Water is supplied to an individual house from any water supply source through an underground pipeline, the probability of freezing in winter is quite high. It is not always effective and technically possible to immerse a water pipeline to a great depth underground; many owners of land plots with an autonomous water supply have to solve the problem of how to insulate a water pipe in the ground.

To supply water to the house, no one uses underground metal pipes, which are prohibited for laying underground without waterproofing by building regulations; the leader in household use is a pipeline made of low-density polyethylene (HDPE) with a diameter of 1 to 2 inches. Although polyethylene has a low thermal conductivity, unlike steel, and is more resistant to freezing due to its elasticity, when laid at shallow depths it should be insulated using one of the many methods used in the construction industry.

Soil freezing depth in the Moscow region (in centimeters)

Main types of pipe insulation

I would like to immediately note that the most effective will be timely insulation, which is best done immediately at the time of laying the pipeline. Many people consider it sufficient to bury pipes to a decent depth.

- However, as we have already said, this is not always possible due to the characteristics of the soil .

- Secondly, if you plan to carry out the work yourself , then you will inevitably face a very long and labor-intensive process . It is advisable to dig deep trenches if you have special equipment at your disposal to make this task easier.

- And thirdly, if you are faced with the need to perform local repairs or replace a damaged pipe segment, this will be problematic due to the great depth .

Doing without insulation , especially now, when the range of thermal insulation materials is so wide, and simply relying on the fact that the climate will be favorable to you, is a rather reckless decision .

After all, it’s hard not to notice that lately the weather has been giving us surprises in the form of abnormal frosts or, conversely, abnormal heat. Depending on the type of materials used, insulation methods can be divided into three types:

- Reflective - when materials with an additional foil or aluminum layer , which reflect the cold from the environment and do not allow it to affect the surface of the pipe;

- Preventing heat loss - we are talking about materials that have a low coefficient of thermal conductivity , water and vapor permeability;

- Heating – when more modern methods are used, for example, a heating cable.

In this case, insulation occurs due to the heat generated by the heater. In order to minimize heat loss and direct it as much as possible to the heated pipe, it is additionally recommended to insulate with materials with a foil layer.

How to insulate water supply pipes yourself

Before insulating a water pipe in the ground, they choose a suitable option, taking into account the financial costs of purchasing materials and carrying out work; they often choose to use cheap high-density foam plastic shells. Some homeowners use a shell of sewer pipes with a cross-section of 110 mm, placing a HDPE pipeline in them - air is the best heat insulator.

Recently, the method of heating the outer or inner shell of pipes with a self-regulating electric heating cable has become popular; ready-made systems with fittings for inserting electric cables into the pipeline are being sold in the retail network. Thus, the highest efficiency of heating the water supply system is achieved.

Insulation of PPS shell

Due to its low price, availability and suitable physical characteristics, a foam shell is the best option for solving the problem of insulating an underground water supply pipe on the street. Do-it-yourself installation of a shell on a HDPE pipeline does not present any particular difficulties for any owner and is carried out in the following sequence:

- A foam shell is put on the pipeline lifted from the trench, snapping the locks and moving each segment approximately 1/3 in relation to the opposite element. The elements are fixed to the surface with tape or plastic ties.

- After fixing the PPS segments, the pipeline is lowered into a trench onto a pre-prepared sand cushion with a thickness of 150 - 200 mm - this will prevent distortion of the thermal insulation shell with possible fracture.

- Then the trench is filled with soil raised to the surface, and the removed turf is laid out.

Installation of PPS shell

Insulation of water supply system with self-regulating electrical cable

Insulating an underground water supply by heating the pipe with an electric cable is one of the effective methods of combating freezing when the water supply line is shallow. The heating cable can be used along the entire length of the pipeline or in a separate section, it can also be immersed inside the pipe shell or left outside on the surface of the pipe. On the construction market, they sell electrical cables with fittings for insertion into the pipeline, equipped with sealing rubber glands; the wire itself is short in length and is usually placed at the outlet of the pressure pipe from the well. In this place, the efficiency of its use is highest - heated water will flow along the entire pipeline from the well to the house, preventing pipes from freezing. In addition, laying the cable at the junction of the pressure pipeline from the electric pump with the water supply line is technically easier to implement than in any other more inaccessible place, which is usually not found along the entire water supply line.

Kit with self-regulating cable for installation in pipelines

Insulation of a pipe, when the water supply is in the ground, and it needs to be heated from the outside with an electric cable, is carried out as follows:

- Place the HDPE pipeline on the surface of the earth next to the trench, clean the area where the electrical cable is laid from dirt.

- Wrap the pipe surface at the point of contact with the electrical cable with aluminum foil tape - this increases the thermal conductivity of the shell at the point of contact. If the wire is placed in a straight line along the length of the pipe, one or more straight strips of foil tape are glued; if the cable is placed in a spiral, the entire pipe is wrapped with tape.

- After laying the heating wire, screw it with the same foil tape to the surface of the pipe along its entire length.

- To reduce heat losses, be sure to use an outer shell made of PPS foam, polyurethane polyurethane foam, which is placed on top of the heating wire and secured with tape or plastic ties.

Tip: If the wire is running in a straight line, it is better to purchase a shell with a groove cut into the inner shell to accommodate the electrical cable.

- After installing the heating section, screw the power supply cable along the entire length to the pipeline with electrical tape or tape and lower the assembled structure into the trench, after which it is covered with earth.

Installation of a heating electric cable on a pipe

To insulate water pipes for individual water supply, an inexpensive foam shell and a self-heating electric cable are most often used, and often both methods are combined. Carrying out installation work on placing a heat-insulating shell and a heating wire does not cause any particular difficulties and does not require high qualifications; with knowledge of the technology, all actions can be performed in a short time without much labor input by one person.

Requirements for thermal insulation materials

Whatever type of insulation you choose, you will still have to face the challenge of choosing the right material. First you need to decide what qualities material should have that can really provide the desired result.

- The most important parameter is the value of its thermal conductivity coefficient . The lower this value, the better the thermal insulation will ultimately be;

- If we are talking about insulating the most vulnerable sections of the pipeline, namely those that run in open ground , it is necessary to select materials with high density and resistance to deformation . The soil layer exerts significant pressure on the surface of the pipe, and therefore the insulation. Moreover, the pressure value may vary depending on the amount and frequency of precipitation, average temperature and other indicators;

- An important condition is increased moisture resistance . Under the influence of moisture, which may be in excess in the surrounding soil, many insulation materials lose their insulating properties;

- Also, moisture in the soil can have a detrimental effect on the surface of the pipes, which over time will manifest itself as corrosion. Thermal insulation material, in addition to protection against freezing, additionally acts as a defense and from this undesirable phenomenon. Therefore its structure should be corrosion resistant;

- For plastic plumbing, fire safety is very important , which means the insulation must be fire-resistant ;

- The material must withstand high temperatures and not undergo deformation during sudden temperature changes;

- For economic benefit, it is better to choose insulation that can be reused ;

- The determining factor is the durability of the material . It will not always be economically profitable to purchase cheaper material in the future. It is better to spend a little more money and ensure reliable insulation that will last for several decades than to regularly replace the insulation simply because it has lost its properties. Not to mention that this would require digging up trenches and then re-burying them.

Raw materials for heat-insulating materials

Let's name the main most popular materials from which heat insulators are produced.

This:

- Glass wool (glass fiber) ( Isover );

- Basalt;

- Polystyrene foam ( expanded polystyrene )

Fiberglass-based thermal insulators are used in the construction of both residential buildings and industrial enterprises. The best option for thermal insulation of metal-plastic pipelines.

One of the disadvantages of using glass wool-based materials is the need for additional insulation with some kind of roll insulator. The reason for this is the low stability of all materials on a similar basis. As a result, not only the cost per linear meter increases, but also the time spent during installation.

Heat insulators based on basalt fiber have virtually no direct disadvantages. Among the indirect ones, let's mention the fairly high cost. Note, as in the previous case, basalt insulation is used in conjunction with one and fabric insulation.

Foam-based thermal insulation, although considered one of the youngest types of insulation, has already firmly gained a reputation as the optimal option. Some of the advantages over competitors include cost-effectiveness, versatility and ease of installation.

Mineral wool for pipe insulation

Thermal insulation using varieties of mineral wool has become widespread due to its affordable cost. With its help you can insulate heating pipes, hot water supply, water supply and sewer systems, as well as air ducts. This material works on the principle of a thermos. In addition, cotton wool protects the surface of the pipes from condensation . In the case of insulation of an underground pipeline, it is imperative to provide additional protection from moisture, so when wet, cotton wool loses its protective properties , and heat loss, in turn, increases. Mineral wool is a fibrous material for the production of which various raw materials are used. The most commonly used types are:

- Glass wool – made from the same raw materials that are used to make glass. Its fibers are quite thick. For convenience, glass wool is available in the form of slabs, rolls or shells. To protect against moisture, one side can be covered with foil or a thin layer of aluminum. The thermal conductivity coefficient is 0.030-0.052 W/m*K. The material belongs to the NG class - non-flammable. When installing glass wool, you must be extremely careful and take care of personal protective equipment. Because with any touch to the material, small sharp particles fly in different directions, which dig into the skin even through fabric gloves. It is especially important to protect the organs of vision and breathing, since particles entering the lungs cause severe and prolonged swelling;

- Basalt cotton wool - made from molten rocks. It weighs more than glass wool. The material is also non-flammable and able to withstand exposure to very high temperatures – up to 870°С. Index thermal conductivity more shortthan the previous variety and is 0.035-0.039 W/m*K. Differs more high density and hardness. In this regard, the release form can be either in the form of plates or in the form of cylinders. Additional foil layer can be implemented on both forms;

- Slag wool – made from waste from iron production. For pipe insulation use enough rarely.

This is explained by the increased friability and acidity of the material, on the surface of which oxides form over time, negatively affecting the surface of the pipes . In addition, the material cannot be classified as environmentally friendly. And its thermal conductivity is quite high for a thermal insulation material - 0.46-0.48 W/m*K .

Insulation materials for thermal insulation of water pipes.

Mineral wool of various types, polystyrene foam, polyurethane foam, and polyethylene foam are widely used for insulating water pipes. Recently, a relatively new insulation material, foam rubber, has become increasingly used.

Mineral wool

This is perhaps the most affordable thermal insulation material for such purposes. But it’s also far from the most convenient.

Of the three existing types of mineral wool, only two are actually used for insulation of pipelines - glass wool and stone (basalt). The so-called slag wool, made from metallurgical waste, is poorly suited for such purposes. It loses in thermal insulation qualities, quickly becomes saturated with water, and not everything is in order with its chemical composition, which under certain conditions can become a catalyst for active corrosion of metal pipes.

What are the advantages of mineral wool insulation:

- Low thermal conductivity coefficient.

- One of the important advantages over many other insulation materials is plasticity. Mineral wool can be used to insulate curved or flat surfaces, tees, bends, valves and other fittings without any problems and without the need to purchase additional products.

- Chemical inertness to most acidic or alkaline compounds that may occur in soil moisture.

- A variety of release forms, any of which, in principle, can be used for pipe insulation. Thus, mineral wool is also produced in mats, including pierced ones, in separate slabs (blocks) of various thicknesses. This allows, by the way, to independently vary the thickness of the created insulation layer, depending on the initial conditions.

Stitched mat with foil coating - designed specifically for thermal insulation of pipelines.

Special products for thermal insulation of pipes are also made from mineral wool - semi-cylinders (“shell” in common parlance) of various internal and external diameters, with or without an external coating. Very convenient for quick installation on straight sections of water supply.

Semi-cylinders (“shell”) made of basalt wool for insulation of pipelines. It can be with or without foil or polymer coating.

- Mineral wool is a practically non-flammable material. For underground sections of the water supply system, this quality may not be so important, but for open sections it will be useful.

Now let's go over the disadvantages of this material:

- First of all, it should be noted that many types of mineral wool are hygroscopic. This applies to a greater extent to fiberglass materials. They can quite actively absorb moisture, losing their insulating characteristics. And when wet mineral wool freezes, it undergoes destructuring and severe shrinkage.

Basalt types of mineral wool usually undergo special hydrophobic treatment, and are more resistant to contact with water.

But in any case, such insulation must be protected from direct contact with wet soil. This is achieved by creating a surface protective layer of aluminum foil, roofing felt, or even just thick polyethylene film. The task is not particularly difficult: such an outer covering is simply wound on top with a certain overlap (overlapping) of turns, and then fixed with wire or other clamps. But at the same time, such additional operations complicate the installation of thermal insulation.

As we saw above, some types of mineral wool pipe insulation are already equipped with an applied external coating. This greatly simplifies thermal insulation work, but such materials are also more expensive.

- Working with mineral wool requires certain precautions and the use of skin, eye, and respiratory protection. The fibers are brittle (again, glass wool suffers more from this; basalt fibers have much better elasticity), and sharp microscopic fragments often cause serious irritation of the skin and mucous membranes.

Working with mineral wool always involves the need to take increased precautions.

- Another disadvantage is the tendency of mineral wool to gradually cake and lose volume (the thickness of the insulation layer). The reason for this is the same fragility of the fibers, which can increase under unfavorable conditions (overmoistening + negative temperatures) or under vibration.

The shrinkage of mineral wool insulation should be taken into account when planning the thermal insulation of pipes. How this is taken into account will be discussed below.

Insulation made from expanded polystyrene (PPR)

Expanded polystyrene (or, as it is often called, polystyrene foam) is very widely used specifically for the purpose of thermal insulation of various areas of the building. Plumbing is no exception.

By the way, this material is rightly criticized for a number of very negative qualities that limit its use in residential premises. First of all, these include problems from an environmental point of view, flammability and extremely toxic combustion products. But in terms of use for thermal insulation of underground sections of water supply, these qualities are completely unimportant. So the use of PPR should not cause any special concern.

The advantages of expanded polystyrene include:

- Excellent thermal insulation properties.

- Low density - the material is lightweight, very easy to process and install.

- High-quality PPR is not afraid of moisture - it practically does not penetrate its structure.

- The cost of products made from PPR is low - the cost of insulation will be small.

- The material is durable if it is protected from external mechanical damage and from contact with organic solvents.

The most convenient way, of course, to insulate pipes is to use a “shell” - half-cylinders with the required internal and external diameters. High-quality products of this type are also equipped with a tongue-and-groove lock, which prevents the appearance of cold bridges at the border of the two halves.

Foam “shell” for pipe insulation. The tongue-and-groove locks are clearly visible, ensuring a reliable, seamless connection of the parts.

Such half-cylinders are put on both sides of the pipe, connected in locks, and then tied with tape or even just wire clamps. On straight sections of the water supply route, thermal insulation will not take much time.

Disadvantages , in addition to those already listed above, include the following:

- The material is quite fragile, and the “shell” is easy to break if handled carelessly.

- Complete absence of any plasticity. That is, even at a slight bend in the route, this section will have to be isolated separately, and then again switched to half-cylinders.

For thermal insulation of the water supply at the bend, the following branch parts can be used.

True, many companies engaged in the production of such “shells” also offer in their assortment special shaped parts for turns, tees and some other components. But, traditionally, the cost of such fittings is significantly higher than the price of “linear” elements. Therefore, many experienced craftsmen try to independently cut out the required parts for bends, tees, etc. from half-cylinders. Or these areas are insulated with mineral wool and then covered with a waterproof casing.

Used to insulate water pipes and polystyrene foam boards. For example, they are laid on top of the pipe before backfilling the trench - this creates a kind of screen that prevents vertical penetration of cold into the depths.

This option for pipe insulation is also possible, although it is difficult to call it particularly successful.

Another option is to build a box from expanded polystyrene slabs at the bottom of the trench into which the pipes are laid. After installing the water supply, the box is closed with a lid made of the same slab, and then the soil is backfilled.

Given the affordable cost of white foam boards, this insulation option will probably be the least expensive.

- Expanded polystyrene cannot be classified as a chemically resistant polymer. Even ordinary fuels and lubricants can cause its destructuring.

Therefore, such insulation should be used with caution if the soil is saturated with petroleum products (which often happens, for example, near a car park). Or, what would be more correct, provide external protection for the “shell”, for example, from thick polyethylene film.

Polyurethane foam insulation for pipes

With a certain external similarity to polystyrene foam (more precisely, with its extruded variety), polyurethane foam is significantly superior to it in almost all respects.

As a rule, polyurethane foam insulation for pipes is not produced in its “pure form”. But manufacturers offer a wide range of pre-insulated pipes. On such products, ready for installation, the pipe is already protected by a layer of high-quality PPU insulation and an external coating that is resistant to mechanical stress, moisture, and chemical attack. By the way, polyurethane foam itself is already much more resistant to various aggressive compounds. Moreover, sprayed onto the outer walls of the pipe, it also becomes an excellent anti-corrosion protection.

Steel pipes, pre-insulated with polyurethane foam, in a metal and polymer sheath - for outdoor placement and laying in the ground.

Consumers are offered a wide range of metal pipes in finished polyurethane foam thermal insulation. But their diameter usually starts from 57 mm and above. As a rule, when installing an autonomous water supply system, you have to use smaller pipes.

Therefore, some well-known companies have launched the production of small-diameter plastic or metal-plastic pipes, which also have PPU thermal insulation and an external polymer coating. Such ready-made solutions extremely simplify the entire process of installing a water supply system, laid both in the ground and in open areas - in basements, ground floors, unheated rooms.

Polymer pipes in thermal insulation made of polyurethane foam

On both sides of these pipes, a small “bare” section protrudes from the thermal insulation, which is sufficient for connection by welding or fitting. After this, a heat-shrinkable sleeve, previously placed on the pipe, is placed over this connecting node. All that remains is to fill the cavity of the coupling with polyurethane foam (which itself is also polyurethane foam), so that after the foam hardens, you get a perfectly insulated, hermetically sealed connection.

As can be seen in the figure above, customers are also offered ready-made parts for installing individual sections of the water supply system - bends with different angles of rotation, tees, transitions, etc. That is, the installation of the system turns into a kind of “constructor assembly”.

Tee for laying insulated HDPE water pipeline - close-up.

By the way, despite the fact that polyurethane foam cannot be called a very plastic material, some polymer pipes in such thermal insulation with an external coating still have a certain flexibility, which allows laying curved sections without the use of additional bends.

Pipes with semi-rigid polyurethane foam thermal insulation and an external protective polyethylene sheath "Isoproflex".

An example of this is the Russian product, Isoproflex pipes. The pipe itself is made of cross-linked polyethylene PEX-A, reinforced with high-strength fiber, has a protective anti-diffusion layer, an insulation core made of semi-rigid polyurethane foam, and an external protective coating made of durable polyethylene.

Coil of pre-insulated pipe “Isoproflex”

Such pipes are sold in coils, which in itself indicates their flexibility. The installation task becomes even simpler - if there are no sharp turns, then one hose, already insulated and protected from the outside in advance, can be laid from the water intake to the entrance to the house, without making a single extra joint.

Polyethylene foam insulation

Another material widely used for insulation of pipelines. In its closed cellular structure filled with air, it is very similar to polyurethane foam. Quite a glare and their thermal conductivity indicators - both are excellent thermal insulators. But unlike polyurethane foam, foamed polyethylene also has high flexibility and ductility. Not at the expense of strength qualities.

The air-filled structure of polyethylene foam with a closed cell - when used for thermal insulation of pipes, it simultaneously becomes excellent insulation, reliable waterproofing and protection against chemical “aggression” of the soil.

The material is very light - usually its density does not exceed 30÷35 kg/m³, that is, no special physical effort will be required when installing thermal insulation. The closed cellular structure becomes an insurmountable barrier to water; the material itself practically does not absorb moisture - no more than 1.5% of the volume even when completely immersed.

Chemical inertness is also a clear advantage - it is difficult to imagine which of the compounds that got into the soil could cause destructuring of polyethylene foam. The operating temperature range is also impressive - from minus 55 to plus 85 ℃, which is more than enough for plumbing.

Various forms of such insulation are produced. These can be simply rolls, usually with one foil side - many craftsmen prefer this kind of material. But nowadays, ready-made sleeves for pipes of different diameters and with different thicknesses of the insulating layer, usually 2 meters long, are more popular.

Insulating sleeves made of foamed polyethylene for pipes of various diameters

Installation of such sleeves is not difficult - along the entire length on the side they have a seam along which they can be opened. The insulation is put on the pipe, and then this seam is glued together almost without a trace due to the applied self-adhesive layer.

But, again, the most convenient solution is to use ready-made plastic pipes, already “clad” in insulation and an outer protective sheath. Several leading manufacturers offer a wide range of such products.

For example, it offers products with a pressure pipe made of polybutene, with multilayer insulation made of polyethylene foam and an external protective casing made of low-density polyethylene (HDPE).

Insulated pipes for plumbing and heating systems

Traditionally, products (the old name “Ecoflex” may appear) and “Watts-Microflex” are in high demand. The pressure part of the pipes is made of cross-linked polyethylene, the insulation is several layers of foamed polyethylene, and the outer shell is HDPE.

Pipes with thermal insulation made of several layers of polyethylene foam and an outer corrugated shell made of durable HDPE: on the left - produced by Uponor, on the right - by Microflex.

Please note that the model range of all these companies includes samples with two or more pressure pipes in a common layer of thermal insulation and a protective casing. This can also be very convenient if, for example, water is sent to two different places, or in heating systems - for supply and return pipes, or for the thermal satellite already mentioned above.

Find out how to insulate a water pipe using a heating cable from our new article - “Self-heating cable for water pipes.”

Concluding the review of insulation materials, we should also mention thermal insulation made of foam rubber. In terms of thermal conductivity, this material outperforms polyethylene foam and competes almost equally with polyurethane foam. And at the same time, it is distinguished by excellent ductility and all other properties necessary for a high-quality insulating material.

Foam rubber insulation sleeves

The traditional form of release of such insulation is similar - in the form of insulating sleeves (cylinders). How insulation is carried out, including complex sections of the water supply system, is clearly shown in the video below:

Video: Thermal insulation of water pipes with Kaiflex foam rubber sleeves

It would be logical to finish the review of materials with a comparative table with the main parameters of the insulation materials mentioned above.

Comparative table of key parameters of popular pipe insulation materials

| Material, product | Average density as part of the insulating structure, kg/m3 | Thermal conductivity of insulation (W/(m×K)) for surfaces with temperature (°C) | Operating temperature range, °C | Flammability group | |

| 20 and above | 19 and below | ||||

| Mineral wool slabs pierced | 120 | 0.045 | 0,044-0,035 | From -180 to +450 for mats, on fabric, mesh, fiberglass canvas; up to 700 - on a metal mesh | Non-flammable |

| 150 | 0.049 | 0,048-0,037 | |||

| Thermal insulation slabs made of mineral wool with a synthetic binder | 65 | 0.04 | 0,039-0,03 | -60 to +400 | Non-flammable |

| 95 | 0.043 | 0,042-0,031 | |||

| Half-cylinders and mineral wool cylinders | 50 | 0,04 | 0,039-0,029 | -180 to +400 | Non-flammable |

| 80 | 0,044 | 0,043-0,032 | |||

| 100 | 0,049 | 0,048-0,036 | |||

| 150 | 0,05 | 0,049-0,035 | |||

| 200 | 0,053 | 0,052-0,038 | |||

| Glass staple fiber mats with synthetic binder | 50 | 0,04 | 0,039-0,029 | -60 to +180 | Non-flammable |

| 70 | 0,042 | 0,041-0,03 | |||

| Mats and wadding made of superfine glass fiber without binder | 70 | 0,033 | 0,032-0,024 | -180 to +400 | Non-flammable |

| Mats and wool made of superfine basalt fiber without binder | 80 | 0,032 | 0,031-0,24 | -180 to +600 | Non-flammable |

| Thermal insulation products made of polystyrene foam | 30 | 0,033 | 0,032-0,024 | -180 to +70 | Flammable |

| 50 | 0,036 | 0,035-0,026 | |||

| 100 | 0,041 | 0,04-0,03 | |||

| Thermal insulation products made of polyurethane foam | 40 | 0,030 | 0,029-0,024 | -180 to +130 | Flammable |

| 50 | 0,032 | 0,031-0,025 | |||

| 70 | 0,037 | 0,036-0,027 | |||

| Thermal insulation products made of polyethylene foam | 50 | 0,035 | 0.033 | -70 to +70 | Flammable |

| Thermal insulation products made of foamed ethylene-polypropylene rubber "Aeroflex" | 60 | 0,034 | 0.033 | -57 to +125 | Low flammable |

Foam plastic for pipe insulation

This material is a fairly effective insulation material that is lightweight . This greatly simplifies the installation process. Due to sufficient rigidity and strength, the foam does not deform under soil pressure. The main form of production of polystyrene foam pipe insulation is cylinders. They consist of two halves, which are connected to each other by means of a tongue and groove.

This is not only very

convenient , but also completely eliminates the possibility of the formation of cold bridges . The most common types of foam are:

- Penoizol;

- Extruded polystyrene foam;

- Expanded polystyrene foam.

The above materials differ in their density . Depending on this, the thickness of the thermal insulation layer also changes, which can range from 20 to 100 mm or more .

The internal diameters of the foam cylinders are equal to the standard external diameters of water pipes , which allows them to be insulated, provided that they fall within the diameter range from 15 to 144 mm .

operating temperature range of the material is also sufficient - from -188 to +95°C . Foam shells are often used for noise and heat insulation not only of plumbing, but also of ventilation and air conditioning systems, sewerage and gas pipelines. By choosing one of the types of polystyrene foam as insulation, you can count on the following advantages:

- Minimal heat loss;

- Protection of pipes from corrosion ;

- Tightness of the heat-insulating layer;

- Possibility of reusable use;

- Opportunity use as additional insulation during insulation heating cable. Since there are varieties of cylinders with special groove for cable routing;

- Resistance to the chemical effects of salts, lime and acids that may be present in the soil, as well as to the vital processes of various microorganisms;

- Durability;

- Resistance to sudden temperature changes ;

- Possibility to choose a protective shell even for fittings connections due to the presence of shaped parts.

Among the disadvantages , one can note increased sensitivity to solvents such as gasoline, acetone, and nitro paint. Under their influence, the material simply melts.

Installation of insulation for sewer lines in the ground

The insulation is installed when all the pipes have already been laid and connected to the sewerage system itself.

In this case, all pipes run at a slope of 1 centimeter per linear meter.

When installing insulation, you should pay special attention to ensure that there are no bare areas left, otherwise this whole procedure will be useless. The beginning and end of the pipe and joints are also carefully processed. In such places, you can put several layers of insulation to be sure.

In such places, you can put several layers of insulation to be sure.

The beginning and end of the pipe and joints are also carefully processed. In such places, you can put several layers of insulation to be sure.

Otherwise, installation of insulation is very simple and takes little time.

Installation features

Having chosen the desired insulation, immediately read the instructions for it, since each of them has its own characteristics.

If you are additionally doing waterproofing, you should immediately calculate how much material you will need.

More careful insulation and waterproofing should be done on pipe bends; any of the above materials will be suitable for this. Thanks to their convenient cylindrical shape and plasticity, they can repeat any bend without breaking.

You can additionally insulate sewer pipes using a pipe heating cable. It maintains the temperature of the pipe well, preventing it from freezing.

The cable can be an independent insulation, but most often it is wrapped on top with another layer of any insulation.

You can see an approximate diagram of insulation with a heating cable in the figure below.

Insulation with heating cable

This cable provides an almost 100% guarantee that the pipe will not freeze in any conditions.

Installation rules

Insulation with the selected material is carried out before filling the pipe with earth, and all pipe edges and seals must be sealed with sealant so that moisture from the pipes does not spoil the material.

If you choose foam shells for insulation, then you just need to put them on the pipe and additionally secure it with aluminum self-adhesive tape.

If it is mineral wool or basalt fiber, then they must be laid with the foil side out, as shown in the photo below.

Installation of glass wool with waterproofing

In this case, all joints must be glued with construction tape very carefully so that there is no access to moisture.

Also, pipes are insulated only in dry weather; dirt and other debris must be removed from them so that nothing prevents the insulation from tightly joining the pipe.

Foamed polyethylene

Many experts note that among the variety of thermal insulation materials, it is polyethylene varieties that are the most optimal in terms of price/quality ratio. The structure of polyethylene consists of many closed cells, inside of which there is air, which, as is known, has the lowest thermal conductivity coefficient - only 0.024 W/m*K. There are:

- cross-linked (FPPE or HPPE) polyethylene foam, which is obtained by foaming the molten composition;

- non-crosslinked (NPE) polyethylene foam, for the production of which an extruder is used.

The structure of NPE is long linear molecules, between which there is no chemical bond. While cross-linked polyethylene has a denser consisting of smaller cells , with a stable molecular bond. You can even distinguish these two varieties visually.

Depending on the production method, the technical characteristics differ .

- Cross-linked polyethylene will have a lower thermal conductivity and higher density , making it resistant to deformation. But its cost higher than unstitched. Density ranges from 25 to 40 kg/m3 ;

- The material has increased elasticity , which is maintained even at low temperatures (-80°C) . This makes installation much easier;

- With a force of 5000 N/m2. the compression ratio of polyethylene is only 0.2;

- Due to the minimum value of the vapor permeability , which is 0.001 mg/m*h*Pa, the material can be classified as completely vapor-proof ;

- Coefficient of thermal conductivity amounts to 0.035 W/m*K;

- Polyethylene also has a low water absorption rate . When the material is immersed in water for a day, it absorbs no more than 0.5% of moisture from its volume. Moreover, upon reaching the figure of 1.9% after more time, water absorption stops increasing;

- The flammability class of the material is G2 ( moderately flammable );

- Moreover, in the event of inflammation, the material does not release substances to the body ;

- The structure of the material is not susceptible to the effects of various chemical elements .

- Polyethylene may have release form in the form of hollow cylinders with a technical slot along the entire length, sheets and rolls.

The material may have an additional protective layer of foil .

What methods are used to protect water pipes from freezing?

It doesn’t matter whether a private house receives water distribution from a central collector (and this also often happens), or whether an autonomous source (well or borehole) will be used, a pipe laying area is still expected where negative external temperatures are likely. The only exceptions can be considered those rare cases when the well is drilled directly in the basement of the house. And even then, on the way to the points of consumption there may also be sections where the water supply runs through an unheated basement or basement. But in order to disable the water supply system, a very short uninsulated section is enough.

What approaches are used to protect water pipes from freezing?

- First of all, if possible, the water main should be laid below the freezing level of the soil in a given region. At this depth of the route (and it is taken with a reserve - the freezing level plus another 300÷500 mm), the temperature should never reach negative values. That is, the probability of getting an “ice jam” tends to zero.

Protecting a water pipe from low temperatures may involve laying a route below the freezing depth of the soil.

However, this approach is not always fully feasible. In some regions, the soil freezes to a very significant depth, and digging such deep trenches significantly complicates the implementation of the project. It is not uncommon to find areas where the soil characteristics completely exclude such an arrangement of pipes.

In many regions, the level of soil freezing reaches very significant depths. It is not always possible to dig such deep trenches for laying water pipes.

In addition, the pipe, one way or another, must be lifted up in order for it to enter the house. And in any case, it will pass through “dangerous” areas - the upper sections of the route, passage through the foundation, through the basement, basement, or even just an unheated room, where negative temperatures can be observed in winter.

How to build an autonomous water supply system in a private house

Much depends on the source of water, its location on the site, distance from the residential building, the climatic conditions of the region and the design features of the building itself. more about how to bring water from a well into a house in a special publication on our portal.

- Those same “problem areas” of the water supply route can be artificially heated using electrical energy. For these purposes, special heating cables are used, which are laid on the pipe walls under a layer of thermal insulation, or even placed directly in the pipe cavity.

The heating cable can be laid along the outer walls of the pipe, under a layer of thermal insulation, or located directly in the pipe.

There are many varieties of such cables on sale these days, as well as automatic heating control units that turn on the power when required.

How to organize heating of water supply?

The advent of heating cable systems has eliminated many problems when organizing autonomous water intakes in private homes. By the way, if you strictly follow the instructions of the manufacturers of such products, then heating the water supply yourself. More details can be found in a special publication on our portal.

- In the basement, basement or other areas of the house, where negative temperatures are not excluded, laying a “thermal satellite” is sometimes practiced. This is a pipe running parallel to the water supply and enclosed in a common thermal insulation shell, which is nothing more than one of the branches of the general heating circuit of the house.

One pipe can be used for water supply, the second - as a thermal satellite connected to the heating system of the house.

Such a hike, of course, complicates both the plumbing and heating systems. But you no longer have to worry about the integrity of areas with such heating. True, only when the heating is on.

- One of the radical ways to prevent water from freezing in pipes is to maintain a constant high pressure in them. To do this, the autonomous water supply system is supplemented with special equipment, and the pipes themselves must be able to withstand these increased loads.

The approach, although effective, is quite complex in organization and in everyday use. In addition, it turns out to be more expensive in terms of energy consumption. Such systems have not gained much popularity.

- The most common method is thermal insulation of pipes, that is, what this publication is essentially devoted to. The use of various insulation materials helps to avoid freezing of the water supply system, if, of course, the material and thickness of the insulation are selected correctly.

All this will be discussed in more detail below.

A special type of insulation sometimes includes the creation of a stationary air gap between the water pipe and the casing, which prevents direct contact of the pipe with the ground. In a nutshell, this can be described as a “pipe within a pipe.”

An integrated solution - a “pipe in a pipe” with a layer of insulation between them and forced heating with an electric heating cable

But, to be honest, this method is not used in its “pure form”. The hollow space, at least in order to accurately position the water pipe inside the outer shell, is still filled with insulating material. Which, in principle, is insulation only because of its ability to create a layer of immobilized air. So the result is classic thermal insulation of the pipe with the creation of an external casing. And by the way, it is always welcome to protect both the insulation and the pipe itself from mechanical influences, from ground moisture, and from damage that can be caused by rodents living underground, attracted by the winter heat.

In practice, a combination of most of the listed methods for protecting water pipes from freezing is usually used. That is, they try to deepen the route from the well or well as much as possible, insure the most vulnerable areas with additional heating and, of course, provide reliable thermal insulation, usually along the entire length of the water pipe.

Such an integrated approach is also necessary for the reasons that even high-quality insulation often does not guarantee complete protection of the water supply system. The table below shows the volumes of heat loss calculated for pipes of different external diameters, enclosed in a layer of thermal insulation of different thicknesses. The thermal conductivity coefficient of the insulation is taken to be average, characteristic of most thermal insulation materials used in this role - 0.04 W/(m×K).

Naturally, the amount of heat loss depends directly on the difference in ambient temperatures and the liquid pumped through the pipe. The table shows several options - from Δt = 20 ℃ to Δt = 60 ℃. For example, if the temperature of water from a well (well) in winter is +2 ÷ 4 ℃, and in the winter the pipe passes through the base of the house, frozen to - 15 ℃, then the temperature difference can be considered 20 degrees.

| Insulation layer thickness | Temperature difference (Δt, °С) | Pipe outer diameter (mm) | |||||||||

| 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 150 | ||

| Average heat loss (W per linear meter of pipeline) | |||||||||||

| 10 mm | 20 | 7.2 | 8.4 | 10 | 12 | 13.4 | 16.2 | 19 | 23 | 29 | 41 |

| 30 | 10.7 | 12.6 | 15 | 18 | 20.2 | 24.4 | 29 | 34 | 43 | 61 | |

| 40 | 14.3 | 16.8 | 20 | 24 | 26.8 | 32.5 | 38 | 45 | 57 | 81 | |

| 60 | 21.5 | 25.2 | 30 | 36 | 40.2 | 48.7 | 58 | 68 | 86 | 122 | |

| 20 mm | 20 | 4.6 | 5.3 | 6.1 | 7.2 | 7.9 | 9.4 | 11 | 13 | 16 | 22 |

| 30 | 6.8 | 7.9 | 9.1 | 10.8 | 11.9 | 14.2 | 16 | 19 | 24 | 33 | |

| 40 | 9.1 | 10.6 | 12.2 | 14.4 | 15.8 | 18.8 | 22 | 25 | 32 | 44 | |

| 60 | 13.6 | 15.7 | 18.2 | 21.6 | 23.9 | 28.2 | 33 | 38 | 48 | 67 | |

| 30 mm | 20 | 3.6 | 4.1 | 4.7 | 5.5 | 6 | 7 | 8 | 9 | 11 | 16 |

| 30 | 5.4 | 6.1 | 7.1 | 8.2 | 9 | 10.6 | 12 | 14 | 17 | 24 | |

| 40 | 7.3 | 8.3 | 9.5 | 10.9 | 12 | 14 | 16 | 19 | 23 | 31 | |

| 60 | 10.9 | 12.4 | 14.2 | 16.4 | 18 | 21 | 24 | 28 | 34 | 47 | |

| 40 mm | 20 | 3.1 | 3.5 | 4 | 4.6 | 4.9 | 5.8 | 7 | 8 | 9 | 12 |

| 30 | 4.7 | 5.3 | 6 | 6.8 | 7.4 | 8.6 | 10 | 11 | 14 | 19 | |

| 40 | 6.2 | 7.1 | 7.9 | 9.1 | 10 | 11.5 | 13 | 15 | 18 | 25 | |

| 60 | 9.4 | 10.6 | 12 | 13.7 | 14.9 | 17.3 | 20 | 22 | 27 | 37 | |

As you can see, even with a fairly thick insulation layer of 40 mm, a pipe with a diameter of 32 mm under the example conditions taken above will lose almost 5 W of thermal energy per linear meter. It doesn’t seem like much, but if there is no water movement in the pipe for several hours, an ice plug may appear in such an area. This means that these heat losses will have to be replenished in one way or another.

That is, when designing your water supply system, you need to carefully analyze theoretically vulnerable areas, and strengthen thermal insulation on them (if possible) or take steps to heat these “dangerous” areas. Which, by the way, are usually located in close proximity to the house or even directly in it. Although, it also happens that the entire route from the source to the house has to be heated, since, for example, rocky soil or high groundwater makes it impossible to dig trenches below the freezing level.

But even in this case, the importance of pipe insulation only increases. The heat generated by the heating system should not be wasted, but should fulfill its intended purpose. And without high-quality thermal insulation it is impossible to achieve this.

Polyurethane foam (PPU)

This material is no less effective insulation. To insulate the pipes, a polyurethane foam shell is used , which is a cylinder. It is made in two ways:

- By pouring liquid polyurethane under high pressure into a special mold:

- Manufactured using the “pipe in pipe” method . In this case, the material is poured into the cavity between two pipes - the inner one, with a smaller diameter, and the outer one, with a larger diameter.

The first option is suitable for yourself . And the product of the second production method is pre-insulated pipes ready for laying a new pipeline .

- This is a completely new product that makes it possible not to think about additional insulation ;

- In this case, the outer layer can be corrugated - flexible, which makes it possible to avoid the need to use rotary fittings , that is, the pipeline can be laid with a minimum number of connections;

- Both one- and two-pipe versions of such ready-made elements are produced;

- For laying cold pipeline designs are better suited with plastic pipes;

- For hot dishes, they produce more expensive options with metal pipes inside;

- Flexible pipes with pre-insulation are supplied in coils and have a length of up to 200 meters .

Regarding PU shell , it has the following advantages:

- Heat loss is reduced by almost 40% ;

- Installation of the elements is so simple that it allows you to independently insulate several hundred meters of pipeline in a day;

- This also indicates the speed of installation;

- The material is environmentally friendly ;

- The insulation can be reused an unlimited number of times;

- Term operation reaches 30 years.

Among the disadvantages is the impossibility of using the material at temperatures above 120°C . A great convenience is the presence of shaped segments, such as tees, elbows and branches. The connection of two shell fragments to each other occurs using a special coupling , which makes the thermal insulation airtight and prevents the possibility of the formation of cold bridges.

The shell also

differs in the material of its outer covering, which determines its scope of application. The coating can protect both from environmental factors, such as ultraviolet radiation, and from mechanical influences.

- Uncoated polyurethane foam is the most affordable, but can only be used for insulating pipes located, for example, in the basement, and then only if there is an additional casing . Either as an intermediate insulating layer;

- Shell with foil coating - the scope of application is not limited, and the material is characterized by increased strength ;

- Shells coated with fiberglass can be used to insulate external sections of the pipeline, for example, places where pipes enter the house. It is distinguished by its resistance to ultraviolet radiation . At the same time, fiberglass is also distinguished by high hardness , which virtually eliminates the possibility of mechanical damage ;

- The glassine coating is resistant to direct sunlight, but is inferior to fiberglass in strength;

- Shell coated with reinforced aluminum foil (armofol) - used for insulation of pipelines operated under conditions of significant temperature changes ;

- Galvanized steel coating is used to insulate pipelines running in air . Steel protects the shell from ultraviolet radiation, mechanical and biological influences, but at the same time is more affordable than a fiberglass coating.

The thickness of the shell is 20-80 mm and increases with increasing diameter. The length of one element does not exceed 1 meter , taking into account the peculiarities of the manufacturing process.

Protection of wells and wells in winter

In winter, water comes into the water supply system at the dacha from a well, a well or the main water supply system, if one is available. Most often, the source of water in dachas, and even in the private sector, is an ordinary well of not very deep depth. The advantage of such a source is that a high-power pump is not required to supply water.

In addition to the pump for such a water supply system, it is advisable to use a hydraulic accumulator, which is a large-capacity barrel. It accumulates a certain supply of water, which can be used at any time. This is especially true during a power outage.

In addition, the hydraulic accumulator helps protect the water supply from water hammer and pressure surges. It and the pump are best installed in a warm utility room where they can be easily maintained.

In addition to pipes, water sources need protection from frost: wells and wells. In order to prevent the water in the well from freezing, a caisson well or pit with a depth of one and a half to two meters is installed, where a person can safely go down the stairs to carry out maintenance on the pump or the well itself.

Caisson well or pit

The walls of the pit can be made of brick, plastic, cast from concrete and made of concrete rings.

They must be sheathed with foam boards, the thickness of which reaches more than 10 cm, or lined with mineral wool. The top of the well must be covered with a powerful lid, well insulated with glass wool or other material. Waterproofing is also carried out to prevent water from entering the coffered well.

Water in wells lined with wooden beams rarely freezes in winter. To protect such wells, a thick protective wooden cover is installed during the winter.

But concrete wells require quite powerful insulation, especially if the water is above the freezing level of the soil. To do this, the well ring is dug out to the freezing level, and then insulated with polystyrene foam compressed in the form of half rings.

Before starting work, the seams in the concrete are treated with a special sealant, then foam plastic is installed. To protect the insulation from sunlight, it is covered with plaster or paint.

It will be useful to read:

Foamed rubber for pipeline insulation

This material is made from natural or synthetic rubber and is classified as a material with increased elasticity. At the same time, high tear resistance . The structure of rubber is 90% closed cells. This allowed us to achieve the following positive characteristics:

- The thermal conductivity coefficient is 0.024-0.038 W/m*K and directly depends on the ambient temperature. The highest indicator is observed at 0…+20°С ;

- The material has excellent anti-corrosion properties;

- Shows resistance to substances such as gasoline and oil ;

- Has a low coefficient of water absorption and vapor permeability;

- operating temperature range is quite wide - from -200 to +150°C ;

- Under conditions of sudden temperature changes, it retains its properties unchanged ;

- In addition to reliable thermal insulation, it also provides high noise insulation ;

- Can be reused ;

- Is durable ;

The form of release of foamed rubber is sheets or hollow cylinders with a technical slot equipped with an adhesive layer. thickness is 6-32 mm , and the internal diameter is designed for pipes with a diameter of 6 to 114 mm .

Extruded polystyrene foam

Extruded polystyrene foam, unlike regular polystyrene foam, is a high-density foam mass with closed cells.

This structure allows the use of this material in wet soils.

Shells made from extruded polystyrene foam consist of separate segments. Their number depends on the diameter of the pipe being insulated. To connect individual parts of the shell, a tongue-and-groove lock is used.

Expanded polystyrene has sufficient strength that allows it to be used for channelless underground installation.

To secure the mounted segments, polymer or metal tapes, wire or mounting tape are used.

Heating electric cable

One of the most effective ways to ensure long-term protection of pipes from freezing is the use of a heating cable. The advantage of this solution is that installation can be done both on top of the pipe and inside it. It all depends on the condition of the pipeline and the diameter of the pipes. When choosing an internal installation method, keep in mind that the cable may reduce the permeability of the pipes if their diameter is too small. The recommended minimum pipe internal diameter size is 40 mm. The heating cable itself can be of two types:

- Resistive;

- Self-regulating.

The latter type is more advanced, convenient and cost-effective. Its cost exceeds the cost of a resistive cable.

However, given that the finished heating system can operate almost completely without human intervention and requires minimal attention, it can be argued that the expense is justified.

A more complete description of both types of heating cable and the features of its selection and installation can be found in our article by following this link.

Basalt insulation and foam plastic

Good insulation is made from basalt using the melting method. Cylinders of different diameters are produced from it, which are used as insulation.

In addition to ease of installation, basalt cylinders fit perfectly into the pipeline. The price of this material is higher than the price of glass wool, but it also requires protection from moisture, which is foil insulation or glassine.

Insulating the water supply on the street is an important point, for which polystyrene foam is most often used in practice. To insulate any pipeline, a shell of suitable diameter is made.

They come with or without coating. The foam shell can be used several times, which saves money, while it has the most suitable operational and technical characteristics as insulation.

Liquid thermal insulation for pipelines

A completely new method of insulation is the use of special coloring compounds. Even a thin layer of such paint can replace 10-20 mm thick insulation . And if you apply the composition in several layers, you can achieve much better results. Heat loss can be reduced by up to 40% , while the coating does not allow water and moisture to pass through, but remains “breathable”. Liquid insulation is classified as energy-saving thermal paint and can be of two types:

- Ceramic , its consistency really resembles ordinary paint;

- As foam structure, which is applied to the desired surface by spraying.

The coating works on the principle of a thermos . The layer of material required for thermal insulation is very thin - only 0.5 mm . The advantages of this method of insulation include:

- When using the composition in the form of paint, its application simple and can be done with a regular brush ;

- If the coating chips or scratches form on it, it can be easily restored ;

- Low thermal conductivity;

- High elasticity , which allows the coating not to crack when the pipe diameter expands and contracts;

- Long service life;

- Health safety

- Condensation and corrosion do not form on the surface ;

- Possibility of application to surfaces of any configuration.

The disadvantages include:

- High cost of the composition;

- a foam composition as insulation , you will need to seek help from specialists . Which, as you know, provide their services only for large volumes of work. If you want to spray just a few meters of pipeline, you may simply not find a contractor.

Underground

The pipe is wrapped in basalt and secured with tape. A protective layer must be placed on top. Roofing felt (or any durable waterproofing material) is ideal for this.

The foam parts are connected to the pipe using special joints cut along the edges. Additional fixation is provided by adhesive tape glued with waterproof glue. A protective layer is also applied on top.

A heating cable is considered the most reliable heating method. Although it is the most expensive, it is suitable even at a depth of 2 meters for seasonal living. It does not require deep trenches (if you live permanently), 50 cm is enough.

The cable must be wrapped around the pipe every 10 cm. After 15 cm, it is fixed with adhesive tape. The top must be covered with insulating material. Some craftsmen suggest placing it inside the pipe, but this is somewhat more difficult to do.

Additionally, temperature sensors are installed. There are 3-4 sensors located along the entire length. Their installation will provide the opportunity to set up automatic heating or manual control.

Such a heating system will provide a continuous flow of water into the house even on the coldest days, and will never fail. The cable sells for an average of 500 rubles per meter. Consumes only 10, maximum 20 W. These costs are justified if the water supply in your area is not too long.

Being under strong pressure, water cannot freeze. Therefore, this method has gained popularity among craftsmen. Installation is carried out from the receiver, we connect the valve to the pump. We check the system: close the tap and start the pump.

In apartments, of course, this method is not used. Only in areas with a well or borehole. And only in case of seasonal residence of the owners of the house. In winter there should be no one in it. Although this method allows you to save on insulation of the water supply system, it is not always appropriate.

Air insulation, mentioned above, requires the creation of special conditions for the water supply. With this method, water pipes are placed in other plastic pipes (for communications) of larger diameter, thus creating a kind of air cushion. Cold air does not reach the water flow from above, and from below the system absorbs the heat of the earth. For this method of insulation, which involves insulating material and additional pipes, it is necessary to dig a trench of at least 1 meter.

However, having chosen this method, you should remember that such a water flow will be difficult to reconstruct if necessary. The method is certainly interesting, effective, and inexpensive. But you may have to pay twice.

High pressure thermal insulation

As a method of insulating a pipeline in a private house or country house, one can consider creating and maintaining high pressure in it. How it's done:

- to embed a receiver into the finished pipeline , which will have to create the necessary pressure - 3-5 atmospheres is quite enough;

- It is also necessary to additionally use submersible pump, to create pressure from 5 to 7 atm.;

- After the pump, a check valve and a tap are installed in front of the receiver;

- To start the system, you need to close the tap in front of the receiver and turn on the pump;

- The resulting pressure must be maintained in the system continuously until it is in use;

- To allow the pipeline to function again, you simply need to bleed off the excess air.

General information

How to insulate street water supply?

Laying a water pipeline two meters deep in the ground does not guarantee that it will not freeze during severe frosts. And under no circumstances should the water inside the structure be allowed to freeze, otherwise it can rupture and damage the entire plumbing system.

Therefore, it is worth taking care in advance about protecting the water supply from freezing outside and choosing the right insulation.

There are two weak points in a home plumbing system.

- The location of the pipeline on the street under a layer of earth.

- The pipeline is located in an unheated room.

If it is easier to insulate the water supply in a private house that is located indoors, then the water supply that is laid outside requires a more thoughtful approach. Basically, it all depends on the quality of the insulation used.

A good insulation for water supply should have the following characteristics:

- low thermal conductivity;

- durability;

- ease of installation;

- resistance to aggressive environments;

- must withstand the operating temperature of the environment;

- fire safety and tightness;

- low price with the possibility of repeated use

Based on these characteristics, the optimal thermal insulation for water supply in a private house is selected. Today there are a large number of insulation materials. Below we will analyze some of them.

Air insulation

Understanding the characteristics of soil freezing in winter, you can use the thermal insulation method, when warm air from the bowels of the earth is used to heat the pipe. As you know, the soil freezes from top to bottom, while heat continues to flow from below. When insulating shells are used, this heat is simply cut off and not used.

To

save on the amount of insulation materials, you can create a structure that will resemble an umbrella . And work on the same principle. The cold from above will be insulated , and the heat coming from below will be concentrated at the depth of the pipeline.

This can be done using a flexible material with low thermal conductivity, which is laid in an arc over the pipe in a trench and then simply covered with soil. Additionally, you can fill the free space around the pipe with expanded clay. The article was written for the site.

Tags:Pipes

Methods for insulating underground water pipelines

There are several ways to insulate water mains, many are used in everyday life or only in the national economy, the main ones are:

- Application of thermal insulation materials . Insulation materials used to isolate water pipes from contact with the ground are widely used in all sectors of the national economy and in everyday life; they occupy a leading position in terms of efficiency and material costs.

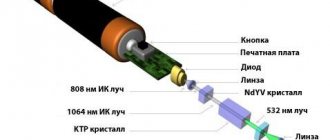

- Electric heating . An electric cable, the sheath of which heats up when alternating current passes, is a popular means of combating pipe freezing in industrial and domestic environments. Modern self-heating cables operate automatically with minimal energy consumption thanks to an internal device that increases energy consumption when the ambient temperature drops. Electric cables are moisture-resistant and can work in water, so they are often laid inside water pipes, and the combination of electric heating with external thermal insulation is the most effective method of combating pipe freezing.

Options for laying electric heating cables

- Continuous flow. Moving water does not freeze, so a small regular use of water or circulation in a closed loop can prevent the pipeline from freezing in winter.

- Air heating. The technology is used in public utilities and the industrial sector; to implement it, underground water supply is placed in a shell of large-diameter pipes, and heated air masses are pumped into the space between the shells.

Note: In domestic conditions, an analogue of this method is sometimes used without pumping warm air; for this, HDPE water supply is placed in a polypropylene PP or polyvinyl chloride PVC pipeline of larger diameter from sewer pipes - the air gap between the pipe surfaces is an excellent thermal insulator.

- Increased pressure. One of the popular Internet myths is the claim that you can lower the freezing point of water by increasing the pressure in the system. It can actually be lowered by 1 °C when a water flow is pumped into a pipeline with a pressure of 132 atm, which is incredible for a household water supply with a maximum pressure threshold of about 5 atm.

Comparison of the best insulation materials

Is it necessary to insulate a sewer pipe?

Owners of private houses often ask questions about insulating sewer pipes. Is this as necessary as the manufacturers of thermal insulation materials advise? The fact is that a properly installed sewer system, which has a normal drainage angle and pipe diameter, can function in winter without additional thermal insulation. But who can guarantee that your system is perfectly designed and assembled, so it’s better to play it safe and equip it with additional protection with thermal insulation materials.