Installing heated floors under laminate on a wooden base is gradually gaining popularity. There are 3 main types of design, each of which differs in efficiency, reliability and cost. Which one you should choose depends on the type of room.

For example, a water floor with a heavy concrete screed is more suitable for private houses, and an electric floor for apartments. You can do the installation yourself, the main thing is to take into account all the recommendations from the manufacturer and follow the instructions.

Find out how to install various types of electric heated floors under laminate: infrared, carbon, cable, in the form of heating mats, amorphous metal.

Advantages of OSB boards

OSB boards are very popular; they are used to level curved surfaces. Laying slabs on wooden surfaces makes the flooring stronger and warmer. Any floor covering can be installed on such a base. OSB is also used for underfloor heating.

The advantages of the material include the following characteristics:

- High density OSB;

- Resistance to moisture, which makes it possible to use in rooms with high humidity;

- Excellent pressing, so the material does not crumble;

- Protection from biological factors;

- Environmental Safety;

- Easy installation;

- Cost savings: it costs little, but covers a large area;

- Reliability: withstands mechanical loads, lasts a long time;

- Can be used for finishing with different means.

Is it true that plywood is a panacea?

When a repair specialist is asked what is the best way to level the base with laminate, he will affirmatively say that it is plywood, and he will be right without a doubt. This material has a whole host of positive properties:

- She is very easy to work with.

- Plywood weighs a little.

- It has no unpleasant odors at all.

- Even a beginner can install plywood.

- Has optimal rigidity.

- Has the ability to withstand enormous pressures.

In addition, plywood is also more profitable financially, for example, when compared with the same cement screed. As for specific advantages, they also exist and are expressed:

- Plywood covering is best suited for laminate flooring. The floors will end up being rigid all the way around.

- Due to the fact that the plywood parameters are quite large, the flooring can be done in a short time.

- If the base itself is uneven, the plywood sheet bends in the desired direction, maintaining all its qualities.

- And besides this, it is practically unpretentious; it can be installed under a wide variety of floor coverings, or used as a full-fledged floor.

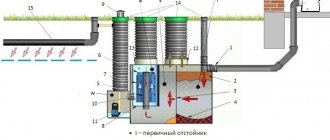

Water floor without screed

A water floor on OSB boards is laid where it is impossible to fill the screed: with low ceilings, on wooden bases. Advantages of this method:

- ease of installation;

- low floor height;

- the ability to lay the finishing floor covering immediately after installation.

The water heated floor system involves installation on a wooden base with OSB grooves using heat distribution plates. The pipes are covered with a moisture-proofing substrate and a finishing floor covering made of laminate or wooden parquet.

- Pipes use copper or polyethylene, but more often the latter option (they are inexpensive and last a long time).

- For work, take modules from OSB or chipboard with grooves for pipes, where plates for pipes are placed. The modules are represented by plates with a width of 130, 180, 280 mm. The size is selected based on the width of the pipe installation step.

- Heat distribution plates made of aluminum have the required diameter. Heat redistribution occurs along the surface from below.

Moisture-resistant chipboard, tongue-and-groove (VDSPSH)

Moisture-resistant particle board with tongue and groove along the perimeter (VDSPSH) is specially created as the upper surface of the prefabricated screed. VDSPSh is used not only in floor structures on joists, but also on backfill materials.

A tongue and groove lock around the perimeter of the VDSPSh slabs allows you to firmly connect them into a single, durable floor base, ready for laying finishing materials.

The tongue and groove lock is coated with a special mastic and connected with threaded connections. Gluing the seams with moisture-resistant chipboard and its moisture resistance allow them to be used even for tile work.

Wooden heated floor

The heated floor system is made from special OSB modules and slats. The modular installation method involves the use of OSB boards - ready-made modules for the circuit. The rack system is made from slats or boards.

The entire process of laying a floor on wooden joists is as follows:

- The logs are installed in increments of 60 cm, and thermal insulation material and insulation are laid between them.

- OSB modules are placed at intervals for normal expansion compensation. The modules are connected with a standard snap lock.

- The wood slatted flooring method requires a rough wood floor. They are placed oriented at a distance sufficient for the location of heating pipes, according to the selected pipe laying pattern (snake, snail, etc.). Laths and OSB modules are laid strictly following the layout diagram.

- Metal plates are placed on the laid models.

- Pipes are laid on the plates.

- A soft soundproofing substrate is placed on top of the laid pipe contour, and a finishing coating of more than 1 cm is placed on top of it.

Attention! If ceramic tiles or linoleum are laid on a heated floor, then chipboard, OSB, plywood, wooden boards, and gypsum fiber boards are laid on top of the plates. They are fixed, the joints are puttied. In this case, the finishing coating is laid in the usual way.

Tree specifics

If the heated floor is laid on a wooden base, then the finish should be laminated

Having a wooden base as the basis for a heated floor system, it is worth taking into account the properties of this material: mobility, slight fluctuations in the size of the guide bars.

At the same time, the entire wooden floor will sparkle not only due to changes in humidity or temperature, but also due to natural aging processes.

In a situation with a wooden base, the choice of heating systems is limited. In this case, it is difficult to use structures that require a concrete screed. When installing a heated floor on a wooden base, perhaps only a laminate panel is suitable as a finish.

Electric floor on OSB boards

Installation of electric floor heating is carried out in compliance with the safety rules for its operation and long-term use. There are the following types of electric heated floor systems: heating mats, heating cable, infrared film. Before starting installation, you need to prepare the base:

- Uneven floors are leveled with a screed.

- After drying, sheets of hard coating are spread: plywood, gypsum fiber board, chipboard, OSB, and others.

- The entire area is covered with heat-reflecting material. The flooring is made with the reflective side down. The material is carefully secured together with construction tape.

Next, the selected heater is installed. If it is a cable, then it is checked (resistance is measured), the guides are fixed according to the layout diagram, laid out on the OSB without twisting or bending, sensors are installed, power is connected, a screed 3 cm thick is poured. The heating mats are laid in the same sequence.

If film heated floors are laid, the technical characteristics of which allow them to be placed under any floor covering, then the following work is carried out: the thermal film is laid out on a rigid OSB base, not reaching the heating pipes 30 cm. Connection and installation of sensors is carried out according to the diagram in the technical documentation.

After installing the heater in the heating system, you can lay an OSB board on top, and the finishing floor covering on it.

It is quite possible to lay a warm floor under chipboard, you just need to choose the appropriate option, follow the instructions, technology and comfort in the house is ensured for a long time.

Installation of heated floors without the use of cement screed:

Candidate of Sciences, permanent expert of the site, a real, and not abstract (unlike other resources) person.

In private housing construction, the combination of “warm floor” with laminate is popular. At the same time, previously, electric cables (electric “warm floor”) and infrared films were mainly used for heating.

However, expensive electricity hinders the widespread use of such heating systems. And until recently, economical water-based “warm floors” were incompatible with laminate panels due to their low moisture resistance, the release of harmful substances when heated above 27 o C, and the destruction of locking joints during sudden temperature changes.

Manufacturers of lamellas took into account the problem areas of their products and offered laminate flooring for “warm floors” made from water heating. This article is about how to make a “warm floor” with water heating under laminate with your own hands, comfortable, beautiful and durable.

How to check work for quality

When all the work is finally finished, and it would seem visually everything is in the best possible way, you should not stop there

It is extremely important to check everything with the utmost care, because if something goes wrong during operation, there will be a risk of dismantling the entire structure

You can check everything in several ways:

- How flat the surface is is checked using a regular flat rod. It is placed on the floor and unfolded in this way in all directions.

- If there is a long building level, even better. With its help, you can reliably find out how horizontal the floors are.

- The last check also has its advantage in that after laying the plywood using a wooden hammer and tapping, you can find out whether there are voids under the sheets. If the knocking sound is of the same nature, then the work has been done efficiently. If in some places dull sounds are heard from tapping, then there are voids, and deflections are possible in these places in the future.

Is water heated flooring compatible with laminate?

Until recently, professional builders refused to lay laminate flooring on a water-heated floor. There are several reasons for this:

- low thermal conductivity of the floor covering: the lamellas in combination with the substrate are a good heat insulator. As a result, heat was trapped below. This reduced the heating efficiency;

- Water heating does not have the ability to achieve strict temperature control, as a result of which the coolant can heat up to 35-40 o C. This leads to two problems at once:

- deformation of the floor covering;

- the appearance of harmful fumes of formaldehyde resin in the room (emission begins at a temperature of 28-30 o C).

- The slightest leak of coolant, however imperceptible, leads to swelling of the panels. Probably every home craftsman knows that moisture is the worst enemy of laminate flooring.

As a result of a series of experiments, the manufacturers of this flooring were able to achieve compatibility between water-heated floors and laminate flooring.

Popular types of plywood used for renovation

Sheets produced by industry are classified according to various criteria:

- wood used;

- presence and method of impregnation;

- variety;

- number of layers;

- surface treatment;

- moisture resistance.

| Brand | Moisture resistance level |

| FSF, FSF-TV | increased |

| FSB, BFS, BFV-1 | high |

| BP-A, BP-V, BS-1 | above average |

| FBA, FC | small |

For repair work, when the part of the structure made of plywood will be hidden from view, it is recommended to use moisture-resistant plywood of grade II or III. The sheet must be at least 10 mm thick, but the recommended value is 14-22 mm. A thinner one will not cope with the load, and a too thick one will be inconvenient to work with.

Plywood thickness and ply

The number of layers is not of fundamental importance. If possible, you should purchase sheets sanded on both sides.

- If possible, the plywood should be dried for 2-3 weeks before starting work. The sheets are dried vertically, at a temperature slightly above room temperature.

We bring plywood into the room

You can increase the strength of plywood using several layers of acrylic varnish

48 hours before the start of work, the material must be brought into the room where it will be installed and laid horizontally. There are two ways to lay plywood.

Which laminate to choose for water-heated floors

For a long time, the “warm floor” and the floor covering made of lamellas walked in parallel courses, without intersecting. Laminate manufacturers did not want to lose a significant market segment. As a result, floor coverings compatible with “warm floors” appeared on sale. It has completely different technical and operational characteristics, suitable for the operating conditions of underfloor heating systems. To navigate them, we advise you to look at the article “Which laminate to choose for a warm floor?”, which explains in detail which laminate is suitable for a “warm water floor”.

For those who have little time and desire to follow the link provided, we will list in a concentrated form the basic requirements for lamellas with a liquid coolant in a cement screed.

Thickness. The optimal thickness of the laminate for heated floors is 8 mm with a density of at least 900 kg/m3. This allows you to get a durable board with good thermal conductivity. Increasing density affects the price. She's taller. But both the strength and heat conductivity of the floor covering increase.

For information: there is no density information on the packaging. Sometimes the weight of one lamella or the entire package is written. Finding out the density figure yourself is not difficult: the volume of one panel is found by multiplying the thickness, width and length. Then the weight of one laminated board is determined. After this, the weight in kg is divided by the volume in m3.

Thermal conductivity. Information on thermal conductivity can be found on the insert. According to the European standard EN4725, the thermal resistance of laminate flooring for hydronic underfloor heating must not exceed 0.10 m 2 x °K/W. On products of foreign manufacturers it is indicated by the inscription “thermal resistence”.

Strength. Laminate is available in different densities. Consequently, it has different service life, which is reflected by the “strength class” indicator. Indicated by two numbers. The first shows what rooms it is intended for:

- 2 - for residential;

- 3 - commercial.

The second is how durable laminated boards are. Under a warm floor you need a laminate of class 32-33.

Moisture resistance. When choosing lamellas you need to be careful. After all, there is a floor covering for infrared and electric floors, and there is one specifically for water ones. The inscriptions will help you figure it out. For water heating, the liner must have the inscription H2O or Warm Wasser. Black and brown pictograms with stylized pipes do not provide information about the type of “warm floor” that needs to be taken into account.

Environmental Safety. As the temperature rises, formaldehyde begins to release harmful fumes. In laminate flooring, chemical reactions in the resin are slowed down thanks to special additives. You can find out about their presence using pictograms (see photo). The designation E0 (NA) shows that up to +30 o C there will be no harmful emissions. E1 claims that the emission of harmful substances is within sanitary standards.

The influence of high temperatures. Laminate does not like sudden changes in room temperature. And a “warm floor,” especially with water heating, can heat the floor covering up to +40 o C. The ability of the lamellas to withstand overheating is indicated by the Latin letter B and the number 1.

Wear resistance. The last controlled indicator for water floor heating is wear resistance. Characterized by abrasion class. May be within AC1-AC5. The best option is AC4.

View of the castle. Until recently, experts did not pay attention to the type of laminate joint. Experience has shown that Click locks are better able to withstand sudden temperature changes.

Type of material. Under a warm floor, you can use a classic laminate made of fiberboard (in the English spelling HDF), vinyl, quartz vinyl and SPC laminate. There is a categorical ban on cork - it does not allow heat to pass through.

Cutting and fitting plywood

How to prepare the floor for heated floors

Plywood is cut in accordance with the floor area. It is necessary to take into account that when laying from the wall, an indent of 10 mm is made and the gap between the seams is 2-3 mm. Having cut the sheets into squares of the required size, you need to check their edges for delamination at the ends and the presence of other defects. If the edge is damaged, the workpiece should be replaced.

The plywood is laid in a checkerboard pattern. The sheets are drilled to the base with self-tapping screws along the perimeter and additionally along the surface in increments of about 20 cm. For quick and convenient installation, it is recommended to number the sheets and also mark the fastening points with self-tapping screws.

After fitting, the blanks are removed, the base is cleaned of dirt and dust. Before laying, the prepared sheets should be impregnated with an antiseptic in order to increase their service life. Then you can begin installation.

Which substrate is best to use?

The importance of the underlay when installing laminate flooring is described in detail here. But there is a special requirement for a laminate substrate under a warm water floor: the heat transfer resistance coefficient must be in the range of 0.04-0.06 m 2 *K/W. Only a substrate made of extruded polystyrene with mandatory perforation meets these parameters. Other types of underlying material (coniferous, cork) will not transmit heat upward. Or rather, they will, but poorly.

Required substrate thickness

The thickness of the substrate can be in the range of 1.5-3.0 mm. At the same time, the owners need to decide when choosing. Thinner material makes it possible to most effectively use the advantages of a water-heated floor, but it affects the durability of the floor covering if there are differences in height on the screed surface of 1 to 2 mm - the service life of the floor is significantly reduced. As the thickness of the substrate increases, the opposite happens: the durability of the laminate increases, and the transfer of heat from the coolant to the room worsens.

From the above, another conclusion follows: the surface of the screed should be smooth, close to ideal. Height differences of more than 2 mm are excluded. In principle, they can be covered with a thicker substrate, which is what is done when installing a simple floor. But then it will not be the room that will be heated, but the screed, due to the low thermal conductivity of the underlying layer. In addition, a thicker backing reduces the service life of the locking joints.

Method 1. Installation on old wood flooring

When laying plywood on a wooden floor, there are many options for fixing the sheets:

- on self-tapping screws;

- on glue;

- for liquid nails.

Adhesive compositions include water-based adhesive, two-component adhesive, assembly adhesive and bustylate. However, fastening with self-tapping screws is preferable.

Materials and tools

To successfully install plywood sheets, you will need the following tools and materials:

- plywood sheets;

- jigsaw;

- level;

- roulette;

- marker;

- self-tapping screws;

- screwdriver;

- substrate;

- construction vacuum cleaner or broom.

You may also need a sanding machine, a roller and primer, glue and sealant.

Preliminary preparation and priming of the floor

Installation of plywood on wooden floors is carried out only if the height difference when checking the level is no more than 1 cm. In this case, you will also need a substrate to compensate for unevenness and tape, which will need to be used to glue the joints of the strips of material.

Inspect the condition of the floors. Strengthen creaking and loose floorboards, replace rotten and damp floorboards. Do not try to restore boards that have traces of mold, damage, or have been attacked by rodents. They definitely need to be removed and the room ventilated.

We remove the baseboards and inspect the condition of the floor

Use a broom to sweep away dust and dirt from the floors. If desired, go over the wood surface primer twice to ensure better adhesion of the materials. And dry the base for at least 16 hours.

Marking and cutting

Only saw plywood on a rigid base

Plywood sheets are sawn so that the number of joints is minimal, taking into account damping joints of 3-4 mm between sheets and 8-10 mm between plywood and the wall. This will help avoid swelling of the sheets, since during operation, under the influence of the microclimate and temperature fluctuations, the workpieces will increase in area by several millimeters.

Laying plywood sheets

Leave a gap between the wall and the plywood

The cutting is done with a jigsaw, while the ends of the workpieces are carefully inspected for delaminations and sanded. On large areas, for ease of installation, plywood can be cut into squares of 50x50 or 60x60 cm. This technique will help to more accurately level the surface and eliminate possible installation defects.

The sawn sheets are numbered, and similar to their numbers, a schematic arrangement of the workpieces is drawn on a wooden base.

Leave the vent open

Laying plywood

Installation of blanks has several features.

- If necessary, a backing is placed on the old wooden covering, and the strips are glued together with tape.

- The holes for the self-tapping screws are drilled in advance and then countersunk with a drill of a slightly larger diameter.

- The screw heads are recessed into sheets of plywood.

Carefully recess the heads of the screws or dowels

Upon completion of installation, you should check the quality of the coating, remembering that the ideal gap between the level and the plywood is 2 mm, the maximum is 4 mm.

Materials and tools

To create a “warm floor” cake, from the ceiling to the floor covering, you need to buy the following materials:

- a set of water heated floors for laminate (boiler, collectors, electric pumps);

- pipes along with special fasteners;

- fittings for polypropylene or coupling-press for metal-plastic;

- roll waterproofing or mastic (only for concrete floors);

- insulation;

- damper tape;

- reinforcing metal mesh;

- metal profile for beacons;

- cement M300;

- sifted river sand;

- fiberglass fiber;

- plasticizers for cement-sand mortar;

- underlay for laminate;

- slats or wedges;

- laminate.

Tools you will need:

For preparatory work:

- perforator;

- level;

- hydraulic level;

- roulette;

- construction cord;

- trowel.

For laying pipes:

- grinder or hacksaw;

- wrench or adjustable wrench;

- soldering machine (needed for joining cross-linked polyethylene).

- concrete mixer (rented);

- bucket;

- rule;

- grinder (rent).

To lay laminate:

- jigsaw or hand saw for cutting laminated boards;

- mount;

- a block or a special metal bracket for padding the lamellas;

- wooden or cast rubber mallet;

- square;

- marker or construction pencil.

Pipe length calculation

The total length of the pipes is calculated by adding the length of each circuit. In turn, the number of circuits depends on the diameter of the pipe. Thus, through a 16-millimeter pipe, a pump of any power can pump water over a distance of 80-100 m (depending on the material of the pipes).

When this indicator is exceeded, a “locked loop” effect occurs - the movement of liquid stops due to the resistance of the pipe walls. Therefore, in large rooms, several circuits are installed. To simplify calculations, the pipe length for each room is determined, and then the number of circuits is determined. The calculation is carried out according to the formula:

L = S/P*1.05+(K*2) , where:

- L—pipe length in m;

- S is the area of the room in m2;

- P - laying step in m (optimal - 0.2 m);

- K is the distance to the collector in m.

For information: a factor of 1.05 is used for the margin for radii and connections.

The value obtained after calculation is divided by the maximum possible length of the circuit for each type of pipe and rounded up. The calculation can be carried out in a simplified way: multiply the area of the room by 5 - according to SNiP, there should be 5 m of pipes per 1 m 2 of floor.

Step-by-step instructions for floor preparation

Work begins with cleaning the floor from dirt, dust, household and construction waste, and remnants of previous coatings. To prevent the wooden elements from getting wet from below, a layer of roofing felt (roofing felt) or plastic film is laid on the floor surface. The film is applied to the entire surface with an overlap of 15-20 cm. The joints of the film are secured with construction tape. If the film thickness is small, you can make the flooring in 2-3 layers. This type of flooring serves as waterproofing.

Before installing the logs, check the level of the floor for horizontalness. The installation sites for the beams are marked and parallel lines are drawn to the middle of future logs. Usually the timber is installed on pads. For them, plates made from pieces of boards or plywood are used. The recommended size of each such lining is: width – 100 mm, length – 200-250 mm, thickness – at least 25 mm. Wooden pads are attached to the floor with anchors on top of the waterproofing along the marked installation line of the joists. The level controls that the height of the floor along the lining is the same over the entire surface. If it is necessary to adjust the height, pieces of roofing felt or linoleum are added.

To prevent the formation of mold in the future, all wooden parts and joists are treated with an antiseptic.

For ease of floor installation, beacons are sometimes used. As beacons, you can use screws (self-tapping screws), which in terms of the height of the head correspond to the height of the installation of the log. Such beacons, screwed evenly over the floor surface, will help control their height and pressing force or the need for additional laying when installing the timber.

How to choose pipes for water heated floors

The efficiency of a liquid heating system largely depends on the choice of pipes. They must have:

- appropriate purpose;

- only two connections: at the input and output. Joining scraps inside the screed is not recommended - it minimizes the risk of leaks;

- optimal diameter for a given room;

- service life of at least 50 years;

- high-quality fastening and related materials;

- time-tested operating experience, which is typical of well-known brands.

Material

During operation, pipes are affected by two factors:

- the pressure of the screed when it expands when heated;

- corrosion processes under the influence of coolant.

This sharply narrows the range of pipe types recommended for water-heated floors. Can be used:

- polypropylene. The only drawback is the lack of flexibility, which makes installation difficult indoors. They are inexpensive. The connection is made using a welding machine, which is more reliable than fittings.

- cross-linked polyethylene. Among the advantages: reasonable price and the absence of dirt on the inner walls - it does not accumulate. Disadvantages: strength and flexibility are lower than those of metal-plastic;

- metal-plastic. Connects using fittings. Installation is complex and expensive, which is compensated by high strength, flexibility and lack of waste during the assembly process.

Some experts advise using pipes made of copper and stainless steel. The experience of the USA, where copper has almost completely replaced other types of pipes from utilities, shows that inside the screed of copper pipes, cracks 2-3 cm long appear at the curves.

When installing heating without a screed, such problems are not observed. However, the cost of such materials is prohibitive. There are no positive or negative reviews on stainless steel pipes yet. Therefore, you should not take risks and buy polypropylene or metal-plastic.

Diameter

For heated floors, you can use pipes of different diameters: 16*2 mm, 18*2 mm, 20*2 mm and 25*2 mm. Let us immediately note that all contours must be made with pipes of the same geometry. Each of them has its own pros and cons. Thus, for small-diameter pipes, the amount of coolant per 1 linear meter is less, and therefore less fuel is needed for heating.

But large pipes have higher heat transfer. Overall, strengths and weaknesses are balanced. The only nuance that influences the choice is the turning radius. In small rooms, a pipe with a diameter of 20 mm cannot be laid in increments of 10-15 cm, which in most cases cannot be avoided. Therefore, 16 mm water pipelines are used in private houses and cottages.

Water circuit installation instructions

To organize water heating, you can use ready-made modules, OSB boards or chipboards with channels cut by a pipe router. You also need to choose pipes, a thermostat, insulation, and waterproofing.

The length of the pipes is calculated based on the installation method and the size of the heating zone - a warm floor can be an additional or main source of heat.

Depending on the layout of the room, the arrangement of furniture and the design of the heating system, pipes can be laid in rings, snails or spirals, but for self-assembly a simple “snake” is considered the simplest” (+)

For wooden houses, slatted masonry is often used. To do this, it is necessary to prepare the surface of the subfloor: lay the flooring on plywood or OSB beams 15-20 mm thick, level and insulate if necessary (maximum permissible unevenness is 2 mm per 1 linear meter).

It makes sense to install a water heated floor if the house is equipped with autonomous heating, but connecting to a centralized network is not recommended for a number of reasons: in an apartment this is simply prohibited, and in a private house there is a risk that the pipes will not withstand pressure surges (+)

Stages of the following work:

- Think over the wiring and calculate the pipes for the floor. It is important that the base of the rack is installed perpendicular to the supporting slats.

- Then cut strips of moisture-resistant plywood, 2.5-3 cm wide less than the pitch for laying the pipes. For example, for a step of 20 cm, stripes with a width of 17 cm are needed, for 30 cm - 27, etc. The thickness of the strips should exceed the diameter of the pipes by 10-15 mm.

- Lay a layer of water and vapor barrier (polyethylene film is most often used).

- A damper tape is attached along the perimeter of the walls, which will provide the necessary space when the materials expand due to heating.

- The layout of the pipes is marked on the floor according to the wiring plan.

- Then cut slats or a flat surface with wooden materials are installed on the logs to form a groove for the pipeline. In places where you plan to rotate the contour along the markings, it is advisable to round off the strips themselves and then secure them with self-tapping screws.

- Heat-conducting plates are now placed between the slats, which must occupy at least 80% of the floor surface to ensure uniform heating of the laminate.

- Hydraulic circuit pipes are installed in the grooves of the profile.

Then the structure is checked for functionality by connecting it to the heating circuit. To make sure there are no leaks or deformation of the pipes, it is worth observing the operation of the system for a couple of days, creating maximum pressure.

If desired, the heat-conducting plates can be replaced with pieces of thin aluminum sheet or metal profile, but using foil for such purposes is useless

At the final stage, all that remains is to cover the “pie” with waterproofing (for example, a layer of polyethylene at least 100 microns thick) to reduce the influence of noise when heating and cooling the pipes. Heat-conducting sheets made of kiln-dried plywood or gypsum fiber are best suited for finishing the floor covering.

Technology for installing water-heated floors under laminate

The technology for installing a heated floor involves two stages of work: preparing the base and laying pipes with pouring screed.

Preparatory work

The step-by-step algorithm for preparing a floor for water heating includes the following operations:

- Using a tape measure, the possibility of installing a water-heated floor in the room is checked. To do this, measure the height of the ceiling from the concrete or wooden floor. From the resulting figure, 14 cm is subtracted for the floor pie and 220 cm for the height of the doors. There should be at least 10 cm left. If they are not there, you should forget about this heating option;

- the ceiling is repaired: cracks, chips, sinkholes are repaired, and damaged areas of plaster at the joints of panels are also restored. You can see how to do the work correctly here;

- The location in the house where the collector will be located is determined. A niche is cut out (cut down) for it;

- a collector is installed;

- the base of the floor is protected from moisture from below - waterproofing work is carried out. Detailed instructions can be found in the articles:

- “Waterproofing a floor in a wooden house”;

- "Waterproofing the floor before the screed."

- To prevent heat loss through the ceiling, the base of the floor is insulated. You can lay a simple heat insulator (foam plastic, extruded polystyrene foam, polyurethane foam boards, basalt mats) or lay it with bosses for pipe routing. You can see how to choose insulation and install it correctly on our website. The following articles are devoted to the problem:

- “Which insulation is better to choose for the floor?”;

- “Floor insulation with mineral wool.”

Attention: when laying a heat-insulating layer of extruded polystyrene foam slabs, they must be additionally secured to the ceiling with disc-shaped dowels - they float when the screed is poured.

Important: almost all sites that post materials about installing a water-heated floor mention the need to use foil insulation or aluminum foil. This is a publicity stunt aimed at increasing the cost of work. After all, the ability of foil to reflect heat rays in an opaque environment - in a screed - is completely lost. In addition, the alkaline environment of the CPR will completely “eat” the foil during the hydration process.

- damper tape 6-12 mm thick is glued to the wall;

- A metal reinforcing mesh is laid on top of the insulation. Wire thickness - 2-5 mm, cell size 50x50 mm.

Installation of heating pipes

Before starting the installation of the heating itself, you need to decide on two parameters: how to lay the pipes in the circuit and the distance (pitch) between them.

Methods for laying the contour

There are several ways to lay out a contour. And each of them has its own strengths and weaknesses.

Snake. The simple snake installation option is a plus. The downside is a significant temperature difference at the inlet and outlet of the coolant: the liquid cools down as it passes through the pipe, which is natural. Therefore, there is a significant temperature difference in different parts of the room.

"Snail". Here everything is the opposite: it is difficult to lay, but the floor temperature is almost the same everywhere (there are differences, but they are leveled out by the body of the screed). In practice, in 90% of cases this is the method used.

Double snake. An even more complex way of laying out pipes. But the heating of the floor is uniform over the entire area.

Combined. Near the walls the installation is carried out with a snake, in the middle of the room with a snail. The method is complex, but it allows the coil with the pipe to be used as efficiently as possible (the least amount of unused residue) and ensures a comfortable heating mode.

Laying step

The laying step is another important parameter when installing a “warm floor” with liquid coolant. It can be from 100 to 250 mm. When laying in a snake pattern on a steep radius, pipes may break. Therefore, the pitch there is different - 150-250 mm. Experience shows:

- near the outer walls, pipes should be laid apart from each other at a distance of 100-150 mm. In this case, there should be 5-6 rows of coolant in the zone;

- in the center of the room you can use a step of 200-250 mm;

- in bathrooms and corridors - 150 mm.

Pipe laying

When laying with a simple snake, work begins from the outer wall - the coolant is hotter. The first row is laid at a distance of 150 mm from the outer wall. Pitch, for pipes with a diameter of 16 mm - 150 mm. Other diameters - 200 mm. The length of the pipe in the circuit should not exceed 80-100 m.

When laying “snail”, the distance between the pipes near the walls is 10 cm, on the remaining area - 20 cm. Each row is secured with special brackets, if the insulation does not have special bosses for fixing the pipes.

After laying out, the ends of the pipes are attached to the collector. It is important here not to confuse the entrance and exit, especially when laying with a snake. The tightness of all connections is checked - the boiler is started, hot liquid is driven through the pipes.

The process of installing a water-heated floor is completed by pouring the screed. There are many nuances and secrets here, and therefore we advise you to view the work “Screed for a warm water floor.” In the same work you can read in detail about laying water heating pipes on a wooden floor base.

Briefly about the method. Two laying systems are used:

- polystyrene boards with bosses;

- wooden modules or slats.

Installation on bosses is simple and convenient: the slabs are laid on the insulation, and pipes are recessed into the grooves between the protrusions (bosses). The cost of the work is lower than when pouring a screed, but there is a drawback: when the heating is temporarily turned off, the room quickly cools down, which does not happen with a screed - it accumulates heat and then slowly releases it into the room. It's like a brick stove - you heat it once and it's warm for almost a day.

Modules are available for sale. But you can do without them by using strips 20 mm thick (for 16*2 pipes) and 130 mm wide (for a pitch of 150 mm). The work is completed by laying plywood, fiberboard, gypsum fiber board or OSB sheets on the bosses or strips - they serve as the basis for the floor covering.

Some tips for safe operation

When planning the installation of a heated floor, do not forget that neither electrical cables nor water pipes should be laid under heavy furniture. Also, do not install heated floors in close proximity to a wood stove, gas fireplace, stove or other heating appliances.

For rooms for various purposes, you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24 ° C, and in the kitchen and in the corridor 20 ° C is enough

Practical nuances:

- After completing the repair, leave the heating system on and maintain the same temperature conditions for 3-5 days. This precaution will allow the entire “pie” of the floor to be heated evenly and accurately and ensure reliable operation of the system.

- At the beginning of the heating season, the underfloor heating system must be properly prepared for use. To do this, increase the heating level by 5-7 units every day until the temperature reaches the required value. This approach will avoid sudden temperature changes that can damage laminate and other materials. In the same way, turn off the heating during the warm period.

- Do not forget that infrared film flooring does not tolerate moisture well. Therefore, it is not recommended to install it in rooms with a humidity level of more than 70%, and to dry the laminate after wet cleaning.

- The optimal temperature for heated floors is 20-30 degrees Celsius.

Last but not least, do not cover heated laminate flooring with carpets or other furniture that will interfere with the efficient distribution of heat.

The nuances of further laying laminate

Laying laminate flooring on a warm water floor is carried out using classical technology:

- a waterproofing film is laid over the screed or flooring, overlapping and extending onto the walls;

- a substrate is attached on top of the film;

- The final floor covering is installed - laminate.

Finally. Warm water floors are used mainly in private houses and cottages (for apartments you need to obtain many permits and it is not a fact that in the end they will be allowed). This allows for very convenient and comfortable heating of the building. The ability to lay laminate floors on top of coolant pipes has expanded these possibilities. You can do all the work yourself, saving a lot of money.

https://laminatepol.ru/24565-teplogo-pola-pod-dsp.html https://stroyguru.com/remont-kvartiry/pol/teplyj-vodyanoj-pol-pod-laminat/

Chipboard flooring on joists: can it be laid in a residential area?

Chipboards are used when it is necessary to level the surface; first, a so-called rough covering is erected, and then the main covering, for example, carpet, linoleum or laminate, is laid on top of it.

The second method of use is insulation. If the base covering is placed on a concrete base, the floor will be cold in winter.

To fix this, chipboard is placed on it in advance. The third method of application is a chipboard floor on joists on top of a concrete screed .

What are particle boards? Chipboard is a board made from wood chips mixed with resin.

The slabs are formed by hot pressing of various thicknesses from 10 mm to 30. For floors, chipboard of 30 mm thickness is used.

Types of plywood used for work

The material varies depending on the type of wood veneer used in production. There are the following types of canvas:

What kind of plywood to lay on a wooden floor? There are different brands suitable for certain types of work. In industrial construction, plywood of the FB and FOV brands is used. The FSF and FC categories are suitable for laying flooring in a residential area.

Canvas marked FC can be used to install a wooden floor under laminate in a nursery or bedroom. The material is impregnated with an adhesive composition that does not contain phenol. The fabric does not pose a risk to human health. Such plywood sheets are quite durable and have an average level of water resistance.

Which glue to buy

How to glue tiles to plywood? This issue deserves detailed consideration, because you will have to glue the tiles to a base made of wood material, which is characterized by its instability.

Therefore, when choosing an adhesive composition, it is necessary to take into account some nuances:

- A sheet of plywood is made up of thin layers of brittle veneer, and if the bond is broken, the plywood will delaminate and will no longer be strong. This feature of the material is a good reason to choose an adhesive that does not penetrate deeply into the structure of the material.

- No matter how strong the base is, it can still bend slightly under load. In this case, the cement-based adhesive will not hold the tile, and it will easily come away from the plywood. Therefore, only elastic adhesive mixtures should be used.

The composition of such mixtures includes highly elastic components:

- microfiber;

- fiberglass;

- silicone;

- silane and other modifying additives.

It is important! When purchasing glue, make sure that the list of listed materials for which it is intended to work includes plywood.

Types and scope of application of penofol

Main types of material

| TYPE | COMPOUND | APPLICATION |

| A | Foiling only on the outside | Used in combination with polystyrene foam |

| IN | Aluminum foil lining on both sides | Can be used without additional materials |

| WITH | Self-adhesive type, foil-lined on one side. On the other hand, it is impregnated with a contact adhesive composition. | Installation is carried out without the use of additional adhesives. |

| R and M | The foiling is one-sided, has a relief base | Suitable for interior and exterior work |

| Super NET | NET – means network. Double-sided foiling. | It is used for thermal insulation of pipelines, heating mains, air ducts. |

| A.L.P. | Laminated penofol. A cellophane film is applied over the foiling. | Widely used in agricultural work. |

You may find the brand "Penofol 2000"

- This is the cheapest type of penofol. It is of low quality and less durable.

Scope of application of penofol

The scope of application of insulating material is extensive. The main thing is to choose the right type of penofol.

In construction

reflective heat insulator is used:

Other applications:

- Refrigerators, refrigerators, vans.

- Cars.

- Railway carriages.

Necessary tools, materials

for installation work:

- Wooden beams.

- The slats are 15–20 mm thick.

- Antiseptic.

- Adhesive composition for certain types of penofol.

- Dowels, self-tapping screws for fastening the frame.

- Aluminum tape for gluing joints.

- Scissors.

- Furniture stapler.

Installation of logs on the surface

The timber is laid according to the markings on the fixed linings. The logs are mounted parallel to the wall with windows, i.e. across the direction of sunlight entering the room. The first lag is installed at a distance of 30-40 mm from the wall, and all subsequent ones - 40-50 cm from each other.

When specifying the distance between the logs, you must remember that the gap between the last beam and the rear wall should also be no more than 40 mm. The distance between the lags should be the same. The logs must be fixed parallel to each other strictly at the same height (along the surface). All logs are chosen to have the same section size, except for the log located at the front door. It is advisable to install this beam from a wider beam (at least 50 mm).

The logs are attached with screws to wooden pads, previously positioned and secured with anchors according to the markings. The heads of the screws should not protrude outward (it is advisable to have them recessed into the joist by 2-3 mm). The height of the logs must be strictly the same, so during installation the height is constantly monitored using beacons (if installed) or using a level. To increase the height, a roofing felt pad of the required thickness is placed under the joist.

The beacon allows you to determine the force with which the screw is screwed in, so the height of the log is adjusted. To strengthen the lags, transverse bars (crossbars) are usually installed. Such bars are fastened across the beam in places where wooden pads are installed and are attached to them with screws.

For reliability, after installing the logs, all wooden elements are coated with parquet or other similar glue. It is advisable to fill the volume between the joists with insulation and sound insulation. For this, mineral wool, expanded clay or expanded polystyrene (foam plastic) are usually used. Before backfilling, all communications are carried out (if necessary). It is also recommended to place a layer of parchment or bitumen paper on top of the lag. Sometimes the timber is installed without the use of wooden supports. In this case, the lags are leveled by placing pieces of roofing felt. The joists are secured to the floor with anchors. The length of the anchor is selected 5-6 cm greater than the thickness of the bar.

Difficulties in working with OSB

However, when finishing work with OSB, you need to follow a number of rules so that the results do not disappoint you.

It must be remembered that the base of the OSB board consists of wood. Consequently, the slab tends to absorb moisture, which leads to its swelling and deformation.

Like any wooden surfaces, OSB panels have poor adhesion to cement-based adhesives, so most tile adhesives will not be able to ensure reliable adhesion of the tiles to the particle board surface. To do this, a number of works should be carried out to increase the adhesion of the bearing surface.

Another feature of OSB is its flexibility, which prevents the panel from cracking under physical stress. Under the weight of people moving around the room, the slab will bend slightly.

Compared to OSB, tiles are almost incapable of bending. As a result, the tiled flooring will inevitably peel off from the base, and the seams between the tiles will crack.

To avoid this, you will have to make the surface of the slab as hard as possible.

Painting OSB panels

The final stage of finishing the OSB surface will be the application of parquet varnish or painting in several layers with paint for wooden surfaces. The paint coating must be applied following the manufacturer's recommendations, including the use of a primer recommended by the manufacturer of the parquet varnish, in order to avoid incompatibility of components. The plinth is attached last and if it is made of wood, it must be painted in the desired color or varnished in advance. You can secure the plinth in several ways - fastening with glue or self-tapping screws. To prevent the plinth from bursting, a through hole is drilled in the places where it is attached; a recess can also be made with a drill of a smaller diameter for the self-tapping screw and under the head, and upon completion of installation, all holes in the plinth are closed with putty, sanded and repainted. As you know, there are nuances in installing oriented strand boards to a concrete base, but if you follow the sequence of work and recommendations, laying a finished OSB floor with your own hands is quite simple.

vote

Article rating

Why choose OSB-3

Increased moisture resistance is mainly achieved by using phenol-formaldehyde as a binder and adhesive material. But these materials are not recommended for indoor use. Moreover, in European countries the production of materials using formaldehyde is prohibited. Manufacturers have developed binders for gluing and pressing chips based on polyurethane resins. OSB-3 Bolderaja ECO is produced in Europe, which uses these safe resins. The material complies with the European product standard EN 300. True, such material is more expensive than usual, but is it necessary to save on health?

For flooring, manufacturers produce slabs with a tongue-and-groove edge, which ensure a tighter fit of the slabs to each other. And to the question whether it is possible to lay OSB on the floor, the manufacturer gives an affirmative answer, offering consumers materials of varying thickness and moisture resistance.

On video : characteristics and features of the use of the material