02.04.2021

Well

Editorial staff of the “New Place” website

Share

From this article you will learn

:

- Reasons for sand getting into the well

- Signs of sand and other contaminants getting into the well

- 6 safety rules when cleaning a well

- Manual cleaning of the well from sand and other contaminants

- Cleaning the well using the drainage method

- Final disinfection of the well

Cleaning a well from sand and other contaminants is a regular event that accompanies the owner of the site all the time. Sometimes it is necessary to carry out cleanup work outside of the plan if the protective barriers at the well are broken and the pollution process is more intense than usual.

There are several ways to clean a well from sand and other dirt - manual and automatic. There is a third option - contact specialized services, but it is used less often. In our article we will tell you how to clean a well, what is required for this and how often the procedure should be carried out.

Reasons for sand getting into the well

If the aquifer is located in a sand-gravel layer and the well is shallow, then the problem of well contamination with sand often arises. Therefore, it is important to equip the well correctly so that sand gets into the casing in small quantities.

If there are grains of sand in the water, and the productivity of the well has decreased, then the problem may be that:

- The caisson and the head are not airtight, which is why sand gets in from the surface;

- the barrier between the casing elements is broken;

- a filter with too large cells is installed;

- the filter is damaged.

You need to carefully select the filter, and when installing it, pay close attention to the casing elements. If coarse sand penetrates through the filter, it will clog the well over time, since it is more difficult to remove than, for example, fine sand. In addition, fine sand is partially washed away on its own when lifted.

There is a way out - to install a sand separator in the casing pipe, which greatly reduces sand accumulation in the filter and increases the service life of the well.

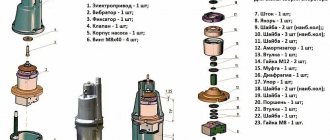

Manufacturing and installation of a filtration device

Direct method

Suitable for wells with sandy soil and where there is quicksand. However, in order to prevent the bottom row of large stones from becoming mired in sand and viscous clay over time, it is necessary to build a wooden shield. It is placed at the very bottom of the trunk, and only then the coarse fraction is poured onto it. The layers look something like this:

- The first is large stones, pebbles, gravel.

- Smaller stones are poured second; crushed stone and other filtration material, such as jadeite or shungite, can also be used.

- The third is the smallest fraction: quartz sand, zeolite. Each row should be at least 15 centimeters, but no more than 25 cm, since a large layer will prevent the passage of liquid.

Reverse method

If the soil at the bottom of the well is quite reliable, for example loose clay, then this option can be used here. In addition, there is no need to install a shield in such a source. In this case, it is better to assemble the filter by placing the layers between two metal meshes.

- The first at the bottom will be a small fraction, for example quartz sand, its thickness is 10–15 cm.

- Next comes crushed stone or another medium-sized stone of 15–20 cm.

- Well, the subsequent layers in increasing thickness are also 20 cm.

There is no need to add too many components, according to the principle “the more, the better.” This can lead to ordinary blockage of the barrel.

Signs of sand and other contaminants getting into the well

There are several clear signs that it is time to clean your well:

- opaque water;

- unpleasant odor;

- impurities are visible, etc.

Before cleaning a well from sand and silt, it is necessary to find out the cause of the problem.

The most common ones are:

| Problem | Consequences and causes |

| Siltation | This causes the liquid to become cloudy. Layers of clay and sand form at the bottom. |

| Oil film | A sign of the presence of petroleum products in the water. This can happen as a result of depressurization of the mine. |

| Rusty water | The liquid contains a large amount of iron. |

| Bacteria | It happens when water from a well is rarely used, as well as as a result of household waste or animals/birds, etc. getting into the mine. Pathogenic microorganisms begin to appear. |

| Unpleasant smell | Seepage of sewage into the well, and this is only one of the reasons. |

| Green water | Sometimes, when there is too much sunlight, algae can start to grow. |

| Muddy water | This often happens due to a broken bottom filter. |

In one more case, besides those listed, the well will need to be cleaned - this is when the liquid level has noticeably decreased.

The work of cleaning the mine can be done with your own hands. Its frequency is once a year, preferably in the spring.

This is interesting!

How to increase the low water level in a well More details

All preventive and cleaning work must be done at the right time for this - when the snow has completely melted. Otherwise, the pumped out liquid may return to the well through the high water.

Note: let’s say you don’t have any of the listed signs, but it’s still better to take preventive measures and avoid problems that may arise.

How to walk correctly when digging

In some cases, it is enough to simply deepen the bottom, bypassing the dangerous area.

This method provides for the accelerated completion of work on digging a mine, every minute counts. Long interruptions in operation are detrimental to the source, since it will receive a large volume of water contaminated with sand. A sump pump should be used continuously to remove this sediment.

An effective method is to use steel formwork in laying the well, which is slightly smaller in diameter than standard concrete rings. It is lowered directly into the soft mass, where it hermetically blocks the flow of liquefied sand into the well shaft. Then concrete rings are installed, which, when covering the connecting seams with sealed material, do not ensure the integrity of the well structure.

It is much easier to resolve the issue at the very beginning of work.

Advice! It is better to do it in winter, when the water level is minimal, and install 3 staples per connection.

Digging one ring of quicksand is comparable to five regular soil, so few people want to take on such work!

Manual cleaning of the well from sand and other contaminants

The method of cleaning the well and the tools needed for this are chosen based on the specific cause of contamination and its degree (walls and water in the well).

The following is a typical procedure for major cleaning of a well (consists of 5 stages):

- Stage 1 – preparation for cleaning activities;

- Stage 2 – removing liquid from the well;

- Stage 3 – cleaning and washing the walls of the shaft, working with cracks;

- Stage 4 – bottom treatment;

- Stage 5 – water disinfection.

Note! After completing the work of cleaning the well from sand and silt, preventive measures should be taken to keep the source in order for a long time. You can read how to do this in the next section of the article.

- Stage 1 – preparation for cleaning activities.

This stage is considered the main one, since the effectiveness of further procedures will depend on it.

For cleaning activities, it is necessary to prepare the following tools:

- safety rope to prevent falls from a height;

- helmet to protect the head from injury;

- a ladder of sufficient length to descend into the shaft;

- gloves to protect the skin of your hands;

- a grab (special ladle) or bucket for cleaning the bottom;

- scraper and brush for cleaning walls;

- concrete mortar for sealing cracks;

- putty knife to seal the seams.

Important! Before starting work on cleaning the well from sand, you need to clear the space near it so that nothing interferes with access. Therefore, if there are any awnings or unnecessary objects, everything must be disassembled and put away.

Also, before pumping out water, you need to catch large debris from its surface. This can be easily done with a net or even with your hands.

- Stage 2 – removing liquid from the well.

Water is pumped out of the well manually (with buckets) or with a pump. Undoubtedly, the first method, unlike the second, is not very convenient and will take a lot of time and effort.

To pump out water with a pump, you need to keep in mind that there is a maximum permissible level to which the equipment is allowed to be lowered. Violation of these recommendations may result in damage.

One more thing - there is no need to pump the water to the bottom, some amount of liquid will remain there, and this is normal.

- Stage 3 – cleaning and washing the walls of the shaft, working with cracks.

Plaque, dirt, and algae are removed from the mine walls manually. A long ladder is lowered inside and the walls are cleaned using a metal brush/scraper and only water. The use of cleaning products, solutions and any other chemicals is prohibited.

You should clean the walls for the first time, rinse everything off with water, then repeat the cleaning procedure and rinse again. All dirt flows to the bottom of the well and is removed from there at the next stage of work.

Upon completion of washing the walls, the shaft must be ventilated and dried. After which you can seal the seams with concrete mortar.

For better cement adhesion at the seams, it is worth cleaning the walls of the shaft so that they become rougher.

- Stage 4 – processing the bottom of the well.

To remove liquid from the bottom of the well that flows down during washing of the walls and silt deposits, a special bucket is used - a grab, but you can also use a regular bucket. Although a grapple is more convenient for this work.

This is interesting!

Licensing a water well: procedure Read more

The correct sequence of steps to clean the bottom using a bucket:

- remove the old filter;

- lower the bucket to the bottom, scoop up liquid and sludge;

- pull out and empty the bucket of contents.

You need to repeat this sequence of steps as many times as necessary to completely clean the bottom. After finishing, you need to install a new filter in place of the removed one.

Important! If the influx of water is strong, then loose clay and large stones on top should be lowered to the bottom of the well. If the current is moderate and the bottom is sandy, place small stones.

Impassable quicksands of high power

Mostly, when digging wells, small quicksands are encountered. And the teams do not experience any particular difficulties when passing them. Unfinished wells remain on the conscience of non-professionals. The exception is the huge masses of underground floating soil, the opening of which is similar to a natural disaster on a local scale. In a few seconds, cubic meters of viscous mass break into the mine. She puts the rings on one side or even tears them off and takes them away.

Even industrial drilling equipment cannot overcome active, powerful quicksand. It completely clogs the installation’s augers and easily tears off the nozzles. It is impossible to continue drilling in such conditions; you just have to move it to another place and hope for a more successful result. You can get through the quicksand using the old method - plugging an Abyssinian well. Fortunately, such quicksand are rare, and the chance of identifying it when digging a well is very small.

Areas with high groundwater levels are more susceptible to the formation of quicksand. If there are dips in the area, then most likely there is a layer of quicksand in the soil. It can be determined using test drilling. As a rule, quicksand has a large area, so if it is not found in neighboring areas, then it will not be on the territory.

Cleaning the well using the drainage method

To clean the mine, it is necessary to organize the use of drainage equipment and water circulation.

The pumping equipment should be installed at the bottom of the well on a stand 10–12 cm wide. If this is not done, the unit will be pulled into the silt. Near the shaft, you need to prepare a storage tank (an old bathtub or a 300-liter barrel will do), and lower the pump pressure hose to the bottom.

How to prepare an autonomous sewer system for winter

It is necessary to attach the injection unit to the top of the pump barrel, which will be needed to pump water back into the well. The unit must be equipped with a hydraulic nozzle, thanks to which a jet of the required density is formed, which acts as a scraper.

When flushing the well, both devices should be turned on in turn:

- drainage pump - for pumping dirty water from the bottom of the well;

- pressure pump - to generate a dense flow that will clean the walls and bottom of the well.

The hydraulic nozzle for removing deposits from the walls of the well can be controlled both from a ladder and from the ground.

During the procedure, the pump for cleaning the well from sand must sometimes be removed and its filter elements cleaned. This must be done until the filters stop collecting dirt, that is, the next time the pump is raised, they will be clean.

For major well cleaning, more powerful pumps are used, equipped with large filters, adapted to pass contaminated water with inclusions of silty fibers. The procedure consists of several stages, which are not so quick to complete - sometimes it may take a couple of days. The frequency of these activities depends on the nature of the soil.

After major cleaning, it is necessary to maintain cleanliness in the mine - carry out preventive maintenance with a drainage pump a couple of times a year.

Precautions during well cleaning

In order to prevent damage to the system during cleaning, you must follow basic rules:

- Do not use equipment for cleaning that is not designed for this work.

- During the cleaning process, you need to constantly monitor it and not leave the well and equipment unattended.

- Stop pumping immediately if large particles of metal or plastic appear.

The video will tell you what other cleaning methods exist. This article gives only some recommendations for cleaning from silt and sand. Periodic cleaning will increase the life of the pumping equipment and keep the system clean and tidy.

Final disinfection of the well

Upon completion of the cleaning procedures, it is imperative to disinfect the well. This guarantees the safety of drinking water and improves its taste.

To disinfect mine walls, it is considered safest and most effective to use a solution of potassium permanganate, which is taken in a proportion of 1 tbsp. spoon on a bucket of water. In addition to potassium permanganate, a 10% solution of bleach (such as “Belizna”) is used for these purposes. They first treat the walls of the mine, and then the bottom.

After disinfection is completed, the well must be closed and the lid covered with a tarpaulin. Then fill with water to the normal level. All this takes time, however, when the water is full, it must be pumped out and drained outside the yard. This water cannot even be used for irrigation. But that's not all. The procedure must be done a couple of times to remove any remaining chemicals. And only after the smell of chlorine has completely disappeared from the water is it allowed to be used for cooking and washing dishes. But it’s still better to boil the water first.

After the disinfection measures are completed, you need to let the water sit for several days to make sure it is safe. It must be clean, transparent, odorless and tasteless.

;

Well

Did you find this article helpful? Share it with your friends:

Shungite

One of the rocks in the form of ancient bottom, but already petrified organic sediments. Shungite can have a black or grayish color. A highly effective adsorbent easily purifies water and is most often used as a backfill for the middle fraction, which serves as a worthy replacement for traditional gravel.

The bottom filter is an important part of any well shaft, so the materials used to equip it must meet a number of requirements, including resistance to water erosion, cleanliness and safety.

When organizing the water supply of a site, owners often consider several options. As a result, many people opt for wells, expecting to receive clean, fresh, tasty water, regardless of the whims of utility services and other organizations. There is a reason for this, but you need to take into account that building a well is a responsible undertaking. The master faces many questions. For example, is it necessary to install a filter for a well? What material should I choose for it? After all, the quality of water, and therefore health, depends on it.

Preparation for dismantling the hydraulic structure ↑

When deciding how to fill a well with water, it is necessary to take into account a number of factors, including:

- location of the log house and shaft;

- water filling speed;

- technical condition of the hydraulic structure.

The ideal location of the well is at a distance of at least 10-15 m from buildings. In practice, it varies. Sometimes the source is installed in basements and basements, which leads to dampness, mold and forces dismantling, even if the facility was recently built.

It is common to locate the well in close proximity to a house, outbuilding or outbuildings. In this case, fair concerns arise regarding threats to the integrity and strength of the foundation. Errors during work can lead to soil subsidence and other geological disturbances.

If the well has dried up over time or the water has dried up for other reasons, dismantling it will not cause much trouble. With a constant flow of water, this unfavorable factor is taken into account and additional layers of backfill are provided.

Particular care is taken when dismantling abandoned and dilapidated sources. The condition of the log area and rings is preliminarily assessed. Possible risks:

- displacement of the rings relative to the vertical, their distortion;

- voids between the outer part of the mine and the soil that have formed over the years of operation;

- physical wear and tear of the elements of a log house, especially if it is made of wood.

Be sure to inspect, as far as possible, the underwater part of the structure. The well may be filled up or littered, and tree branches and other foreign objects often fall into the shaft.

IMPORTANT TO KNOW: If the well is located on quicksand, in some cases it is recommended to fill the trunk with tree branches, bunches of dense bushes - the so-called fascina.

Passage of moving soils

The appearance of a cloudy brown liquid indicates that the well trunk has entered the quicksand. A depth of 1-2 meters is passed quickly.

A thicker layer is more difficult to penetrate. This layer is easy to dig through.

The difficulty is in excavating the rock . Due to its fluidity, the liquid mass seeps into the mine, instantly taking the place of the removed soil.

The quicksand fills the bottom faster than people take out the liquid mass. The pump cannot be used. There is a possibility of damaging the shaft walls and causing the rings to move.

The passage of the liquid layer is complicated by the composition. A homogeneous colloidal mass, often containing pieces of hard rock and compressed layers of sand.

The movement of inclusions under pressure destroys the walls of the shaft, displaces the rings, and makes it difficult to remove soil.