Despite their advanced age and serious competition, Russian stoves are still in demand among owners of country houses. They are also used in homes, as a main or additional heating unit, as well as in various outdoor complexes. The FORUMHOUSE portal has a lot of examples of both classic versions, with beds, and modified ones, focused only on the preparation of pickles. Consider:

- What is a Russian stove?

- What are its design features?

- What kind of furnaces do our craftsmen build?

The working process of a Russian stove

Despite serious competition and a solid history, the design is still in demand among country property owners. Based on how the Russian stove is structured from the inside, it will be possible to focus on the dimensions from the outside and accordingly plan a place for it and lay the foundation.

Before you put together a Russian stove, you need to understand its operating principle - the design is a periodic heating device, that is, when burning wood, it accumulates heat, then releases it for almost a day. The structure can warm or languish like this for almost a day, which makes it possible to cook baked milk in it, steam porridges and soups, without controlling the process.

Before making a Russian stove, you should build a separate foundation that is not connected to the tape, since the structure is usually heavy. This is especially important when the house “dances” on heaving soil during freezing and thawing. In this case, the stove will move along its own amplitude along with its foundation, without destroying the finish or affecting the walls and openings.

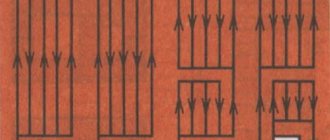

Cross-section of a Russian stove during heating and simmering Source 2proraba.com

Work principles:

- the entire structure stands on a brick or concrete slab;

- firewood for kindling is stored in the stove, where it dries very well and, when ignited, lights up instantly;

- the top of the sub-peck is made with a hemispherical arch, like a trough;

- sand, clay, broken brick - any heat-intensive material is poured onto it, and the front part of the firebox (cooking chamber) is laid on top of it under the stoves; it is placed without clay mortar.

If you ignore the topping, then you can forget about real hearth bread and pies. By the way, they are baked on cabbage leaves.

Next comes an injection with an overtube and a highlight in the form of a tapering nozzle. On the sides of the fold near the walls there are ash pits - recesses for smoldering coals (for the next kindling) and ash. Sometimes they are raked into a fringe - a part of a cast iron or stone slab (pole) protruding from the face (brow) of the stove.

To reduce costs and cleanliness in the room, there is no need to make an ash pan and ash pan. Previously, they were raked into a nook of the mouth, then the coals of birch, maple, elm, oak and aspen retained their heat for only a day.

Cooking in a cast iron pot over coals Source yandex.net

Most likely, this is where the belief came from that the Russian stove is quite picky when it comes to fuel. But this is not so - it works on any solid fuel, including:

- brushwood;

- dung;

- dead wood;

- sawdust

- straw;

- peat briquettes.

Thanks to this configuration, the combustion chamber acts as an economizer, where the following happens: the smoke circulation heats the air, which enters the firebox without removing oxygen from it and without interfering with combustion - mixing of heat flows should not occur. In essence, a combustion chamber is an energy recuperator (heat exchanger).

Before building a Russian stove, you should check the dimensions in advance - this is important so that the structure does not smoke, does not cool down quickly and does not use a lot of firewood. For the same purpose, perfectly smooth haila vaults are made. Moreover, they cannot be plastered, so the bricks are chipped from the inside and polished until glossy - then there will be no swirls in the slit.

Smoke from the stove goes into the chimney Source stroyfora.ru

Chimney pipe

The beginning of the chimney pipe was laid out dry. The smoke collector was constructed: the author picked out the outer halves of the bricks to make it a little wider, planted them on the mortar and from the top a couple of rows of bricks on the edge. A brick was cut into a smoke collector. Then it became clear that making the semicircular cutouts was in vain, it was necessary to catch up to the overlap of the smoke collector without cutouts, time was wasted. Cutouts were made in the ceiling for a diameter of 180 pipes. The pipe went: an old 180 mm disc was used as a guide.

The pipe is made of a quarter of a brick and there is simply no room to install a damper. Therefore, it was decided to lay a slab larger than the pipe. The result is protrusions of 8-10 centimeters. According to the design, protrusions must be made. We bought 10 kg (there is no smaller package) of heat-resistant cement called GC 40, they will be sawn.

Next, the oven was insulated, a mesh was laid on it, and one layer of mortar was placed on it.

Making a pipe from a used roofing sheet took one day. The distances to the roof locks seemed to specifically coincide with the 180 diameter I needed. All that remains is to saw off the sheet to length and bend it along the mandrel cut from the outlet.

The firebox is the heart of the stove

The firebox consists of two parts:

- firebox;

- bakery (cooking chamber).

In small stoves (124 x 178 cm) the bottom is laid out with a rise to the rear wall of 6-9 cm evenly, and in medium (147 x 213 cm) and larger (160 x 231 cm) with a break in the middle or far (2/ 3) parts. This is done to ensure that the dishes stand evenly on the surface. The crucible must have a slope underneath. By the way, Domostroy states that the height of the beds (beds) should be 142 cm.

Before you make a Russian stove, you should decide on its parameters. The dimensions may vary somewhat, depending on the size of the brick - an even amount should be laid out for all dimensions (length, height, width), taking into account the clay mixture. Stoves in which the firebox on the sides also narrowed 6-9 cm towards the mouth are heated better.

“Aerobatics” is considered to be the execution of the crucible arch in the form of a three-center barrel (smoothed dotted line in the first photo), and not hemispherical and the expansion of the crucible in the middle part. Then no sparks are formed, the stove does not smoke, the fuel burns completely - 100%.

Sectional diagram of a stove on a wooden base Source stroyfora.ru

A la russe

The “a la russe” style involves the use of traditional authentic elements of Russian life. Once upon a time, classics were written about stoves with such decor. Shelves were placed near the whitewashed hearth.

Wood is an absolute favorite. The main decorative elements are samovars, brooms and spinning wheels, animal skins (not exotic) and towels with embroidered ornaments. It is not at all necessary to decorate the stove with drawings. A perfect white background is enough.

Pros and cons of the design

The undoubted advantages of modern buildings are the following:

- high efficiency: even for the simplest units it is 65%, for complexly modified ones it is 85%;

- “omnivorous”, while when switching from one type of fuel to another, no change in heat transfer and a decrease in technical parameters were identified;

- availability and cost-effectiveness of materials: brick, clay and sand are used in construction;

- fire safety: the fire burns in the depths of the stove and coals and firewood cannot fall out;

- ease of maintenance and operation: with one morning heating, the heat lasts 24 hours;

- health benefits: the bed warms and heals the body and joints, and food cooked in a Russian oven does not have carcinogens;

- multifunctionality: in addition to the firebox itself, you can make a hob that opens into the kitchen and fireplace on the second floor.

Three hearths operate simultaneously - a firebox, a stove in the kitchen, a fireplace in the attic. Source yandex.net

The disadvantages include:

- quite large dimensions;

- the need for cleaning;

- inability to use gas;

- a separate foundation is required;

- heating a relatively small room - 50 sq. m.;

- after a long break, gradual warming up throughout the day is required.

It is believed that not all the secrets and capabilities of the Russian stove have been revealed yet.

Features of use

The oven is easy to use. To warm up the product you need to do the following:

- Load pallets into wood stove. Gas and electric models are connected to the gas pipeline and the electrical network, respectively.

- Dry the heating element after idle time in an electric oven. Other types can be enabled immediately.

- Select the desired program mode.

- Preheat the chimney for 6-7 minutes.

- Check the thermostat indicators. The temperature is maintained automatically in most modern models.

If the oven is used for cooking, you need to open the lid and place sheets of kitchen utensils into the oven. After finishing, the device turns off. It should not be kept in working condition for more than an hour.

Types of construction

By design, the units are divided into two types:

- Traditional - with an under-bake (lower part) that cannot be heated, so it can be made from any material, including wood.

- Improved (modern) with channels in the oven, which allows it to warm up well. Often complemented with a hob, oven, fireplace.

Modern designs have the following dimensions:

- from 230 x 150 cm (large);

- 175 x 150 cm (medium);

- up to 175 x 150 cm (small).

In addition, they can be erected both indoors and outdoors.

A lightweight version of the Russian stove with a foundation on the site is used for cooking, the stove bench is used as a table Source mobilizacia.kiev.ua

See also: Catalog of companies that specialize in the installation of fireplaces and stoves, extensions to finished houses

Also, structures can have different geometries (shape of the pole, presence or absence of cornices) and finishes (brick, tiles or plaster). The most popular, judging by public surveys, is the improved version according to Podgorodnikov with a two-burner stove. In second place is “Housekeeper” - often due to lack of space. In the traditional design, the floor was not heated, and, as you know, warm air rises to the top, in the lower part of the hut it was cold, the lower crowns of the house froze and could rot. Podgorodnikov proposed making the basement out of brick with a system of channels.

Type 1 – simple

It takes up little space, heats the house well, and consists of a cooking chamber, oven and pipe. The presence of a two-burner stove allows you to quickly prepare food. For this design you will need:

- solid bricks – 1620 pcs.;

- solution - 72 buckets;

- samovar;

- plate;

- flap;

- 2 valves.

This is considered an ideal option for a small country house with an area of 32 square meters. m. You can make a flood for additional heating of the lower zone in the floor area.

Structure of a simple type stove Source fireplace.su

To increase the heat transfer effect, separate chimneys are installed near the walls of the flood chambers. You can also make a fire in the fire pit, equipping it with a stove for faster cooking.

Type 2 – adobe

Perhaps the cheapest way to build a Russian stove with your own hands. Here, brick is needed only for the pipe and hearth, the rest is clay mortar. For a medium-sized Russian stove, it will require approximately 3.5 cubic meters. The correct consistency is checked in this way: they form a brick, place it on a stick perpendicularly - if the edges do not bend and the shape is preserved, then the thickness is required.

The process is as follows:

- the sand-clay mixture is laid out on a flat surface in a layer of 15 cm;

- the top is carefully leveled;

- Fragments in the form of bricks are cut from the resulting layer.

A modern version of a clay oven in a round adobe house Source gidkaminov.ru

Bricks are usually made 20-25 cm wide, then masonry is carried out, while home-made elements are tapped and leveled, removing excess clay with a scraper. Be sure to use a level to check the vertical and horizontal. A common mistake when laying yourself is to wet the bottom row with water - this leads to a weakening of the mortar and the appearance of cracks. If a break in work is required, the last row should be covered with damp rags.

The clay oven needs to be dried for 7-8 days, after which they begin to slowly heat it with dry wood. In this case, the clay will release steam and acquire the desired structure. After 5 days with daily heating, the structure will be ready for full use.

Type 3 – “heater”

These stoves can vary significantly in size, but what they have in common is that the room is heated evenly from floor to ceiling over its entire height. The surface of the “heatbox” is almost 2.5 times greater than the outer volume of a simple type.

Russian “teplushka” stove with a large heating surface Source msk-kamin.ru

This stove has many advantages compared to other types:

- less fuel required;

- In addition to firewood, you can also heat it with coal;

- Cooking occurs relatively quickly (30-60 minutes), it can be stored warm for up to a day, and cooking can begin even after the wood has burned, since the heat remains sufficient.

The design includes the following elements:

- the cooking chamber (upper) is located at the hearth level;

- heating chamber (lower) - in the oven, under the hearth.

Before you build a Russian brick stove with your own hands for a house with a stove, you should not cross out this option - the “teplushka-4” model provides for installing the stove in a shelf. Its dimensions are 120 x 120 cm, the "teplushka-2" is 168 x 129 cm, it does not have a stove, but does have a small hot water boiler.

Recommendations for use by stove makers

The efficiency of fuel combustion and the overall condition of the stove depend on compliance with operating rules, which should be followed not from time to time, but regularly.

Brick, like mortar, is a “living” material that can become deformed over time due to temperature changes. Therefore, you will have to not only clean it, but also cover up the cracks so that condensation does not form and the heat capacity of the structure does not drop.

This happens very simply, here is an example: over time, a gap of only 2 mm wide has formed around the valve. It turns out that in an hour it passes as much as 15 m³ of air heated to a temperature of 90-100 ° C, that is, approximately 10% of the total heat emanating from the stove.

Heat loss increases up to 40% if you simply open the door, and by 20-25% if air is supplied through the vent

Furnace repairs and cleaning are carried out once a year, before the heating season. But chimneys need cleaning much more often - about 2-3 times per season. Before starting the fire, remove ash from the grate to ensure free access of air for efficient combustion.

Fuel is prepared in advance, since the logs must dry. To do this, they are put in woodpiles under a canopy and left for at least a year. It is not recommended to use wet firewood, since evaporating moisture settles on the walls and mixes with soot.

It is better if the firewood is the same length and thickness no more than 10 cm. This way they will burn equally quickly and evenly, which is important for heating bricks

Typically the combustion process takes from 1.5 to 2 hours.

Firewood is stacked in the combustion chamber in rows or in a cage, with a small distance between logs. It is important that they burn at the same time, as the heat will be greater.

It is not recommended to heat the stove for a long time for increased heating. This can provoke the appearance of cracks, as a result of which first cosmetic and then major repairs will be required - laying the masonry again.

For kindling, quickly flammable materials are usually used: wood chips, paper, shavings. Before lighting, open all the dampers, the view, the door

As soon as the wood ignites, the firebox is closed and the vent is opened. The draft is regulated by the position of the valve or view.

Some more useful tips:

- A bright red flame and black smoke indicate a lack of air - the flow needs to be increased.

- A white flame and a hum in the chimney is an excess of air; it is better to cover the vent a little.

- You can move the logs only after they have thoroughly burned out and formed wastelands that allow air to pass through.

- The firebrands are pushed into the center of the hot coals so that they burn out faster.

- As soon as the coals stop burning with a blue flame, they are distributed over the hearth, moving closer to the mouth.

- To protect against carbon smoke, the pipe is not closed for another 10 minutes to prevent carbon monoxide from entering the room.

If the stove is heated with coal, it is still recommended to heat it with wood.

When finishing external walls, remember that beautiful cladding can partially reduce the flow of heat into the room.

Foundation

Before you build a Russian stove with your own hands, you need to carefully study the drawings and only then begin building the foundation and purchasing materials. Although it is better to lay the foundation for the structure at the stage of forming the foundation for the house. However, they should not be connected.

A separate foundation for a Russian stove with a gap of at least 5 cm - wet sand is poured here and compacted Source chertegnik.ru

If it happens that the stove needs to be built in an already rebuilt house, then you should cut the floor down to the ground, make formwork and pour concrete, if necessary, with reinforcement. Depending on the location of the furnace, there are the following nuances of constructing its foundation:

- If the Russian stove will stand against an internal wall with a shallow base, then both soles should be at the same level, and the upper platform for the stove remains 14 cm below the finished floor.

- If the furnace is planned to be placed against a load-bearing wall on a buried strip foundation, then the foundation pit for the furnace base is expanded, a sand and gravel layer is made with a tamper, and concrete is poured into the formwork. In this case, the gap between the two foundations of 5 cm is filled with sand, the sidewalls directed into the house are formed with brickwork. The depth of the sole should be at least half a meter.

The foundation for the stove is in the corner - on both sides of it there is the foundation of the house Source remont-system.ru

- If the structure is located in a cut-out opening in a load-bearing wall, then the interrupted lower crown should be connected with steel strips (6 mm thick and 60 mm wide) by placing them on both sides of the ends of the logs and tightening them with bolts (16 mm diameter). The resulting opening is framed with wooden posts; the resulting gap (cut) should be 5 cm.

When you have decided on the location and foundation, you can.

Drawing plan of a Russian stove from different angles Source kaminproekt.ru

Financial and economic aspect of building a Pompeian oven with your own hands

What is the reason for the relatively high price of such a stove?

- The Pompeian stove is made of fireclay bricks, which cost an order of magnitude more than usual.

- The design of the stove is quite heavy, and for ease of use it must be raised to a height of 80-100 cm. To do this, you will have to lay out a brick stand on which the stove itself will be built, which means you need to think about a good foundation.

To slightly reduce the cost of building a stove, any materials available on the farm are suitable for the stand: blocks, ceilings, old bricks, etc.

Building a pizza oven

Another disadvantage is the lengthy process of laying a Pompeian stove. A rather complex design, which requires the presence of a foundation, a pedestal, the stove itself, and a large countertop, indicates that the whole process will take at least a month.

In addition, you will need significant technological breaks to harden the concrete for the foundation, etc.

If you come to the dacha only for the weekend, then the entire masonry process can be rationally distributed into several stages, calculating that the technological break for “setting” the materials occurs during your absence.

Traditionally, the Pompeian oven has the following layout:

- solid foundation;

- pedestal for the stove;

- bake.

Pompeian pizza oven

The oven itself, in turn, consists of four parts:

- base (furnace bottom);

- dome (vault);

- entrance arch;

- chimney.

The base (pedestal) is made of small cinder blocks, 20*20*40 cm each.

The tabletop is a monolithic slab made of reinforced concrete 10 cm thick.

Tabletop

Unlike a traditional stone stove, here the chimney is located at the front. This determines one of the main differences in the design. The fire rises up along the dome, heating the vault. Thanks to this, heating is carried out simultaneously from above and below, which contributes to fast cooking.

The Pompeian stove has undergone many changes over the many years of its existence, and today you can find several of its varieties.

Neapolitan oven

There are Tuscan and Neapolitan ovens. The Tuscan stove has a higher arch and is more versatile in use. You can bake not only pies in it, but also cook stews, meat, and soups.

The Neapolitan oven is traditionally used for baking pizza and has a small dome that is approximately 80% of the total dome height.

Tuscan oven with a higher arch

As for the shape and size of the stove, the most optimal design is the one with an internal diameter of 80-110 cm. It is not recommended to make the stove smaller than this.

The spherical arch of the oven serves for maximum heating and heat accumulation, and the arched entrance is used for storing firewood and the food itself.

The size of the oven may vary, but in any case, strict proportions should be adhered to: the height of the arch should be approximately equal to 60% of the total height of the dome.

The width of the entrance for storing firewood should be equal to the total height of the dome.

Multilayer dome of a Pompeii oven

The vault itself has several layers:

- the internal surface is made of fireclay bricks;

- clay coating;

- 1st layer of basalt wool (thermal insulating);

- 2nd layer of perlite;

- Facing layer made of cement mortar.

In this case, the thickness of each layer should be approximately the same size, 5-10 cm. The more heat-insulating layer is laid, the longer the oven will cool down.

The facing layer can be made from any moisture-proof and water-repellent materials, since its main purpose is protection from precipitation. If the stove is being baked in the house, then this protection can be omitted.

In addition, the facing layer also performs a decorative function, so you can make it to your taste: decorative plaster, painting, mosaic, etc.

Video description

In this video, watch how a brick foundation is made for a Russian stove:

To lay a structure 165 cm long, 153 cm wide, 154 cm high and 238 cm high, you will need:

- red brick – 2000 pcs.;

- sand with clay - 1.7 cubic meters;

- samovar – 1 pc.;

- fire door 24 x 25 cm – 1 pc.;

- blower door 13 x 13 cm – 1 pc.;

- smoke valve 37 x 17 cm – 2 pcs.;

- grate 26 x 28 cm – 1 pc.;

- composite cast iron stove with 2 burners 53 cm long – 5 pcs.;

- damper 40 x 34 cm – 1 pc.;

- water heating box 40 x 28 x 16 cm – 1 pc.;

- view (inner diameter 22 cm) – 1 pc.;

- half-door 33.5 x 16 cm – 1 pc.;

- steel sheet for flooding - 1 pc.;

- strip steel or angle for blocking the mouth.

Russian stove with hot water boiler, shield and stove Source fireplace.su

Order:

- 1 – 153 x 165 cm: the outer sides are made of whole bricks, the middle is acceptable from halves and quarters.

- 2 – walls of various thicknesses form a well (see drawing). If you then make a hole in front of the stove, then you can store a poker, grip, and scoop in the oven (a laid out well).

- 3 – at this stage, the blower door is installed, cleaning, an ash pan and a channel (the unshaded area between the walls) are arranged. The corner of the channel is beveled and rounded, while the brick is ground down and ground down.

- 4 – like 3.

- 5 – like 4, cleaning and the blower door is covered with masonry. From the inside of the well, on the side walls, the brick is trimmed to obtain the heels needed for the vault (frequent shading).

- 6 – vault with a rise to the 8th row with installation of a water heating duct on the front side.

Russian stove with stove and heating shield Source pinimg.com

List of tools

To work you will need the following tools:

- Shovel.

- Construction and hydraulic level.

- Plumb.

- Master OK.

- A pick hammer or, if possible, an electric tile cutter for cutting bricks, as well as a mallet for adjusting the masonry.

- Jointing for making seams on the facade.

- Cord as a guide for laying.

- Ordering - to control the thickness of the seams.

- Rule for leveling the foundation when pouring.

Russian-style stove on the street

This option has recently been preferred by owners of country houses instead of a barbecue complex or in addition to it.

Before you build a Russian stove with your own hands on the street, you should prepare the foundation. It must be strong, made of concrete with reinforcement, so that the structure does not collapse or sag.

Red brick is used for the construction and fireclay is used for the vault. The stove is closed with a valve; a separate pipe runs along the back wall to the cauldron from the stove. The chimney can be made of facing bricks. The smoke is discharged through stainless steel pipes wrapped with basalt cardboard to avoid strong heating of the lining.

Before building a Russian stove on the street, you should prepare:

- red brick 800 pcs.;

- fireclay – 70 pcs.

It is better to cover the tabletop with tiles, the apron - from brick, it is good to equip such a stove with a damper with a thermometer.

It is advisable to install a stove structure or complex under a canopy or in a gazebo, since materials quickly deteriorate in the open air.

Additional materials

Auxiliary parts and additional materials for a traditional Russian stove are not only functional elements, but also serve as effective decor. When working on the creation and design of a stove with a stove bench, you may need the following:

- brick;

- sand;

- accessories for stoves;

- grate;

- valves;

- corners;

- fireclay slabs;

- fireclay brick;

- tile;

- ceramics;

- stone cladding;

- basalt insulation.

The old Russian stove is very economical in everyday life. She will decorate a modern country cottage, and housewives will appreciate her ability to prepare original dishes.

conclusions

So, let's summarize.

- Bottom combustion is a slower and less intense process; as a result, the wood burns longer and the stove takes longer to heat the outside, rather than the room. Firewood consumption is higher

. - Combustion in a firebox with an ash pan and a grate is optimal for heating needs: the combustion process proceeds more efficiently, at a higher temperature, with greater heat release. And, as a result, it requires less fuel

. - The design of a modern furnace with an ash pan and a grate makes it possible, if desired, to organize both a faster combustion process using a grate and blowing air through the ash chamber, and a slower one, like bottom combustion. While a deck oven lacks the ability to optimize the combustion process. The grate stove is universal.