When purchasing a jigsaw file at a retail outlet with a salesperson or manager-consultant, it is enough to name the jigsaw model and the material that needs to be cut. A competent salesperson or manager-consultant will select exactly what you need and can give advice on the features of each manufacturer.

When purchasing in a self-service store or online market, the buyer must understand the labeling and quality characteristics of the files themselves. Otherwise, there is a chance of making an unnecessary purchase. Therefore, when buying, you need to know the main points.

Marking of files and its decoding without a table

The difficulty is that there is no unified labeling system in the world. However, many manufacturers try to adhere to the labeling system used by Bosch. And the main marking elements are the same on many products.

The purpose and compatibility of files is determined by color, as well as by digital and letter markings. Often the markings are applied to the shank of the file. There it is not erased during operation, and it will always be possible to determine what material it is intended for. But sometimes markings are placed throughout the canvas. Then, during work, the markings are erased, and the master will have to remember what kind of file it is. The colors mean the following:

- Gray – only for wood.

- Blue is for metal.

- White – for metal and wood.

- Red - for various plastics.

- Black - universal for many materials, specified by additional marking.

A saw for hard materials can be used to cut softer materials, but never vice versa. That is, a metal file can be used to cut wood, but not vice versa. But for effective cutting, you should select a file that is suitable for the material or a universal file.

Compatibility with the jigsaw in terms of the shank shape is important. The most common is the T-shank. As a rule, all such files have a standard shank size that fits all jigsaws. But sometimes there are models, especially old ones, that use saws with different shanks and their markings:

- U stands for U-Shaped Shank.

- M - straight shank with two holes, found on older Makita models.

- F – two crossbars and a straight end.

For the buyer, this marking letter has little meaning, since the shape of the shank is visible at the first glance at the file, even in a picture on the Internet.

The markings begin with these letters T, U and others. For example T101B.

The first number after the letter indicates the saw length group.

- 1 – the shortest files, up to 75 mm long.

- 2 – files of medium length, from 75 to 90 mm.

- 3 – files of increased length, from 90 to 150 mm.

- 4 are the longest, over 150 mm.

Special files with a length of more than 200 are marked with two numbers (the number) 10. In this case, there is a four-digit marking after the letter.

For sawing different materials, saws with different tooth shapes and sizes are used. tooth The last two digits indicate the shape and size of the tooth and its intended use for a particular material.

- 01 – teeth without set, ground to obtain a clean cut.

- 02 – for cutting various plastics.

- 08 – special tooth shape for the cleanest cut.

- 13 – wave-shaped file for soft materials.

- 11 and 19 – wood saws.

- 23 and 24 – files with different shapes and tooth pitches.

- 27 – files for copper, brass, aluminum.

- 41 – saws for sheet building materials – gas silicate (foam concrete), plasterboard, fiber.

- 44 – large tooth with a large set for fast rough sawing of wood.

These numbers are followed by a letter marking - one of the first four letters of the Latin alphabet - A, B, C, D. It indicates the size of the tooth in four main groups. A – the smallest tooth, further enlarged.

As an example, the marking of the T101B file is deciphered as follows:

- T – T-shaped shank.

- 1 – short file, up to 75 mm long.

- 01 – teeth without set, ground to obtain a clean cut.

- B is the second smallest tooth size.

This is the simplest marking. At the beginning it was said that the meaning of the marking may differ among different manufacturers. For example, if after the numbers there are symbols other than A, B, C, D, then the marking does not indicate the tooth size, but the pitch, that is, the distance between the centers of the teeth. Deciphered according to the following table:

- G is the smallest step, up to 1 mm.

- E - pitch from 1.4 mm to 1.5 mm.

- A - step from 1.5mm to 2mm.

- B from 2 mm to 3 mm.

- BC - marking of different (variable) steps, alternating larger and smaller steps.

- C - from 3mm to 4mm.

- D - from 4 to 5 mm.

- X - files with different tooth pitches, increasing towards the end of the blade

- RIFF is a blade with a special fine-grained coating for cutting ceramic tiles.

In addition, the purpose of the file can be simply indicated by an English word. Specifically:

- Wood - used for regular wood.

- Hardwood - for hard wood.

- Alu - the first letters of the name of the metal - aluminum.

- Metal - for ferrous and other metals.

- Inox - specifically for stainless steel.

- Acrylic - for cutting polycarbonate and acrylate materials.

- Fiber&Plaster - for cutting plastics and fiberglass.

- SoftMaterial - for soft sheet materials (linoleum, artificial leather and leather, polystyrene foam, polystyrene foam, etc.)

Sometimes the inscription is in Russian instead of English. For example, just “wood/plastic”.

The grade of steel from which the file is made is important. If the length, shape of the shank, dimensions and pitch of the teeth can be seen and assessed without markings, simply by examining the file, then the grade of steel can be determined solely by markings.

- HCS is a steel with a high carbon content, suitable for cutting soft materials.

- BiM—bimetal (two metals). The use of two different metals increases the strength of the canvas. Bimetal blade can be used for different materials.

- CV is an alloy of chromium and vanadium.

- HSS (high-speed cutter) is the most common tool cutting steel. Used for cutting metal.

- Carbide Technology (CT) or NM - files with a super-hard coating of tungsten carbide, cobalt or artificial diamond powder. They can cut ceramic tiles, finishing bricks, various plastics, asbestos-cement sheets, slate and many other materials.

The metal mark is applied separately from the rest of the markings. Most often, also on the shank, located perpendicular to the rest of the markings. For example, look at the markings of jigsaw files, which are shown in the table below.

Table. Files from Rebir and their compliance with expensive analogues from Bosch.

Shank type

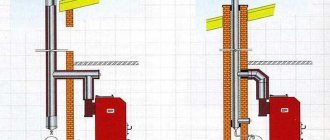

The shape of the part of the file inserted into the jigsaw - the shank - determines the way it is clamped in the tool.

Saws with a T-shaped tail are ubiquitous. They are suitable for most modern models of jigsaws for wood, such as those developed by BOSCH, a trendsetter in this area. In jargon they are called "European type".

American models (DeWalt, Black&Decker) use saws whose tail end ends in a semicircular cutout resembling the letter U. Such shanks fit all clamps with a block or screw. In the jargon - “American type”.

There are still special Makita shanks and T-shaped “Bosh” shanks, but with two stops. They are suitable only for old models of jigsaws from these companies and, rather, are rarities.

Classification and features according to the type of material being processed

The modern market offers a large selection of different saws for sawing the same material. They differ in length, shape and size of the tooth, pitch and metal from which they are made. But they belong to the same group, for example, a type of wood saw.

We also recommend reading an interesting article on how to choose a jigsaw; it contains 9 best tips from an expert that will help you make the right choice.

Tree

For this material, you can choose a file with a length from 75 mm to 150 mm.

As a rule, they are all labeled with the word Wood (wood) or Hardwood (hard, hard wood). Different types of files are selected for different tasks.

- A saw with large, sparse teeth, up to 6 mm, will provide a quick rough cut.

- A cleaner cut is made with saws with teeth of about 3 mm.

- For curly cutting along curved lines, a narrow file with a fine tooth, about 2 mm, is suitable.

Laminate

For sawing various laminates, saw blades are selected according to the same principle as for wood. The only difference is that the file must have a medium or fine tooth, designed for laminate, or be universal (wood/plastic).

Metal

An electric jigsaw is rarely used for cutting metal. There are cutting methods that are much more efficient (angle grinders with cutting wheels for metal, hand jigsaws with long files, gas cutters, etc.). However, in some cases it is rational to use a jigsaw with a suitable file.

For example, a long cut with a complex curvilinear shape (rounds and circles, sharp triangles, etc.) cannot be made with a cutting wheel and a hand jigsaw. It is not recommended to use a jigsaw to cut metal thicker than 3 mm, especially black.

Metal files are marked Alu for soft metals or Metal for ferrous metals, galvanized and stainless steel.

Steel grade – high-speed cutter HSS or bimetal BiM.

Plastic

The plastic is sawed off by turning off the pendulum stroke. Files with small and medium teeth of short length are used. Fiber&Plaster marking. For certain types of plastic (PVC), files for hard wood (Hardwood), or universal ones with the inscription “wood/plastic” in Russian or English, are sometimes well suited.

Glass

It is impossible to cut ordinary glass with saws. For this, glass cutters with a diamond wheel are used. You can use saws to cut plexiglass, which is a transparent type of plastic. They also cut it with the same files as plastics (see above).

Ceramics

Ceramics are hard and brittle materials. To cut it, special saw blades with a carbide coating are used, which is much stronger than ceramics. Most often it is tungsten carbide or artificial diamond powder. The file itself is made of ordinary tool steel. The marking of such files is Carbide Technology (CT) or NM. The blade is smooth, without teeth.

Soft materials (rubber)

Universal and special files are suitable for such materials. The first ones should be tried in practice during practical cutting. Rubber, paper and other materials are cut completely differently. Special files are made specifically for a specific material. They can have teeth or be wavy (for cardboard, foam, rubber, etc.). Suitable files may be labeled SoftMaterial or Acrylic.

Universal

There are no absolutely universal files “for all materials”. But often the same files can be used to cut different materials with different densities, structures, viscosities and strengths.

For example, a metal saw can cut wood and plastic. In this case, the file may get stuck in rubber or linoleum due to strong friction and sawdust sticking in the slot . Therefore, the selection of saw blades, even if they are positioned by sellers and manufacturers as universal, is only possible with trial cuts.

Files are often sold in a set that includes files for a variety of materials. This is convenient for users.

- Firstly , there is no need to look separately for special files for different materials.

- Secondly , it is possible to try how the saws will cut different materials. For example, a saw for metal – wood.

Choosing a tool

At home, you can cut plywood with both hand and power tools.

Power tools for cutting plywood:

- circular (circular) saw,

- jigsaw

Less commonly, but still can be used for cutting plywood, power tools such as grinders or band saws.

| * Rice. 1.a. Cutting plywood with a circular saw | Rice. 1.b. Cutting plywood with a jigsaw |

* All images are taken from open sources and are provided as examples and illustrations. And are not subject to copyright of our company. If you find your photos here and want to delete them, write to us.

A few words about circular saws

Among the advantages of a circular saw, we note, for example, the ability to cut several sheets of plywood, chipboard or fiberboard (stacked) at once. And also the fact that circular electric saws allow you to cut both thick and thinner sheets of plywood.

The disadvantages of disk tools include the difficulty of obtaining geometrically complex cuts and parts made of plywood. This cutting method is mainly suitable for straight line cutting.

Jigsaw for plywood - ideal for the home craftsman

However, at home, more “piece” or even small shaped work is often in demand. For which a regular manual or electric jigsaw is quite suitable. The latter, of course, significantly speeds up and facilitates the process of cutting plywood sheets.

Hand tool for cutting plywood:

If we talk about hand tools, then for straight and long cuts special hacksaws for plywood and chipboard can be used. For example:

Rice. 2. Hand hacksaw for plywood and chipboard.

Such hacksaws and saws are usually made of spring steel** with the so-called. reverse teeth. And they can be additionally equipped with materials that are harder than the main saw blade.

** Spring steel is a medium- or high-carbon steel, products from which have the ability to easily return to their original shape (despite significant bending and twisting). What happens due to the high yield strength of this type of low-alloy alloys.

If you plan to cut fairly small and geometrically complex parts or shaped workpieces from plywood, then you will, of course, need a jigsaw using a hand tool. Something like this:

Rice. 3.(a). Straight cutting from plywood with a hand jigsaw

Rice. 3.(b). Sawing out shaped parts from plywood with a hand jigsaw

Hand tools or electric?

Let us however note that sawing plywood with hand tools in some cases may not be a very pleasant procedure. The layered structure of plywood with wood fibers in different directions in these layers makes the process quite complex. You won't cut much like that.

Therefore, when choosing how to cut plywood at home, we recommend choosing a modern electric tool. Among which, it seems to us, the most versatile for working with plywood is a jigsaw.

Varieties of cutting edge geometry

All files differ in the size of the teeth, the pitch between them and the setting (deviation in different directions).

Milled, classic layout

These are teeth cut out on the canvas by milling with a regular set. One tooth is deviated to the left, the next to the right, etc.

It is called classic or traditional because the teeth on all hand saws, two-handed and sawmill saws, etc. are set in exactly the same way.

With this cut, the cut is wider than the blade. Therefore, clamps are eliminated, sawing is easier, and sawdust ejection is easier.

Milled, wavy layout

It also provides a wider cut than the blade, just like a classic routing. The difference is that the deviation in different directions is not just one for each tooth, but wave-like for several. “Waves” enter the material more smoothly, with less resistance.

Files with wavy layout are used for clean cuts on laminated chipboard, MDF, as well as for cutting metals.

Polished, classic layout

The geometry of the teeth of such files is the same as that of the milled ones described above. The difference is that after cutting and setting, the teeth undergo grinding, during which they are sharpened and acquire a smooth surface. Due to this, friction is reduced and sawing is accelerated, the cut is cleaner, and there are fewer chips of the material.

Conical grinding, without routing

The file has an even row of polished, sharpened teeth. In this case, the shape of the teeth is such that the cut is slightly wider than the blade and without setting. Provide precise, even and neat cuts on various materials.

Which manual jigsaw is best to use?

The metal is sawed by a file, and the jigsaw only sets it in motion and guides it. Therefore, you can cut with any working jigsaw that has a speed control. The blade swing mode (pendulum stroke) is not needed when cutting metal. There are no special manual jigsaws for metal. Regular jigsaws are used, only the blade is selected.

For your information! The more powerful the jigsaw, the easier it cuts metal. Professional models can cut thicker material than household ones.

There are stationary metal band saws that can be purchased for a home workshop, but these are no longer hand-held jigsaws.

The main parameters of canvases and what do they affect?

All main parameters are described above. Briefly about what determines each of the main parameters.

Shank types

The shape of the shank must match the model; for example, a file with a U-shaped shank cannot be mounted in a jigsaw designed for T-shaped files.

Sometimes it happens that thick files with a suitable shank do not fit into the fastening groove. This occurs on models with an auto-clamp (without threaded fastening). In such cases, take a thinner file, or slightly sharpen the shank on both sides.

Dimensions

The length of the files is divided into 4 groups from 75 to 150 mm. Each group is marked in the marking with a number from 1 to 4. When selecting the length of the file, proceed from the thickness of the material. At maximum reach, the end of the file should come out of the workpiece.

The longer the file, the more prone it is to move to the side. As a result, the cut may end up crooked. Short, thick files are less prone to bending and cut more accurately.

Saw blades of maximum length - 100-150 mm are used for cutting large-sized wood, soft and light materials such as polystyrene foam.

Tooth shape

Most teeth are shaped like a triangle with sharp corners. Their sizes, layout, and inclination may be different. In addition, there are blades with a wave-shaped cutting edge for soft materials and blades without teeth, with super-hard coating for ceramics, bricks and other hard materials. Here, a layer of diamond chips or tungsten carbide acts as a cutting surface.

What is the maximum thickness that can be cut?

For marketing purposes, it may be stated that these tools can cut steel up to 20 mm thick and soft metals up to 30 mm. Perhaps if you buy a hundred blades and spend a week of time.

In reality, if necessary, you can cut through several tens of centimeters of steel up to 10 mm thick and soft metals up to 20 mm at a time. In rare cases, when necessary, you can make a short cut to the entire depth of the blade.

How to choose a canvas for a specific task

The file is selected taking into account all the markings described above. (Wood – tree, etc.).

A few more basic rules:

- A short, thick file bends less and moves less to the side.

- A large tooth cuts faster, but rougher.

- A small tooth will tear the surface less.

In addition, to make selection easier, manufacturers sometimes put additional verbal markings on the files:

- basic – basic, standard files,

- speed – speed, fast rough cut,

- clean – thin clean cut,

- progressor - files with floating teeth of different sizes, most often universal,

- flexible – wavy layout for sawing metal,

- special – blades with super-hard coating without teeth for ceramics, some types of plastic, etc.

Which saw to choose for cutting out a tabletop

Countertops made of laminated chipboard and MDF are sawed with saws of sufficient length to cut, but not longer. Long files tend to move to the side. Fine tooth files are used for hard wood (Hardwood) or metal (Alu, Metal).

For quick rough cuts, saw blades with additional speed markings are suitable. A more accurate cut can be made with basic (basic standard) and clean (thin cut) files.

Depending on the characteristics of the material and the jigsaw itself, files can perform differently in their work. A more accurate selection of saw blades is carried out by making trial cuts on an unnecessary piece of material.

For wood

For wood, saws marked Wood (wood) and Hardwood (hard wood) are used. Files with large teeth will provide a quick, rough cut, while files with fine teeth will provide a cleaner and more precise cut.

In some cases, wood is effectively sawed using soft and ferrous metal saws. It is better to cut thick wood with long saws with large teeth. For example, with the marking T344C.

For sawing laminate and chipboard

To avoid chipping surfaces, use fine-tooth files. When sawing, the pendulum motion is turned off. The difficulty is that laminated sheets or slabs are heterogeneous and consist of pressed sawdust, shavings, wood, plywood, coated with laminite.

Laminate is plastic, the base is fiberboard or MDF, in the case of parquet, wood. Therefore, different files are used, including for wood, plastic, soft and ferrous metal. The most effective option is selected by trial sawing on a piece of material.

For figure sawing on wood

For figured cutting, narrow blades with fine teeth are used. The narrow blade allows you to make turns while sawing without breaking, bending or jamming the blade. The fine tooth makes a precise cut and also does not interfere with the rotation of the file when sawing.

For cutting drywall

Drywall, despite its loose structure, is an abrasive material. That is, it is able to quickly grind down the teeth of a saw, for example, on wood. Therefore, special files with a hard coating, straight or wavy, are used for it. As a last resort, files for ferrous metal, but they will not last long, since the plaster quickly wears off the teeth.

For sawing chipboard

For sawing chipboard, short saw blades (up to 75 mm) with a medium tooth (pitch 2-3 mm, marked A or B) are used. Chipboard consists of sawdust and shavings that can easily be cut through by regular wood or hardwood saws.

However, the resins used to glue them together can be harsh, causing the files to wear out quickly. Therefore, for chipboard saws, the quality of the steel is important. Better if it's HSS.

For figured cutting of chipboard, narrow files with a medium tooth are used. For example, T101VO.

For sawing plywood

Plywood can be sawed with wood saws with medium and fine teeth. A large tooth (for quick cutting) tears out pieces of plywood and saws with noise and vibration of the sheet. In practice, plywood is also sawed with fine-tooth metal files. This gives a high-quality, even cut.

Disadvantages: sawing with such files is slower and they can overheat during operation due to friction; clamps are possible due to a small gap. Severe overheating should not be allowed, as this will cause the material to turn black (burn), and the metal of the file may loosen (lose its hardening).

How to cut an artificial stone countertop + work procedure

Artificial stone is often used in finishing works. It is much cheaper than natural, but also durable and beautiful. Manufacturers have learned to make not only a complete imitation of the material, but can also offer unusual and interesting solutions. Before sawing a countertop made of artificial stone, it is worth understanding what the main difficulty is and how to solve it. It is also worth listening to the advice of experienced craftsmen - they will help you get the job done quickly and efficiently.

What is the problem

Deciding how to cut artificial stone starts with a definition. Artificial stone is an artificial material that imitates natural stone. The material is an adhesive substance mixed with a mineral filler, for example, it can be polyester resins and natural stone chips.

Artificial stone is used to make cladding for buildings, flat surfaces for furniture (countertops, window sills), decorative elements (including sculptures) and plumbing fixtures.

Countertops made of artificial stone have a number of advantages: they are durable and strong, non-toxic, look good due to the absence of a seam and a large number of colors.

Disadvantages include price and weight. Artificial stone weighs almost the same as natural stone.

The main problem when sawing a tabletop is its strength. Artificial stone countertops can be made of acrylic, polymer or natural resins, and concrete.

Before starting work and choosing what to cut artificial stone countertops with, it is worth examining the types of material in more detail:

- Agglomerate . The most durable stone. It consists of polyester resin, large pieces of natural marble, granite, and quartz are used as fillers. To add strength, a fiberglass mesh can be placed. The share of natural materials is 80-95%, due to which the properties of the agglomerate are extremely close to natural stones.

- Porcelain tiles . It has approximately the same strength as agglomerate, although it does not contain natural stone. They are produced by semi-dry pressing of kaolin clay followed by firing at a temperature of 1200-1300 degrees. Porcelain tiles easily replace natural stone.

- Artificial stone made of concrete . Consists of sand and cement, sometimes gypsum is added. It is cheaper than agglomerate and less durable, it is easier to saw.

- Acrylic stone . Consists of acrylic resin and fine-grained filler.

Countertops made of concrete, plaster or acrylic are much softer and more pliable. They are easier to work with at home.

What to cut

When choosing how to cut artificial stone, it is worth remembering the above types. You can use a fine-tooth saw or hacksaw to cut acrylic or plaster. It is worth remembering that gypsum generates a lot of dust when sawed with a grinder. In addition, this tabletop is fragile. You can simply break it by first making a depression in the right place - at the risk.

For cutting porcelain stoneware and agglomerate use:

- Grinder and diamond-coated discs;

- Electric tile cutter;

- Circular saw.

You can also use a hacksaw with a diamond or pobedite blade, but electric tools are more convenient and faster to use.

How is the work going?

First of all, you need to prepare the place of work. It should be well ventilated, the furniture nearby should be covered with a cloth so that dust does not fall on it when cutting. It is also necessary to protect your hands, eyes and respiratory organs: use a respirator, mask or goggles, closed clothing.

Rating of the best files for electric jigsaws

Manufacturers of jigsaws are interested in ensuring that their tools work efficiently. Therefore, many brands themselves produce files for electric jigsaws. Moreover, they are suitable not only for the instruments of these brands, but also for others.

Makita and Bosch are considered leaders in quality. In terms of sales and popularity on Yandex.market and other platforms, Makita is the leader. Bosh is in 3-4th positions. But not because of worse quality, but because of a significantly higher price. If a set of 5 files from Makita can be bought for 380-400 rubles, then Bosch files cost from 600 rubles.

Original Bosch files are of high quality.

Hammerflex files are also popular.

Reasons for chipping

If you observe the process of chipping, you can discover a pattern: when sawing from top to bottom, the teeth of the file do not saw through the material and do not form chips as they come out of it. When the process proceeds from bottom to top, the teeth catch and form kinks.

In a wooden material, fibers located in the vicinity are caught, and in laminated chipboard, the coating and chips are caught. If you try to saw two layers of laminated chipboard at the same time, the layer located below will be sawn efficiently, since the layer on top prevented the formation of chips.

An increase in processing accuracy will be provided by the “Soft Start” option, in which the jigsaw gradually picks up speed, and the cut itself proceeds as expected. Move the tool slowly. It is necessary to continuously visually monitor the position of the cutting point and marking.

What should you pay attention to when choosing first?

The shank must fit the specific tool. If in doubt, you can take the original file that was included in the sales package and visually compare it with what you are supposed to buy.

There must be compliance with the upcoming tasks. The file is selected for the required material and the required length.

When purchasing branded files (Makita, Bosch), it is important to avoid counterfeit products. Unfortunately, when buying in absentia, only a low price can indicate a counterfeit, and not always.

Poor quality is revealed upon closer inspection and operation. A counterfeit product may have unevenly milled or set teeth. Or they are separated only in one direction. The surface of the files is rough, the location and colors of the markings are different.

The quality of steel can only be assessed during operation - weak steel does not cut well.

Why can you cut metal with a jigsaw?

In principle, it is not the jigsaw itself that cuts, but the file. If you use a special metal file, then this tool will successfully cope with the task. They can cut both soft non-ferrous metals - copper, brass, bronze, aluminum with a thickness slightly less than the length of the blade, as well as ferrous metals up to 10 mm thick.

There is experience in sawing thicker steel workpieces, but it is slow, requires frequent changes of files and lubrication during sawing, and is suitable for one-time work when there are no other options.

Correction of chips that have arisen

Cutting material using a jigsaw and avoiding chipping is almost impossible. You can do this: cut the part with a jigsaw with a small allowance (2 mm), and then mill or grind off the allowance with a belt sander. When milling, the edge is cleaner than when working with a grinder. Usually, the material is milled using a self-made guide bar (modeled on a circular saw guide). Spiral cutters will improve the quality of milling. It is necessary to prepare them in the amount of two pieces.

If you need one front side to remain clean, you need to use an ordinary two-flute cutter. If you need both clean sides, then you should use a four-flute cutter with two main branches, which have a left direction, and two scoring branches, which have a right direction. Then it turns out that when cutting material, the upper branches press the material down, and the lower ones pull it up. This prevents chipping on the edges.

Laminated chipboard is one of the most widely used materials used in the independent manufacture of furniture. We can talk about its advantages and disadvantages for a long time. But it is much more important to learn how to cut laminated chipboard with a jigsaw without chipping.

Application of adhesive tapes

Adhesive tape (for example, ordinary tape) is used to protect the back side of the material. It is necessary to glue a tape to the cut line to protect the processed fabric from tearing off large elements. Masking tape cannot be called a very effective option for preserving material when cutting with a jigsaw, since its strength indicator is extremely low.

A fairly wide (each side of the cut material should be covered by at least fifteen centimeters) aluminum or fiberglass reinforced tape is best suited. In addition, the adhesive tape must be pressed with a dry cloth to eliminate the risk of wrinkles.

Ensuring a clean cut

In many cases of material processing, the size of chips can be reduced to half a millimeter. Such minor imperfections are not noticeable; they can be removed by chamfering with sandpaper or covering up the chips with a correction pencil. You can also sand the end with sandpaper or cut through the top layer of the surface with a utility knife.

To begin, make 2 cuts half a millimeter deep on both sides of the part, indicating the thickness. Two grooves should be marked along the edges of the cut, which can be done using an oblique shoemaker or segment knife (for uncoated wood material or chipboard), or using a sharp drill and a pobedite cutter (for laminate).

Methods of working with a jigsaw without chipping on various materials

The jigsaw is suitable for processing a large number of products (wooden, metal, tin, plastic surfaces). For each type, there are specific methods and tool settings: a certain stroke rate, pressure force, smooth movement of the device.

Wooden canvas

When choosing a saw, remember that the wood must be cut with standard tools (with the teeth facing up). The size of the teeth is average, and the pitch interval is from two and a half to four millimeters. The length of the file depends on the thickness of the surface being cut.

The stroke frequency must be set to the maximum value. You need to reduce it if the material tends to overheat or you feel inconvenience while working. To increase the cutting speed, you need to use the pendulum function. The quality of sawing is reduced, but this option significantly reduces work time if you don’t have much of it.

During the process, it is necessary to carry out all operations on the back side of the canvas to avoid damage. Marking must be done in advance. When sawing begins, you need to press the jigsaw against the blade and slowly control the direction of its movement. You should not push the tool, as it will move along the canvas on its own.

Laminate and chipboard

When choosing a file, you need to choose a variety such as a reverse cut file. Even with vibration characteristic of this type, the quality level of the result will not be reduced. Using an ordinary file, it is necessary to carry out the operation on the back side of the blade.

The stroke rate, as in the previous paragraph, should be maximum. To avoid chipping, the pendulum mechanism should be turned off. During the process, the jigsaw should be pressed firmly and gradually moved along the blade (there is no need to press the tool hard).

Chips occur on the side facing the tool. In this regard, when using a regular saw, you need to determine the front side in advance and cut on the back. In addition, you can purchase a special anti-splinter insert - a small element with a cut, which is inserted into the corresponding guides in the sole. The best option for an insert is one with a cut that exactly matches the thickness of the file.

Metal

When choosing a file for metal, you should give preference to options with small teeth, the pitch of which should be in the range of one to two millimeters. The stroke rate indicator should be set as low as possible and should be turned off.

When using, do not press the tool, but move it smoothly. The blade itself should be secured, while placing its cutting line as close as possible to the support. Be sure to take short breaks and use a cooling system to prevent the tool from overheating.

If it is necessary to make a curved cut on a thin sheet of metal and place the cut line tightly to the support, the metal should be placed between two sheets of fiberboard. In this case, it is necessary to mark the top fiberboard layer, since this will prevent the formation of burrs.

Plastic

It is worth choosing a file with a small tooth, as this will improve the quality of work. The jigsaw should be adjusted based on the type of plastic. The evenness of the cut will ensure a minimum or complete absence of pendulum motion. The stroke frequency should be no more than 40% of the maximum value.

Tile

You need to prepare a file without teeth and apply abrasive to it. The pendulum stroke must be turned off and the speed reduced to minimum. In this case, a jigsaw is one of the effective devices for cutting out curved elements on tiles.

Tin

To easily cut tin material, you need to attach it tightly. The canvas should be laid from the edge of the workbench or placed on a backing. In this case, the cutting line should be at the shortest distance from the provided support. It is necessary to press down the material with a beam so that nothing hinders the freedom of movement of the jigsaw.

"Swap" should be set to o or "1". The file used must be designed exclusively for metal. If the blade being processed has a thickness of more than two millimeters, then it is better to lubricate the cut area with oil (for machines). For a good result, the tin sheet must be laid between thin plywood. This will make it possible to work far from the support line, which is important in conditions of curved cutting.