying opening sections of monolithic structures, etc. Withstands significant load impacts, resistant to external aggressive factors. The masonry does not have high aesthetic qualities and requires subsequent decorative finishing;

- facing. Like the previous type, facing stone is a decorative variety. It is used for finishing walls, erecting fences, gazebos and other structures. One or two of its surfaces are glossy, a significant part of the internal volume is occupied by void areas created by molding presses and increasing the degree of adhesion between the brick and the masonry mortar;

- clinker. The material has a high density, glossy surface, and is used for the construction of small architectural structures and flooring. It has one significant drawback - the high price.

The need to calculate the volume of material

The amount of materials is determined on the basis of the building design, which reflects the type of brick for the construction of walls, the type of masonry, depending on the regional affiliation of the object, and the structural complexity of the surfaces.

The need to calculate the brick is as follows:

Uniformity of color if construction is carried out without finishing surfaces. Discrepancies in the shades of different batches will spoil the appearance of the facade.- Savings on purchasing. Purchasing bricks in bulk, loading, unloading and delivery to the site will be reflected in the price of one unit of material. The larger the purchase volume, the lower the price.

- Customer control over the rational expenditure of funds by the contractor according to the cost included in the construction estimate.

When calculating the amount required for one of the most expensive materials during the construction of buildings, it is necessary to make a reserve of 5-10% of the total volume of bricks for scrap.

What determines the amount of stone per 1m2?

This rate depends on many factors. One of them is the bricklaying method. It comes in the following subtypes:

The material consumption can be affected by the method by which the master lays it.

- Press it in. The seams are filled with a rigid mixture, and each new brick is pressed tightly.

- Back to back. Builders use moving mortar, which concentrates on vertical joints.

- With trim. A combination of the two previous options.

The following factors also influence the consumption of bricks per 1 m2 of masonry:

- Surface thickness area. Depends on the number of rows of stones. Can be from 12 to 64 mm.

- Seam sizes. Vary from 10 to 15 mm. Their joints can be of 2 types. In the undercut - in this case, all free space is filled. Hollow - there are empty gaps in the seam.

- Stone fight. Before construction, you should take into account the deterioration of the material, which takes approximately 5-6%, and add this to the calculations.

How to calculate?

To carry out the calculation, you need to decide on the type of brick. Calculations can be as follows:

- To calculate what the brick consumption per square meter will be for an ordinary red one, you need to add 1 cm to its parameters. Example of calculation based on a single stone. For 1 meter in length you need bricks: 100/26×2 = 7.68 pieces. Height 100/7.5 = 13.3. From this we get the result - stones per 1 square meter need 13.3 × 7.68 = 102 pieces per square meter.

- The consumption of facing bricks per 1 m2 will be 95 pcs. Calculation using the formula: 1/0.01056, where the last amount is obtained as follows: 0.12x0.088. So, for facing a red regular one, you will need 54 pieces, and a large front one - 14 per square meter.

- You will need 379 pieces of sand-and-a-half brick. bricks per cube per meter of masonry. You can calculate this amount as follows: multiply the parameters of the stone, and after 1 m3 divide by them. We get: 1/(0.25×0.12×0.88) = 378.8 bricks per 1 meter square masonry. Round up to 379 pieces.

To save time, specialists use previously calculated tables. The norm for them is as follows:

| Type of masonry | Consumption taking into account the solution and type of stone, pcs. | ||

| Single | One and a half | Double | |

| 0,5 | 51 | 39 | 26 |

| 1 | 102 | 78 | 52 |

| 1,5 | 153 | 117 | 78 |

| 2 | 204 | 156 | 104 |

| 2,5 | 255 | 195 | 13 |

How much solution is needed and its approximate calculation

In practice, there are tables that indicate the required amount of concrete mixture per m3 based on certain parameters. Table below:

| Type of masonry | Consumption of mortar for masonry depending on the type of stone, m3 | |

| Single | Double | |

| Half a brick | 0,189 | 0,160 |

| 1 | 0,221 | 0,20 |

| 1,5 | 0,234 | 0,216 |

| 2 | 0,240 | 0,222 |

| 2,5 | 0,245 | 0,22 |

But the store doesn’t sell the solution in cubic meters, but it should be bought in bags. The standard weight of the dry mixture is 25 kg. How many bags are needed and how to transfer them is calculated as follows. First, they find out the total volume of the masonry, then determine the type of masonry and type. For example, for a wall of 10 × 12 m, built using standard bricks, as well as with a double type of masonry and for a height of 3.2 m. We obtain a total laying volume = 71.808 m3. From the table above it can be seen that the required parameters will require a mixture of 0.240 m3. Multiplying these 2 numbers, we get 17.223 cubic meters. Next, from this figure you need to calculate the amount of cement. According to the data on the components, their ratio is 1:3, then it follows 17.233/4 = 4.308 cubic meters. In bags this number = 112 pieces, weighing 50 kg.

The number of facing bricks in a pallet depending on the type

To optimize shipment and safety of brick material, manufacturers store it in batches on wooden pallets.

Pallets for facing material are used in two types:

- 52x103 cm (small);

- 77x103 cm (large).

As a rule, the manufacturer indicates how many elements are in one pallet. If such an indicator is missing, then you can calculate how many pieces are in the first row of the pallet using the following formula: divide the area of the pallet by the area of the part. Multiply the result by the number of rows laid on one pallet.

According to the standard, the following number of parts (pieces) is placed on board pallets 77 cm wide::

- standard (25x12x6.5) - 420;

- one and a half (25x12x8.8) - 390;

- double (25x12x13.8) - 200;

- double with corrugation - 192;

- M150 - 280;

- single with torn edge - 308;

- corner with torn edge - 352;

- basement - 478.

It is not difficult to understand how many pallets are needed for a certain area.