Roofing made from soft tiles is known for its excellent performance characteristics, but it has the only drawback - the lack of sufficient ventilation. Thus, the regular accumulation of condensation under the roof destroys the insulation, wooden rafters and sheathing, which calls into question the safety of the building.

Agree, it is better to think about installing roof ventilation before purchasing a roofing covering, rather than spending a lot of money later on restoring the roof structure. Plus, ventilation of a soft tile roof will forever solve the problem of mold formation indoors. After all, such a neighborhood has never benefited anyone.

Before you start designing roof ventilation, you should study in more detail all methods of air exchange, including the installation features of each of them. Later in the article you will learn which type of ventilation is best to choose, and what rules are important to follow at the stage of designing and installing a ventilation system.

Ventilated roofing and its design

As you know, daily temperatures fluctuate constantly. Because of this, condensation appears in certain areas of the roofing.

This most often occurs during the winter months when the difference between indoor and outdoor temperatures becomes significant.

In this case, the thermal insulation layer experiences maximum load. Its upper and lower edges experience temperatures that can differ by tens of degrees. Water vapor, rising upward from the room, accumulates in the under-roof space and creates pressure.

As a result, the insulation layer absorbs a large amount of moisture and ceases to fulfill its main task - retaining heat.

Atmospheric precipitation and melt water can also be considered sources of moisture.

Water entering the roofing structure has a negative effect on it. .

A ventilated roof copes well with this problem. Thanks to it, the costs of heating the premises will be reduced in the winter months. And in summer such a roof will counteract the heat.

The ventilated roof has a fairly simple design. It consists of three elements:

1) Space ventilation located between the heat-insulating and waterproofing layers;

2) Ventilation located between the waterproofing layer and the roofing material, covering all planes;

3) Ventilation under the roof itself;

A ventilated roof is distinguished from others by the location of the ventilation. Moisture is removed outside thanks to constant air flows. It is important to note that ventilation is highly dependent on the correct installation of the roof sheathing.

Installation of a ventilated roof has its own characteristics. For example, a non-insulated type of coating is perfect for garages and outbuildings. It consists of sheathing, waterproofing layer, rafter system and roofing material.

The waterproofing film is attached to the rafters using slats. The film prevents water from getting inside, thereby extending the life of the roof.

This design does not have an insulating layer, so it will be cold. But this is not suitable for residential buildings. The composition of the roofing cake, in addition to the layers that have been listed, should include slab insulation and anti-condensation film.

In addition to all this, a ventilated roof must have a ventilated ridge and vents in the lower part of the roof eaves.

Preparatory work

Soft tiles are installed differently than metal tiles; timber sheathing is not suitable for them, since the material does not have a clear fixation. If a board is placed below, it is recommended to purchase it in winter and use it in the warm season. Then the humidity level will be completely optimal. The best board options are approximately 100 mm wide, and all elements should be approximately the same size. The under-roof carpet next to the ridges should have a length of 250 mm, and on the sides of the valley this distance is 0.5 m.

According to the diagram, it is required to equip a ventilation system ; if it does not work efficiently, the rafters will quickly be destroyed by condensation, ice and rot. It is imperative to install vents and air outlets under the eaves. The gap from the tiles to the base of the roof also plays a role in the ventilation of the internal parts of the roof. This technique also solves the problem of water vapor escaping. Rolled materials are fixed using cold and hot mastics.

A cold mixture is needed for the internal segments of the roof; outside work is done exclusively with the help of hot substances.

If bitumen is used, it must be supplemented with dust-like fillers (lime, gypsum or ash) or fibrous structure. The best mastics among professionals are those that contain polymers. Preparing cold mixtures from available ingredients is not difficult. Take two working containers, one of which is filled with bitumen, and the other with diesel fuel and filler (in a ratio of 2:2:1).

The tanks are heated to 180 degrees; After drying the bitumen, you need to mix the prepared substances. Obtaining hot mastic is achieved somewhat differently: bitumen is heated to 200 degrees and gradually, with caution, filler is added to it. During mixing, substances should not cool to more than 160 degrees. To evaluate the quality of the resulting composition, you should cool it to 60 degrees and then apply it to the slope at an angle of 45 degrees. A decent mastic should not flow off the surface on its own, and when it hardens, a smooth surface is formed without a single crack.

The base of the structure is made of wood, which is impregnated with a mixture of diesel fuel and bitumen. Then the surface is smeared with mastic, and only after that can glassine and roofing felt be laid. The pitch of the sheathing under an ondulin roof, the slope of which exceeds 12 degrees, should be small; its exact value is determined for each specific underlying material. The vapor-waterproofing film under the soft roof is made of polyethylene and polypropylene, it is reinforced with mesh or fabric. Microscopic perforation allows you to protect the coating from moisture, and if it is not there, the film will allow steam to pass through.

What are the advantages of a ventilated roof?

This type of roofing has many advantages. These include:

1) Installation of this roof can be carried out even at sub-zero temperatures, if it does not reach minus twenty degrees Celsius.

2) When carrying out reconstruction, it is necessary to remove the old roofing covering to a minimum. And the preparatory work does not require much time. This will allow you to save money and time.

3) Over time, all roofing elements, such as floor slabs, roofing, and thermal insulation, dry out completely. This eliminates the possibility of rot and mold, which negatively affect the roof structure;

4) This type of roofing is resistant to temperature changes, frost, ultraviolet radiation and mechanical damage;

The ventilated roof is installed in the following order:

1) First you need to prepare the foundation for the work. To do this, it is necessary to eliminate cracks and holes. It is important to note that the roof slope must be at least 2-3 degrees.

2) Then a vapor barrier film and an insulating layer are laid. As a rule, mineral wool or glass wool is used as insulation. They provide high quality and low installation costs.

3) In the future, installation work may differ. They depend on the type of roof.

But most often a layer of waterproofing and a cement screed are laid.

4) roll fused materials are used as roofing.

They will provide high quality. A gas burner is used for installation. The overlap of the material should be 1-5 mm.

Types of protective coating

Binders that are used in the production of rolled roofing materials require protection from weather conditions. Sprinkles of varying degrees of grinding are used as a protective layer:

- coarse-grained (K);

- fine-grained (M);

- dusty (P);

- scaly (H);

- special resistant to alkalis or acids.

Coarse-grained topping not only protects, but also gives a decorative appearance.

In the marking, the letter indicating the type of sprinkle is placed third. Rolled materials used for lining are sprinkled on both sides with fine-grained or dusty powder. Its task is to prevent the roll from sticking together.

Fine-grained or dust-like crumbs are also applied to the back side of the roofing roll material, and coarse-grained or scaly crumbs are applied to the front side, which not only protects the coating, but also gives it a more attractive appearance. To give it an even more aesthetic appearance, the sprinkles are painted in different colors. Typically the colors are red, grey, burgundy, brown, green and blue.

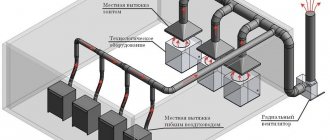

Design and further installation of ventilation

- Steam always goes upward.

- Water always flows downwards.

- When installing a vapor barrier, it is necessary not only to lay the roof overlapping, but also to seal the joints with special tape.

- If there is no ventilation system inside the room, then even sealing will not be enough - steam under pressure will penetrate into the lower layers of the vapor barrier and moisten it. To correct the situation, you will need a ventilation outlet to the roof.

- It is necessary to completely exclude the possibility of the walls of the house to “breathe” so that cracks do not form in them, which will subsequently lead to the penetration of steam into the roofing pie.

- You should also pay attention to small rooms in the house. Ventilation must be everywhere.

- The vapor barrier must be installed as close to the interior space as possible. If this is hampered by improperly installed waterproofing, then you will have to completely dismantle the covering, correct the necessary points, check the ventilation outlet to the roof of the house, and then start doing vapor barrier.

Rules for installing a ridge system

Since the ridge option is the most reliable type of roof ventilation today, it is worth considering in more detail.

Regardless of the type of ridge aerator, all designs have the same structure and include the following components:

- protective barrier;

- connecting endings;

- partitions;

- structural ribs.

To install the structure, it is necessary to make several grooves in the ridge beam, 1.5 cm long. The distance between them should not be less than 30 cm. The marked grooves will subsequently be covered with a ridge element.

To achieve a high level of aesthetics, the ridge element installed along the entire roof can be covered with soft tiles, leaving the ventilation gaps open

Today, ready-made structures for installing ridge ventilation can be purchased at any store, and the element is selected in accordance with the angle of the roof.

If you have a ready-made ridge product, you need to figure out how to install vents on a roof made of soft tiles:

- if the system is installed on a finished roof made of flexible tiles, then, first of all, you will need to dismantle the old ridge, partially disassembling the tiles;

- Next, you need to mark the new ridge aerator, and it is important to make an allowance of 1.5 cm from the top;

- at the next stage you will need a circular saw, with which you can make a neat cut, based on the markings;

- Flexible tiles will be nailed to solid areas, but in this case the partitions should be left open;

- The ridge aerator has special latches, through which the element will be connected to the roof ridge. Having installed the aerator using small latches, it will need to be secured using small self-tapping screws;

- for greater reliability, the end part of the aerator should be treated with silicone sealant;

- Next, the installed profile will need to be covered with soft tiles.

Despite the popularity of the “do-it-yourself” method, in some cases it will be more advisable to purchase a ready-made structure than to undertake its own manufacture.

The cost of ventilation ridge systems is not so high that you should try to save money on their purchase.

In some cases, for complete air exchange of the under-roof space, ridge ventilation alone may not be enough, so it may be necessary to install additional point aerators

In large houses, in addition to continuous roof ventilation, a point ventilation system is also installed for soft tile roofs, since continuous roof ventilation is often not enough.

Ventilated roof installation

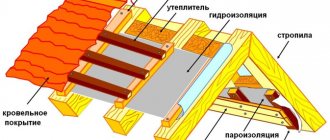

- Rafters;

- Lathing;

- Roofing material;

- Waterproofing films.

But the use of diffusion film is justified only during the installation of certain gaps. The film can best show itself by filling the gaps between the thermal insulation structure, the roof and the film. In almost all other cases, this film will not allow water vapor to pass through, causing the roof vent outlets to stop working properly. Instead, it would be better to use anti-condensation film.

Construction technology includes dozens of engineering solutions related to roof construction. The comfort of residents depends entirely on how well and competently it is done. All the power of the elements - rain, wind, snowfall and hail - falls, first of all, on the roof, so its design should be very carefully thought out.

Special requirements for roof construction are imposed in regions with high humidity, frequent rain or fog. Exposure to moisture significantly reduces the service life of wooden structures and roofing pie, even despite treatment with special compounds and waterproofing . However, it is quite possible to minimize the problem of dampness; installing a ventilated roof will help with this.

Advantages of a ventilated roof

The design of a ventilated roof has been developed quite a long time ago, its high efficiency has been proven by many years of practice. The popularity of this technology is due to the following advantages:

- high degree of protection of all layers of the roofing cake from getting wet;

- no swelling of the roof covering;

- the possibility of using organic insulation;

- economical due to the possibility of installation on top of an old roof.

If a ventilated roof is built on top of an old structure , then the latter “comes back to life”: the wooden elements become dry again, moisture is removed from the materials of the roofing cake. As a result, the roof turns out to be double , its resistance to adverse weather conditions increases, and the whole house becomes truly warm and cozy.

Ventilated roof: design

The design of a ventilated roof provides for air circulation:

- between layers of insulation and waterproofing;

- between waterproofing and roofing material;

- in the attic space (as part of the general ventilation of the house).

Thus, the entire roof structure is very well ventilated, due to which it is not only possible to get rid of excess moisture, but also maintain an optimal temperature regime. In this case, competent installation of the sheathing plays a decisive role.

The design of a ventilated roof has a number of varieties , which are related to the purpose of the building. For garages or outbuildings, an uninsulated option is used , which consists of the following components:

- rafter system;

- lathing made of wooden slats;

- waterproofing;

- roofing covering.

Polyethylene film is used as waterproofing , which is attached to the rafters on slats.

- This publication will tell you what the drainage system consists of.

- How to correctly calculate a roof taking into account the weight of the roofing material, read here.

- You will learn about passive and active lightning protection of a private home from our article.

For heated buildings, slab insulation and anti-condensation film are added to the roof structure, which protects wooden elements from condensing moisture. In general, the order of layers in such a roof is as follows :

- two layers of laminated film;

- non-woven material with high moisture absorption capacity;

- polypropylene fabric.

An important part of this type of roof is the vents located in the lower part of the eaves, as well as the ventilated ridge.

Compound

Soft roofing is a modern, technologically advanced material made from durable polymers. The flexible, elastic structure gives this practical roof covering additional advantages when installing complex, multi-pitch structures. According to SNiP definition, flexible tiles are a multilayer material, which includes:

- Fiberglass . Soft tiles have a durable non-woven base made of compressed, randomly arranged fiberglass. Flexible, elastic fiberglass gives the material resistance to temperature and cracking. Products priced in the highest price category are additionally reinforced with polyester, making the coating even more durable.

- Modified bitumen . During the production process, the fiberglass base is impregnated with petroleum bitumen enriched with polyester resins and synthetic rubber. Thanks to impregnation with this composition, the soft roof becomes highly resistant to moisture and the effects of mold and putrefactive microorganisms.

- Booking powder . The flexible tiles are sprinkled with colored mineral granules on top, which impart color and a rough texture to the material. Granite, marble or basalt chips are used as a topping that protects the bitumen coating from mechanical damage and prevents overheating of the roof.

Important! Bituminous shingles manufactured in accordance with SNiP have high performance qualities and effectively protect against the penetration of moisture, wind and cold. As a rule, the cost of the material indicates the quality of the product and its components.

Composition of soft roofing

Shingle laying technology

Underlay carpet for soft roofing

Project development procedure

During design work on the installation of a ventilated roof, it is necessary to provide for the following:

- Proper drainage . The roof structure must be such that water flows freely from its surface. This is especially true for flat roofs, where, due to improper installation, depressions often form in the covering in which water accumulates.

- Steam removal exclusively through the roof.

Flat ventilated roof

Such roofs began to be built in the 80s of the last century. It was during this period that it became possible to install a heat insulator with ventilation ducts to remove excess moisture. Roofs of this type were most widespread during the construction of apartment buildings. The roof structure consists of the following layers:

- reinforced concrete floor slab, which is also the basis for the roofing pie;

- vapor barrier;

- a slab heat insulator made of mineral wool, inside of which there is the head of an aerator - a ventilation pipe (excess moisture is removed through this pipe);

- screed made of cement-sand mortar;

- waterproofing based on bituminous materials;

- polyurethane;

- a layer of polyurethane-based mastic;

- roofing material

The roof structure is complemented by side parapets , which are separated from the roofing pie by bulk or sprayed material. In modern construction, this role is played by polyurethane foam , which provides high insulation and sealing. It is also used to insulate the terminals of aerators.

The advantage of a flat roof is its low cost and the possibility of quick installation. Disadvantages: the need for frequent repairs and poor thermal insulation.

Pitched roofs

The design of this type of roof provides excellent air circulation, which penetrates into the under-roof space through the lower overhangs and exits through the ridge . In this way, it is possible to avoid the accumulation of dampness, which causes rotting or the appearance of fungus on the parts of the rafter system and roofing materials.

In some cases, a forced ventilation device is required. For this purpose, roof fans are installed on the roof.

Mostly lightweight materials with a wavy surface are used as coatings A pitched roof can be either cold or insulated. The difference between these two options is the presence of an insulating layer. Mineral wool boards are usually used as an insulator . Insulation with this material provides the following advantages:

- ease of installation;

- insulated coating;

- absence of cold “bridges”.

Flat roofs

Such flat roofs began to be used in the early eighties, when it became possible to use thermal insulation materials with ventilation ducts that help remove excess moisture. Most often, such roofs were made for apartment buildings, where they were most effective.

The pie consisted of the following elements: Installation of a ventilation passage for the roof.

- concrete slab as a base for the roof;

- vapor barrier;

- a layer of mineral wool slab insulation, in the thickness of which there was the end of a ventilation pipe, the so-called aerator, which removes excess moisture;

- cement-sand screed;

- waterproofing layer made of bituminous materials;

- polyurethane material;

- a layer of polyurethane mastic;

- roofing material.

A concrete parapet was erected on the sides, which was protected from the roofing pie by a layer of sprayed or bulk material. Today, this function is performed by polyurethane foam, which provides excellent insulation and sealing. All outlets of ventilation pipes and aerators are also insulated with this material. All flat roofs are considered cold, but they still continue to be popular due to their convenience and savings in building materials during installation.

[my_custom_ad_shortcode6]

Installation of ventilated roofing

The list of roof installation operations is as follows:

- Preparing the base . At this stage, work is carried out to level the surface, eliminate cracks, chips and potholes. A screed made of cement-sand mortar or asphalting floor slabs is best suited for this purpose . The result should be a smooth surface with a slope of 2-3 degrees.

- Laying vapor barrier film and insulation . These layers must be laid in a continuous mass; cracks or breaks are not allowed.

- Installation of a waterproofing layer and cement-sand screed.

- Laying roofing. For flat roofs, fused rolled materials are used as a covering. During installation, the bitumen included in the coating is melted using a gas burner, after which the coating sheet is firmly glued to the base. The rolls are laid in a direction transverse to the slope with an overlap of 80 - 100 mm. During installation, it is necessary to clearly mark the outlets of the ventilation ducts for their subsequent insulation.

Laying of roll materials

Roll materials are more often used for the construction of large industrial facilities. They are also convenient and profitable to use for flat roofs of apartment buildings. In any case, the roof slope should be no more than 30° .

First, the base is leveled, hydro- and vapor barriers are laid, and mastic and primer are prepared. You need to glue from the corner opposite to the place where you climb onto the roof. The coating is fixed to the base with mastic heated with a burner if there is no self-adhesive layer. Typically, the material is laid in several layers, overlapping the joints with the next one. The layer is rolled with a roller.