The Shingle architecture movement appeared at the end of the 19th century in New England, when designers and architects decided to move away from the complex and sophisticated Victorian style to a simpler and more laconic style. At this time, many craftsmen began to use tiles in the decoration of walls and roofs.

These days, this material has become widespread, and any homeowner can choose cladding panels of different sizes, shapes, orientations and textures for their cottage to give the building expressiveness and authenticity.

When installed correctly, this coating requires less maintenance. Today we will tell you about the various types of roofing building materials used for cladding unusual houses .

Cold rolled steel

This raw material has excellent performance characteristics, while adding aesthetic appeal and creativity to the appearance of the mansion. It is excellent for buildings located in harsh terrain. It can also be noted that the tiles are similar in appearance to wood that has blackened over time, but differ significantly from it in texture.

Types of metal siding

Each material used for siding production has pros and cons, but definitely deserves attention.

We will look at two basic types that are widely used for finishing facades:

- Steel. A common option for external cladding of various buildings. Also used as a base trim. It imitates brick and wood well. Suitable for finishing a wooden house, as well as buildings made of brick, concrete and used panels. Only galvanized steel, which is resistant to various environmental influences, is suitable for siding. Steel has many advantages, including a rich range of colors, and is therefore the best option for cladding buildings. Among the disadvantages, it is worth noting the large weight and the likelihood of deformation as a result of exposure to temperatures. Also among the disadvantages, it is necessary to note the likelihood of condensation if you install steel siding without insulation.

- Aluminum. It is distinguished by its low weight, practicality, aesthetic appearance and long service life. Aluminum panels are available in different colors and textures. Due to its low weight, reinforcement of supporting structures is not necessary. The material does not create loads on walls, is not afraid of exposure to temperatures, and is suitable for cladding any construction projects. Cons: aluminum is not resistant to mechanical stress, quite high cost compared to its steel counterpart.

It is impossible to say for sure which metal is better, since each material has its own pros and cons. Many property owners rely on reviews and recommendations from professionals, this allows them to make the right choice. You can purchase metal siding made of steel or aluminum inexpensively from any specialized company.

The cost of metal siding directly depends on the type of metal and its functional features.

Hot rolled steel

This facing building material, as a rule, has a low cost, but also more unpredictable characteristics. The appearance of the surface is scaly, so it is excellent for finishing facades.

In the following example, the architect used steel plates with a complex and expressive bluish tint decorating the walls Tiles paired with protruding fasteners give the appearance of the building brightness and authenticity.

Types of coatings

A rich color palette allows you to choose the optimal solution for any design idea. A variety of color solutions will help you choose the desired shade so that the façade fits organically into the overall style.

Below we consider the basic types of polymer coatings for protection and decoration:

- polyurethane – has good strength, is resistant to temperatures and mechanical damage, and is not afraid of exposure to ultraviolet radiation.

- PVDF (composed of acrylic and fluorine-containing polymers) is a special coating that can be used to create a glossy surface. Resistant to environmental influences, durable and versatile.

- Plastisol is a matte coating, not inferior in characteristics to a polyurethane coating, its thickness is 200 microns. Among the disadvantages: it is not resistant to high temperatures.

- Pural - resistant to fading, thickness varies within 50 microns, protects steel well from corrosive influences;

- Polyester is a relatively inexpensive material, a wide color palette, and a layer thickness of 25 microns. On sale you can choose different coatings: matte or gloss.

Modern manufacturers of coatings for siding panels offer many standard and original solutions. Among the latter you can find unique imitations of stone, velor, granite chips, and wood. Special polymer coatings provide adequate protection from various types of influences. It is impossible to say for sure how much the cladding costs, it all depends on the square footage. m of working area and specifics of work. To cover the facade with siding, it is better to contact professionals who will first calculate the amount of work in square meters and help you decide on the type of material.

Consider the contrast

Steel tiles have a distinct texture and unusual color. So, for example, in the following photo two buildings are shown to your attention. The owner used metal and wooden roofing building materials decorate the facade of the house

Notice how the smooth metal surface of the wall blends perfectly with the pebbles, and the wood with the surrounding forest.

Technical specifications

The structure of the material has the form of a profiled panel, which has special slots to make it convenient to attach them to vertical surfaces and a locking type of connection. Elongated holes are made in the edges of the sheets. The end area has small indentations for an effective fit when installing overlapping. Sheet thickness can range from 4 mm to 26 mm. You can inexpensively buy the material directly from the manufacturer. It is also always possible to place an order according to individual sizes (thickness, length, width). It is also worth considering that for a specific type of product you need to buy special elements: fastening parts that will ensure good joining of the products. The elements must be fastened correctly to ensure the integrity of the structure. Only professional finishers will be able to correctly install structures, so it is better to hire professionals.

For facing the facade you will need the following elements:

- Start and finish stripes, which are attached at the top and bottom. They play the role of guides.

- J-profile – necessary for attaching the first sheet.

- Base protection strip.

- Panels for corner joints.

- End strips.

- Window and door slopes.

- Low tide profile

- Corners – Outside corners are needed to hold and disguise joints. Internal corners will be needed to cover the profile.

When purchasing auxiliary elements and fasteners, you should definitely pay attention to their quality. Metal cladding of the facade will create reliable, long-lasting protection for the external walls of the house.

Slate

This popular roofing material is great for finishing the walls of luxury homes . Slate is expensive, but it can give any building a bright and memorable appearance.

Take a look at the following image. Slate harmoniously combines the interior and exterior. At the same time, green and purple plates give the wall texture and incredible charm.

Typology of cladding

Let's look at the most popular types of metal siding:

- Metal siding under timber - has the form of narrow sheets, is visually similar to timber, and has good relief. A popular option for facade finishing; You can find out how much the material costs at a hardware store.

- Block house - has the form of plates imitating wood or timber. Imitation of wood texture looks expensive. May have a glossy or matte finish. The fastening can be done from above or below.

- Facade panel – attractive appearance, rich colors. Using panels, you can finish the base with an imitation of brick, stone, sometimes wood or log.

- Eco-timber is distinguished by a specific shape, thanks to which the façade has the ability to self-clean. Suitable for vertical and horizontal installation.

Log metal siding is widely used in suburban construction. Its cost per m2 is quite affordable. The basement siding deserves special attention. Wide and short in appearance, the material is intended specifically for cladding the base. Basement siding is covered in several layers of paint, and it is also resistant to corrosion. You can buy basement siding at a hardware store. You definitely need to pay attention to the material parameters: length, width and thickness. The cost of installation depends on m2 and the specifics of the facade.

Technical parameters of products vary from manufacturer to manufacturer. One company’s assortment will not always have all types available. This is explained by the fact that expensive equipment is needed to produce a specific type of profile. If you choose the right type of siding and correctly determine the dimensions, you can advantageously emphasize all the advantages of the facade and skillfully hide existing shortcomings.

Weathered steel

This raw material has a deep orange rust color, which is a natural barrier to corrosion. The architects used recycled steel to renovate this home, taking inspiration from the natural environment. Use weathered steel to create a modern, warm and industrial façade.

The bold geometric look of this cottage was accentuated by stunning roof tiles.

We have presented to your attention several unique design options for buildings using metal roofing material, which helps to give its appearance incredible expressiveness and creativity. Did you like these decor ideas from talented artists?

Scope of application of metal sidings

The panels are designed to perform decorative and protective functions. They can be used to cover residential buildings, commercial and industrial buildings. Innovative production technologies and the unique shape of the panels make it possible to use them for cladding administrative and public buildings. According to reviews, the panels occupy a leading place among all modern finishing methods. With their help, you can beautifully decorate a hinged ventilated facade. A facade finished in this way will last a long time and will not require repairs for a long time. Manufacturers offer a variety of types of products that perfectly imitate wood, brickwork, timber, logs or block houses. Metal siding under timber or wood (log) looks very expensive, but requires proper installation in compliance with all the rules. The metal siding façade must be installed by an experienced team of professional finishers so that the installation can be carried out without errors.

Design

In addition to differences in the material from which façade panels are made, they can differ in surface topography.

- Smooth. Regular steel panels that differ only in color. They can repeat the wood pattern, make up one large picture from fragments, or be coated with gloss, creating a mirror effect.

- Corrugated. Curved with a soft wave or hard angular protrusions.

- Perforated. They come in a variety of patterns: from geometric to individual, custom-made patterns. In the dark, such panels transmit the light emanating from the building and create a bizarre picture, embodying all sorts of designer ideas.

- With additional decorative ribs. Depending on the distance between such ribs, you can visually expand the facade or make it higher.

When finishing industrial and public premises, cassette panels are usually used.

There are several types of such panels.

- Cassettes are three-dimensional panels consisting of aluminum sheet or steel coated with polymer coating. Such a cassette has a bend at the edges and is manufactured not only in factories, but also directly at construction sites due to the simplicity of the design. Most often they have a square shape and a smooth surface.

- Linear – elongated panels for exterior and interior decoration. Due to this design, the facade is mounted with a minimum number of gaps at the joints or without gaps at all. Linear designs are similar to long cassettes, but can have a perforated or 3D surface.

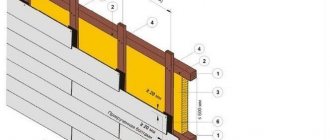

Despite the variety of materials, most facades are faced with sandwich panels made from several layers of different materials. The simplest products have three layers: two facing layers (metal, wood board or other materials) and one layer of filler (most often this is insulation).

Installation instructions

To perform facade finishing on any object, you must adhere to the correct sequence of work.

Required Tools

To mark, you need to take a level, tape measure and marker. A grinder, drill, scissors and a hacksaw for cutting metal will also come in handy. You also need to prepare accessories, components for mounting the frame and fastening all the elements.

Preparatory work

The facade is cleaned of debris, foreign objects are removed from the entire surface of the building (roller shutters, window sills, cornices, drains). Existing defects (traces of corrosion, pits, cracks) must be repaired. Antiseptic impregnation is used for wooden facades.

Marking

Using a hammer drill, holes are drilled to install the profile in the areas that were marked with a marker. The distance between the marks depends on the pitch of the sheathing.

To determine the required volume of material, the façade area is measured and the size of the door and window openings is subtracted from the resulting value. Additional parts are also considered, the number of which depends on the parameters of the corners, the perimeter of existing doors and metal-plastic windows.

Lathing

The sheathing is created from metal or wooden slats. The best choice for the frame is a durable, reliable metal profile. Its dimensions must exceed the thickness of the insulation (if insulation is used). Brackets are suitable for attaching the sheathing.

After fixing the metal profile frame, insulation is laid from bottom to top, which must be dry. It is covered with a waterproofing film, after which the panels are attached.

Installation

The procedure begins with fixing the additional parts (initial, corner, end strips), after which the walls near the openings are lined. When using a finishing strip, installation of elements is carried out in the reverse order. A seal is attached around the perimeter and at the corners.

At the next stage, the fastening of other planks begins from the bottom of the left area of the wall. The parts are connected to each other with screws or built-in locks. Locks can be mounted with additional screws. Once the cladding is ready, you can reinstall the removed elements (shutters, slopes, gutters, cornices, etc.).

In general, the installation steps for different materials are carried out according to a similar principle. This is an inexpensive solution for a summer house or cottage, and the result will last for years.

Review of manufacturers

Iron panels are produced manually at the construction site or automated at the enterprise. Among foreign manufacturers on the market, there are several brands that have become especially popular:

- British-Dutch brand Corus Group;

- American company Alcoa, which produces aluminum siding;

- Finnish company Ruukki with metal panels.

Among the Russian suppliers, the Grand Line brand, the products of the Severstal enterprise, and the products of the Lipetsk enterprise and the INSI holding have proven themselves well. They have more affordable prices per m2.

Cost of metal siding finishing

The price of finishing with metal siding is determined by:

- location (region) of the building (transportation, loading and unloading services);

- finishing area (the larger the area, the lower the price);

- number of floors;

- exclusivity of design;

- qualifications of performers;

- the cost of the material (steel, aluminum), the complexity of the profile, the composition and method of applying an external coating that imitates plaster, brick, wood;

- manufacturer (manufacturer);

- type of frame or subsystem (metal, wood);

- option on the facade - simple, ventilated, insulated.

The average price for 1 square meter of finishing buildings with metal siding panels can vary from 400 to 3000 rubles;