Ergonomic metal stoves are an excellent alternative to bulky brick heaters, which are suitable for heating a private bath.

The devices are characterized by fast heating, high thermal conductivity, ease of installation, minimal maintenance and durability. And if desired, a simple metal stove that would fully meet all the owner’s needs can be constructed independently from available materials.

Basic requirements for metal furnaces

Modern designs of metal sauna stoves are subject to high technical and operational requirements, which include the following:

- Wide functionality. Possibility to select different temperature modes to quickly heat the air and maintain an optimal microclimate in the premises.

- High efficiency. Efficient use of fuel material with the possibility of long-term heat accumulation. At the same time, increasing the volume of the firebox ensures complete combustion of fuel and increases efficiency.

- Ergonomics. Iron heaters should remain compact to occupy a small area of the room. In small steam rooms, it is more rational to install a vertical type of structure with a firebox located in the technical room.

- Fire safety. Heating equipment must be safe for visitors and the premises. To avoid burns and injuries, the body of the device is covered with a metal convection casing, and the surfaces near the oven are lined with heat-resistant material.

- Equipment. More advanced models of devices can be equipped with water heaters that provide hot water supply in the bathhouse.

- Aesthetics. Metal heaters can have various designs with forged and glass decorative elements.

Vertical model

A vertical stove for a bathhouse, made by yourself, is most similar to a potbelly stove. The body is elongated in height, the heater tanks are located on top. Kamenka is closed. The heater heats up when hot smoke moves through the stones. The tank is located above the heater. The pipe in such models is mounted - it is mounted on the furnace body from above.

It is possible that the body will have to weld an additional box with a door, and cut a hole in the body for the firebox - and take the firebox into the dressing room. In this model, you can also weld the heater on the side.

Advantages and disadvantages of metal structures

We can highlight the main positive characteristics that a metal sauna stove is endowed with:

- Rapid heating of the body - you can begin basic procedures within 2-3 hours after the oven starts heating up.

- Ergonomic body – compact dimensions allow the stove to be installed even in small rooms.

- Lack of foundation - the equipment does not require the construction of a solid foundation; it is enough to limit yourself to a lightweight foundation.

- Maintaining a constant combustion process - the design allows you to maintain optimal temperature conditions throughout the entire duration of health procedures.

- Generation of soft and clean steam and heat accumulation indoors.

- Affordable cost of materials for self-production of the structure.

- Long service life of the finished device, which can range from 6 to 26 years.

- Reliable operation if the basic fire safety requirements were met during the assembly and installation of the structure.

Along with the positive aspects, a metal sauna stove has significant disadvantages:

- Rapid cooling of the metal after completion of the combustion process.

- Not suitable for heating large areas.

- It is necessary to ensure fire protection of the structure and adjacent surfaces.

Foundation structure

The location for a stove made by hand from metal is determined during the design process - a foundation must be poured under the stove. Under a light wooden bathhouse there may not be a strip foundation - only a columnar one.

Therefore, the foundation for the stove is often poured separately from the foundation of the house. The best option is to pour a concrete foundation with reinforcement. The minimum dimensions are 1x1m or 1x1.5 for a horizontal oven.

The top of the concrete is covered with two layers of fire-resistant solid red brick in a mortar of clay and sand (the cement mortar will crack from the heat). The foundation should be raised 300 mm above the floor. The top is covered with steel sheet.

Selecting a finished metal stove

To choose the right stove for a metal sauna, it is recommended to take into account a number of important parameters, such as:

- Operating temperature range.

- Room heating speed.

- General dimensions of the equipment and volume of the combustion chamber.

- Material for making the case.

- Type of arrangement of structural elements.

- Type of fuel used.

- Features of operation and maintenance.

The modern market is represented by metal heating stoves for baths of the following sizes:

- Mini-devices for heating rooms with an area of 10 to 12 square meters. m.

- Standard stoves for rooms ranging from 12 to 25 square meters. m.

- Large units for heating air in rooms with an area of 25 square meters. m.

Many stove models are equipped with a water heater installed on the rear panel of the structure.

Heat-resistant and durable materials are used as decorative finishing for the metal body - ceramic tiles, bricks, tiles and stone.

Having studied all the operational parameters of sauna stoves, you can easily select the appropriate device model, taking into account the design features of the structure, technical requirements for heating equipment and the financial capabilities of the owner.

Creation of sand-clay composition

After preparing the base, the next step is mixing clay and sand. It would seem that why exactly such a composition is needed if there is cement, but the answer is obvious - the cement mortar is completely unable to withstand exposure to high temperatures. That is why all designs of a brick heater stove for a bathhouse require a sand-clay composition.

The best clay for laying a stove in a bathhouse can be obtained at a depth of about half a meter. Naturally, the material must be thoroughly cleaned and soaked for several days before use. For soaking, you can make a small groove next to the bath. It is necessary to prepare not only clay, but also sand - it must be cleaned of various impurities and thoroughly sifted so that there is no debris in the masonry joints.

The clay is kneaded directly in front of the slave. Experienced stove makers use a special “oar” for these purposes, which is perfect for these purposes. Next, water is added to the clay, and it all mixes well until it becomes sour cream. Moistened sand is added to the clay mixed with water.

To determine the quality of the resulting solution, a dry and clean stick is lowered into it, and the result is determined by the following criteria:

- If a layer of mixture less than 1 mm thick has stuck to the stick, you need to add clay;

- If the thickness of the adhering layer exceeds 3 mm, sand is added;

- If 2 mm of the mixture adheres to the stick, then the solution is suitable for use.

Types of metal sauna stoves

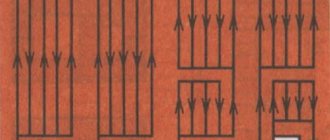

In accordance with the design features, the following types of metal furnaces are distinguished:

- Closed type. The units are compact in size and light weight, designed for small family baths. To increase heat output, the metal body of the stove is lined with heat-resistant bricks on the inside and outside. Iron staples are used to secure the bricks. The middle part of the structure is equipped with a grate for stones.

- Open type. The devices are represented by large structures equipped with an open heater and a water heating tank. They are able to provide rapid heating of rooms in a short period of time. To increase the thermal capacity, such stoves are equipped with a galvanized protective plate for the heater.

- Combined type. Such stoves are equipped with a firebox with sliding mechanisms, a heater, a blower and pipes (diameter from 11 to 14 cm). For the manufacture of structures, sheet steel up to 5 mm thick is used.

Horizontal model

The body is positioned horizontally. In such models, the open heater is welded on the sides to the body. The outlet for combustion products is located on the side.

Note!

DIY birdhouse: step-by-step diagrams and drawings for making it yourself. Types of birdhouses and materials + design ideasDo-it-yourself landscape design: planning and zoning of the site, selection of decorative elements. New products and design ideas (photo + video)

Do-it-yourself sliding gates at the dacha: options for construction materials, preparation of the territory + step-by-step instructions for doing it yourself

The advantage of the horizontal model is that the door to the firebox can be moved into the rest room, so you don’t have to carry firewood into a humid room with steam.

In addition, such models heat the dressing room better - this is important if the bathhouse is spacious enough. The tank is usually hung from the end of the stove.

Types of fuel material

Universal heating equipment for a bathhouse can operate on various types of fuel material. The following categories of furnaces are distinguished:

- Wood-burning. The most practical and reliable devices. They are easy to operate and maintain, operate on available types of fuel - wood, pellets, sawdust. Stoves help to quickly heat rooms, but at the same time they require a large amount of fuel for each load and the installation of chimneys to remove combustion products.

- Gas. More reliable and durable heating units equipped with a thermostat and built-in protection that is triggered in the event of an emergency. Heating stoves are quite economical and can operate on natural gas and liquefied gas mixtures.

- Electrical. Another type of sauna stove, which consists of an iron body, inside of which there is a heating element and a built-in thermal protection system. Additionally, they can be equipped with a touch panel for selecting temperature modes and a remote control. They require a constant power supply, so for uninterrupted operation it is recommended to additionally install an autonomous generator.

- Combined. Such units can operate on alternative types of fuel - fuel oil, diesel fuel, distilled composition. They are safe, reliable and economical. Many device models are equipped with a special switch for selecting the desired type of fuel.

Correct temperature in the steam room

A lot can be said about the rules of classic health bath procedures, but in this article we will dwell in detail on the temperature. If we talk about the temperature in the steam room that is most suitable for health in all respects, then this indicator lies between 50 ° C and 70 ° C

. In the classical Russian bathhouse, the stoves were always built of brick and, as a rule, they had closed heaters. This design was simply not able to heat the steam room above 60 ° C and in order to get a good sweat, it would have been necessary to sit in it for too long, but a way out was found.

A ladle of water was poured onto the stones, heated red from the direct flame, which instantly turned into light, hot, finely dispersed steam, most comfortable for both the respiratory tract and the skin. A cloud of steam rose to the ceiling and a person lying on the shelf was gradually doused with small portions of this steam using brooms. With the right technique of pumping steam onto various parts of the body, the steaming process brings not only unforgettable positive sensations, but also the strongest healing effect.

When designing your own sauna, it is important to understand that in addition to the correct temperature to obtain the full range of positive effects of steaming on the body, the sauna must also have a certain humidity. The optimal figure is within 60%. It is this combination of temperature and humidity that provides ideal conditions for the health of the whole body.

It is this combination of temperature and humidity that provides ideal conditions for healing the entire body.

It is possible to ensure that the steam room has both the specified temperature and the correct humidity at the same time only if the stove is in it with a closed heater

To obtain high-quality finely dispersed steam, it is very important that the stones in the furnace are heated to at least 300 °C. And if the heater is open, then when the stones in it are heated to such an extent, the stove itself will be so hot that the temperature of the steam room will go beyond 70 ° C

Do-it-yourself iron sauna stove assembly technology

In a small-sized bathhouse, you can use a homemade version of an iron heater, the dimensions of which would fully correspond to the heated area. As an example, the technology for assembling a heater with a diameter of 70 cm and a height of 150 cm is considered. Such a heating device is characterized by ease of manufacture, ease of operation, and requires a small amount of fuel material to quickly warm up the bath.

Furnace materials

For self-assembly of the stove, ferrous metal is suitable, the thickness of which is 0.5 cm. The service life of such material is from 6 to 10 years. To make a firebox and a water tank, you can use a centimeter sheet of iron.

For work you need to prepare the following materials:

- Sheet metal 1 cm thick.

- A metal pipe with a wall thickness of 1 cm and a length of 160 cm.

- A chimney pipe with a wall thickness of 0.5 cm and a diameter of 10 cm.

- Metal rod 1 cm thick.

- Grate for the grate.

- Door hinges.

- Door latches.

- Water tap with shut-off valve.

Tools

To work with a metal structure you will need the appropriate set of tools:

- Equipment for hot welding.

- Hacksaw for metal.

- Bulgarian.

- Roulette.

You will also need personal protective equipment when carrying out welding work:

- Mask.

- Uniforms and shoes.

- Gloves made of dielectric material.

- Glasses.

Step-by-step instructions for assembling a sauna stove

To independently make a compact metal stove for a private bath, you must follow the following sequence of actions:

- The pipe is cut into two parts - 70 and 90 cm.

- The blower chamber should be located at the bottom of the pipe for easy cleaning of ash. A hole measuring 22x6 cm is made in the pipe. A metal piece can be used to make a door for the blower chamber. Another hole is made above for adding fuel.

- Door hinges and latches are welded on the outside of the pipe, and the latches themselves are mounted on the doors. Next, the doors for the blower chamber and the loading compartment are installed.

- A circle with a diameter of 70 cm and a corresponding hole in the center for the grate are cut out of metal. The workpiece is welded inside the furnace structure above the ash chamber.

- On the back side of the pipe, a hole is prepared for watering the heater and a protective door is installed.

- A lattice for laying out stones is made from reinforcement. The dimensions of the grate should be determined taking into account the size of the stones that will be used for the stove.

- Another round blank with a diameter of 70 cm is cut out of metal, a hole is made in it for the chimney pipe so that it is offset to the rear wall of the stove. Next, the chimney and the circle underneath it are welded on top of the structure.

- A water tank is made from a smaller piece of pipe, which is welded to the stove. A hole is made in the container to fix the tap by welding.

- Another round piece of metal is prepared and cut into two parts - large and smaller. A hole is made in the larger element for the chimney pipe. After this, it is placed on top of the chimney and welded around the hole.

- A smaller semi-circular element is used as a lid for the water tank. Fixation to the pipe using door hinges.

Important! The size of a homemade metal stove for a bath depends on the total volume of the steam room. Such a unit can provide heating for a room with a volume of up to 25 cubic meters. m.

From the pipe

If there is space to install a stove, you can make a homemade electric stove from an iron pipe and U-shaped industrial electric heaters. The following is recommended:

- select the pipe diameter according to the size of the electric heaters;

- place the heaters in one of the pipe holes with the contacts facing outward, make grooves around the perimeter of the hole for inserting ceramic bushings for wires connected to the electric heaters;

- close the pipe hole with a durable metal sheet, which will become the base of the stove;

- connect the sheet to the pipe;

- the connection can be either welded or threaded;

- the free space of a vertically standing pipe must be filled with basalt-type stones measuring 6–11 cm.

Stones at the bottom of the pipe should not put pressure on the electric heaters.

To do this, you can place reinforcement rods along the pipe between the electric heaters, which will become a supporting device for the stones. The pipe and support sheet must be grounded. That’s it, the smallest stove-heater for a mini-sauna is ready. All that remains is to make the correct connection to the network and grounding device. Stoves with a power of up to seven kilowatts are connected to a 220-volt network, more powerful ones are connected to a 380-volt network. The same design can be used to construct a stove in a fairly large bathhouse. A large diameter and length of pipe and a larger number of electric heaters should be used. Date: September 25, 2021

Features of stove installation according to fire safety rules

In order for an iron sauna stove to work properly for many years, you must follow the basic installation rules:

- Heating equipment is installed on a pre-prepared platform with a diameter of 70 cm and a height of 18 cm. Additionally, a 30-centimeter foundation base made of heat-resistant bricks is installed. The distance from the stove body to the wall should be 100 cm. It is recommended to insulate the walls with heat-reflecting foil to prevent the surfaces from catching fire.

- The minimum distance from the top of the device body to the ceiling surface is 120 cm, and from the firebox door to the opposite wall - 135 cm.

- The chimney pipe is also insulated. For this purpose, installation of an internal and external protective casing with a layer of heat-insulating material is provided.

- When the chimney pipe is routed through the roof, at the junction with the ceiling, a protective galvanized steel box filled with basalt insulation is installed.

- The doors to the combustion chamber should be directed towards the entrance door, and the heaters should be directed towards the near corner.

- The shelves in the steam room are fixed along the wall opposite the one where the heating equipment is installed. The best option is a multi-tiered design.

- Lamps in the steam room are mounted above the front door or along the perimeter of the room, with the exception of the wall behind the stove. To avoid possible short circuits, it is not recommended to install lighting equipment on the ceiling.

- If a metal sauna stove is used in a wooden building, the body will need to be lined with heat-resistant brick. The optimal height of the structure is 125 cm, and the length is 85 cm.

- A test run of the equipment is carried out before the start of operation of the steam room to identify possible design defects or errors in its installation.

Possible difficulties

Matching seams is a difficult task for a beginner. Solution: make guides from metal rods. Diameter - 3 or 5 mm. Before laying the stove row, place them on the edges of the brick and press the next block down. Get the rods. The remaining notches will disappear on their own after completing the row.

If the laying mortar does not “grab” the bricks, wet them with water. This way the coupling will become reliable.

During construction, the errors are invisible, but in the end you can see them all. Solution: check each row of the stove horizontally and vertically with a building level.

If you do not follow safety precautions when laying a stove, you can injure your hands. Wear rubber-lined gloves and wrap duct tape around your knuckles.