When operating heating devices, it is necessary to control the degree of heating of the coolant, as well as the air in the room. Temperature sensors for heating help to capture and transmit information, information from which can be read visually or immediately sent to the controller.

We suggest you understand how temperature sensors work, what types of monitoring devices exist, and what parameters should be taken into account when choosing a device. In addition, we have prepared step-by-step instructions that will help you install a temperature sensor on a heating radiator yourself.

Why is it important to control your blood pressure?

For proper operation of the heating system, it is important that the pressure is within certain limits. Otherwise, the process of movement of the coolant through the pipes will be disrupted and the necessary heating of the room will not be provided.

In a heating boiler, the pressure level is related to how heating is carried out. Therefore, a temperature sensor is often used simultaneously with its sensor. If the pressure increases excessively, this can lead to an emergency. When it drops, the heat transfer process will be disrupted due to the slowdown in the movement of the coolant.

The use of an autonomous heating system helps citizens not to depend on a centralized system. This is useful where a private house does not have such an opportunity. Some owners choose this solution in order to save money.

If there are malfunctions, you need to contact a specialist Source priority-perm.rf

In both cases, it is important to achieve savings in fuel consumption. The pressure sensor saves money because it can be used to adjust the heating depending on the temperature and pressure in the boiler. It helps to turn on the pumps only when really needed. This saves energy for their operation and reduces equipment wear.

The sensors in question affect the quality of operation of the entire heating system. It is believed that the functionality of the heating boiler, pipes and radiators determines the efficiency of heating by 80%.

When the boiler functions as a hydraulic accumulator in a private house, water is pumped into it using pumps, which is necessary for consumption inside the house: for working in the kitchen, washing and other functions. If the pumps to ensure the supply of water operate continuously, the pressure in the boiler will increase, which can lead to damage to it or damage to elements of the home water supply network. If the pumping becomes weak, then the water from the tap will have little pressure.

Pressure sensors are connected to relays, which at the right times turn on or off the flow of water depending on the achieved pressure level. The timeliness of these actions ensures that the pressure in the boiler is maintained within the required limits. At the same time, the organization of the optimal mode of use of pumps is ensured.

Pressure sensor device Source crast.ru

conclusions

Connecting sensors to Arduino is the transformation of an algorithmic robot, controlled automatically or manually, into a full-fledged environment for the interaction of devices and circuits with the environment. Do not forget - this is not a panacea for all ills. And not the final high-tech product or the final application. Arduino is a set of hardware and software solutions that will help:

- master algorithmization systems for novice engineers;

- master basic design skills;

- learn to program.

Regardless of your level of training, your knowledge, you can always choose tasks within your capabilities. You can put together a simple solution to automate some simple task without soldering together with a schoolchild; Or you can set a global task, which requires, in addition to knowledge and logic, the ability to solder efficiently and correctly draw and read drawings. And active communities, forums and knowledge bases on the Arduino system will help solve almost any issue.

Control methods

The state of the heating system can be partially controlled using temperature sensors. They are used to perform various functions. In particular, the pressure in a gas boiler depends on temperature. Using such sensors, you can evaluate the heating efficiency.

However, its use is not enough to regulate the operation of the heating boiler. In this case, the pressure sensor plays the main role. Failure to control the increase in pressure can lead to an accident. Therefore, the installation of such a sensor is necessary. If it is not included in the boiler design, then if there is forced circulation, the owner must install it additionally.

Industrial boiler for heating water Source temron.ru

What are pressure sensors used for?

Pressure is influenced by two factors: the flow of water into the boiler and its heating. The maximum permissible pressure should not exceed that which the boiler can withstand. It is desirable that it be less than the limit value by 0.5 atm or more.

The lower value is selected based on ensuring the required degree of heating in the house. In this case, it is necessary that the heating is not turned on too often. Usually in private houses the minimum value is 1.5 MPa and the maximum is 2.5 MPa. However, each time it is necessary to select individually. In this case, the optimal value can be in the range of up to 6 MPa.

Boiler pressure sensor Source teplo-plus.net

Sensors can have different types of designs. The simplest ones are mechanical or electrical. Some are designed to control a relay that closes or opens pipes.

Some varieties are equipped with pressure gauges so that a person can control the pressure level. A mechanism may be provided to prevent sudden changes in water.

It is important that the relay operation frequency is not too high. It depends on the volume of the hydraulic accumulator used in the pressure system and the number of devices consuming water at the moment.

Connecting a pressure sensor Source eteh.com.ua

For example, if in a private house they take a bath, do laundry and wash dishes at the same time, the relay will turn on the pump more often. This is due to higher water consumption than usual. Because of this, the pressure will begin to drop and the relay will operate. As a result, water pumping will begin. Due to the waste of water, the pressure will again drop to the lower limit and the relay will have to turn on the pump again. When the flow rate decreases to the normal value, the operating frequency will return to the normal value.

If the device is equipped with a pressure gauge, the owner can control the pressure level in the system. If it differs from the standard, it will be possible to understand the reasons for what is happening and take appropriate measures.

Heating boiler design Source teplo-teh.com

Prices

| Manufacturer (intended for manufacturer's boilers) | price, rub. |

| Specialized | |

| BAXI | 1 400 |

| Protherm S010075 for boilers Panther, Cheetah, Skat | 2 550 |

| Ariston | 2 100 |

| Ferroli | 1 100 |

| Universal | |

| Shuft ATF2-NTC10K | 2 100-2 250 |

| Gira 130200 | 2 280-2 900 |

Features of control of heating boilers

When measuring pressure in heating boilers, two types of sensors are used:

- for steam;

- for water.

Such devices are usually called pressure switches. They have a more complex organization compared to conventional pressure sensors. The sensor readings determine the level of coolant pumping, the operation of fans to cool the boiler, and control the operation of the burners. Pressure switches can be designed to operate with a maximum pressure level, a minimum pressure level, or use a combined approach.

Sensors that monitor gas pressure are designed primarily to control the intensity of water heating. If the pressure is too high, the burners must work less intensely. If it is not enough, you need to heat the water better. When choosing relays for heating boilers, you need to ensure that they correspond to the features of specific models.

When the heating system is operating, the pressure in the system must be within certain limits. It should be such as to ensure normal coolant circulation. If the value goes beyond the limits, then as a result the movement of the coolant may stop.

Heating systems can provide for static or dynamic pressure changes. In the first case, the coolant moves naturally and without the use of pumping. In the second, a higher pressure must be provided at the inlet than at the outlet.

For the boiler to operate efficiently, it is necessary to correctly configure the pressure sensor Source oboiman.ru

Review of manufacturers

There are many companies involved in the production of heated floors. The most popular brands are Devi, AEG, Thermo Industri AB. Each manufacturer's sensors have their own characteristics.

Devi devices

Temperature regulators of this brand work with any type of heating elements. They are divided into mechanical and electronic, with conventional or touch controls. In addition, the Devi line of regulators includes models controlled remotely via smartphones.

Advantages of devices of this brand:

- availability of models for outdoor installation;

- savings on the operation of heating appliances up to 30 percent;

- availability of control via the Internet.

The advantage is the variety of options to solve any problem.

AEG regulators

Thermal sensors of the German brand belong to the premium class. Excellent quality guarantees durability and trouble-free operation. But such devices also cost a lot.

The product range is wide: from simple basic devices to “smart” temperature sensors that fully control the operation of the heated floor and the microclimate in the room.

But even basic models have many advantages:

- maintain temperature indicators at the required level;

- controlled very simply - by manually turning the key on and off;

- Thanks to convenient controls, they are suitable for older people who are not familiar with programming.

An external timer can be connected to the device to control the temperature reduction mode.

Devices Thermo Industry AB

Such thermostats are installed exclusively indoors. Capable of controlling elements of a heating cable or thermomat. Models have been developed that are ideal for parquet or laminate flooring. Most devices are equipped with smart air temperature meters.

Electronic devices are capable of adjusting heating with an accuracy of 1°C.

They are used for anti-icing systems if it is possible to combine them with a thermostat in the house. Built-in intelligent heating sensors make it possible to reduce electricity consumption, and Swedish quality guarantees many years of operation.

Principle of operation

Water pressure adjustment is carried out in accordance with the following algorithm:

- The taps open. After this, water from the boiler enters the heating system. At the same time, the coolant level decreases, and the pressure also decreases.

- The sensor monitors the pressure so that it does not become too weak. At the moment when the pressure reaches the threshold value, the relay contacts close.

- As a result, a pump is started that pumps water from a well or other external source.

- Due to the influx of water, the pressure will increase. The sensor will monitor when it reaches the maximum permissible value.

- At the moment when this happens, the relay is activated, causing the contacts to open. The pumps now stop working.

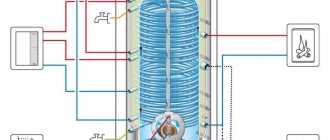

Boiler operation diagram Source teplo-klimat.com.ua

As a result, it is possible to maintain pressure within the specified limits. At the same time, it will not fall too much and will not rise so much that there is a risk of an emergency. The sensors not only regulate pressure, but also transmit its value to an external sensor so that the necessary information is available to the master. Periodically turning off the engine prevents it from running idle.

Features of choice depending on the floor covering

Sensors for the “warm floor” system are divided according to the type of coating they are installed under. However, the installation differs.

Under soft cover

A temperature sensor mounted under carpet, linoleum, or cork flooring is a small cylinder attached to the end of a piece of cable. Place it when the screed is completely set. To do this, a narrow groove is made in it.

Under hard surface

Mounted, for example, under wood, tiles. The temperature sensor here is larger and covered with gel that protects it from damage. Its installation is somewhat more complicated and can be direct or using a mounting box.

Mechanism of action

The main element of a mechanical sensor is an elastic membrane. On the one hand, it is affected by the liquid in the boiler. It bends, acting on structural elements that allow you to accurately determine the amount of pressure. When the threshold value is reached, the relay performs its intended action - closing or opening the contacts. The minimum and maximum thresholds are set using two springs of different diameters. As soon as the membrane presses on them, the corresponding action is performed.

A mechanical pressure sensor in a heating system can also have the following operating scheme. It is mounted so that water enters the cylindrical hole.

It will put pressure on the elastic membrane, which will bend under the influence of pressure. Behind the membrane there is a conductive metal disk, which will be displaced by a greater amount, the stronger the liquid acts on the membrane.

Sensors must be easily accessible Source sovet-ingenera.com

There are protruding parts along the edges of the disk. When the disk advances, the contacts are closed. This will turn on the relay. If the pressure decreases, the curvature of the membrane will decrease and the disk will open the circuit. As a result, the relay will turn off.

In this way, the pumps will be turned on or off depending on the presence of a certain pressure in the boiler. The disk may have two pairs of protrusions of different sizes. Depending on the degree of exposure to water, the connection of different contacts will occur at different pressure values.

The electrical sensor uses a different operating principle. Here the main element is still the membrane, but its deformation is converted into an electrical analog signal. Next, it is strengthened to the desired level. Then it is converted into a discrete form. It is supplied to the control unit, which, depending on its value, supplies the corresponding control signal intended to close or open the contacts.

There are also electromechanical devices. They must include a pressure gauge. However, it uses three arrows. Two of them indicate the minimum and maximum pressure values, and one indicates its current value. When the parameter reaches a critical value, the circuit closes and, as a result, a command is given using a relay to turn the pumps on or off.

Heating system in a private house Source aqua-rmnt.com

Typically the membrane is located inside a tube of circular or elliptical cross-section. It shifts from the pressure in the boiler and affects the pressure gauge readings and the operation of the relay. When choosing mechanical sensors, the following requirements must be taken into account:

- It is important to consider measurement error. It should not be so large that it distorts the results.

- When choosing a household pressure gauge, the accuracy class should not be lower than 2.5.

- It must be remembered that the sensor is used in intensive mode. As a result of prolonged use, the instrument's readings may become less accurate.

It is recommended to calibrate the sensor before the start of each heating season.

The advantages of mechanical type sensors are affordable cost and higher reliability. Electric ones provide better functionality. For example, here you can organize a connection after an emergency shutdown has occurred. Some models provide transmission of signals to the owner's mobile phone.

Pressure sensor with a relief valve Source otivent.com

It should be borne in mind that there are other types of sensors under consideration, but they are relatively rare. An example is liquid devices. This scheme uses the principle of communicating vessels. In this case, the liquid inside the boiler is discharged outside into a vertical transparent tube.

Depending on the height to which it rises, one can judge the amount of pressure. This method is highly accurate, but it is usually used only in laboratory conditions.

Differential type devices are also used. Here, two cameras are used for measurement, the connection between which is made in the form of a sensitive element. Typically, such measuring instruments are used as remote ones.

Multifunctional electronic boiler pressure and temperature control system Source owen.ru

Types of devices for taking temperature

Thermal devices can be classified according to a number of important criteria, including the method of transmitting information, the location and conditions of installation, as well as the algorithm for taking readings.

By method of information transmission

According to the method of transmitting information used, sensors are divided into two large categories:

- wired devices;

- wireless sensors.

Initially, all such devices were equipped with wires through which thermal sensors communicated with the control unit, transmitting information to it. Although such devices have now replaced their wireless counterparts, they are still often used in simple circuits.

In addition, wired sensors are more accurate and reliable in operation.

To ensure consistent operation of a wired sensor used in a composite device, it is advisable to combine it with equipment that is made by the same manufacturer

Currently, wireless devices have become widespread, which most often transmit information using a radio wave transmitter and receiver. Such devices can be installed almost anywhere, including a separate room or open air.

Important characteristics of such temperature sensors are:

- presence of battery;

- error of measurements;

- signal transmission range.

Wireless/wired devices can completely replace each other, but there are some peculiarities in their functioning.

By location and method of placement

Based on the mounting location, such devices are divided into the following types:

- overheads attached to the heating circuit;

- submersible, in contact with the coolant;

- indoor, located inside a residential or office space;

- external, which are located outside.

Some units may use several types of sensors simultaneously to control temperature.

According to the mechanism for taking readings

According to the method of displaying information, devices can be:

- bimetallic;

- alcohol.

The first option involves the use of two plates made of different metals, as well as a dial indicator. As the temperature rises, one of the elements is deformed, creating pressure on the arrow. The readings of such devices are characterized by good accuracy, but their big disadvantage is their inertia.

Bimetallic and alcohol thermostats are often installed on heating equipment, such as boilers. They allow you to monitor heat, exceeding which can lead to fatal consequences.

Sensors whose operation is based on the use of alcohol are almost completely free from this drawback. In this case, an alcohol-containing solution is poured into a hermetically sealed flask, which expands when heated. The design is quite elementary, reliable, but not very convenient for observations.

Installation location

When water enters the boiler, filter elements are located after the tap. The pressure sensor is usually mounted between them. This is due to the fact that pressure surges occur less frequently in this location. When installing, you must take into account the operating requirements specified in the instructions. For example, some types of relays can only be used indoors. Tees are used for connection. They make it possible to connect not only a sensor to the boiler, but also a pressure gauge.

The connection location is selected depending on the technical features of the device. In some cases, it is more advisable to install the relay directly on the water pump in the well. In this case, they must be placed in a moisture-proof housing. To install an electrical type sensor, you will need to connect an electrical cable for power.

Its thickness must correspond to the power of the pumping equipment. For example, if it is 2 kW, then the cable cross-section should not be more than 2 square meters. mm. After completing the connection, you need to check the functionality of the structure. To do this, turn on the pump and check the pressure. If the installation was carried out correctly, then it should increase.

Heating system in a private house Source project-home.ru

Installation sequence

Before installing the regulator, be sure to read the attached technical documentation. It is best to install the thermostat next to sockets at a height of 60–100 cm from the floor. Before installation work, turn off the electricity in your home network.

Directly

To install a temperature sensor using this method, the regulator and heating cable are connected directly. With this type of connection, the heating element itself is in conjunction with the thermostat.

Using a junction box

This part is used as an intermediate part between the thermal device and the heating element. The connection diagram is as follows: one cable is pulled from the regulator to the wiring block, and another to the heating wire.

In order to mount the regulator you will need: corrugated tube, screwdriver, mounting screws, mounting box, level, indicator.

Step-by-step installation instructions:

- A hole is cut in the wall for a box for mounting a thermal device. Below is a groove for pulling electrical wires. The box is placed in the right place.

- Electrical wiring is being pulled. The power cable and temperature sensor element are connected to the junction box.

- The electrical wires are connected to the thermostat, after which it is mounted in the box and secured.

- The main system components are connected to the product in accordance with the technical documentation.

- Once finished, the front panel is leveled and secured with screws.

Continuous operation of the heating system should begin no earlier than 3–4 weeks after pouring the screed. And if you chose tiles, after laying them. Under the influence of heat, the screed may simply burst.

Adjusting parameters

When purchasing a sensor, the owner can proceed in various ways. It can leave the factory settings. This makes sense in cases where the pump operates under standard conditions.

If the design used has its own characteristics, then it is better to configure it yourself. How to do this is described in detail below.

After installation, it is necessary to adjust the minimum and maximum pressure values. It is important that the difference between them is approximately 1 atm. Before making adjustments, perform the following steps:

- All pump elements are disconnected from the network. Now you need to completely drain the water from the pump.

- You need to check the pressure level in the boiler. To do this, you can use any available pressure gauge.

- It is necessary that the pressure be equal to 1.5 atm. If it is less, you need to pump up water.

- If it is exceeded, you need to lower it by pressing the nipple.

Electronic pressure switch Source kty.com.ua

After the boiler has been prepared, it is necessary to begin the adjustment procedure. Here, as an example, we consider a mechanical type sensor. The adjustment is carried out as follows:

- To begin the adjustment procedure. The pump must be turned off. Then drain the water completely. Check the pressure gauge readings. It should show zero value.

- Start filling the boiler with water. When the process is completed, it is necessary to measure the pressure again. This value must be fixed.

- Now you need to drain the water to get the minimum pressure value. It is also fixed.

- Using a nut, the springs are approximately adjusted so that they correspond to the desired value. Weaken a spring with a smaller diameter. Using a nut, the compression of a larger diameter spring is adjusted. It must be remembered that when tightening it increases the minimum response pressure, and when unscrewing it decreases it.

- Fill the system with water, then drain it. It is necessary to determine the moment when the pump will automatically turn on. If it is more or less than required, additional adjustment of the spring is carried out.

- Start adjusting the spring with a smaller diameter. It is tightened to set the value at which the pump will turn off. Compression will lead to a decrease in the difference between the maximum and minimum pressure values, and weakening will lead to an increase in this parameter.

- Check the set values. To do this, start the pump and determine at what pressure value the shutdown will occur.

- If the maximum value is not set accurately, then by tightening or unscrewing the nut, adjust the degree of compression of a small diameter spring until the parameter is set accurately.

When the pressure thresholds are accurately set, the adjustment procedure is completed.

Gas boiler pressure switch Source stroy-podskazka.ru

Selecting a sensor when purchasing

It is important to clarify for what operating pressure range it is intended. This data can be found in the technical data sheet of the device. If the range is not sufficient for this boiler, then it is better to look for another sensor model.

In this case, it is necessary to provide for a gap of 0.5 atmospheres. By this value, the limit value with which the sensor can operate must certainly exceed the maximum permissible value for the accumulator.

In most cases, a measuring range from 0 to 4 bar is sufficient for home pressure gauges. If we are talking about industrial use, then we can talk about higher pressure.

Various models of pressure sensors Source thermoexpert.ru

It is necessary to take into account the diameter of the fitting for fastening. Previously, most of these devices had a diameter of 0.25 inches. Now the production of devices with 0.5-inch fittings has increased.

It is important that the pressure gauge is installed in such a place that it is easily accessible. The pressure sensor must be suitable for the operating conditions. For example, some applications may require pressure gauges designed to operate in high or low temperature environments.

Each measuring device has a specified testing frequency. It is advisable to choose a model so that monitoring of correct operation is required less frequently.

Connecting a pressure sensor Source stroyfora.ru

Depending on the principle of operation of the device, its characteristics will differ. The most common sensors are those that use springs. This is due to the fact that they provide acceptable accuracy, but are affordable. Membrane devices provide higher accuracy, but also cost more. Electrical devices provide high-quality control, but are much more expensive, so they are rarely used in private homes.

It must be taken into account that the number and location of sensors should be determined by the boiler usage pattern. In some cases, you can limit yourself to installing one instance, and sometimes you may need more. In simple cases, if the boiler is used as a simple source of water raised to the desired height, then you can simply pump water by turning the pump on and off manually.

If we are talking about a heating boiler, then monitoring the pressure in the boiler is vital. Uncontrolled heating of the coolant will lead to an emergency. In such cases, an automated control system for heating and pump operation is created. This is especially important if there are two or three heating circuits.

When defining parameters, different units of measurement are used. In order to navigate them well, you need to know how to determine the relationship between them. 1 bar is equal to 0.99 atmospheres. When giving figures using megapascals, it must be taken into account that there are 10 bar in 1 megapascal.

Correct adjustment of sensor parameters is necessary for uninterrupted operation Source strojdvor.ru

Introductory information

If previously there were specialized construction sets with limited sets of functions and strictly defined parameters, today’s variety of construction sets is simply amazing: real microprocessor systems, assembled on the knee, have almost unlimited functionality. Rich imagination, a wide element base, large communities of fans and engineers, and manufacturer support are the main distinguishing features of such robotics kits that are in demand on the market.

One of them, and the most popular, naturally, is Arduino. Constructor for instant assembly of electronic automatic devices of any degree of complexity: high, medium and low. This platform is otherwise called “physical computing” for its close interaction with the environment. A printed circuit board with a microprocessor, open source code, standard interfaces and connecting sensors to Arduino are the components of its popularity.

The Arduino system is a board that combines all the necessary components to provide a full development cycle. The heart of this board is the microcontroller. It provides control of all peripherals. Sensors connected to the system allow the system to “communicate” and interact with the environment: analyze, mark, change.

Sudden drop in pressure

When measuring pressure in the heating system, the owner may encounter emergency situations. One of the most common is sudden changes in pressure. In these situations, automatic adjustment will not be enough. It is necessary not only to find out that a difference has occurred, but also to determine its cause. The most common are the following:

- There is a malfunction of the pumps used. The automatic adjustment system is built on the basis that they work normally, but in an emergency an unpredictable situation will actually arise.

- The appearance of a leak in the accumulator. It will provide a constant decrease in pressure, which will lead to constant operation of water pumps or to heating of the heating boiler above a critical level.

- Random failure of the settings used by the pressure sensor.

- Damage to the boiler shell. For example, microcracks may form. This dramatically reduces the strength of the equipment and increases the risk of an emergency.

- If direct control is carried out via an electronic board, then its failure is possible. In this case, for repairs you will need to contact specialists or replace with a new one.

- A sudden shutdown of heating or pumps may occur, after which the switching on does not occur for a long time. This is usually due to a malfunction of the relay.

- For the equipment to function properly, it is important that the power supply meets the required parameters. Electrical devices may malfunction due to power surges or sudden shutdowns.

These reasons are the most likely, but other options are also possible. If pressure surges are detected, the following should be done to analyze the situation:

- First you need to make sure that all connections are tight.

- It is necessary to carefully visually inspect all elements of the structure one by one and make sure there is no damage.

- If you shut off the valves one by one and monitor this using the pressure gauge readings, you will be able to determine the expected location of the malfunction.

If an unreliable connection is detected, it must be sealed and then tightened. If repair cannot be achieved, the problematic parts must be replaced. If microcracks are detected, installation of a new unit is mandatory.

Sometimes problems with pressure regulation are associated with a broken or malfunctioning sensor. Often in this situation the cause is due to damage to the membrane. During inspection, it is necessary to check the power supply connection.

The water pressure in the system must comply with the standards Source sovet-ingenera.com

Strong increase in pressure

Unnecessarily high pressure increases the risk of an emergency. The most likely reasons for this situation are:

- Random formation of air pockets in pipes.

- During operation, gradual contamination of pipes and filters occurs. They need to be cleaned regularly and replaced if necessary. If this is not done on time, it leads to increased pressure.

- In case of a malfunction of the pressure regulator.

- The pumps are not switched off regardless of the relay signals.

- In case of complete shut-off valve closure.

If the cause of the problem is an air lock, then you must first bleed the water and then begin normal operation of the system.

If the filters are dirty, they need to be cleaned. Pipes will function normally only if they are cleaned regularly. Sometimes it is impossible to remove contaminants in pipes. In this case, it will be necessary to replace the corresponding section of the system.

Hydraulic accumulator for water supply systems Source art-liga.rf

If, after diagnosing the system, it becomes clear that the cause of the problem is the regulator, then you need to check the correctness of its settings. If necessary, it is necessary to re-calibrate and set the parameters.

The occurrence of problems with the power supply may, for example, be associated with power outages or sudden surges. In this case, care must be taken to install appropriate devices to ensure uninterrupted power supply.

When the regulator is controlled by an electronic board, sudden voltage surges can damage it. It is necessary to check the functionality of the device and, if necessary, replace it.

In some cases, an increase in pressure occurs due to the complete closure of shut-off valves. If a problem situation arises, you need to check the condition and, if necessary, open them.