Varnish for stoves and fireplaces made of brickwork must be of high quality, resistant to high temperatures, and it must create a stable coating on the surface of the structure. No matter how strange it may seem, in the modern world, heating a home with stoves is becoming increasingly popular. The use of fireplaces is not only beautiful and unusual from an aesthetic point of view, but also makes it possible to save money spent on utility bills during the cold period.

If the brickwork is done correctly, then there is no point in masking the structure under the facing coating. On the contrary, the beauty and authenticity of the structure should be emphasized by using the right coating. Below we will tell you in more detail about the best varnish to coat a brick oven and the method of applying it.

Lacquered red brick stove

Heat-resistant paint: what is it?

Any heating equipment needs maintenance. It should not only look beautiful, but also not emit harmful substances during operation during heating. For these purposes, there are special heat-resistant paints .

These products are intended for coating the surfaces of stoves and fireplaces. The composition of heat-resistant products must meet all requirements and differ from conventional analogues. Metal products will definitely develop rust due to moisture. A crack may appear in the masonry of the fireplace or stove, and the brick sometimes begins to crumble. In such a situation, repairs with painting cannot be avoided. In addition to maintaining an aesthetic appearance, good paint can extend the life of individual elements of the stove or fireplace.

These paints contain special protective components . Thanks to this, they will help withstand the influence of aggressive external factors:

- precipitation;

- moisture;

- dirt;

- dust.

Heat-resistant paint and varnish coatings are produced using the latest technologies. Due to their composition, when applied to a metal surface, they form a protective layer. It is able to protect them from oxidative corrosion processes. Almost all such products are produced in the form of suspensions. They are based on heat-resistant varnishes containing silicon and silicone.

For metal surfaces that are exposed to the highest possible temperatures, special paints are used. They are great for covering surfaces and elements that come into contact with open fire. There are also products designed for treating brick and stone surfaces.

Almost all manufacturers indicate the composition and temperature parameters . This makes it easier to choose products for painting heating equipment.

Varieties

There are different types of insulating paint designed to perform in specific environments. They are usually divided into two main categories:

For interior work

These are materials that ensure that walls are cut off from internal warm air. This allows you to maintain the temperature in the room, since thermal energy is not spent on heating the walls. In addition, interior paint is used to insulate basements, open utilities, and building elements;

For outdoor use

These are materials for insulating facades, external elements of buildings, open areas of shut-off valves and other problem areas.

There is another principle of division by purpose:

for pipes;

for walls (universal material suitable for application to internal and external surfaces);

façade heat-insulating paints (used only for application to external walls).

Liquid insulation can reduce heat loss by 30%, which provides savings on heating and increases indoor temperature by 2-4 °C.

In addition to general purpose, paints are distinguished by composition:

- water-based materials . As a rule, they are used for internal insulation, since they practically do not emit a pungent odor and do not cause inconvenience to people in the premises;

- acrylic paints . They have greater density and form a continuous elastic film on the base. The specificity of the material allows the white base to be painted in any color using conventional tinting pastes, which significantly expands the decorative possibilities of the coating.

Acrylic paints are stronger than water-based paints. However, they are nearly impervious to water vapor, making them not the best option for interior walls.

Characteristics of heat-resistant paints

Heat-resistant paints and varnishes include products that can withstand temperatures from 100°C. After drying, they form a reliable, plastic and vapor-permeable protective film. This coating does not change its properties even under temperature loads up to 700°C.

The main advantages of paintwork materials:

- Environmental Safety. During operation, no toxic substances are released from painted surfaces.

- Thermal conductivity . Paint applied to a fireplace, radiator or stove does not interfere with heat transfer.

- Elasticity of the coating. When heated and temperature changes, cracks do not form on the protective layer.

- Inert to household chemicals. Painted surfaces are inert to detergents, do not fade from their use and are easy to clean.

- Good hiding power. To obtain an even and high-quality coating, one to three layers are sufficient.

Heat-resistant products also play a decorative role. For this purpose, compositions of different colors and structures are produced. Coolants do not lose their performance characteristics when used.

Types of heat-resistant paints

Manufacturers offer a large selection on the coatings market. There are four groups based on the content of paint components.

- Organosilicon. They are a suspension consisting of polyorganosiloxane polymers, resins and solvents. A variety of colors are obtained from inorganic and organic pigments. The painted layer does not fade at temperatures up to 150˚C. It dries within two hours and can withstand heat up to 600˚C.

- Acrylic. They are produced by mixing acrylates in water or in a hydrocarbon composition with pigments, antiseptics and modifiers. The coating does not change its properties at temperatures up to 400°C. Paint enhances the strength of brick and mortar by penetrating deeply into their structure. Drying speed up to 24 hours. The disadvantage of this type is the lack of bright colors. Color-enhanced shades quickly fade.

- Alkyd. This type contains resins, dyes, white spirit solvent, plasticizers and fillers that increase resistance to high temperatures. The protective coating does not lose its properties at temperatures up to 150°C. Paints are used to treat the outer walls of boilers, heating radiators, and hot water pipelines. Drying speed of layers is from 8 to 24 hours. The disadvantages of this type are: pungent odor, low elasticity and the formation of cracks in the coating.

- Heat-resistant varnish. The basis of the material is organosilicon resins. To increase heat resistance, acrylic is added to them. The varnish has good hiding power, moisture resistance and film strength. Drying time 30 – 50 minutes at 20˚C. The coating does not change its structure at temperatures up to 200°C.

Coatings and varnishes for metal are produced. Components are added to their composition that increase anti-corrosion properties. Coloring agents for mineral structures are used to process stone, brick, and cement.

There are universal paintwork materials suitable for any surface. Metal, brick and cement surfaces are coated with such products. They are suitable for processing wood, glass and fabric. The range of paint and varnish products includes powder paints. They give the products a characteristic shine.

Heat-resistant paint and varnish coatings are produced in tin and plastic containers, in cans, containers, buckets, and spray cans.

Features of aerosol paints

The use of sprays allows you to evenly paint products of non-standard design, hard-to-reach places, cracks, and gaps. They do not require special preparation, mixing or dilution. Aerosol paints are easy to apply, dry quickly, and form an even, durable layer.

When choosing such paint, you need to look at the characteristics and carefully study the instructions for use. It is necessary to take into account the maximum temperature that the coating can withstand during operation.

Spray dyes thicken when stored for a long time. It is impossible to return them to their original state. A can that has not been used for a long time should be disposed of.

Scope of application of heat-resistant coatings

These types of paints are used in all areas of the national economy. Application of heat-resistant coatings is necessary in the following cases.

- Protection of heating metal coolants and units in industrial enterprises, factories, utilities and in the private residential sector.

- Finishing of evacuation places in buildings according to fire safety requirements.

- Applying a protective layer to pipes of main heating networks and gas pipelines.

- Processing of vehicle parts, mufflers, drums.

- Creation of thermal protective coating for all types of stoves, pipes, heat exchangers, chimneys, fireplaces, radiators.

- Painting of fireplace components: handles, doors, dampers and frames.

Heat-resistant paints are used in the production of household appliances. They cover parts of electric and gas stoves, electric dryers, boilers, and water heaters. Heat-resistant products are used to paint equipment in baths and saunas.

We recommend: How to make a chimney for a potbelly stove: installing a proper chimney with your own hands

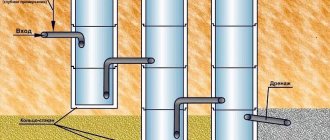

Fighting condensation with heat paint

Liquid thermal insulation allows you to avoid the manufacture of complex structures necessary for attaching a thermal insulation layer near the roofs of hangars and residential buildings. Painting pipelines of engineering systems is much cheaper than protecting pipelines with polystyrene foam shells, winding with basalt wool, and then waterproofing the insulation.

Condensation control is available to a home craftsman with minimal painting skills. Liquid thermal insulation is sold in convenient buckets and jars, is completely ready for use, and has instructions for use. The weight of the roof practically does not increase when applying a millimeter layer, while the comfort of using the premises increases many times over.

How to choose the right one

Only correctly selected paint will allow high-quality painting of a metal element that is operated at elevated temperatures.

To paint a solid fuel stove, it is also necessary to use fire-resistant dyes. If you ignore this rule, then with significant heating, ordinary paint will not only lose its aesthetic appearance, but can also cause a fire.

When painting parts of stoves and fireplaces, it is necessary to determine whether they are made of non-ferrous or ferrous metal. What type of surface the paint composition is intended for is usually indicated on the packaging, so you should study it very carefully when purchasing the product.

Video:

Functional Features

The quality of thermal protection of thermal paint directly depends on the applied layer and the number of stains. However, it is also not recommended to apply an excessively thick layer; the best option is 2-4 paintings, no more than 6 mm thick. The number of layers depends on the type of heat-insulating liquid material, as well as on the type of surface to be applied. The service life is 12-40 years, and the temperature characteristics are -70°C, +260°C.

Main advantages

The main advantage of liquid insulation for work inside buildings is thermal insulation without reducing space. It is important to note the material’s resistance to temperature changes, which occurs in winter during the heating season: it’s minus outside and plus inside, condensation collects, which forms a favorable environment for the development of fungus. Additional benefits:

- environmental friendliness - the paint does not emit harmful toxic compounds at high temperatures and does not react with other building materials;

- saving on heat bills due to thermal insulation;

- strengthening treated surfaces.

Thermal paint for oven

Almost all fireplaces are made of stone or brick. They definitely have several cast iron elements:

- dampers;

- doors;

- covers;

- frames

When painting a heating device, you should paint everything, including the listed elements. To paint the stove and fireplace, you need to use different paints for different surfaces.

First of all, you need to pay attention to the type of oven. If it is completely metal, it can warm up to 600-800°C and even higher. In the combustion zone of the flame, the temperature will be higher, depending on the design of the furnace. An important requirement when choosing heat-resistant paint for a stove is suitability for indoor use. If this is a sauna stove, then the paint should protect it from high humidity.

For application on surfaces with high temperatures, it is necessary to choose the following products:

- heat resistant;

- heat resistant;

- fireproof.

There are also fire-retardant ones, but they are not suitable for such purposes, since already at a temperature of +200°C the paint will swell with bubbles . Heat-resistant products can be used up to +600°C. They are perfect for painting metal parts of a stove or fireplace. For sauna stoves, it is better to use enamels that can withstand higher temperatures at +800-1000°C. It is better to use them to cover the body of a sauna stove, since the temperature there will be higher.

Manufacturers also offer heat-resistant varnishes that can withstand 250°C-300°C well. After treatment with this product, the surface of the oven will look brighter and acquire shine.

Manufacturers

There is a significant variety of heat-insulating paint and varnish compositions on sale. Among the most popular paints are the following brands:

- Liquid thermal insulation Corundum. Under the popular brand “Korund”, several types of heat-insulating compounds are produced, varying in functionality. In particular, Corundum Classic is designed for insulating pipes heating up to 200 degrees. "Corundum Facade" is used for external thermal insulation. "Corundum Anticor" is used to protect metal in conditions of high humidity (for example, when covering a roof). Corundum paint is offered in 3 or 10 kg cans, as well as in 20-liter buckets. The coating retains functionality at temperatures from 60 degrees. frost up to 250 degrees. heat.

- "Astratek". It is a paint without organic solvents. In this regard, Astratek is completely environmentally safe. This paint is used to treat especially hot surfaces (pipelines, boilers, industrial equipment). There are modifications with anti-corrosion additives.

- Thermal insulating paint "Armor" contains ceramic components. The anti-condensation additive, together with anti-corrosion properties, allows the use of painted coatings in extreme conditions. Another feature of the Armor is its ability to withstand ultraviolet radiation, regardless of the duration of exposure to radiation.

- "Akterm - Standard". The paint creates coatings that can withstand very high temperatures - up to 600 degrees. The minimum temperature at which the coating retains functionality is 60 degrees. below zero. The paint is versatile; it is used both for residential premises and industrial facilities (pipes, refrigerators, etc.). Versatility is achieved due to the lack of toxicity and fire safety of the composition. The paint can be applied even in winter, provided that the air temperature is not lower than 25 degrees. frost.

There are many other paints with thermal insulation properties. These include such compositions as Alfatek, Teplomet, Keramoizol, Magniterm, Tezolat, Teplokor, Kare, Termosilat, Maxidom, Gidrostop pro and others.

Surface preparation and painting

The preparatory stage is simple, but all stages must be completed. Otherwise, you will get a low-quality result that will not last long; the cost of many paints is high, so it is irrational to waste them. As a result, before painting you need to get a surface free of dirt and any impurities.

Perform the following actions:

- The surface is cleaned with a metal brush.

- Eliminate existing oxides using a 5% concentrated solution of sulfuric acid.

- Then the solution is removed using laundry soap.

- The oven is degreased.

Before painting, check the expiration date and quality of the paint and varnish; it is important that there are no lumps or unnecessary impurities. The composition is thoroughly mixed so that all sediments from the bottom are evenly distributed.

Before painting, check the expiration date and quality of the paint and varnish; it is important that there are no lumps or unnecessary impurities.

It is necessary to achieve an even layer, paying special attention to corners and seams. In order not to stain nearby objects, you can first cover them with film.

The tool you can choose from is a brush, roller and spray gun. If the oven is small, then a brush is enough. The spray bottle cannot be used with all formulations; please refer to the manufacturer's instructions. The walls of the stove can be painted well with a brush, but it will be easier to cover the fittings evenly with an aerosol.

The drying process for paints is different; to find out when you can light the stove after painting, you need to read the manufacturer's recommendations. This usually requires waiting 3-4 days.

It is better to take your time in this matter so that the paint can set well and serve for a long time, reliably protecting the metal surface from moisture and high temperatures.

It will be easier to cover the fittings evenly using an aerosol.

Heat-resistant paint for metal

Metal and brick stoves, fireplaces and their elements, heating communication systems of the residential sector are coated with paints and varnishes not only to improve their decorative qualities, but also to maximize their service life.

The classification of coloring agents for metal is similar to the division of mixtures intended for mineral structures. But it is not recommended to replace them with each other.

Means for processing metal products are supplemented by the following compositions:

- Epoxy - can withstand heat up to 200°C.

- Ethyl silicate and epoxy ester - suitable for use at 400°C.

- One-component silicone - have proven themselves when operating up to 650°C.

Paints are produced that contain liquid glass and composite materials. The protective properties of such grades are maintained at 1000°C.

Dyes intended for metal surfaces have good adhesion to stainless steel, cast iron, and aluminum. Substances are added to their composition that increase the anti-corrosion properties of the treated surfaces.

How to paint a grill

A special feature of this metal structure is that it is outdoors, under constant exposure to weather conditions. To protect such a surface, heat-resistant paint with the following properties is used.

- Resistant to moisture and adverse weather conditions.

- High level of anti-corrosion properties.

- Resistance to temperature loads from 500 to 1000°C

- Compliance with environmental safety standards.

- High elasticity and durability of the coating.

Stage-by-stage execution of work:

- The surface of the structure is cleaned of dust, dirt and debris.

- If rust is detected, it is removed with abrasive devices.

- All parts of the structure are degreased using alcohol or solvent.

- Before using the coloring mixture, mix it thoroughly and dilute it to the thickness required according to the instructions.

- Paint is applied sequentially. The layers are applied perpendicular to each other. The procedure can be repeated only after the surface has completely dried.

The optimal ambient temperature for painting the grill is from -20 to +40°C.

Application

The material is applied using all known methods:

with a brush (it is most convenient to use for painting pipes or air ducts; it works well with viscous materials);

roller (for flat surfaces);

sprayer (air or airless spray using mechanical or electrical devices can be used).

The most economical methods are brush or roller application.

There are a lot of claims online about maximum spray efficiency. However, this method differs only in performance. From the point of view of economy, it is the most expensive, since it requires bringing the material to working viscosity. The paint must be diluted with water or solvent, which requires additional costs. When applied, a large amount of material goes into the mist or gets in addition to the surfaces being painted.

Therefore, it is worth using a sprayer only for large areas or for complex base configurations.

Application order:

The surface is cleaned by removing old paint, peeling or crumbling areas.

The paint is mixed and prepared for application (sometimes you have to add water or a solvent to achieve the standard viscosity).

Apply using hand tools or sprayers.

The coating is dried, and additional layers are applied if necessary.

Additional layers are necessary if the operating conditions of the surface are too harsh, or if the paint had to be heavily diluted before application.

Painting stoves and fireplaces

To protect the surface of this type of coolant, special heat-resistant compounds are used. Their use provides a number of positive effects.

- Contamination from brick dust disappears.

- Makes everyday care easier. The painted surface can be easily cleaned with a damp cloth.

- Decorative qualities are improved. Heating devices acquire a style that matches the overall design project.

- The formation of cracks on the brick stops.

- Heat transfer from treated surfaces increases.

- Irregularities and defects are eliminated and smoothed.

The components of paints for metal furnaces increase their anti-corrosion properties and protect against high moisture content.

For brick and stone ovens, finishing materials are produced that can withstand temperatures from 200 to 400°C. Extreme conditions from 600 to 1000°C do not affect the structure of coatings formed by heat-resistant paints for metal.

You can treat the brick stove and fireplace surface with heat-resistant varnish. It not only protects the masonry, but also improves its decorative qualities without changing its structure. The coating is applied to the entire surface at once, which reduces painting time.

We recommend: Glass infrared heaters - operating principle, differences, how to choose, best models and manufacturers

Brick coated with varnish takes on a rich reddish tint. The grout is protected from crumbling during thermal expansion.

Treatment of stoves in baths and saunas is carried out with compounds that are resistant to high levels of humidity.

When choosing a coloring agent, you need to clarify whether it is recommended for use indoors. To treat heaters located outdoors, materials resistant to low temperatures are needed.

Painting stoves and fireplaces

Precise adherence to painting technology allows you to obtain a smooth protective surface. Stages of work:

- Preparing the base. To do this, dust and dirt are removed from the surface. Cast iron elements are cleaned of rust using abrasive paper or a wire brush.

- Wipe with a damp cloth and dry.

- Before painting the fireplace or stove, they are heated and cooled to a warm state.

- Applying paintwork in a thin layer. After it dries, the procedure is repeated.

- Repeated heating and cooling of the coolant is carried out before applying each new layer.

Staining is repeated until a smooth film without visible gaps is formed. The final stage can be the application of a drawing or print that matches the style of the entire room.

If the instructions for paintwork materials require preparation of the base, the work is carried out in accordance with its instructions. Painting the surface of metal stoves and fireplaces can be done in the same way as painting a barbecue.

The room in which work is performed must be well ventilated. Avoid getting paint on your face, hands and eyes. To do this, you must use gloves and safety glasses.

What is it used for?

The name itself - heat-insulating paint - speaks about the purpose of the material. The coating protects surfaces from heat loss, forming a barrier from direct contact with the external environment.

Expert opinion

Torsunov Pavel Maksimovich

The specificity of the material is such that one cannot expect a thermos effect from it. However, in most cases it is quite enough to reduce heat loss to an acceptable minimum.

In addition, the method of applying the material allows you to insulate bases of complex shapes - curved, embossed, with a lot of small details.

At the same time, heat-insulating paint practically does not change the dimensions of the base, which makes it possible to insulate structures and sections of utility networks located in limited spaces - in shafts, boxes, in crowded and cramped conditions.

Considering that 1 mm of thermal insulation paint is equivalent in performance to 50 mm of mineral wool (or other similar insulation), the use of the material will only expand and become more common.

How to apply

The first thing you need to do before applying heat-resistant paint is to properly prepare the surface. Many high-temperature compounds do not require any special preparation methods. In this case, it will be enough to clean the material from dust and dry it if there is moisture on its surface, and also degrease it with some solvent.

If the instructions say that the surface must be primed. Then a layer of primer should be applied to the cleaned metal and the surface should be completely dry before applying the main coat of paint.

To obtain a high-quality coating, a heat-resistant layer must be applied to the metal surface several times. In this way, it is possible to obtain a higher-quality coating that will have excellent decorative qualities and well protect the metal surface from corrosion destruction.

Video:

Areas of use

Thermal insulating paints are used in the following areas:

- insulation of industrial equipment;

- painting of technological containers;

- agricultural production;

- insulation of basements;

- protection of heat transport systems;

- processing of automobile and other types of transport;

- thermal insulation of housing (both interior spaces and building facades);

- protection of utilities, pipelines, ventilation and air conditioning systems.

Protective paint and varnish compositions are used in almost all industries where it is necessary to protect materials from freezing. Thus, heat-insulating paints act as a direct competitor to building insulation materials.

Rating of the best thermal paints

The list below contains compounds that can easily be found in hardware or specialty stores.

All of them, according to user reviews, are of good quality.

1st place – Alpina Heizkoerper

The paint produced by the German DAW group is made on the basis of alkyd resin with the addition of titanium dioxide. The product is of good quality - it fits tightly, and the resulting coating is scratch-resistant. The price is quite high, but you need a little of this paint due to its insignificant consumption.

The heat-resistant composition Alpina Heizkoerper can be applied to any type of metal from which heating radiators are made: steel, cast iron, aluminum and copper

Main parameters:

- color: white (with the possibility of tinting);

- gloss type: glossy;

- permissible surface temperature (0C): 100;

- type of packaging and volume (l): can (0.75, 2.5);

- country of origin: Germany.

The main purpose is to process elements of a water heating system. The possibility of tinting allows you to create an original color scheme and diversify the interior of the room.

The short-term temperature of a painted object can reach 1800C. The paint can be applied by brush, roller or spray gun to steel, cast iron, aluminum, copper and other metals. Consumption ranges from 90 to 120 ml/m2.

2nd place – Elcon

After the tinting process, Elcon products are available in 250 shades. But pigmentation reduces the maximum temperature that paint can withstand. Thus, classic black enamel retains its properties up to 10000C, copper – up to 7000C, and blue – only up to 6000C.

Using Elcon colored enamels, you can create exclusive custom coloring for radiators, stoves, fireplaces, boilers and barbecues

Main parameters:

- color: black, graphite, gold, copper, etc.;

- gloss type: matte or semi-gloss;

- maximum temperature (0C): 1000 (black), 700 (graphite, gold, copper);

- type of packaging and volume (l): can (0.52), jar (0.8), bucket (25);

- country of origin: Russia.

The presence of a large number of color solutions allows the use of Elcon enamels for complex interior designs. With its help you can create simple patterns using stencils.

In addition to painting metal products, this enamel can protect other types of surfaces - concrete, asbestos or brick. After application and drying, it is necessary to perform a thermal hardening procedure.

3rd place – Tikkurila Termal Silikonimaali

Silicone resin paint from the Finnish company Tikkurila is used to coat metal surfaces.

Small packaging (0.1 liter) is convenient if there is a need to paint a small metal product. No need to think about where and how to store leftover enamel

Main parameters:

- black color;

- gloss type: semi-matte;

- maximum temperature (0C): 400;

- type of packaging and volume (l): can (0.1, 0.33);

- Country of origin: Finland / Russia.

One liter of paint is enough for a single-layer treatment of 16-20 m2 of surface, depending on its roughness. The fine structure of the solution allows you to use the sprayer without the risk of frequent clogging of its nozzle.

The quality of the products is very good, but the price is also high - this is due to the promotion of the brand. The disadvantages include the need for thermal hardening, which must be carried out for 1 hour at a temperature of 2300C.

4th place – Bosny Hi-Temp

This heat-resistant paint from a famous British brand is produced in Thailand. It is distinguished by its volume, which is atypical for Russia, and is characterized by good quality and a slightly high price.

Bosny Hi-Temp aerosol is often used to treat hard-to-reach areas such as car mufflers or metal pipe fittings.

Main parameters:

- color: silver, black;

- gloss type: matte;

- maximum temperature (0C): 650;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

Made on the basis of alkyd resins, this thermal paint can be used not only for metal, but also for wood, plastic, ceramics and other materials. It adheres well to untreated surfaces, including rusty ones.

5th place – Tikkurila Termal Silikonialumiinimaali

Tikkurila Thermal paint (silicon-aluminum) from a well-known Finnish manufacturer is distinguished by its excellent quality and high price due to the popularity of the brand.

Paint from the advertised brand “Tikkurila” in aluminum color. It is used for painting boilers, furnaces and other metal objects exposed to extreme heat.

Main parameters:

- color: aluminum;

- gloss type: semi-gloss;

- maximum temperature (0C): 600;

- type of packaging and volume (l): jar (0.33);

- Country of origin: Finland / Russia.

Heat-resistant paint based on silicone resin, aluminum color with a slight metallic sheen. Its consumption (for one layer) depends on the type of surface being painted and is 16 m2/l for rough areas and 20 m2/l for smooth areas, which is a very good indicator.

We recommend: Specific heat of combustion of kerosene: the physical meaning of the value, the meaning of the indicator and its comparison with oil

To harden the paint, it is necessary to heat the surface to a temperature of 2300C. A month after application, you can clean the painted surface with mild detergents.

6th place – Bosny Hi-Temp (color)

Acrylic-based paint with silicone pigmentation from Bosny has a lower permissible temperature than black or silver. It is characterized by good quality at an average price for products of this class.

Due to the lower permissible temperature, the scope of application of Bosny Hi-Temp color paints is slightly different than that of black or silver composition

Main parameters:

- color: red, orange, yellow, green, blue;

- gloss type: matte;

- maximum temperature (0C): 205;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

The most common area of application is painting pipes and heating radiators. It is also used for decorative painting of car parts. It dries quickly, does not peel off, but requires thermal hardening. Thus, it is better to paint the batteries a day or two before turning them on.

One can is enough to paint 1.5-2 m2 of surface in 2 layers. In addition to sanding, it is advisable to prime the surface. This will significantly increase its resistance to physical damage.

7th place – Veslee

Heat-resistant, high-quality metal paint on an acrylic-epoxy base is in the middle price range.

Small capacity cylinders (0.1 l) are used for painting automotive parts. To treat the heating system, it is financially more profitable to take a standard volume (0.52 l) packaging

Main parameters:

- color: black, white, red, silver;

- gloss type: matte;

- maximum temperature (0C): 400 (black), 250 (all others);

- type of packaging and volume (l): can (0.1, 0.52);

- Country of origin: China.

The composition is intended for painting heating circuit elements (excluding fireboxes) and automotive parts (mainly the exhaust system). The availability of small-volume cans for sale is a definite plus when you need to paint a surface with a small area.

The paint is quick-drying - the drying interval between layers is 2-3 minutes.

8th place – MagicLine

Spray paint made in China, based on synthetic resin, is located in the middle price range. According to consumer reviews, the temperature indicated on the label is not the maximum allowed for an indefinite period of time, but acceptable for a short-term period.

The most ordinary paint made in China, without any significant pros and cons. Available as an aerosol can

Main parameters:

- black color;

- gloss type: matte;

- maximum temperature (0C): 600;

- type of packaging and volume (l): can (0.4);

- Country of origin: China.

Medium quality products designed for processing metal parts. Not suitable for application to high temperature objects such as the firebox door of a steel oven or hob.

9th place – Thermoxol

Russian-made paint is intended for metal surfaces. It is distinguished by good quality, four main colors, packaging of varying volumes and an average price.

If you need to process a lot of radiators and pipes, then it is better to take paint in buckets - it will be much cheaper

Main parameters:

- color: black, white, red-brown, gray;

- gloss type: glossy;

- maximum temperature (0C): 160;

- type of packaging and volume: jar (0.9), bucket (3, 10, 20);

- country of origin: Russia.

The paint contains formaldehyde resin and an acid thinner, so the area must be well ventilated. It can be used for processing ferrous and non-ferrous metals, as well as alloys. The composition can be applied to tightly adherent rust.

Short-term (up to 5 hours) heat resistance – 2100C. The main purpose is painting heating radiators and pipes.

10th place – Decorix

This enamel can often be found in stores and retail outlets. It has a low price and acceptable quality.

This cheap enamel is best used for painting sauna stoves and other metal products whose appearance is not particularly important.

Main parameters:

- color: white, aluminum, black;

- gloss type: glossy;

- maximum temperature (0C): 800;

- type of packaging and volume (l): can (0.52);

- Country of origin: China.

Decorix enamel is available in the three most popular colors for metal coating. The mass fraction of paint for such a volume is insignificant - only 0.315 kg (usually 0.34 - 0.36 kg).

The sprayer leg is soldered into the can, so if the composition dries out, it will not be possible to replace the mechanism. Therefore, it is better not to leave partially used paint for a long time.

Do-it-yourself thermal paint, can it be done and how?

You can make heat-resistant paint yourself. The best option would be to prepare it from liquid glass and aluminum powder. The main thing is to understand that after the first fire, strong smoke may appear; the shelf life of such a coating is up to five years.

You can also use heat-resistant varnish; aluminum powder is added to it to obtain the desired effect. This option can withstand up to 350 degrees, and receives an anti-corrosion coating. Making paints is not difficult, the main thing is to get the necessary ingredients.

You can use heat-resistant varnish; aluminum powder is added to it to obtain the desired effect.

High-temperature paints and varnishes for metal make it possible to create a reliable coating against various influences. Metal products will be protected from corrosion and the harmful effects of elevated temperatures, which will extend the shelf life of the product itself. There are different types of similar materials on sale; when choosing, it is important to pay attention to the purpose of the paints. The dyeing process itself is easy, you can do it yourself, the main thing is not to neglect the preparatory work. If you wish, you can prepare the composition with your own hands; the recipe was described in the article.