A hose for the pump can be purchased at a hardware store or a specialty store. You should think about purchasing a hose before or immediately after installing a water pump. There is a wide range of them, but how to choose a good reinforced one for drainage? The manufacturer, the material from which the pump hose is made, the purpose, the diameter - all this is important when purchasing, since only a high-quality and correctly selected part will last a long time, will not become cracked and will not leak water.

Main characteristics

Both water supply and tire inflation occur using pressure. It doesn’t matter which hose is used: for a drainage pump, for a car pump or for a 1-inch pumping station - in all these cases, water is supplied under pressure. Product quality is the main indicator when choosing.

When choosing a hose for a pump, pay special attention to the diameter

Hose characteristics:

- Rigidity (the product should not lose shape and become soft when the pressure is reduced). For example, reinforced products and corrugated products with compacted walls retain their shape under all conditions.

- Frost resistance if pumping equipment will be used all year round.

- Material of manufacture (important if the pump will pump food liquids).

Sleeves according to the type of material are divided into rubber, PVC, silicone and thermoplastic elastomer. Currently, several types of tubes are produced for hose pumps, the most common being reinforced and conventional.

Then you need to check whether the product and the pump seat are compatible. For fixation, adapter clamps or fittings are used.

The hose for submersible units is considered a popular product because it is an excellent thing for lifting water from various types of wells. For a submersible pump, the hose is made of rubber or metal. Rubber hoses are more popular, and buyers choose them more often, but they are sensitive to changes in water temperature, crack and burst.

Leading manufacturers

The greatest demand among consumers is for hoses from Elitech and Metabo.

The brands Belamos, Gilex, Kalibr, SIBRTECH, Gardena, Karcher have also proven themselves well.

The most popular are inch suction hoses for Marina-Speroni SET ASPIR MT7 pumping stations made in Italy. The cost of a seven-meter hose with the included filter mesh and check valve is about 1,500 rubles

The 1-inch Gardena pumping station hose is designed for use over a wide range of temperatures of the flowing liquid - from 10 to 50 degrees. The transparent hose with textile reinforcement is durable, its wall thickness is 3.5 mm. Able to withstand fairly high pressure.

Previous articles Next articles

Related Posts

- 25.03.2017.

What is a hydraulic accumulator and how it works

- 25.03.2017.

Replacing the membrane in the hydraulic accumulator

- 25.03.2017.

Parameters and selection criteria

A hose for a submersible deep-well pump must have a number of characteristics, good rigidity and withstand heavy loads. Such products are intended for use inside a well; they are called intake hoses.

When choosing them, you should pay attention to the following characteristics:

- Degree of hardness . Rigidity is imparted by reinforcement, corrugation, increasing wall thickness, etc. Such hoses should not shrink when pressure changes. Products reinforced with steel spirals are considered the most reliable.

- Frost resistance . If the well will be used year-round, then you should pay attention to this. The hose should not flatten or lose strength at low temperatures.

- Material of manufacture . If you need well water for drinking, do not buy rubber products. Such water will have a bad odor, and rubber, breaking down over time, will release harmful substances into it.

A hose for a submersible pump can pump clean and waste water from a well, but the pressure should be no more than 0.1 MPa. Such products are manufactured, for example, by Polix and are used for submersible units.

When purchasing a pump hose, you need to check it for damage.

The hose with a diameter of 32 mm is made of flexible PVC, its operating temperature ranges from -25 0C to +60 0C.

This product is resistant to chemicals (alkali and acid), frost-resistant, inexpensive and lasts a long time, its weight is 1.64 kg. The hose is widely used in industry, agriculture, farming, and gardening. Sewage and drainage pumps are often used in everyday life. They are visually similar, and each is used for pumping out sewage. Fecal is used where drainage cannot cope, since it is capable of pumping out very contaminated liquid. Drainage systems are used in places where there are no impurities in the water larger than 5 cm. If it is not possible to drain the liquid into the central sewer system, then use a fecal pump, which was designed and needed to pump out contaminated water from washing machines and dishwashers and bathrooms. For sewage disposal machines (it is not always possible to clean a cesspool using even a powerful home pump), large models of larger diameter are produced from PVC. They are very durable, resistant to aggressive substances, and insensitive to ultraviolet radiation and temperature changes.

What types of pumps are there?

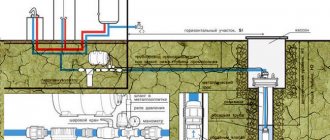

First, let's look at the types of pumping units and their purpose.

- submersible pumps are units that are designed to pump water when immersed below the liquid level

- borehole pumps are also submersible in nature, the difference is that these are deep-seated devices capable of operating at great depths

- drainage pumps – used to pump out accumulated liquids (swimming pools, basements, flooded areas, etc.)

- fecal pumps - as the name suggests, help clean septic tanks and cesspools by pumping out (in some cases, pre-grinding) fecal matter

- surface pumps and stations are designed to stabilize and increase water pressure in water supply systems, watering plants and pumping clean water

Disadvantages of use

For a pump that will be used in a suburban area, buy a flat textile pressure hose. This product is made of two layers: the textile on the outside provides good protection from kinks and deformation, the inner layer of PVC does not allow solid elements to settle on the walls and increases flexibility.

Typically for fecal hoses the diameter is 50 mm, 40 mm and 32 mm.

For a well, it is necessary to use not a watering hose, but an intake type. The hose for collecting water from the well is made taking into account the requirements for rigidity, since the hose is subjected to heavy loads. To prevent compression of the hose when the pressure decreases, reinforcement technology is used. Such well pumps are more durable, unlike corrugated and rubber ones. When choosing a product, you need to pay attention to the possibility of using it for food purposes.

But the silicone product has several disadvantages:

- The material often begins to crack at the junction with the pump and fittings, and then bursts.

- Very weak rigidity.

If the hose is damaged, it is easy to replace, and it is inexpensive.

It is for these reasons that silicone water supply can only be used in the warm season, in the summer. A PVC product is suitable for all-season use. An excellent option is a silicone hose, which is coated on the inside with a special food-grade coating. The water from it does not have an unpleasant odor and/or taste.

What to consider when temporarily cutting off water to your home

If the water stops temporarily, the water must be released immediately and there should be no air movement in the hose.

How to do it:

- The hose from the well to the water supply point should run in a straight line, without kinks, at a slight slope. To do this, it is better to place it in a plastic pipe or wooden box. Such a base will prevent it from bending or moving from its place.

- At the point where the water is supplied, the hose should sag slightly - water will accumulate in it, creating a barrier to the passage of air. Thanks to this, frost will not form.

To supply water to the house, an intake hose is used, which must be below the freezing level of the ground. In this case, insulation of the motor and hose is not required.

Intake hoses are used in stations with a surface motor. To prevent water from returning back into the hose, they are equipped with a check valve. To protect the motor from debris and soil particles, it is necessary to install a mechanical filter.

Well hose options

Submersible pumps are used to pump water from a well. The line of such units includes borehole and well type models. Both of these options are suitable for equipping a well, but when purchasing, you should pay attention to the second one.

Such units are designed for pumping clean water without impurities. If well water is intended for drinking or cooking, you should choose a hose that will not affect its taste.

It should be noted that it is best to buy a hose for drinking water from a well in a store that has all the necessary documents and a guarantee for the product, otherwise there is a high probability that the product will be of poor quality and hazardous to health. When choosing a hose for a well pump, you must have all the information about them and understand the climatic conditions in which the product will be used.

Please take careful measurements before purchasing a hose.

You have to choose from 2 options:

- Silicone;

- PVC.

An inch sleeve is quite suitable for watering the garden. It is used for watering and construction sites.

All pumps require the purchase of additional equipment. It is better to choose a hose not on the construction market, without saving on money and, accordingly, on its quality, and also purchase expensive additional parts for its installation: fitting, mounting clamps, pipe, etc. It is worth noting that it is better to take a hose for the pump with a reserve length. Long sleeves are better than short ones, which may not be enough.

Trusted brands

Drainage pumps with good reliability can be found among examples of varying prices. Let's consider popular options.

Italian brand Pedrollo

One of the main manufacturers of pumping equipment. These are drainage pumps for dirty water with an open rotating element of the centrifugal type. The block and other components are made of plastic using fiberglass, resulting in increased resistance to possible damage.

As an example, we can consider the Pedrollo TOP Vortex device, which has its own characteristics:

- all main elements are made of good quality plastic;

- it is capable of pumping dangerous components;

- It is possible to pump liquid with additives up to 20 mm.

This device is designed for long-term operation, can be used during partial immersion, and has an emergency shutdown device. It is powerful and easy to use. Can be used in a sprinkler system.

Russian pumps Gilex

This brand appeared on the market in the 1990s and quickly earned the attention of its fans. After all, these devices are distinguished by their unpretentiousness and are able to operate during voltage surges.

They are inexpensive, yet they are a quality product.

In our country there are many service workshops capable of performing high-quality maintenance or repair of equipment. These are submersible pumps for dirty water, pumping liquid with additives measuring 5-40 mm. They have a long service life.

For example, you can take Drainage 200/10f, which has its own uniqueness:

- submersibility up to 8 m;

- 880 W electric motor;

- A float is provided to create an autonomous operating mode.

Works in ponds, well shafts, sewer tanks.

German quality from Karcher

The brand produces a high quality product and has a good throughput capacity of up to 18,000 l/h.

As an example it is worth citing:

- Drainage pumps for dirty water Dirt are capable of transporting liquid substances with components up to 30 mm in size. They are successfully used in flooded buildings.

- Flat models are used to transport a cleaner environment and are installed in drainage wells and storage tanks. Capable of pumping water to a minimum depth of 1 mm. Such designs use intelligent sensors that instantly respond to sudden changes in the environment.

- The SDP 9500 models are distinguished by their power and ability to transport working media with solid elements up to 20 mm in size. There is a switch in the form of a float mechanism and a special gasket that increases operating time.

Gnome brand dirty water pumps

The brand has options for different purposes. They differ:

- housings with increased tightness;

- capable of pumping liquid media with a density of 1100 kg/m³;

- possible size of hard additives up to 5 mm;

- can transport substances heated to 35-60 °C.

One of the interesting specimens is Gnome 10-10. It has a 1.1 kW electric motor, is capable of delivering a pressure of up to 12 m and transporting liquid over a distance of 18 meters. Such a device is well used for irrigating a home garden and can be used for a long time.

Inexpensive drainage pumps from Prorab

This brand appeared not so long ago, but already has many fans. The price-quality ratio of the product is excellent here.

For example, you can consider the PRORAB 8720 PP submersible pump for dirty water, which differs:

- excellent performance characteristics and low cost;

- can transport contaminated liquid media with solid fractions up to 35 mm in size;

- has a switching device in the form of a float;

- immersion depth up to 5 m;

- The throughput of the device is 12,000 liters/hour.

It is economical and small in size. Used in a well shaft.

Inlet pipe diameters

The choice of pump inlet diameter depends on the environment in which it will operate. For clean water, a diameter of 0.5 - 1.5 inches is sufficient, for dirty liquid with mechanical inclusions - at least 8 inches.

Pay attention to the location of the outlet pipe: horizontal or vertical. Choose the one that suits your case

The price of a drainage pump for sewerage in a private house depends on the chosen model and its design. Typically, buyers choose universal models that can pump both clean water and water with sand and silt. The best choice for a private home would be a submersible pump with water intake in the upper part of average power. It is small in size, does not require frequent maintenance, is easy to install and has a long working life.

Installation of a condensate drainage system

This process is very simple.

It is necessary to remove the lower fasteners from the air conditioner body so that it can rise. In the lower part, under the fan that blows the evaporator, there is a tray for collecting condensate. There is a pipe on its side, and it is to it that you need to attach the drainage pipe for removing condensate from the air conditioner using a clamp. The indoor unit housing is lowered and installed in place

In this case, it is very important that the corrugation passes through it through a special hole made in the side wall. The fasteners are screwed into place. Now all that remains is to take the attached corrugated hose either into the sewer or onto the street

If the withdrawal process is associated with the installation of a drainage route, then you must first decide how easier and more convenient it is to carry out the entire process. As mentioned above, the best option is to make grooves into which to lay the hose. The most important thing is to maintain an inclination angle of at least 3%.

Now all that remains is to remove the attached corrugated hose either to the sewer or to the street. If the withdrawal process is associated with the installation of a drainage route, then you must first decide how easier and more convenient it is to carry out the entire process. As mentioned above, the best option is to make grooves into which to lay the hose. The most important thing is to maintain an inclination angle of at least 3%.

Basic drainage problems

The most common malfunction of the condensate drainage system from the air conditioner is a clogged hole in the bath. Dust and dirt with condensation settle to the bottom of the pan, where sludge forms. It grows and covers the pipe. The consequence is the flow of water over the edges of the bath. The liquid begins to drip onto the floor and leak down the walls.

And other malfunctions:

- If the air conditioner works for heating in winter, then often the drainage pipe on the street simply freezes.

- The slope of the drainage route was set incorrectly.

- If the pump fails.

- If the amount of refrigerant in the system has decreased, which leads to icing of the evaporator and supply pipes, so the ice begins to melt along the entire length of the route, pouring water onto the floor.

- The evaporator may become covered with ice if the pressure regulator stops working. If the temperature outside the window begins to decrease, this can lead to a decrease in the freon temperature due to a drop in its pressure.

Cleaning the drainage system

You can clean the condensate drainage system from the air conditioner with your own hands only if the bathtub pipe is clogged. To do this you need:

Remove the filters located on the device body in front of the evaporator. They must be washed thoroughly. The air conditioner housing is raised. The drainage tube is disconnected from the pan. The latter is removed and washed

Pay special attention to the hole. If the tube is clogged in the same way as the drain hole, then it must be blown out. If that doesn't work, you'll have to replace it with a new one. All other steps for assembling the condensate drain system are performed in the reverse order.

Experts recommend using a chlorhexidine solution to disinfect drains and the condensate drain pan. Although any household detergent that contains chlorine will easily cope with the task.

For other malfunctions associated with the failure of one or another device or part, it is better to call a specialist. Independent actions can lead to irreparable consequences.

https://youtube.com/watch?v=L-4-BgJKNoo

Kinds

Hoses of conventional and reinforced design are designed for pumping equipment, allowing for uninterrupted operation of the pump.

Most often, when using a drainage pump, several types of hoses are used.

- Normal

is the simplest option. Rubber and silicone materials are used for its manufacture. This product has good strength and resistance to deformation. The low frost resistance of the material does not allow its use at sub-zero temperatures. Its productivity is 150–250 l/min.

- Silicone.

The material from which the hose is made is chemically inert and odorless. It is characterized by ease of use, which determines its long service life. But still, a high susceptibility to deformation and its low rigidity are the criteria that reduce the competitiveness of this product. Based on this, this product is recommended for use only in spring and summer. - Polyvinyl chloride.

This type is used to supply drinking water. At sub-zero temperatures it exhibits better properties than silicone hoses. However, there is still a considerable possibility that it may burst at the bending points when exposed to severe frosts.

PVC (polyvinyl chloride) has greater rigidity than silicone, due to this it has the ability to resist compression due to changes in internal pressure.

- Reinforced.

This type of hose includes a reinforcing layer, which is made of thin fiberglass. A lattice of this material is located between two layers of main fiber. This option is the most popular because, thanks to the use of unique technologies, it has very high technical parameters. - Corrugated

is a type of reinforced product. The design principle of this product is based on a metal spiral, divided into small sectors, which increase the flexibility of the product. It is inexpensive, practical and easy to use, and is intended for supplying drinking water. Corrugated hose varies in severity: light, medium and heavy. The lightweight hose is used for drinking wells; the medium and heavy forms are intended primarily for drainage structures. Hoses, which according to their characteristics are designed for a drainage pump, provide reliable and efficient pumping of dirty liquid and wastewater.

Insulation of water supply

In order for the well to be used in winter, it is necessary to prevent the hose from freezing. This is not insulation, in the literal sense of the word, it’s just that the water supply system, after supplying water from the well, remains empty, so there is nothing to freeze over.

This method is the most effective, and practically does not require additional costs. You just need to properly organize with your own hands the supply of water from the pump to the point beyond which the aquifer system will be at above-zero temperatures.

General information

It should be said right away that there are two types of hoses:

For a well, it is necessary to use products of the second type. They are made with a certain requirement for the level of rigidity, since the product is subjected to quite large loads .

Their manufacturing technology involves reinforcement, which prevents compression of the hose. A similar situation can arise as a result of a decrease in pressure. In addition, reinforced hoses are more durable because they do not tear, unlike rubber and corrugated products.

Sleeve reinforced with steel spiral