Improper drainage - what you need to know?

Installing a sewer system is a very responsible undertaking. Mistakes made during sewer installation can cause many problems in the future. First of all, these are frequent blockages, which are not so easy to deal with. The second is the unpleasant smell from the sewer, noise when draining water, and much more.

When installing a sewer system, you should know where to lay the pipes, what slope angle they should have, and how best to position the siphon. Often, ignorance of the basics and rules leads to many errors, which, in turn, threaten a lot of alterations in the future.

Vacuum valve for sewage systems

The opportunity to enjoy all the benefits of civilization would be incomplete without a modern drainage system.

The first sewer networks rid city streets of sewage and unpleasant odors accompanying human waste. But there is no limit to perfection. Sanitary technology keeps up with the times, new technologies and equipment make our lives easier and more comfortable. These new products also include a vacuum valve, which makes it possible to make intra-house sewage simpler and more perfect.

Materials for organizing ventilation

In the modern world there are a lot of materials that can be used as sewer pipes and for ventilation.

For years, fairly massive and heavy cast iron pipes served as the main material. In multi-storey buildings that were built during the Soviet Union, the use of cast iron or steel systems is quite common. Most often, this structure is repeatedly damaged, or rather damaged by corrosion. It is recommended to replace such pipes immediately. As a last resort, carry out local repairs using modern materials that can combine pipes of different diameters. There are a lot of disadvantages when using cast iron:

- Difficult to install.

- Additional loads on the floor.

- Requires regular maintenance.

- Subject to corrosion.

- High price.

All this together caused quite a lot of inconvenience, which was eliminated when plastic pipes were released for sale.

- The first thing I would like to note is that this material is absolutely not susceptible to corrosion, which increases the service life tens of times.

- Each pipe, as well as each corner, is equipped with rubber cuffs that prevent water and unpleasant odors from escaping.

- Any design is easy to assemble, which greatly reduces installation time.

- Use minimal effort for maintenance. If the structure is not disassembled, then when assembled it can last more than 10 years. Important. For long-term use, cleaning is necessary. To do this, it is enough to use one of the chemicals, of which there are quite a lot on the shelves of household chemical stores. Since the procedure is performed quite rarely, it is not worth saving on it. It is better to purchase a high-quality product that can properly remove plaque.

- The cost of plastic is much lower than the cost of metal, making it even cheaper to design everything from scratch.

The ventilation system uses the same pipe as the main riser. That is, the diameter of the pipes must be completely consistent. In addition, the connection will be much easier.

Why is a vacuum valve needed in a sewer system?

The vacuum valve is a special automatic device designed to ensure normal hydraulic conditions and tightness of the building's sewage system.

All plumbing fixtures are equipped with special water seals in the form of a V-shaped siphon. Thanks to them, the device always has a certain amount of liquid left, which does not allow gases and unpleasant odors formed in the sewer to enter the premises.

However, during the “drain-flush” process, the waste liquid, having filled the entire cross-section of the pipeline, creates a kind of “piston” in it. As it moves through the pipe, a vacuum zone forms behind it, literally sucking water out of the siphon.

It is to compensate for these pressure fluctuations that the vacuum valve serves.

Being installed on such a sewage system, it will automatically open when the pressure in the pipeline decreases and equalize it with atmospheric pressure. Now, even with the simultaneous operation of several plumbing fixtures, discharge and “breakdown of the siphon” are practically impossible.

Vacuum valves are recommended for use in the following cases:

- If it is impossible to install a ventilated sewage system in a building due to its design or other features.

- When connecting several devices at once to a long horizontal section and if it is possible for them to operate simultaneously.

- If the installed plumbing equipment is located at a significant distance from the ventilated riser.

- For installation of local sewage systems for low-rise buildings.

- In order to save materials.

Note! Hermetic shut-off of the valve, especially in the event of excess pressure in the pipeline (in case of blockage), makes installation possible at any, even the lowest point of the network.

Harm from sewer gases

If sewer is blowing from the sink, you need to react immediately. This is not just an unpleasant situation, the problem is much deeper and more dangerous. Biogas is a mixture of several components, including:

Each of these gases is harmful to humans in its own way. It is necessary to take into account that the mixture has its own properties that are more dangerous for people. Biogas is heavier than air and tends to collect above the floor of rooms. The first animals to suffer from this are cats and dogs.

In addition to being harmful to health, biogas is dangerous in terms of fire. It is flammable and can explode at a certain concentration. Accumulating at floor level, it can ignite from any spark. The consequences of this can be very sad. The flow of gases does not always occur quite intensively; they often penetrate in small portions. However, even small amounts are dangerous for people, as they contribute to headaches, interfere with concentration, and cause general malaise. It is unlikely that you can directly die from them, as some sources claim, but less intense exposure is undesirable.

Valve device

The sewer vacuum valve is a cylindrical shut-off and control device made of plastic. Despite the importance of the functions it performs, it is a very simple product and consists of the following parts:

- Housing (has a specially shaped partition separating the receiving chamber with a side window from the working one).

- Protective cover (attached to the housing to prevent debris and foreign objects from entering the receiving chamber).

- A rod with a damper (installed above the dividing partition, serves to automatically respond to pressure differences in the network).

- Rubber gasket (mounted under the damper rod, designed for its tight seal and shock absorption).

The valve is designed for installation in a socket connection.

When installing on plastic (PVC) pipelines, a standard seal is used; for a cast iron sewer pipe, a special adapter is required.

Products from some manufacturers are equipped with a rubber membrane instead of a plastic rod. There are two main standard sizes of valves in accordance with the connecting diameters: 50 and 110 mm.

Operating principle of the aerator

The valve actuation mechanism is simple; it can be classified as a direct-acting device, that is, the system parameters directly affect the valve stem. The working chamber of the aerator is directly connected to the pipeline, and the pressure in them is the same.

Due to the special design of the aerator valve body, the rod is located above the seat hole in the partition separating the receiving and working chambers. At the same time, it can move from the seat to the upper part of the working chamber, opening free communication between the chambers.

When the pressure in the sewer system is equal to atmospheric pressure, the valve rod is pressed by its own weight to the seat hole and closes it. The chambers are isolated from each other, the escape of gases and the spread of accompanying unpleasant odors is impossible.

When a vacuum occurs in the sewer pipeline (due to flushing the toilet or emptying the bathtub), the rod, under the influence of higher atmospheric pressure, moves upward to a lower zone.

In this way, the chambers are combined into one whole, the pressure in them and, accordingly, in the pipeline, is compared to normal. Breaking the siphon becomes impossible.

Note! The valve has high sensitivity and is triggered “to open” when the vacuum in the pipeline is more than 5 mm of water. pillar

Reasons for appearance

Let's look at why an air lock forms in the sewer. Most often, the cause of its appearance is a combination of several factors:

Any of these factors can cause an air lock. However, there must be one more, most important reason - a dome-shaped section of the system where air will constantly be present. This is a unit that is the complete opposite of a plumbing siphon. The bend is vertical, but surrounded by liquid, and there is air in the knee. Often the existence of such sections becomes possible only in lines where there is a water seal. The open channel allows the air lock to escape from the elbow as it is pushed out by the flow of fluid. However, this is not a mandatory condition. Difficulties with air outlet may also occur in an open system if the dome is large enough. The plug in the sewer pipe is maintained regardless of contact with the outside atmosphere, since the bend is never filled with fluid flow.

Sometimes it is enough to break the rules of system assembly. A section of horizontal pipe laid at a negative slope (or even horizontally) can cause an air bubble to appear. The flow of water cannot push it out, since there is no slope in this place. But all the conditions arise for the settling of suspended particles and the formation of a blockage.

Valve selection criteria

When selecting a valve, it is necessary to take into account all the features of the newly installed or reconstructed sewerage system. The type, size and number of vacuum valves directly depends on its length, diameter, slopes, number of devices, and the likelihood of their simultaneous use.

When selecting a vacuum valve, consider the following:

- design features of the valve. Different models can be equipped with a membrane or a rod;

- place of its installation. It is necessary to consider where the valve is installed: indoors or outdoors. Whether the installation will be open or hidden, take into account the likelihood of contamination and environmental influences;

- diameter of the pipeline at the installation point. The devices are produced for socket connection of two diameters 110 and 50 mm;

- price and quality of the product. Products from Russia and Germany have proven themselves well on the market. However, with comparable quality, domestic products are three times cheaper.

Note! According to experts, valves with a stem are more reliable, more durable and easier to operate and maintain.

Installation: step by step instructions

Installation work is carried out in two stages: preparation for installation, and making connections.

First stage (preparatory):

- Determination of connection points and the required number of valves.

- Procurement of necessary materials and equipment.

- Preparation of the workplace and tools.

Second stage (main):

- Make the necessary switches.

- When working on an existing pipeline, a tap is made at a selected point and an adapter is installed. Installation on newly installed sewer systems is carried out on the sockets of vertical risers or through tees on horizontal sections.

- Clean the bell and valve body insert from dirt.

- Install the sealing ring into the groove on the socket.

- If the valve is mounted on a cast iron pipeline, a special adapter is installed in the socket.

- The housing insert is lubricated with glycerin or soap solution for better sliding.

- Then carefully, without distortions, insert it into the socket of the riser or tee until it stops.

- Check the quality of the connection of parts for leaks. If necessary, the pipeline together with the installation is fixed with a clamp or supported on a bracket.

Danger of air bubbles in the pipeline

Water hammer can rupture a pipe.

Bubbles, especially large ones, can destroy even strong elements of the pipeline. The main troubles they cause to owners of private houses:

- They accumulate in the same areas, leading to breakdowns of pipe sections and adapters. They also pose a risk for turning and twisting pipe sections where air is trapped.

- They break the water flow, which is inconvenient for the user. The taps “spit out” water all the time and vibrate.

- Causes water hammer.

Water hammer leads to the formation of longitudinal cracks, which causes the pipes to gradually collapse. As time passes, the pipe breaks at the point of cracking and the system stops functioning. Therefore, it is important to equip additional elements that allow you to quickly get rid of dangerous bubbles.

Ventilation of the sewer riser

However, I will have to start with a small lyrical digression. To understand why a sewer vacuum valve is needed, you need to have a good understanding of the processes occurring inside the sewer riser.

Full-time job

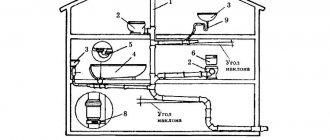

- All risers are brought out by the builders beyond the flat or pitched roof . As with any other vertical pipe, a constant draft occurs in the riser. Foul-smelling sewage fumes are drawn outside the home and dispersed into the atmosphere;

The outlet of the vent pipe is made 20 cm above the roof level.

The thrust increases in windy weather (Bernoulli's law: static pressure in a moving flow is inversely proportional to its speed) and when warm water is drained into the sewer (heated air rushes upward).

- During a volley discharge of water (draining a toilet tank), a flow rushes down the riser, completely or partially blocking its entire cross-section . The flow forces the air filling the riser into the sewer through an outlet or into the basement through one of the open tees. A vacuum is formed in the upper part of the riser, which is compensated by air suction through the fan pipe - a ventilation outlet on the roof.

Below the water front is a region of high pressure, above is a region of rarefaction.

Role of Vacuum Valve

Now let's do a little thought experiment - we'll turn off the fan outlet of the riser. What happens when the toilet flushes?

- A vacuum will arise in the upper part of the riser;

- To compensate for this, air will begin to be sucked in through plumbing fixtures with a minimum height of water seals - washbasins and sinks;

- In this case, the water seals will be torn off - part of the water from the siphons will flow into the riser;

- The unavoidable draft that arises in the vertical pipe will begin to transport air, along with the accompanying moist fumes and odors, to the bathrooms and kitchens of the apartments on the upper floors.

Breaking the water seal will create a channel for unpleasant odors.

Now let’s install a vacuum sewer valve instead of a drain pipe - a simple device that allows air to flow in one direction and blocks its movement in the opposite direction.

What it is

An air lock in the sewer is one of the types of technical blockage in the pipeline. Most often, this is a bend (“hump”) in a section of the pipeline within which air collects. Waste liquid cannot pass through this unit, especially if it carries a large amount of organic matter, suspended matter or other components. They accumulate in front of the problem area, forming a continuous blockage. At the same time, there are no mechanical obstacles to the passage of wastewater, only an air bubble.

Sometimes a complete blockage does not occur; the drainage gradually passes through the channel. However, you have to wait until the waste comes out of the toilet flush, the dirty water comes out of the kitchen sink or from the bathtub. All attempts to push the liquid using a plunger or cable are unsuccessful, since you have to act blindly, not knowing the exact cause of the problem.

Until the sewer system is repaired, the air lock persists and continues to cause a lot of inconvenience. By itself, it will not disappear anywhere, since there is a physical phenomenon taking place here. As long as there are conditions for its existence, the defective area will exist. Over time, the problem will increase due to accumulating waste, fatty deposits, and organic matter. A section appears with a reduced cross-section of the channel, where the drains lose speed. Suspended particles settle to the bottom, little by little forming a regular clog. It is cleaned, but since the air bubble has not disappeared, the problem occurs again.

What is the function of a sewer air valve?

Quite often, when several plumbing fixtures are used simultaneously, an unpleasant odor escapes from the wastewater disposal system into the room. To solve this problem, an air valve for sewerage is installed in the drainage structure. This simple device effectively neutralizes pressure drops in the system, eliminating the cause of gas penetration through siphon water seals.

Hydrodynamics for sewer cleaning

If the above cleaning methods do not help and the water also slowly flows into the collector, creating unpleasant odors in the system, you can invite specialists to flush the collector using a hydrodynamic method. In this case, special equipment is used that supplies water to the system under high pressure. Thanks to the high power of the supplied jet, the collector is cleared of all plugs and blockages. It is fashionable to clean pipes with a diameter of 5 to 100 mm in this way.

The official application from the bookmaker 1xBet is absolutely free and you can click on the link and place bets on sports.

Important: you can also use a similar technology for cleaning the system in an apartment. But it is necessary to invite specialists who have the appropriate equipment.

The reason for the penetration of unpleasant odors from the sewer system

To understand the principle of operation of the fan valve, we will briefly analyze the operation of a household wastewater disposal system using the example of an ordinary apartment in an apartment building.

All plumbing fixtures (sink, sink, toilet, shower, automatic washing machine) are piped to one sewer riser, the lower part of which is connected to a collector that discharges wastewater to the central sewer system.

There are two main design options for internal sewerage systems:

- The sewer riser can go into the attic or go above the roof, remaining open. This design maintains atmospheric pressure inside the structure.

- There may be no fan riser (unventilated sewer).

What happens if the top of the drain pipe is frozen, clogged with debris, or the house has an unvented drain?

When water is drained, a vacuum is created in the system, which draws water out of the “weak” siphon water seal, creating popping noise. As a result, unpleasant odors from the wastewater system penetrate freely into the room. The sewer valve balances the pressure in the system, eliminating the possibility of water seals breaking. You should know that in specialized literature, a sewer ventilation valve can be called differently: fan valve, vacuum valve, air check valve, aerator.

Air pipe obstruction

Fan risers most often become clogged due to birds, nests, and leaves getting into them. The sounds in the sewer lines will be similar to those that occur when the water seal breaks.

To clean the air channel, you will have to free the outer edge of the pipeline on the roof from the nets and caps. Then a special extended plumbing cable is passed inside. With its help, you can remove even deep-seated debris that impedes the free movement of air masses.

In winter, noise from the sewer can also be associated with insufficient air inflow and outflow. Ice freezing inside the drain pipe is a consequence of condensate settling and narrows the pipe through which gases are discharged. Warming up the fan riser with hot water will help restore air exchange.

As an alternative to this method, the use of chemical solvents that are safe for the atmosphere can be considered. It is worth considering that each type of pipe requires the use of certain means. Incorrectly selected chemicals will make the plastic brittle and lead to its destruction.

Design and principle of operation of the device

The vacuum valve-aerator consists of the following elements:

- A housing with an opening through which air enters the system. Case material – PVC.

- A cover that provides access to the internal elements of the device.

- Rod with membrane.

- Rubber seal that ensures the tightness of the structure.

The operating principle of a vacuum valve for sewage is extremely simple. When the pressure in the riser is equal to atmospheric pressure, the valve membrane is pressed tightly against the body of the device. The sewer system is sealed. If a vacuum of more than 0.007 kg/cm 2 occurs, capable of breaking the water seal, the membrane opens the passage for atmospheric air into the system, the pressure is equalized, and the valve closes.

The design feature of the ventilation valve for sewerage is the location of the membrane. In operating condition, the device allows air to pass in only one direction: from the room to the sewer system. The valve operates almost instantly. With proper calculation and compliance with installation rules, the use of these devices guarantees protection of the fan system from pressure drops.

Freezing pipes and other factors

The randomness factor cannot be foreseen or prevented. Even if all residents follow the rules for operating the system, problems still occur. The list opens with a bird that got into the ventilation shaft of the sewer system. As the volume of air entering the toilet decreases, a distinct gurgling sound is heard when flushing. Only an experienced plumber can remove the bird.

Before disassembling the pipe, place a container

The second common reason is frozen pipes.

Events develop as follows:

- An imbalance is created when the air temperature is low and the water temperature in the tubes is high;

- Frostbite on the internal surface of the system gradually increases;

- The plug forms within 4-5 days;

- It can only be removed while on the roof.

Even if you follow all the rules for operating the system, it is not always possible to avoid problems. If the results of the inspection indicate that it is possible to exclude a situational factor, for example, a traffic jam caused by neighbors, then you need to immediately check the factor of chance.

Specifications and manufacturers

The main technical characteristics of the air check valve are:

- outer diameter, which is selected according to the cross-section of the sewer pipeline;

- air flow per unit time.

The modern market of plumbing equipment offers drain valves of three sizes, corresponding to the diameter of the drain pipeline: 50; 75 and 110 mm. The use of air valves for sewerage in systems with a pipeline of smaller diameter (for example, 32 or 40 mm) requires the use of special adapter pipes. Some models are initially equipped with a stepped pipe, which allows the device to be used in various sewer systems. Valve performance varies depending on model and installation location. Devices with flow rates from 7 to 37 liters of air per second are offered for sale.

Removing grease and soap residue

Roetech K-87.

Natural cleansing of a cesspool is possible if fats and soap scum do not get into it along with the drains. At outside temperatures they harden and clog the pores of the soil and sewer pipes.

The liquid does not go through the formed film into the soil, which lacks absorbent capacity. The problem appears sooner or later if the sewer system is not equipped with a grease trap.

They are combated by erosion using biological or chemical means.

Preparations that process soap and fat well:

- Roetech K-87 - the bottle is designed for 1 m³ of wastewater, decomposes fats, soap and organic matter;

- Drainage Comfort from BIOFORCE - use 1 sachet per 10 liters of water to clean clogged sewer pipes;

- Doctor Robik 809 - frees the pit and pipes from soap deposits.

In practice, cleaning using biological products is carried out as follows:

- The liquid is pumped out of the pit and filled with clean water. If it is from a city water supply, let it sit to get rid of chlorine.

- Drugs in the dose recommended by the instructions are poured through sinks and toilets.

- Start using sewerage. Monitor whether productivity has improved. If necessary, repeat the cleaning.

Biological products along the way decompose deposits in the pipes and continue to act in the tank. Microorganisms that break down fats and soap are periodically introduced into it.

Advantages and disadvantages

The valve for the sewer riser has many advantages, among which are:

- Preventing situations of water seal failure, which provides protection against the breakthrough of unpleasant odors from the plumbing system into the room.

- The ability to create a sewer system without installing a drain pipe, which significantly simplifies the design and reduces the cost of the wastewater disposal system.

A serious drawback of this device is the possibility of seal failure due to natural wear of the seal and contamination of the membrane.

It should be understood that installing a sewer ventilation valve in the drainage system of an apartment building requires an accurate calculation of the number of devices based on their throughput.

What to do if a septic tank with a closed bottom silts up

The bottom part also silts up in a septic tank with a sealed bottom. Precipitation reduces the usable volume. The phenomenon occurs when the activity of bacteria is greatly reduced due to their insufficient number. The number of colonies decreases under unfavorable factors.

The main ones:

- There is a high concentration of chlorine, alkali and acids in wastewater, which destroy living microorganisms. Substances enter together with preparations for cleaning, washing and washing.

- Fresh wastewater is rarely discharged - there is not enough food for bacteria. If wastewater from the toilet or kitchen is sent to another treatment facility, and water enters the pit only after washing, bacteria will not survive in such conditions.

- The structure is poorly insulated, the temperature of the liquid in it is less than +4ºС. Constantly draining warm water saves the situation, but if this does not happen, the bacteria die.

When the consistency of the wastewater resembles sour cream without separation into liquid and solid fractions, microorganisms cannot cope with their task. Artificially grown ones are introduced, which are contained in biological preparations, such as Doctor Robik 509, Septic Shock Bioforce, Vodogray, Microbec, etc. Those intended for cesspools are used.

If dietary supplements do not help, then the products will not cope with the task. It is necessary to limit the use of household chemicals. Bacterial preparations process sludge and fats, even toilet paper, producing compost and liquid. As a result, there is less waste and the pit is pumped out less frequently. After the septic tank is restored to working order, biological products are regularly introduced into it.

Septic tank with a closed bottom.

If a drainage pump is available and there is running water, use the flushing method. Pump out liquid and sludge. Connect a hose from the water supply and direct the stream to the sediment. The water washes them away, and the contents are pumped out again. The option gives results if the sludge has hardened slightly.

In addition to these methods, chemical methods are used. In a pit with an open or closed bottom, nitrate oxidizers and ammonium compounds can be used without fear of consequences. The use of formaldehyde is allowed only in a sealed cesspool.

When these drugs get into the ground, they destroy all plants within a radius of 10 m.

Air valve for sewerage: installation rules

The ventilation valve is installed on the vent riser or on a specific device. Depending on the diameter, the device can be placed as follows:

- The valve with a diameter of 110 mm is intended for installation at the top point of the sewer riser. When installing, it is important to ensure that the valve is located 500 mm above all drainage points.

- The vacuum sewer valve with a diameter of 50 or 75 mm is intended for installation after siphons of plumbing fixtures.

The design of internal sewerage systems is regulated in accordance with SP 30.13330.2012

Installation of a ventilation valve requires compliance with a number of rules.

- The valve must be easily accessible for repair and maintenance.

- Correct operation of the device requires free access of air to the membrane.

- If installation is intended to be on a drain pipe, then the temperature at the place where the valve is installed (for example, in the attic) should be above zero.

If drainage in a private house is carried out into a septic tank, then the presence of a drainage pipe for ventilation of the drainage system is mandatory. An air valve for a septic tank is installed to supply air to the aerobic bacteria involved in processing sewage. A ventilation valve is installed at the top point of the drain pipe as additional protection to prevent the water seals from breaking.

In the residential premises of a multi-storey building, an air sewer valve is installed on any vertical section of the drainage system. To do this, a tee is built into the horizontal structure, into which a vertical pipe with a valve is installed. Installation is carried out as follows: if there is a drain ladder - 350 mm above the floor level; in the absence of a drain - 100 mm above the outlets from plumbing fixtures. The distance from the device to the nearest siphon should not be less than 200 mm.

Why does a cesspool fill up quickly after pumping?

The design of the cesspool assumes that wastewater penetrates the soil through the bottom or its walls. Over time, the liquid does not seep into the ground and fills the entire hole. This happens because the soil has lost its filtering ability. There are several reasons that caused this.

Solids accumulate at the bottom of the cesspool. They must be removed periodically after pumping out the liquid. If this is not done, a dense layer will form, blocking the path of liquid runoff into the soil.

Another probable reason for the formation of a buffer between the liquid and the soil is the low activity of bacteria that do not have time to process organic matter.

This happens in several cases:

- little organic matter in the pit;

- a lot of chemicals harmful to microorganisms are discharged;

- The drains are cold, the temperature is not conducive to bacterial activity.

Tire cesspool.

A common reason why a hole quickly fills with liquid is due to the high content of soap scum and grease in the drains. The substances form a dense film on the bottom and walls, preventing liquid from passing through. This sediment even clogs sewer pipes, preventing drainage.

A preventative measure that prevents an undesirable phenomenon is the installation of grease traps. Folk remedies include weekly flushing of pipes with boiling water or soda and vinegar.

It may be that the volume of the receiver is not sufficient to accommodate all the wastewater. This happens when calculations are incorrect. According to the rules, the septic tank must accept water flow for 3 days. If the capacity is less than the volume of wastewater received during this time, it does not have time to go into the soil. Perhaps the number of residents has been added or additional plumbing fixtures have been installed, but the volume remains the same.

The next reason for the tank to overflow is due to errors in the construction of the pit and poor insulation. If the bottom of the cesspool is above the freezing point of the soil, in winter a crust forms on it, which does not allow liquid to pass through.

Ice may appear in an uninsulated pipe and interfere with the movement of drains.

Stages of installation work

Recently, plastic pipes of various diameters have been used to create indoor sewer systems.

Based on this, the material for air valves is selected - PVC or polypropylene. Let's consider installing a ventilation valve behind the toilet siphon:

- Dismantle the horizontal section of pipe on which the ventilation valve is supposed to be installed.

- Install the aerator in a vertical position in the outlet or tee.

- Install the tee into the pipeline section.

The tightness of the connections is ensured by rubber seals, which must be installed in the connected elements of the system.

What does the speed of the current depend on?

The flow rate through the collector depends on two components:

- hydraulic radius;

- slope of sewer pipes.

In practice, the flow of wastewater moves at a non-uniform speed: in the middle of the flow they move at a higher speed than in the bottom part and at the pipe walls.

For this reason, sediments form in the collector. The larger the pipe diameter, the higher the bottom velocity should be.

Minimum speed (critical or self-cleaning) - the lowest permissible speed at which self-cleaning of sewer pipes is ensured.

For domestic sewerage systems, the minimum speed values are as follows:

- 0.7 m/s – for pipes with a diameter of 150-200 mm ;

- 0.8 m/s – for pipes with a diameter of 300-400 mm .

Self-cleaning flow rates of waste liquids are ensured by the purpose of pipe slopes.

Read all about pipe slopes and a lot of other useful information when installing a septic tank in a country house in the article Construction of a septic tank from concrete rings, create your own autonomous sewage system.

Recently, bidets have become increasingly popular in restrooms. What is it, are there toilets with a bidet function and what types of bidets are there? Read here, the most important and interesting information.

Additional Security Measures

A possible breakdown of water seals is far from the only problem that arises during the operation of an in-house wastewater disposal system.

To provide additional protection against flooding, check valves are installed on devices in tandem with ventilation valves. These devices differ in the design of the working mechanism:

- Ball. The shutter element is a movable ball that blocks the flow through the valve during the reverse movement of wastewater.

- "Clapperboard." The sewer firecracker valve is equipped with a plug, the action of which coincides with the direction of movement of wastewater. If there is no flow, the valve is closed. When the wastewater flows back, the plug takes its place in the valve “seat”, reliably blocking the passage hole.

- Disk. A steel disc inserted into a rubber holder acts as a locking mechanism for the check valve of this design. When sewage flows back from the sewer system, the disk moves and blocks the passage opening of the device.

Among the types of check valves presented, the most popular are “clackers” (not to be confused with the anti-clap valve installed on a car’s gas pump). When installing them in a sewer system, follow the manufacturers' recommendations, since various types of valves are intended exclusively for horizontal or only vertical sections of the pipeline.

The principle of operation of the air valve in the sewer - video

Reasons for the appearance and elimination of an air lock in the sewer

We have an air lock in the sewer, how can we eliminate it and prevent it from appearing again? Similar questions often appear on thematic forums or other public pages dedicated to the operation of drainage systems.

The problem is quite rare, but this only makes it more complicated - few people understand the reasons for its occurrence. Eliminating such a malfunction is not easy - you must first find the place where it appeared, find out the cause, and only then correct the configuration of the drainage line. The problem will not disappear on its own; it must be solved immediately. Let's figure out together how air pockets appear and what to do about them.

An air lock in the sewer is one of the types of technical blockage in the pipeline. Most often, this is a bend (“hump”) in a section of the pipeline within which air collects. Waste liquid cannot pass through this unit, especially if it carries a large amount of organic matter, suspended matter or other components. They accumulate in front of the problem area, forming a continuous blockage. At the same time, there are no mechanical obstacles to the passage of wastewater, only an air bubble.

Sometimes a complete blockage does not occur; the drainage gradually passes through the channel. However, you have to wait until the waste comes out of the toilet flush, the dirty water comes out of the kitchen sink or from the bathtub. All attempts to push the liquid using a plunger or cable are unsuccessful, since you have to act blindly, not knowing the exact cause of the problem.

Until the sewer system is repaired, the air lock persists and continues to cause a lot of inconvenience. By itself, it will not disappear anywhere, since there is a physical phenomenon taking place here. As long as there are conditions for its existence, the defective area will exist. Over time, the problem will increase due to accumulating waste, fatty deposits, and organic matter. A section appears with a reduced cross-section of the channel, where the drains lose speed. Suspended particles settle to the bottom, little by little forming a regular clog. It is cleaned, but since the air bubble has not disappeared, the problem occurs again.

Air drain valve

Sometimes there is a situation when a smell from the sewer seeps into the bathroom or toilet. In normal condition, it is cut off by water seals. This is a certain amount of water that remains in the bend of the siphon and blocks access to the apartment for gases from the sewer. Sometimes, when several plumbing fixtures are operating at the same time, these valves break - a sharp change in pressure occurs, which pushes out water, and sewer gases break into the room. To prevent such situations from arising, install an air valve for the sewerage system. It neutralizes most of all air pressure changes in the system.

The most common types of air valve for sewerage

Reasons for appearance

Let's look at why an air lock forms in the sewer. Most often, the cause of its appearance is a combination of several factors:

Any of these factors can cause an air lock. However, there must be one more, most important reason - a dome-shaped section of the system where air will constantly be present. This is a unit that is the complete opposite of a plumbing siphon. The bend is vertical, but surrounded by liquid, and there is air in the knee. Often the existence of such sections becomes possible only in lines where there is a water seal. The open channel allows the air lock to escape from the elbow as it is pushed out by the flow of fluid. However, this is not a mandatory condition. Difficulties with air outlet may also occur in an open system if the dome is large enough. The plug in the sewer pipe is maintained regardless of contact with the outside atmosphere, since the bend is never filled with fluid flow.

Sometimes it is enough to break the rules of system assembly. A section of horizontal pipe laid at a negative slope (or even horizontally) can cause an air bubble to appear. The flow of water cannot push it out, since there is no slope in this place. But all the conditions arise for the settling of suspended particles and the formation of a blockage.

Where to put

When installing, the air valve for the sewer must be placed 20-30 cm above the axis of the main sewer pipe. In two and three-story private houses, the device is installed on the top floor.

It must be installed in a place where splashes or dirt will not get on the membrane. The performance of the device depends on how clean the membrane is. Salt, grains of sand, pieces of garbage, etc. will appear on it, it will not be hermetically pressed against the body, and a stench will begin to seep into the room. By the way, if you observe this, clean or change the membrane for now.

You need to find a place so that air can flow freely to the membrane. This is the basic condition for normal operation. When 1 liter of water falls down the drain, it can carry 25 liters of air with it. Therefore, air access must be free.

If you decide to install a ventilation valve on the sewer, you need to know that sometimes during operation it can make “grunting” sounds - the membrane sucks in air when a slight vacuum occurs in the pipe. Not all models behave this way, but there are such complaints. So it’s better to find a place where these sounds (if any) will not interfere.

In apartments

If we are talking about an apartment in a multi-story building, then you can install an air valve on any vertical section of the pipeline. To do this, you can build a tee into the system, install a pipe vertically upward into it, and place a ventilation sewer valve on it. This will not solve the problem of ventilation of the entire riser globally, but your particular site will work without problems.

It is advisable to place it above the main sewer pipe

In a private house

If we are talking about a private house, then most often they want to install an air valve for the sewer system so as not to remove the drain pipe through the roof. The correct passage of a pipe through the roof is a complex matter, and it is not easy to achieve its tightness. This is often the reason why people don't want to make holes in their roofs. Many people also don’t like pipes sticking out above the house. In principle, you can take the ventilation pipe into the attic and place a sewer ventilation valve on top. In this case, the riser will be unventilated. But this is far from the best solution. At least that's what the plumbers say. They argue that for normal operation of a septic tank, ventilation is needed to provide bacteria with oxygen.

If your wastewater treatment takes place in a septic tank, you cannot do without a drain riser; you will have to remove it through the roof. If hydraulic valves fail periodically, it will be possible to install an air valve for the sewerage system as an additional element of the system - on the highest floor (it does not need to be installed in the attic).

If you have an autonomous sewage system based on autonomous treatment stations, you can try to make it unventilated - put the pipe into the attic, and put a vacuum valve on top of it. The attic must be unused, of large volume, with good ventilation. The smell will be present and it will need to be removed outside somehow. If the attic is cold, the pipe must be insulated (but not the valve).

Where to install an air valve for sewerage in a private house

And all the same, plumbers and designers insist that in private houses an air valve for the sewer system should be installed only as an addition to the drain riser.

Air lock in the sewer: how to eliminate it, what to do, why it forms

We have an air lock in the sewer, how can we eliminate it and prevent it from appearing again? Similar questions often appear on thematic forums or other public pages dedicated to the operation of drainage systems.

The problem is quite rare, but this only makes it more complicated - few people understand the reasons for its occurrence. Eliminating such a malfunction is not easy - you must first find the place where it appeared, find out the cause, and only then correct the configuration of the drainage line. The problem will not disappear on its own; it must be solved immediately. Let's figure out together how air pockets appear and what to do about them.