Home » Automation and controls » Why and how automation is needed on old-style gas boilers

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

…

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

About company

Before the Great Patriotic War, the Zhukovsky Machine-Building Plant produced a variety of metal structures, and in the post-war period, equipment for aviation maintenance. It still produces similar equipment for the domestic and foreign markets.

The company also produces heating equipment. Today, over 30 options are produced with a power from 11 to 68 kW. The most popular modification of the Zhukovsky MZ is the AOGV boiler. The remaining series - AKGV and KOV - are in demand among Russian consumers. The company has diplomas and distinctions for the high quality of its products.

Manufacturers

Let's look at the most popular companies that produce gas valves.

p, blockquote 17,0,0,0,0 —>

Dungs

A German company that is one of the most popular in the production of gas control valves.

p, blockquote 18,0,0,0,0 —>

Dungs products began appearing on the Russian market in 1999 and were able to firmly consolidate their position. Users constantly purchase products from this manufacturer because they are distinguished by high quality, reliability and long service life.

Double gas valve device DUNGS type DMV

The only drawback that can be noted is the high price.

p, blockquote 20,0,0,0,0 —>

The most technologically advanced development of the Dungs company in the mass segment is the Dungs DMV-D valve - this is a two-way device, which, in fact, is a connection of two independent valves in one compact body. Thanks to its technical characteristics, it can function in high pressure working environments (up to 500 mbar). The cost of devices starts at approximately 12,000 rubles.

p, blockquote 21,0,0,0,0 —>

SIT GROUP

The Italian manufacturer SIT GROUP began its activities in 1953. The company has existed for more than 60 years and during this time has managed to establish itself extremely positively. The company's products are widely used due to their optimal price/quality ratio.

Gas valve SIT 845 SIGMA

The Sit 845 Sigma valve is the most popular device that can be bought in the budget price category. The 845 Sigma gas valve has a two-way design that can be mounted on gas-consuming appliances from most common manufacturers; it is also suitable for a gas boiler. This valve is equipped with an electric drive, so its operation requires a constant voltage of 220 Volts, in the absence of which the valve locking mechanism takes the closed position. The main advantages of 845 Sigma are the minimum period of valve activation and compact dimensions.

p, blockquote 23,0,0,0,0 —>

Advantages of ZhMZ products

Any of the ZhMZ gas devices can operate independently of electrical networks - this allows you to expand the scope of their application. Advantages:

- Designed for the harsh Russian climate. Adapted to changes in water and pressure. Hardy, powerful, reliable, unpretentious.

- Can operate at very low pressure in gas and water supply systems.

- In severe frosts, they will ensure a comfortable temperature in the house.

- Highly reliable automation ensures high productivity of each unit and safe operation of all systems.

- Service life - 14 years or more. Warranty - 36 months.

- Capable of heating large areas.

- Some modifications can switch to liquefied gas.

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6…12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be lower than the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5) .

Design Features

- Fire adjustment is made in two ways: automatically and manually. The models differ not only in power, each of them has a certain range of capabilities.

- Some models have a pump to circulate water in the pipes. This allows you to effectively heat the room due to uniform heat distribution. Cheaper modifications do not have pumps, and water circulates according to the laws of physics. Therefore, when installing such boilers, the pipes are mounted at an angle.

- All modifications have an expansion tank. It allows you to achieve optimal pressure in the system, and if the liquid expands due to strong heating, it stores its excess.

Varieties

All boilers at the Zhukovsky Plant are floor-standing. There are three modifications:

- "Economy";

- "Universal";

- "Comfort".

In the first case, automation manufactured in the Russian Federation was used, in the other two - foreign ones. The brand presents only single-circuit versions - for heating buildings; double-circuit versions are not produced at ZhMZ.

Device

The efficiency of the equipment is 89%, which is quite good for domestic products. This productivity can be achieved due to the original design of the heat exchanger. The cast iron heat exchanger is equipped with turbulators. The burner is atmospheric, air comes from the room. Thanks to automation, continuous operation for a long time is ensured.

Heaters from the Zhukovsky Plant have a number of innovations that increase their environmental friendliness. Developers are trying to keep up with global trends, but still, domestic products are far from achieving the indicators of European and some Asian competitors. But Russian products have an undeniable advantage - a low price that satisfies all consumers.

Typical breakdowns and repair methods

The types of valves listed above perform ambiguous functions and differ in design. The reasons why they become unusable and the ways to fix the breakdown also differ.

Gas valve malfunctions

The main purpose of the gas valve is to regulate the gas pressure supplied through the nozzles to the burner. The flow can be adjusted so that from 25 to 100% of the flow enters the chamber. It all depends on what type of gas will be used in the operation of the equipment, how much air will be supplied for normal combustion.

In fact, it is an electromagnetic device, the main work of which is carried out only when connected to the power supply. However, when its solenoid coils are de-energized, the gas valve functions as a safety feature. In this case, it tightly blocks the channels through which gaseous fuel moves.

The charge generated by the thermocouple of the gas water heater or heating boiler hits the electromagnet (coil) of the gas valve, as a result of which the metal washer of the shut-off valve is magnetized to the coil. The washer opens the membrane so that gas can pass to the igniter and burner block nozzles.

When the flame fades or decreases below standard values, the thermocouple stops generating electricity. As a result, the coil holding the washer is demagnetized. The blue fuel supply channels are closed.

The need to take action will be indicated by a drop or increase in static pressure, i.e. inlet pressure when the boiler is not operating. For units processing main gas, it must be at least 17 mbar. For boilers powered by liquefied fuel - not lower than 35 mbar.

The list of typical gas valve failures includes:

- Disturbances in the electrical circuit supplying the electromagnetic device. In this case, all wiring and contacts in the connection areas should be checked with a multimeter. If a break is detected, it is eliminated in a trivial way: by replacing the damaged wire, stripping and tightening the contacts.

- Gas valve clogged. The channels of the device can periodically become clogged with mineral particles supplied along with low-quality gas, elemental carbon deposits and calcium salts formed when there is condensation in the supplied fuel. Simple mechanical cleaning helps.

- Thermocouple failure. Often requires complete replacement due to complete burnout of the working edge. In this case, no current is transmitted to the electromagnet at all, as a result the boiler does not ignite at all or is blocked after a couple of minutes of operation.

- Mechanical damage to the gas valve. For example, the washer above. It either stops pressing tightly and ensuring a tight seal, or does not respond to adjustment, which is why an uncontrolled volume of gas enters the chamber. To eliminate this, either the valve or the damaged part is replaced.

- Short circuit to the housing of the electromagnetic coil winding. Most often it occurs due to short-term overheating and subsequent melting of the plastic sleeve on which the turns of the electromagnet are wound.

It is clear that the list of all breakdowns can be divided into two groups: violations in the electrical part and mechanical damage to parts.

We immediately warn you that when carrying out any repairs for which it will be necessary to remove the unit body, the owner automatically deprives the owner of the right to take advantage of the manufacturer’s warranty. In addition, neither the company nor the organization with which the service contract is concluded will bear the slightest responsibility for a negative result.

It happens that instead of learning how to properly repair the solenoid valve of a gas boiler, the owner of the unit stubbornly tries to turn it on. At the same time, he continuously presses the button on the gas supply device, trying to start the burner. It is absolutely impossible to do this.

If you open the path to the gas flow yourself, the boiler burner will still not light. But the gas will flow uncontrollably into the room as long as the owner literally keeps his finger on the trigger. What is the threat? At best, mild poisoning, at worst, an explosion.

The following selection of photos will familiarize you with the steps to restore the electromagnetic coil of the gas valve:

About old-style boilers

AOGV is a later modification of the AGV brand. They, like their predecessors, do not have particularly high efficiency and do not have thermostat control. When gas was cheap, no one paid attention to low performance; today efficiency is one of the most important characteristics when choosing heating equipment. AGV models were distinguished by low-quality automation, which broke after one or two seasons of operation.

AGV and AOGV can work without automation: if it breaks down or is turned off on purpose, it will not interfere. When buying a heating boiler, you need to take care of a sufficient number of pipes - their diameter should not be less than two inches. If you take a smaller diameter, the circulation of the coolant may deteriorate - there will be additional costs for heating it.

What is the improvement?

The developers have made a number of improvements to the design:

- Glass thermometers were replaced with Italian, more modernized ones.

- German automation from Honeywell was installed.

- Piezo ignition.

- The appearance has improved thanks to the high-quality coating. The design has changed: the body can be round or rectangular. White color. Painting: powder.

Nuances of operation

When using gas equipment from ZhMZ, you should know: the burner, when starting, creates noise - cotton. In some modifications it is minimized - it turns on more smoothly.

The chimney is installed outside the residential premises. The diameter of the chimney is 14 cm. Under its pipe there is a container for collecting soot, which needs to be cleaned from time to time.

Important! A household heating boiler can only be connected by gas service specialists - independent connection is excluded.

Floor-standing devices are installed in separate rooms, on the lower level of the building. The new equipment comes with instructions, connection diagram and technical data sheet.

Gas water heater valve device

In order to make it easier for home craftsmen to restore the functionality of a gas boiler, in particular when there is a malfunction of the gas valve, we will consider the design of the unit and the technical nuances of diagnostics and repair.

But, if you do not have experience in disassembling geysers and relevant knowledge on the topic, then it is preferable to invite a specialist for repairs and maintenance.

A device called a gas solenoid valve performs an important function of a gas water heater - controlling the flow of the fuel component (natural gas). The picture below shows a common version of the design of the control unit, which includes the valve.

In fact, the control unit is a two-stage mechanism, the first stage of which is the gas solenoid valve (1). The second stage is a mechanical device that provides adjustment via a manual control rod (2).

The design of the gas valve is quite simple - it is made on the principle of an electromagnetic traction device, which are used as part of a wide variety of devices and instruments. If you dismantle this component from the control unit diagram, for which it is enough to unscrew a couple of screws, the valve part, which is attached to a spring-loaded metal rod, will appear before the eyes of the master.

As you can see from the picture, the design consists of a skirt body , which includes a valve part - a membrane and an electromagnetic module . The valve part is mounted on a metal rod , spring-loaded for the return stroke to the “closed” position.

When voltage is applied to the electromagnet coil, the metal rod moves upward under magnetic influence and moves the membrane away from the passage hole of the skirt. This opens the gas passage towards the manual valve and further to the burner.

Principle of operation

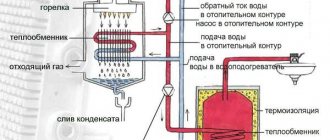

The supply of cold water is carried out without forced circulation - by gravity. That is why the gas appliance is placed at the very bottom of the heating system. It happens that you even have to artificially lower its location.

The burner is ignited through the igniter. A prerequisite for combustion is draft. To control it, there is a special sensor. When the traction is lost, the gas supply automatically stops. If there is insufficient vacuum in the chimney or it is blown out by the wind, the gas is also turned off and the igniter goes out. The emergency situation is prevented.

The heating level of the coolant is controlled by a thermocouple. When the coolant heats up above the set value, the flow of fuel stops - the burner turns off. As soon as the coolant temperature reaches a critically low value, the gas begins to flow again and the burner lights up.

Such a control system cannot ensure a stable temperature in the room, but the equipment is able to function under any circumstances: without electricity, at low gas pressures, in severe frosts.

Automation system tasks

- Blocking when traction disappears.

- Switches off when the coolant heats up to a critical value and switches on when it cools down.

- Blocking gas flow at low or pulsating pressure, as well as in case of thermocouple failure.

The main advantage of AOGV is the possibility of use in gravity heating systems. Expansion tanks are installed in them, and circulation pumps are simply not needed. It is advisable to equip gravity flow systems with large volume radiators.

Ignition transformer

This element supplies the burner with a current discharge (spark), which is necessary to ignite the fuel. In addition to other elements that directly affect the operation of the unit, the component can also fail. As a result, all automation will work, but fire will not appear, since there is no source of ignition.

How can you quickly check the ignition transformer of a gas boiler for functionality? Just. You need to make a few simple movements:

- Through a special window, see whether the discharge is going on or not.

- Using a tester, check the voltage coming out of the controller during the ignition attempt. A figure falling within the range from 187 to 235V is considered normal.

- If a problem is detected, you need to disconnect the power from the transformer and connect it back.

- Check again.

Any gas boiler is equipped with many safety elements and sensors that allow you to monitor the correct operation of the unit. In the event of situations that clearly threaten human life, the system completely shuts down the installation.

In case of any breakdown, most owners of a gas water heater call a specialized service technician. However, services usually come with financial costs, right?

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you must connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

How to test a thermocouple using a multimeter

In private houses and apartments where gas is installed, in addition to kitchen stoves, gas boilers are often found to provide hot water supply and heating. Most heating and household gas appliances have a thermocouple in their design, which protects the device from overheating, which in turn ensures the safe operation of such equipment.

What is a thermocouple?

The thermocouple design includes two dissimilar conductors that are in direct contact with each other at one or more points (in rare cases, they are connected by compensation wires). When a temperature change occurs in the sensor area, voltage is created inside the device.

This ensures temperature control and overheating protection. Thermocouples can also be used to convert thermal energy into other types of energy, including electric current.

The main characteristics of a thermoelectric converter directly depend on the material from which they are made. Any temperature sensor made from two different metals will produce an electrical potential when exposed to temperature, but the response temperature will be different for each combination of metals. Due to this, thermocouples differ in their level of temperature control.

There are many types of thermostats, but their resistance to corrosion will be important. In those models of thermoelectric converters where the temperature sensor is located at a sufficient distance from the measuring device, expansion wiring is used in the design to connect them, thereby reducing the cost of the device.

Most thermocouples are standardized during production to a temperature standard of 0 degrees Celsius. Most manufacturers use electronic cold solder compensation technologies, which correct temperature differences at the device terminals.

Also, due to special electrical engineering, it is possible to minimize the deviation of other characteristics, which makes thermocouples more accurate and measurements as close to reality as possible.

Thermoelectric converters have become widespread in both household and industrial heating equipment. These simple yet useful devices can be found in the design of geyser, kitchen stove, industrial furnace, exhaust gas turbine, diesel engine, etc.