Interior mirror, 90 cm x 40 cm

1993 ₽ More details

Hose "Meteor", reinforced, 3-layer (3/4, 25m)

860 ₽ More details

Gray curtains for the living room

Plumbing in a basement is just as important as the foundation, walls, or heating. Many owners organize baths, toilets and other rooms with running water in the basements. In this case, it is necessary to organize the lifting of waste liquids to the level of the main sewer lines.

The relevance of the problem of drainage from basements

The ground level of buildings is increasingly being mastered by the owners of the building. This is due to the need to rationally use all available space. The basement is not always an ideal option for creating a bedroom, living room or children's room there. It is better to use it as a sports room or a second kitchen. In this case, the question arises about creating a bathroom and bathroom.

Sewerage is one of the main elements

Basement drainage is a pressing issue that requires careful planning. The basement floor is below ground level, while all the main sewerage nodes are above. Therefore, it is necessary to provide for effective drainage with raised wastewater. Severely and moderately polluted wastewater must be lifted using special equipment.

Optimal microclimate in the cellar

To preserve food, it is necessary to create a favorable microclimate in the basement. The humidity level of the room is of great importance.

Equipping a cellar with a ventilation system is undoubtedly important, but it is far from the only condition for maintaining optimal humidity and the required temperature conditions. It is necessary to make a good waterproofing of the basement and periodically carry out a number of measures to drain it

There are several ways to get rid of excess dampness

It is necessary to make a good waterproofing of the basement and periodically carry out a number of measures to drain it. There are several ways to get rid of excess dampness.

With high humidity, you need to ventilate the basement more often. This is especially true in the summer, and if natural ventilation is installed in the cellar.

To get rid of dampness and lower the humidity level in the basement, you must ventilate it by opening the entrance hatchTo dry the basement, you can use simple but quite effective methods. For example, ordinary coarse table salt and quicklime absorb moisture well. They can be brought into the basement and left there for a while.

Another old method that our grandmothers used is to place a lit candle near the exhaust pipe. The flame creates a strong draft in the air duct, thereby accelerating the circulation of air flow.

This method only works in a small cellar, and even in this case it will take several days to dry the room.

To prevent the candle from falling, it must be placed on a flat metal surface.

You can dry the cellar using an electric heater, heat gun or fan, which are installed in the middle of the room. But all these methods are quite expensive, because... will require large amounts of electricity.

Sometimes, on the contrary, it is necessary to increase the humidity in the cellar. In these cases, you can spray water using a spray bottle. A good method is to bring a box of wet sand into the basement or sprinkle the floor with sawdust; they must be periodically sprayed with water.

The need to separate the disposal of heavily and moderately polluted wastewater

Before you begin installing pump equipment or other elements of the sewer system on the basement floor, you should find out the ratio of the waste being pumped out. The choice of special settings depends on this.

For example, when installing one toilet, it will be enough to install a sololift - a device with low power required for pumping out fecal waste. It is used for the removal of heavily contaminated waste.

Interesting! As a rule, the ground floor is used to accommodate several sources of water volumes, which means it requires calculation of future water consumption. If the consumed volume of water does not exceed 1 m3, then a sololift will help cope with this task.

In this video you will learn more about sewage systems: Sololift refers to universal pumping stations designed for fecal wastewater. They can be used to remove various types of sewage waste. If the norm is exceeded, it is planned to create two systems. For example, there is a swimming pool in the basement. This means that you need to install a separate pump, which will simply need to pump out water without much contamination.

Ventilation care

To ensure quality ventilation, it is necessary to regularly monitor the operation of the system.

The easiest way is with a lit match. If there is little oxygen and the air contains excess carbon dioxide, it will quickly go out. This is a signal - it's time to start cleaning your air ducts. Dust, debris, cobwebs, ice or frost can accumulate in the gaps of pipes. Sometimes foreign objects are found in the ventilation ducts, and often rodents or other small animals.

To clean, you need to remove valves and electrical appliances from the pipe. Place a container underneath to collect debris and use a thin, strong wire with a brush at the end to move along the entire air path.

In winter, condensation collects in the air ducts. When it freezes, it turns into ice. It is quite difficult to remove the solid mass without damaging the pipe. This is done by heating with hot water or warm air. If traction is restored, the cleaning was successful.

Types of wastewater and options for its disposal

The reliability of the sewer system in the basement of a private house should be high. This involves the use of multiple but suitable pumps. Clogging too much free space with installations is not the best solution. First of all, it is necessary to calculate the possible volume of water that should be pumped out, and only then buy equipment.

The water that forms in the basement can be classified as moderate or severe contamination. Heavy contamination is water in the toilet. Solids that enter the system must be crushed before being discharged into the general sewer system. This will ensure normal throughput.

Cellar ventilation schemes

To ventilate underground rooms, you can use 1 of 3 schemes:

- classic system with one exhaust pipe;

- diagram with two pipes - inflow and exhaust;

- forced air exchange.

Single-pipe ventilation system - fresh air enters the storage through the door.

The choice of option depends on the design of the basement, its location and other conditions. The system with 1 air duct shown in the picture is applicable for cellars with a separate exit to the street. How the scheme works during the cold season:

- The temperature underground is always positive (if the basement is built correctly). Warmer and humid air rises to the upper zone and goes out through the vertical exhaust duct.

- Cold air masses take its place - they seep through the supply openings in the door (hatch), then fall to the cellar floor.

- As the air warms up + humidifies, it begins to lose weight, rises and is thrown out again through the pipe.

Ventilation scheme for a summer kitchen basement with external pipes.

A ventilation system with two pipes is used in cellars without a separate entrance - under private houses, garages and other outbuildings. The natural circulation of air masses is organized in a similar way, only the influx is a second vertical channel, descending to the floor itself. Cold outside air descends through the supply air duct, replacing the gases escaping into the street.

The pipes are located in opposite corners of the storage facility and are removed in two ways:

- in the ground outside the building;

- straight through the roof, as shown in the ventilation diagram of a garage with a cellar and inspection pit.

In the first case, the head of the supply pipe is at the level of the base; it is better to raise the exhaust shaft to a height of 2 m (counting from the intake hole in the basement). If the building is surrounded by other buildings and there is no place to remove the second duct, the air duct is laid in the second way - on the roof. The end of the exhaust pipe rises above the ridge.

Layout of ventilation ducts and air flow in the garage. A transfer pipe cannot be placed between the pit and the cellar

Active air exchange with forced impulse is organized according to a single-pipe or two-pipe scheme, the fan is placed on the exhaust duct. The ventilation operation can be automated by connecting the blower to the power supply via a thermostat. A device with a sensor will turn off the fan when the temperature drops below a preset threshold. Watch the video for details:

Combined disposal of various wastewater

A pumping station is an element that is capable of providing a combined discharge of various wastewater. Several sources of small water consumption that are not polluted can be diverted in this way.

A pumping station can be compared with a sololift, but with greater power and a large storage tank. Some models have a system that prevents reverse current flow. Such a pump is capable of pumping out up to 10 m3 of water per day and providing frequently used sources with a reserve.

The pumping station has one significant drawback - increased noise level. Today there are already models in which this problem has been eliminated. Background noise is reduced at the same power.

Don't forget about the pumping station

Input of water supply: recommendations of a professional

It is very good when the introduction of water supply into a house without a basement is provided for when pouring or assembling the foundation. That is, a special opening is provided for its installation. It is much more difficult to carry out such installation in a finished building, when you have to not only dig the ground, but also make a hole in the concrete or stone layer.

However, both options are possible. We will look at the main indicators that should be followed when laying, installation methods, and also show you a video in this article.

This is what the water supply input to the building should look like:

How to provide backflow protection

The basement, due to its location, requires special attention in terms of creating a sewer system. Pipes that are located at the bottom are most at risk of blockages and contamination. The system is constantly overcrowded.

Reverse flow is a process in which the system overflows and water begins to flow back from the outflow nodes. In this case, you can flood the room with water with an unpleasant odor.

There are effective ways to prevent basement water from backflowing:

- Install equipment that has built-in current resistance. Today there are already many installations that have this possibility. Availability in a specific model must be asked upon purchase.

- Install intermediate backup tanks installed near the house, as well as blocking valves to prevent backflow. The disadvantages of this method include clogging of sewer pipes in the basement.

Disputes among professionals continue to this day. They argue that the likelihood of a drain backflow is so low that it is not worth the cost. Others say it's more important to keep your space safe and sanitary than to think about the money you're spending.

Leaks

Sewer leaks in the basement can also occur in addition to blockages - due to a violation of the tightness of the pipes themselves and their connections.

Symptoms

Drains flow onto the basement floor through the flared connection of the bench, through the riser from the ceiling between the basement and the first floor, or through a break in the pipe.

Causes

- Caulking the socket of a cast iron sewer;

In the photo there is a leak in the hammered socket of the bedspread

- Pipe subsidence in the ceiling. In this case, the sealing of the socket is again broken;

- Destruction of a socket or pipe under deforming loads;

Incorrect fastening of the pipe (large step between hangers) led to the appearance of a crack

- Destruction or loss of elasticity of the sealing ring on the socket of a plastic sewer pipe.

Solutions

The cast iron socket is hammered with a heel (tow with resin impregnation) or a graphite gland, followed by sealing with cement mortar.

This work is done like this:

- Using a hammer and a narrow chisel or a strong screwdriver, break up the remains of the old caulk;

- Remove the remaining heel from the bell;

- Place 4-5 turns of a heel or gland into the socket, sealing each turn with embossing;

Chasing a cast iron socket with a graphite gland

- After sealing, cover the socket with a solution of cement and sand in a 1:1 ratio. Pure Portland cement diluted with water to the consistency of very thick sour cream will also work.

Sealing the socket of a cast iron sewer

The subsidence of the riser in the ceiling is eliminated by lifting it to its original position and fixing the pipe with clamps to the wall. To lift a heavy pipe, overcoming its friction against the ceiling, you will need a lever - a pipe or a crowbar.

If the socket is destroyed, it is easiest to replace it with an assembly of a short (0.3 - 0.5 meter) pipe, a coupling and a compensating pipe with an extended socket.

Compensating pipe with a diameter of 110 mm

Sewer coupling

The replacement is done like this:

- The problem area with the socket is cut out with a grinder. This tool with a metal cutting wheel is equally suitable for cast iron and plastic pipes;

Both cast iron and plastic sewerage can be cut perfectly with a grinder and a metal circle

- A compensating pipe is put on one of the ends of the pipe (usually against the direction of movement of wastewater) until it stops;

- A coupling and a pipe inserted into it are mounted on the second end;

- The compensator is seated into the pipe socket, after which the assembly is fixed with clamps.

If it is impossible to completely dismantle the pipeline pipes, a compensator is used for repair.

The destroyed pipe is replaced with a new one - if necessary, using an assembly of a coupling and a compensating pipe.

Useful: the socket of a plastic pipe fits perfectly onto a cast iron pipe, cleaned of paint, dirt and lubricated with any neutral lubricant.

Small leaks (cracks in the socket or straight section of the pipe, holes punched in the bench or riser) can be eliminated using a bandage made from a bicycle inner tube cut along the circumference or bandage rubber and knitting wire.

Rubber bandage. Ask at pharmacies

The rubber is wound in several turns and tightened with one or two turns of wire.

Rubber bandage on a through fistula of a cast iron riser

Finally, if a socket joint on a plastic bench leaks, the O-ring in it needs to be replaced. If dismantling the connection is difficult, an assembly of a coupling and compensator will again come to the rescue.

In problematic cases, the connection can be sealed with silicone

Prevention

It comes down to monitoring the absence of deforming loads on pipes and sockets. Simply put, the bench pipes must be laid on supports, or suspended at a constant pitch.

Supports and hangers must prevent pipe subsidence

Features and advantages of operating pumping stations for draining wastewater from basements

The pumping station is a sealed container that plays the role of a mini-storage unit. In this case, wastewater is removed as needed when the container is filled. Pumping stations use special pumps that pump water up into the general sewer system in the basement of an apartment building, or directly into the drain.

The main advantage of the pumping station is the ability to install it in a bathroom or toilet at any stage, and not just during construction. If it is necessary to replace the pumping station, this can be done without difficulty by replacing the new system.

Installations with the following characteristics have advantages:

- Small in size, allowing installation in a bathroom, toilet or other rooms with a small area.

- Providing simple installation and maintenance that does not require calling specialists.

- Having a chopper.

- They have carbon filters that provide the lowest level of odors.

The sewage pumping station is capable of pumping wastewater with high temperatures. Most manufacturers assure that their models do not lose their characteristics, even if the drain temperature reaches 50-55 °C.

The power of the device also plays an important role. To provide for the average family, it is necessary to use a system that can transport wastewater to a height of up to 4 meters and a length of up to 100 meters. The sewage pumping station must have a capacity in the range from 8 to 24 m3/h.

Sewerage in the basement is the optimal solution for hiding pipes

How to make a hole in the foundation for sewerage

The easiest way to make a hole for the sewer is when pouring the foundation. Lay the mortgage in the form of a piece of thicker pipe, firmly securing it to the reinforcement frame.

If for some reason the passage under the sewer was not made during the pouring of the foundation, you can use the services of diamond cutting of concrete. You will have to pay several thousand rubles, but the output will be a neat hole in the right place without any hassle.

A hole in the foundation made using diamond cutting.

If you have an irresistible desire to save money, you can make a hole in the foundation for the sewer with your own hands. You can’t do without a hammer drill; it’s not easy and time-consuming, but it’s completely doable.

In order to independently hollow out a hole in the foundation for the sewer, you will need:

- Approximately 4-8 hours of time.

- Hammer.

- A good chisel about 40 cm long.

- Sledgehammer.

- Hammer.

- A hammer drill with a length of at least 400 mm.

The process is labor-intensive, drilling, hollowing out, and so on in a circle, but you can actually do everything with your own hands.

Video describing the process of hollowing out a hole for sewerage in a stone foundation:

Sololifts

As noted above, sewerage can be organized using sololifts. They are selected according to the same principle as pumping stations. The sololift must have a grinding system. In addition, there is a volume in which wastewater accumulates.

Sololift is the same pumping station, but used for rough waste. At the same time, they are small in size, so the issue of installation is not so relevant. The units have several inlet pipes, so several elements of the system can be connected to it. But Sololift has a small volume, which imposes slight restrictions on pumping capabilities in a certain period of time.

What pipes to use when laying sewerage in the foundation area

Under no circumstances should gray pipes be used when laying in the ground or in the foundation area. Gray pipes are for indoor use only. They have thin walls and are not able to withstand soil pressure.

Pipes in the ground can experience very significant loads, so there are special red-colored pipes for outdoor work. They have a wall thickness of 3.2 millimeters and, when buried in the ground, can even withstand movement on the surface of freight vehicles.

Red pipes for external sewerage.

When purchasing, be sure to look at the inscriptions on the pipe. Unscrupulous manufacturers often fake red pipes by simply adding orange pigment to ordinary thin-walled pipes. A high-quality pipe must be marked SN8 and have a wall thickness of 3.2 millimeters or more.

Basement window materials

Windows in the basement are made low, about 20 cm above the ground, so it is quite difficult for them to withstand high humidity. The process of arranging windows in the basement should include the selection of materials that are so moisture-proof that operation is long and problem-free.

Thus, wood in its usual form is definitely not suitable - in hot weather it will shrink, and in cold weather it will swell from moisture and freeze in an expanded form. Structures impregnated with special compounds designed to withstand such loads are required.

Plastic

The PVC profile used to make structures is quite large in size. But it is precisely this design of window openings that is most popular. PVC window structures can increase luminous flux by 15% without loss of thermal properties and rigidity. The use of this material is recommended in the case of a basement that is half underground.

It is necessary that the windows have a ventilation system and shutters that can be opened slightly so that condensation does not accumulate on the walls and other surfaces in the room. Where the opening comes into contact with the wall, additional insulation and protection from water are required; most often, installers use polyurethane foam for these purposes.

Aluminum

Aluminum structures for basements are usually not used, the only exception being an unheated basement with a boiler room or warehouse. Even in the cellar it is necessary to maintain a certain temperature, so aluminum will not work.

If the base is residential and used, then aluminum is not able to provide the necessary protection from the cold. Such structures are much cheaper than plastic, but have better thermal insulation. There are many options for aluminum basement windows to suit every taste and need.

Tree

The base has a high level of humidity, which makes it impossible to use untreated wood for window openings. But more and more often, builders are offering wooden profiles with impregnation, which allows them to successfully resist moisture for many years.

Coating with a special laminate, polymers or compounds gives both the attractiveness of the material and durability without repairs during operation.

Wooden windows are made in different thicknesses; in addition, the material retains heat well and is environmentally friendly, unlike other types of structures. Externally, a wooden profile looks very attractive, especially if the house is built from timber or timber.

Do-it-yourself plumbing in a private house

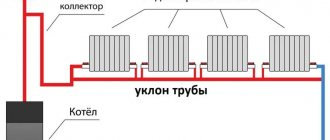

Having connected the pipe sections, they proceed to laying the water supply system inside the building. It is recommended to start laying from the consumer. The pipe is connected to the water consumer using an adapter with a threaded connection. Providing for future repair work, a ball valve is installed, occupying the space between the adapter and the hose connected to the valve. If repairs are necessary, the ball valve will shut off the water. Next, the pipe is laid to the collector with the obligatory installation of shut-off valves, which allows the consumer to be disconnected from the system for repairs or for another purpose.

When installing a water supply system, it is mandatory to use shut-off valves

When installing water supply in a private house, adhere to the following requirements:

- Avoid, if possible, laying pipes through elements of building structures. When laying through a wall, the pipe is placed in a special glass;

- to facilitate access to pipes in case of repairs, they should be laid at a distance from the wall, at least a couple of centimeters;

- approaching the outer corner, the pipe is moved one and a half centimeters away from it. The pipeline segment is removed from the inner corner by three to four centimeters;

- to attach products to the walls, use single or double clips, placing them on straight sections at a distance of no more than one and a half to two meters from each other. Fastening corner joints is mandatory;

- when joining PP products at an angle, they use special fittings and tees that allow connecting products of the same and different diameters;

- installation of the drain valve (and accumulator) requires a slight slope in its direction.

Following simple rules will allow you to successfully carry out the wiring and ensure proper operation of the installed system.

Backfilling the soil cushion for the floor on the ground

The surface of the future floor is raised to the required height by installing a cushion of non-heaving soil.

Any soil that can be easily compacted can be used as a material for constructing a cushion: sand, fine crushed stone, sand-gravel mixture, and if the groundwater level is low, sandy loam and loam. It is beneficial to use the soil remaining on the site from the construction of the foundation, well and septic tank (except for peat and black soil).

The soil of the pillow is carefully compacted layer by layer (no thicker than 15 cm) by compacting and pouring water on the soil. The degree of soil compaction will be higher if mechanical compaction is used.

It is recommended to make the thickness of the bulk soil cushion within the range of 300-600 mm. It is still not possible to compact the bulk soil to the state of natural soil. Therefore, the soil will settle over time. A thick layer of fill soil can cause the floor to settle too much and unevenly.

To protect against ground gases - radioactive radon, it is recommended to make the top layer of the cushion from compacted crushed stone or expanded clay. This underlying captage layer is made at least 100 mm thick. The content of particles less than 4 mm in size in this layer should be no more than 10% by weight. The captage layer must be ventilated.

Read: “Protecting your home from radioactive soil gas radon”

The top layer of expanded clay, in addition to protecting against gases, will serve as additional thermal insulation for the floor. For example, a layer of expanded clay 18 cm thick corresponds to 50 mm in heat-saving capacity. polystyrene foam To protect insulation boards and waterproofing films, which in some floor designs are laid directly on the backfill, from crushing, a leveling layer of sand is poured on top of the compacted layer of crushed stone or expanded clay, twice the thickness of the backfill fraction.

Before filling the soil cushion, it is necessary to lay water supply and sewerage pipes at the entrance to the house, as well as pipes for the ground ventilation heat exchanger. Or lay cases for installing pipes in them in the future.