One of the essential plumbing fixtures for a bathroom is a sink. Bathroom washbasins differ in shape, configuration, installation method and connection to communications. One of the most used options is to install a sink with a cabinet in the bathroom, since this model allows you to organize the storage of towels, detergents and various useful items in a convenient place.

Bracket installation technology

- Determine the density of the load-bearing wall using a small-diameter drill. If the wall is not dense, then powerful and long dowels will be needed for fastening.

- Drill through the plaster to the base (brick, concrete, other material), going 3-4 cm deep into it.

- Choose special anchors with a length of 8 to 12 cm.

- Be sure to insert a plastic or nylon dowel.

- Secure the bracket.

- Check the installed (attached) bracket for reliability: pull it with your hand - it should not move.

- Proceed to install the bowl onto the attached brackets.

Attaching the sink will not be a big problem if you do not disturb the order of work

It is important to choose high-quality brackets that match the type of bowl

Now you know how to secure a sink. Mounting on brackets is the most difficult installation option. They need to be matched to the interior of the bathroom and securely fixed, because there will be no other support for the sink.

Care requirements

Of course, a lot depends on the material from which the overhead device is made, what its porosity is, whether the coating absorbs dirt strongly and whether it is prone to streaking.

Countertop sinks made of earthenware or porcelain are easy to clean. In order to clean such products, you need to have a soft cloth and any liquid detergent on hand, preferably without an abrasive component.

Acrylic overhead bowls do not like hard brushes with coarse bristles. To clean acrylic, use gel-based detergents that do not contain alcohol.

Caring for a countertop sink will depend on the type of material.

Glass sinks that are overhead must be handled with extreme care, and not primarily because they can break, but because any drops and splashes after drying leave untidy marks and stains on the glass surface. That is why it is recommended to wipe them dry.

Wooden devices can withstand everything except rough processing and abrasives. But if scratches appear on the surface and the top protective layer is damaged, the product may become moldy and even begin to rot.

Do not wash natural marble countertop sinks with acid-containing solutions or caustic powder. Damage to the stone increases its porosity, which means that the resulting dirt and stains will be almost impossible to remove.

Installation of a sink without brackets

A mounting kit must be included with the sink upon purchase; if for some reason it is not available or the quality leaves much to be desired, purchase such a kit separately. Focus on products from well-known brands so as not to worry about the quality of installation later.

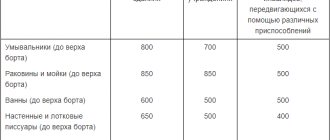

Decide on the location where the sink will be installed and take measurements. It is usually recommended to install the bowl at a height of 70 - 85 cm from the floor.

At the selected height according to the building level, draw a horizontal line. Now we place the upper edge of the bowl to the set aside line and mark the attachment points. We drill holes according to the marks and insert dowels. We screw the pins into the dowels. The screwed-in pin should be 2 cm longer than the width of the washbasin. After final installation, tighten the nuts until they stop.

Materials used to make siphons

| Material of manufacture | Short description |

Plastic | The most popular material for the manufacture of siphons, in terms of its performance indicators, completely satisfies the majority of consumers. Due to modern fillers, it has high levels of mechanical and chemical resistance. The material is very technologically advanced, which not only reduces production costs, but also allows you to create various geometric shapes. In terms of cost, plastic siphons are the cheapest and have many types and modifications. |

Stainless steel | The service life is virtually unlimited, they have excellent design characteristics, and are often used in open sewer systems. The price is much higher than plastic siphons; during installation they require accurate measurements. Assembly and installation require some experience in plumbing work. |

Non-ferrous copper-based alloys | The most expensive materials for the manufacture of sanitary equipment are used only on exclusive sinks. Physical characteristics do not differ from stainless steel products. They are not afraid of large dynamic and static loads. |

Cheap chrome or nickel alloys | They occupy a middle position in terms of cost and performance indicators; they are most often used for the manufacture of individual elements of plastic siphons. |

Sink siphons

Despite the different types of materials and the wide range in prices, all siphons operate efficiently and perform their main technical tasks for a long time.

Installation of a wall-mounted sink with a cabinet

This option is good because you can hide all the plumbing connections in the cabinet.

At the required height, draw a horizontal line along the level. We try on the cabinet, see how it will fit with the siphon and mixer. If necessary, immediately measure and drill additional holes for plumbing in the back wall. Now we install the brackets and the cabinet on them. We described above how the brackets are attached.

We install a washbasin on top, connect a siphon and sewerage to it. If the bowl model provides for additional fastening to the wall, then drill holes in the right places and tighten the anchor bolts. Or glue the sink to the wall with silicone for greater reliability.

Determining the optimal installation location

One option is to install a new sink in the same place where the old plumbing was located. But this is not always possible, since the cabinet box most often does not fit into the previously allocated space. And moving the location of plumbing fixtures during repairs is not uncommon. Therefore, it is best to think through the location of all plumbing fixtures, as well as pieces of furniture, at the renovation design stage. To do this, the bathroom is conditionally zoned into several areas, in each of which a device is installed (bathtub or shower, toilet, sink, washing machine).

Based on the planned location of the plumbing, water supply and sewerage pipes are laid, because the optimal supply points are different for each plumbing fixture. When supplying hot and cold water, the location of the fittings for connecting flexible hoses must be calculated so that they are located between the shelves. This will ensure convenient connection and replacement of hoses during operation.

As for the siphon and connecting the corrugated sewer pipe, you often have to cut holes in the shelves to connect it. It is for this reason that it is better to calculate everything in advance and bring the sewer pipe to the level of the connection points to the water supply.

To avoid having to cut holes in the shelves of the cabinet, all supply points must be brought out in advance to a place convenient for connection.

Secrets of the master

In order to efficiently install a sink on a wall, it is worth learning some of the nuances of this process, without which the installed structure will not be as reliable and stable. These are tips from the best installation specialists:

- The wall structure has a significant disadvantage - it is visually open pipelines and fittings. The excellent aesthetics of the bowl is achieved thanks to a cabinet that matches the design, which will cover all these connections and the siphon. An additional advantage of this installation is a good place to store various necessary accessories.

- In practice, the entire set of fastening equipment should be included with the product. Check this issue yourself, because often: either the manufacturer forgets to complete the sink with fasteners, or their quality itself is not particularly high.

- To avoid moisture vapors from entering the space between the bowl and the wall, it is necessary to use a high-quality sealant, for example, silicone.

Upon completion of installation work, check the system drainage for leaks by filling the siphon with water. If you find a leak, make a tighter twist and an additional sealing layer.

- Install the bowl only after completing all finishing work. Be very careful when installing fasteners.

- The surface of the wall on which you mount the bowl must be strong and stable, otherwise use a supporting frame.

- If after installation the sink does not “move”, this is a clear indicator that the bowl installation procedure was successful.

A well-executed installation procedure is synonymous with excellent functionality and durability of the product. In view of this, before installation work, seek the support of an experienced specialist.

Installation technology for an overhead sink

Step-by-step instruction

If you have ever installed a built-in fixture or a kitchen sink before, you will be able to handle the installation of an overhead sink easily and quickly, because the fixing technology is almost the same. The only difference is in the nuances of inserting the product into the cabinet and connecting it to the pipeline and sewer drains.

Your primary task is to use fasteners to align the main hole with the drain; in extreme cases, you can glue it with special means or use dowels on the frame, which is fixed under the washbasin. Step-by-step instructions on how to make an overhead sink are as follows:

- Clean the area where you plan to place the countertop sink from dirt, stains and dust. Here, taking into account the stencil, prepare the surface.

- Place the drain pipe connection to the hole.

- Fix the lower part in the washbasin, and install the bowl itself on top, then tie the structure from the bottom of the cabinet using screws. This method involves a separate connection of the mixer. The water inlet holes should be located under the faucet.

What to pay attention to

The smaller the diameter of the hole intended for connecting the siphon, the better. Avoid cutting large holes; a neat hole is enough to accommodate the drain pipe inside. The ideal hole size is no more than 50 mm. Determine the location of the siphon flask at the bottom of the device.

When it comes to installing a faucet, there are several methods for installing it. The faucet can be placed in the washbasin itself (this option involves cutting a hole with a diameter of up to 80 mm), in a hole in the cabinet (which over time can lead to damage to the furniture, enlargement of the hole and drying out of the surface) and on a wall structure similar to a conventional faucet in the bathroom room.

Do not forget to pay attention to the installation location of the mixer

If you decide to make slits in the countertop to prevent moisture from getting inside, it is recommended to carefully process the edges of the hole and seal the joints.

To install a countertop sink on a countertop, the store may offer you a special siphon that has an additional nut that presses the countertop sink to the cabinet. If this nut is not available, use silicone. By following these steps, you will solve two problems - you will fix the bowl and achieve better tightness between the washbasin and the cabinet.

Frame structure for installing a washbasin

If the walls in your bathroom are not strong enough to install a sink, and you really want just such a model, then you can solve this issue by installing a frame structure. It is attached to the floor and walls and consists of profiles. The height is adjustable with legs, so that the sink can be installed at the desired height from the floor. All communications are hidden inside the structure.

The procedure is as follows:

- the frame is leveled and secured to the floor and wall;

- At the required height, screws are screwed in to secure the sink;

- cover the frame with moisture-resistant plasterboard and line it with tiles or any other finishing material;

- between the wall and the sink, a rubber washer is placed on the stud to reduce noise during operation;

- attach the wall-mounted sink to studs on top of the cladding.

A properly assembled installation can withstand a load of up to 400 kg, and this is not only a sink, but also other plumbing fixtures. In addition, you can make a niche in the design and use it as a shelf.

A few more tips for choosing

To ensure that your new washbasin brings you only positive emotions from the convenience and beauty of the product, you should remember a few simple rules when choosing:

Choose a sink that matches the style of the entire bathroom

- Check items carefully, especially those made from materials such as porcelain and glass, for cracks or chips. If found, request a replacement item. After all, even the smallest crack can grow into a big nuisance over time.

- If there are children in the family, it is better to refrain from purchasing models with sharp corners to avoid possible accidental injuries.

- Decide on the sizes in advance. When choosing a countertop sink, you should know the expected countertop size and placement location.

- The selection of the mixer must be carried out according to the height of the washbasin. The deeper your sink, the higher the faucet should be.

Specifics and models of wall-mounted sinks

The latest modern trend in sink installation is to mount the unit to the wall surface. This type of arrangement is one of the most familiar and favorite among Russians, since this type of installation has worthy and significant advantages. By installing the sink on the wall, you will save the desired meters of space, and the space under the sink is very convenient to use and keep clean.

Before you begin installation work, choose the model of wall-mounted sink that has the most ergonomic design. A separate model has specific design aspects, which, of course, affects the method of its installation. Therefore, it is so necessary to have at least some knowledge about the installation and specifics of connecting the device to the general water supply system.

An interesting solution is to install a sink above the washing machine; this saves precious space in the bathroom.

Design features of different types of siphons

The simplest design is a pipe siphon. This is a curved pipe in the shape of the symbol “S” or “U”, which can be collapsible or non-dismountable. Its advantage is the need for precise alignment with the inlet to the sewer, resulting in a rigid drainage system.

USEFUL INFORMATION: Wooden bathroom design: 20 photos

A classic of the 20th century – the bottle siphon. It is well known for its simplicity and ease of use and has the following features:

- takes up relatively little space under the sink;

- the connection to the sewer pipe can be made with either a straight or flexible pipe;

- it is easy to disassemble during cleaning;

- To rinse and remove sediment, simply unscrew the bottom of the tank;

- ideally protects sewer pipes from contamination.

The miracle of the late 90s of the last century - the corrugated siphon - became fashionable along with interest in apartment redevelopment. This type of design has its advantages:

- makes it possible to connect non-standard sinks to the sewerage system;

- very easy to install;

- By bending the tube you can form any slope and create a water seal.

Hidden siphons began to be used relatively recently. They entered the apartments along with built-in sewage systems. This is the same bottle device, but hidden behind a partition and ennobled by a stainless steel pipe located outside.

A new product on the domestic market is a dry siphon, which functions not by creating a water plug, but thanks to a special membrane. When water enters, it opens and releases water, and then contracts again, tightly closing the flow hole and preventing water and odors from returning.

Step-by-step installation instructions

https://youtube.com/watch?v=8d-LyqQfngQ

Mark the central horizontal line using a ruler, marker and spirit level. Installation will be carried out along its line

This will be, sort of, the upper limit of the bowl. It is important to consider the thickness of the side walls of the sink. They must be strong enough to withstand the pressure of the brackets

Measure the thickness and record the remaining parameters of the future installation on both sides of the bowl. Connect horizontally all the existing marks indicating the mounting height of the brackets. Finally, work begins on the sink itself. Turn the bowl over and fix the brackets on its outer walls.

- Move the sink closely to the horizontal and mark with a marker the places for mounting fasteners. This is done through recesses on the outside. Constantly check the alignment of all brackets and lines.

- Using a drill, make holes that are slightly smaller in diameter compared to the size of the fastening devices and dowel screws.

- Drive plugs or bushings made of durable plastic or nylon into the prepared drilled places, and screw the screws into them.

Support brackets are installed on this mount, on which the sink bowl is mounted. Mark the places where the device will be attached to the wall, drill and install the sink. Connect the outlet end of the siphon pipe into the socket of the sewerage system, install the mixer, and connect the water supply. Having made a light fastening “bait”, finish aligning the bowl horizontally. Then go through all the fasteners again and secure them.

Features of installing a drain with overflow

Information about drain collection is included in the instructions that came with the siphon. To work you will need:

- flat screwdriver;

- insulating tape;

- siphon;

- bucket;

- sealant;

- adjustable wrench;

- a napkin made of paper or fabric.

When choosing a sealant, preference is given to products based on rubber or silicone. The products must be suitable for connecting plumbing parts.

System assembly

First, connect the drain to the sink. The structure is placed under it and the dimensions are first checked for compliance. Next, unscrew the plug from the bottom of the device and inspect it for damage, thereby checking the reliability of the structure.

Before assembly, inspect the threads on the body. If there are burrs on it, they are carefully cut off. If this deficiency is not corrected, damage to the O-ring may occur during installation. Before installation, check all threaded connections, nuts, joints and gaskets.

To assemble the device flask, you will need:

Siphon assembly process

- put the gasket on the threads of the upper section of the structure;

- screw the bottom of the siphon;

- place a rubber seal of the appropriate diameter on the drain tube and put on 2 tension nuts;

- insert the drain pipe into the hole at the bottom of the siphon, push it to the desired height and tighten the nut loosely;

- install a gasket in the cover of the device and screw the drain to the body.

The rubber seal placed in the groove is coated with a small amount of sealant. To ensure reliability, the substance is lubricated with the lower thread of the plug, which is screwed into the body. To tightly connect the parts, a winding is used to remove the element when necessary. Before collection, the length of the tube is selected, the height of which is determined by the depth of the shell.

The main pipe is connected to a tube with clamps. Subsequently, the part is mounted to the sink, placing a gasket between the elements. The area between the pipe and the overflow with outlet is secured with a nut. It is recommended to tighten plastic parts by hand to avoid breakage.

Installation of the structure

First you need to turn off the water, connect the protective grille and the sink drain hole, placing a rubber seal no more than 5 mm thick between them. If the grille dimensions are larger than the hole, use a sealant rather than a gasket. A rubber seal is placed on one edge of the outlet pipe, and a chamfer is removed from the other edge, improving the fit of the pipe into the siphon.

To connect the sink and the pipe, you will need a screw with a diameter of 6 mm. The part is inserted into the protective grille and tightened. Then the drainage pipe is connected to the outlet pipe. In this case, it is necessary to monitor the connection points. For reliable sealing, you can use plumbing tape.

Installation diagram of a siphon to a two-section sink

The assembled siphon must be connected to the outlet pipe, which was previously connected to the drain. After this, a connection is made between the sewer and the drain. Before installing the cuff into the pipe, a layer of sealant is applied to it and the outlet end of the outlet pipe is placed in the part. For connection, a rigid assembly is used, connecting the sewer outlet and the pipe with a conical gasket and a nut.

If corrugated hose is used, the length of the soft hose should be such that it does not sag during use. If the dimensions of the outlet and the sewer pipe do not match, a plastic adapter will be required. You can prevent smell from entering your apartment by using a rubber cuff, which is placed in the socket.

Features of operation depending on the model

The types of fastening for a sink to the wall differ greatly depending on the modifications of the device:

For suspended installations, installation is carried out directly to the wall, so gravity is directed not only to the mount itself, but also to the wall

Therefore, it is very important that the base is strong and thick. Usually there are no problems with this if the installation is carried out in the place designated by the builders.

The “Tulip” model will look good in a spacious bathroom. When installing between the planes of the sink, floor and wall, polymer gaskets are installed, gluing them to silicone sealant

This technique prevents the appearance of squeaks and ringing of ceramics in the event of a careless impact. Another important point is that fastening and pulling the bowl to the wall should in no case cause it to be lifted on its “leg” in order to avoid splitting

Why do you need undermount sinks?

When a home owner is developing the design of his bathroom, the first thing he does is allocate locations for plumbing fixtures and household appliances. Quite often it turns out that all the devices are placed along one wall. In such cases, interior experts recommend using a tabletop for decoration . This solution provides an opportunity for different things to acquire a common appearance and form a general direction in this room. By taking a non-standard approach to creating a washbasin with a countertop, you can get a bright detail in the interior of the bathroom.

Indeed, only a countertop can combine both a sink and a washing machine in one place. However, we note that not all sinks are suitable for carrying out such a modification. The most appropriate sinks are wall-mounted sinks and models that have a tulip leg as part of their design. For such purposes, the best solution is to use overhead sinks or built-in models. They are best suited for tabletop decoration.

Types of sink brackets

The fasteners for mounting a washbasin on the wall must be able to withstand the weight of the plumbing fixtures with a margin. They are made from various metals.

special mounts designed for mounting a specific model. Often these are exclusive designer washbasins with an unusual shape. Brackets for such plumbing fixtures are included and can be made in the form of specially shaped pins, pipes that go around the sink, or unusual welded structures. Such fastenings are treated with special decorative compounds (ceramic or metal).

Brackets for standard wall-mounted sinks are made of cast iron or steel and coated with anti-corrosion paint. They are produced in the form of T-shaped or L-shaped racks, and can also be made in the form of frames with a sliding unit to adjust the size of the fastening. Brackets in the form of a metal frame into which the washbasin is placed are particularly reliable.

What is a countertop sink

Advantages and disadvantages

An overhead sink has a lot of advantages and only one disadvantage. Unfortunately, due to a lack of square meters, not every bathroom can accommodate such a washbasin. But if you really want it, you can find smaller copies of the compact type, in which the cabinet is represented by a small shelf attached to the wall structure. This model will allow you to place household supplies under the shelf, but will not solve the issue of covering the water supply and sewage system.

Now let's talk about the benefits:

- It makes no difference whether the wall plane is reliable or not, because the overhead device is not mounted to the wall. This option is suitable for those who do not want to spoil the appearance of the finish in the bathroom or doubt the durability of the surface. The countertop sink goes well with a large mirror and, if chosen correctly, looks like a single whole.

- If a countertop sink takes up its proper place on the countertop, all unsightly communications are located inside the cabinet. Designers suggest additionally decorating the front side of the tabletop with a light, airy curtain to match the color of the finish or individual areas of the room.

- An overhead sink allows the owner of an apartment (private house) to place an order for the manufacture of his own cabinet, taking into account the style of the bathroom, its size and furniture content.

- The top covering of the tabletop is suitable for decorating with candles, as well as for placing shampoos, towels and other frequently used bath accessories.

Technical features

Convenient are the countertops offered for purchase complete with overhead sinks. This stand-stand is equipped by default with a mirror, a cabinet, and in the upper part there can be shelves and even lamps. What is the disadvantage of such units? They are quite bulky and are available exclusively in several colors, which are not always appropriate for a particular room design. But even in this case, there is a way out - order a device of the required size, configuration and shade.

There are several ways to fix the tabletop - with corners or by placing it on legs. The first method is carried out in parallel with the installation of the support, if the size of the tabletop is more than 1–1.5 m. Another option for a heavy cabinet may be unreliable. What is commonly used as a support? A tube-shaped leg made of metal, such as those found in the design of a bar counter, is suitable.

The set of a countertop sink may include only the countertop and legs or the body with side bars and jumpers. The body is often made of wood or sheet metal. For reliability, it is sheathed with a protective layer of plasterboard or thick plywood.

Under a homemade device with an overhead sink, you can place a washing machine, for which there is always not enough free space. If the countertop is divided into 2 parts, one of which is open, the washbasin is located slightly to the side. A product that is not covered by doors and has shelves and curtains covering them is easily perceived. But it is still advisable to hide communications by installing an appropriate strip. There may also be holders for towels and bathrobes.

An overmount sink with a cabinet trimmed with tiles that cover the walls of the bathroom looks interesting. Small mosaics and special bricks intended for cladding add a charming piquancy. Using artificial stone is more than beneficial - in this case, no additional finishing is required. As a rule, countertops for overhead sinks are made from acrylic stone and agglomerates, and chipboard or MDF serves as the base.

Classification of countertop sink shapes

The choice of the shape of an overhead sink depends primarily on the style of the room. For example, classic design involves rounded, streamlined structures, conciseness and harmony in the combination of equipment, furniture and plumbing fixtures. High-tech, on the contrary, requires clear lines and angular geometry of outlines.

Overhead sinks are a very stylish solution for any interior.

Round bowls look elegant, oval bowls are the most convenient to use, rectangular and square bowls with rounded edges fit any bathroom style. Triangular washbasins are considered the pièce de résistance—stable and comfortable products. Extraordinary people will appreciate the whimsical shapes of the bowls, taking the form of a flower, a cloud, a blot or a drop.

Tools and materials

For installation you will need: a sink, a set of auxiliary materials and various tools. Make sure everything is at hand. Tools you will need:

- Gas key.

- Electric drill + drill with pobedit tip.

- Screwdriver.

- Building level.

- Hammer.

- Marker.

- Special tape for threaded connections or tow.

The choice of fasteners is important if you have to deal with installing a sink in the bathroom for the first time. Most models are mounted on metal brackets, which come in different shapes (including openwork forged ones) and sizes. Installation is carried out using powerful bolts and studs. It is not always necessary to mount the sink to the wall. Depending on the model, it can only be placed on mounting brackets.

There are several types of shells:

Depending on the variety, the methods of attaching the bowl to the wall also differ. Most often, in about 50% of cases, conventional suspended structures are installed, this also includes “water lilies”. The installation of “tulip” type models is somewhat different: the bowl rests on the “leg”, and the sink needs to be attached to the wall only for additional fixation.

Design features with built-in sink

Such products owe their name to the method used during installation. That is, when installing them, the washbasin crashes into the countertop. The tabletop is installed on legs fixed to the wall, using corners and special brackets. The entire structure of the console and bedside tables is built under the tabletop. Methods for embedding products can be very different:

- plumbing fixtures can be recessed below the level of the countertop;

- the product may protrude above the tabletop level.

Currently, cut-in washbasins, based on the criterion of design form, are divided into the following types:

- oval;

- square;

- rectangular;

- round;

- asymmetrical.

Preparatory work

The sink for the bathroom has been purchased, the necessary tools are ready, all that remains is to install the structure correctly. To do this, you need to prepare the wall on which the washbasin mounts will be mounted, and make markings so that the bowl is located at a height convenient for all household members.

The fastening for the sink to the wall must be installed after careful preparation of the surface. It is best if it has been finished (textured plaster, tiles or any other finishing material for the bathroom). If the wall is simply plastered, it must be treated with an antiseptic. There are many varieties of them in different price categories.

It is more convenient and easier to use liquid glass. It will perfectly protect the surface from exposure to water and at the same time destroy possible bacteria and fungi. After treatment, you need to wait a while until the surface is completely dry, then paint and begin installing the sink.

- Turn off cold and hot water.

- Stand at your full height in front of the installation site for the future sink.

- Select the upper limit for installing the bowl so that all household members can comfortably reach the sink.

- At the marked place, using a long ruler, pencil and level, draw a horizontal line along which the main work will be carried out.

- Check the dimensions of the sides of the bowl (measure it).

- Record the size with marks on both sides.

- Connect the marks with a horizontal line, thus obtaining the installation height of the sink brackets.

- Turn the bowl over and place it against the wall. Mark where the grooves for the brackets are.

Material for the production of washbasins

Despite the constant search by designers for new ideas and materials for production, washbasins made of sanitary porcelain and sanitary ware remain the most popular. This material is resistant to scratches and cracks, and does not collapse under the influence of temperature changes.

And although they can split from an impact, this still happens quite rarely. The traditional white color of the material will suit almost any design.

Glass sinks look airy and elegant. The disadvantage of such washbasins becomes obvious after you start using them - every drop of water, when dried, leaves a mark. Since it is unlikely that anyone will wipe it after each use, such a washbasin does not look very neat. From this point of view, frosted glass behaves much better.

Natural or artificial stone sinks can be made from marble, stone chips, sand and a binder. It would seem that this is a very durable material, but even with stone products problems can arise if used incorrectly - small cracks appear, or even completely split.

The manufacturer describes how to properly care for such plumbing fixtures in the product instructions. Most often, there are recommendations to wipe them dry and not to use too hot water.

Like any product made from natural material, a countertop sink made of stone always looks expensive and elegant.

Wood sinks are also produced, using hardwood with a beautiful texture. Washbasins arouse interest simply by the choice of material, and in combination with a successful design they can become a real decoration of the bathroom.

The wood from which plumbing fixtures are made is treated with special oils that prevent water from penetrating into its pores. Caring for such a sink is quite difficult. It cannot be cleaned with detergents containing high acids or alkalis, or with abrasive substances.

To produce sinks from natural wood, oak, teak, and bamboo are used. Some of them require periodic treatment with special oils

They also produce overhead sinks made of acrylic. The material is more familiar in connection with the production of bathtubs, but washbasins made from it are also deservedly popular. Strength, lightness, resistance to temperature changes, ease of maintenance, as well as the ability to create the most incredible design solutions make acrylic attractive to both buyers and manufacturers.

Device and functions

A sink drain is a plumbing device that connects the drain hole at the bottom of the bowl and the entrance to the sewer. It is a curved structure consisting of a drain pipe and a siphon. The drain is a mandatory element, the installation of which is carried out when installing a sink, bathtub or shower. It performs the following functions:

- Carries out timely and efficient transfer of “waste”, dirty water from the sink through the drain pipe into the sewer.

- Filters out light debris. The grate, which is placed on top of the drain hole in the sink, not only performs a decorative function, but also protects against the penetration of small debris and hair, thereby preventing the formation of blockages in the sewer.

Drain grate - Prevents the penetration of unpleasant odors from the sewer. The siphon for a bathroom sink is designed in such a way that it forms a “hydraulic seal”, a natural water barrier that prevents sewer odors from penetrating into the bathroom.

Important! The main feature of the sink drain system is a curved, sigmoid pipe. Thanks to its special shape, water never leaves the bend of the drain pipe, which is why a so-called “water seal” is formed, which locks sewer odors inside, preventing them from penetrating into the bathroom.