So, another big wash has arrived. Pre-sorted items are thrown into the washing machine, the required amount of powder is poured, conditioner or bleach is added, and a water softener is added if necessary. Select the appropriate program, press the “Start” button and…. after a while we discover that the drum in the washing machine does not spin. In this situation, the main thing is not to panic, but to determine at what exact moment the drum stopped rotating. This information will significantly help when diagnosing a breakdown:

- During the spin cycle, the items are damp or wet, but not soapy; the rinsing and draining function has worked. There is a high probability that the belt came off at maximum speed.

- When washing, things and the entire internal volume are covered in foam. Moreover, if the drum cannot be moved from its place by hand, then the reason is purely mechanical; most often, the movement is jammed by a foreign object. If the drum can be easily turned by hand, then the cause of the breakdown is in the electric motor or electronics.

There are several other reasons why the washing machine does not spin the drum:

- A foreign object has entered the space between the drum and the inner wall of the tank.

- The failed bearing is jammed.

- The belt drive from the electric motor has fallen off or broken.

- The brushes in the electric motor have worn out due to frequent use.

- The engine completely failed.

- Control module failure.

The main reasons why the drum of a washing machine does not spin can be domestic, mechanical or technical.

Household items include:

- Overload Many modern washing machines have a weight sensor and block operation if the limit value is exceeded. As a rule, an overload message is displayed on the display.

- Water pressure in the water supply. Almost all new models of washing machines are equipped with water pressure sensors. If the pressure is insufficient, the operation of the equipment will stop.

Mechanical damage is most often caused by foreign objects, which with minimal disassembly you can try to remove yourself.

Technical problems are caused by long and intensive use, as well as lack of preventive maintenance. As a rule, such damage and defects are quite serious and in most cases require the replacement of expensive parts and the involvement of specialists.

Drum does not spin in Bosch washing machine

When the drum in a Bosch washing machine does not rotate, the owners of this equipment usually have only one thought - is it over?

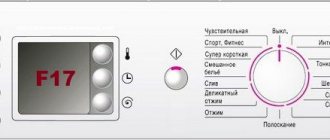

But, fortunately, if such a breakdown occurs, it can be repaired with a 97% probability. And then the Bosch washing machine will wash like new. Typically, a Bosch washing machine does not respond to this problem with error codes. There are only two codes that describe the lack of rotation of the drum - these are F21 and F43 . Actually, you can understand whether the drum is rotating or not without error codes.

Take advantage of the Miele brand online store

You are on the Miele brand store website. We sell not only high-quality washing machines from Germany, but also many other home helpers: economical refrigerators and freezers, stylish cooktops and ovens, multifunctional dishwashers and other categories of Miele household appliances. Visitors have access to a convenient catalog with a huge variety of product offerings, which can be grouped using filters. If necessary, our consultants will help resolve any issue you may have by phone or online chat.

All equipment presented in the catalog of the company’s online store has special certificates of conformity and is approved for sale in Russia. All models are 100% original and have an extended manufacturer's warranty of 24 months. The user can order home delivery in Moscow, St. Petersburg and any other locality in Russia.

Supported range of Bosch washing machines

See the list of models below:

The MAXX 4 series includes two common modifications - Speed Edition and Speed Perfect.

The most popular models of them are:

W.F.C.

2062 OE, WFC 1664 OE, WFC 1666 OE, WFC 1665 OE, WFC 1667 OE, WFC 2060, WFC 1262 OE, WFC 1263 OE, WFC 1600 BY, WFC 1662 OE, WFC 1663 OE, WFC 2066 OE, WFC 2063 OE , WFC 2064 OE, WFC 2065 OE, WFC 2067 OE.

WLF

16180 OE, WLF 20180 OE, WLF 20181 CE, WLF 20164 OE, WLF 16060 OE, WLF 16062 BY, WLF 16164 OE, WLF 20060 OE, WLF 20170 CE, WLF 20271 CE, WLF 20281 CE, WLF 242 71 CE, WLF 16170 CE , WLF 16260 OE, WLF 16165 CE, WLF 16261 OE, WLF 20062 BY, WLF 20160 OE, WLF 20171 CE, WLF 20260 OE, WLF 20261 OE.

WFO

1640 OE, WFO 1261 PL, WFO 2050 GR, WFO 1661 BY, WFO 1662, WFO 2040 OE, WFO 2042 OE, WFO 2051 GR, WFO 2060 BY, WFO 2064, WFO 2264, WFO 2440 OE, WFO 2442 OE, WFO 2 450 , WFO 2451 GR, WFO 2464, WFO 2840 OE, WFO 2864, WFO 1660 BY.

WFR

2440, WFR 2441, WFR 2466, WFR 2830, WFR 2841, WFR 2866, WFR 3240.

WFH

2061 OE, WFH 1660 OE, WFH 2461 OE, WFH 1260 OE, WFH 1262, WFH 2060 BY, WFH 2460 OE, WFH 2062 OE.

The SpeedPerfect and SilencePerfect modifications are the highlight of the MAXX5 series.

Main model range:

WLX

20462 OE, WLX 2048K OE, WLX 20362 OE, WLX 20364 OE, WLX 20161 OE, WLX 16163 OE, WLX 20160 OE, WLX 2036 KOE, WLX 20361 OE, WLX 20480 OE, WLX 2046 1 OE, WLX 20370 CE, WLX 24460 OE , WLX 24363 OE, WLX 20460 OE, WLX 24361 OE, WLX 24362 OE, WLX 24462 OE, WLX 24463 OE, WLX 2448 KOE, WLX 20162 OE, WLX 24163 OE, WLX 20363 OE, WLX 24364 OE, WLX 16162 OE, WLX 20463 OE, WLX 16161 OE, WLX 16160 OE, WLX 20163 OE, WLX 24461 OE, WLX 24360 OE.

W.V.D.

24520 EU, WVD 2446 SOE, WVD 24460 OE, WVF 2400 EU, WVF 2401, WVT 1260, WVTI 2841 EU, WVIT 2842 EU, WVT 3230, WVD 24420 OE, WVTI 3240 EU, WVTI 2840 EU, WVTI 28 42 EU.

Main model range:

W.A.E.

2037 KOE, WAE 16160 OE, WAE 20440 OE, WAE 24160 OE, WAE 24360 OE, WAE 24440 OE, WAE 20360 OE, WAE 20370 OE, WAE 16440 OE, WAE 20160 OE.

Main model range:

W.A.E.

24463 OE, WAE 24164 OE, WAE 24467 OE, WAE 24443 OE, WAE 2049 KOE, WAE 16161 OE, WAE 20161 OE, WAE 20163 OE, WAE 20164 OE, WAE 20361 OE, WAE 2444 1 OE, WAE 24466 OE, WAE 16442 OE , WAE 20364 OE, WAE 2047 SOE, WAE 24163 OE, WAE 24468 OE, WAE 20363 OE, WAE 16443 OE, WAE 24444 OE, WAE 24462 OE, WAE 24364 OE, WAE 16163 OE, WAE 24442 OE, WAE 28444 OE, WAE 28443 OE, WAE 28441 OE, WAE 24361 OE, WAE 20443 OE, WAE 24363 OE, WAE 20362 OE, WAE 24464 OE, WAE 20442 OE, WAE 16441 OE, WAE 20441 OE, WAE 244 65 OE, WAE 2046 SOE, WAE 20444 OE , WAE 16444 OE, WAE 2044 SOE.

Vario Perfect translated from German means ideal quality. Sensitive - sensitive wash. These two qualities combine in the latest line of Bosch LOGIXX washing machines.

Model range of the Logic 6 series.

What happens if the metal flaps of the machine drum sink?

It may seem like there is nothing serious here. However, this problem can cause serious damage to your washing equipment.

The following parts may fail:

- tank walls. As a result, the washing machine begins to leak;

- the metal doors of the drum are damaged;

- The heating element breaks and bends.

In some cases, when the doors are opened during the spinning process, all three breakdowns described above occur. This will result in the need for very expensive repairs. You may even have to replace your washing equipment.

Belt in a Bosch washing machine

Of course, it was worth starting with the engine, since it is this that creates the rotation of the drum. But, perhaps, we will first identify the most common malfunction. The belt in a washing machine is the element that is most susceptible to physical wear and tear.

Replacing a belt in a bosch washing machine is one of the most common services in our service center. Any story that clients come to us with regarding this problem begins with the following words: “during washing, a bang occurred and the drum stopped spinning.” Here we have only two options:

- - the belt is broken;

- — the belt came off.

It is very easy to understand whether the problem is in the belt; just unscrew the back cover of the washing machine and look at the belt. If it falls off, but is in perfect condition, you can try to put it on. If the belt breaks, then it will need to be replaced. It is impossible to prevent such a malfunction, but you can extend the service life of the belt - just do not overload the drum during washing. 1-3 kg of laundry is more than enough for one wash cycle.

How much will the repair cost?

Unfortunately, it is not possible to say the exact price of repairs in this case, because... breakdowns are of various types and the cost of fixing them can vary significantly. Also, a lot can depend on the brand of the washing machine, as well as on how easy it is to get original spare parts.

In order to get the highest quality repairs, it is best to contact an official service center, whose contacts can be found both on the manufacturer’s website and in the device’s operating instructions. However, repairs in such a center can be very expensive. Sometimes the price tag for post-warranty service can reach 70% of the cost of the device. In this case, the issue of car repair becomes quite controversial, because the new car will work much better, wash better, and the consumption of water and electricity will be significantly reduced, which will save on utility bills and take care of preserving the planet for our children.

In addition to official service centers, repairs can be performed by private craftsmen, who will ask for a lower price. However, it is worth understanding that such masters will install non-original handicraft spare parts, often second-hand ones. Such repairs can backfire and lead to more expensive breakdowns or even flooding of neighbors. Such craftsmen do not pay taxes and do not provide a guarantee for their work, so we strongly do not recommend using the services of such private “kulibins”.

Problems with the Bosch washing machine motor

Now let's move on to the engine. To the very engine that drives the drum rotation process. In Bosch washing machines, the motor is located under the tank and is protected by a special gasket from water ingress. But even such seemingly modern protection cannot guarantee its constant operation. There can only be 3 problems with the engine - brushes, bearings, and the coil itself.

Replacing motor brushes in a Bosch washing machine is required at least once every 3 years. For intensive washing (2-3 times a day), maintenance must be carried out more than once every two years. The brushes have graphite components, and of course, when the engine rotates, they wear out, after which the contact on the engine disappears and it stops spinning. Accordingly, the drum itself stops rotating. The brushes do not immediately fail; before that, the washing machine seems to spark from below during washing for some time; this is easy to notice both by the noise and by the characteristic sound.

Call the master

In a situation where the Bosch washing machine does not rotate the drum, and you cannot cope on your own, you need to call a specialist.

It is better to call a specialist not privately, but officially - from a company that repairs washing machines. Such companies can be easily found on the Internet, giving preference to reliable ones with a good reputation.

The cost of repair work depends on its complexity. Prices can vary greatly by city and region. , you will have to spend the following amount on average to repair a Bosch washing machine

- bearing replacement – from 4,000 rubles;

- replacing the wiring harness - about 2000 rubles;

- drum pulley replacement – from 2,000 rubles;

- repair of the control board – from 3,000 rubles;

- replacement of the drive belt – from 1,000 rubles;

- get a foreign object - from 1,500 rubles;

- replacement of brushes – from 1800 rubles;

- motor replacement – from 2,000 rubles.

The cost of replacement parts is not included in the price of the work and is paid separately. After the repair, a guarantee is issued for the work performed. The duration of the warranty issued by the technician depends on the unit that was repaired.

Is it a problem? — Bosch washing machine does not spin the drum

You were doing the laundry, everything was fine, when suddenly the drum in the washing machine stopped spinning. The first thing everyone will think about is that a breakdown has occurred. But it is not always the case.

For example, overload protection has tripped. This mechanism protects the belt and engine drive from damage when the tank is overloaded. That is, if you put in more laundry than expected, the drum will stop spinning . To restart, just take out some of the laundry and wash it later.

As you can see, if the drum stops rotating during washing, this does not necessarily mean a malfunction has occurred. But no equipment works without breakdowns. Now we will look at them too.

Bosch service engineer visit

Diagnosis of faulty equipment

Consultation from our experts

Summing up

All the information in this article was provided with the purpose of identifying the reasons why the drum does not spin and what to do in this case. However, I want to warn you once again that with complex breakdowns that require complete disassembly or replacement of key parts, it is better to contact a professional service technician in half of the cases, which does not bring the required result. Since the technician is not able to bring with him all the necessary parts, test equipment and tools, the quality and speed of the repair are significantly reduced. Which will lead to repeated breakdowns in the very near future.

The main reasons when the drum does not spin due to breakdowns

We would like to immediately note one similar problem, but not related to this issue. This is when the drum stops during the wash, or more precisely, during the spin cycle.

The belt has fallen off, stretched or broken

The drive belt is used in almost all Bosch washing machines, with the exception of those models with direct drive. Using a belt, the motor drives the drum during washing or spinning.

During the rotation of the drum, the belt always receives increased load and has a constant tendency to lose elasticity. That is, over time, even the best belt will stretch and fly off during high drum speeds. You can put it back on for a while, but it’s not serious.

When the belt breaks, there is a bang that sounds like a firecracker exploding. Most often this happens during a spin cycle, and the drum immediately stops spinning. In this case, the only option left is to replace the belt.

The graphite brushes of the engine have worn out

When the brushes on the engine wear out (shorten), contact with the commutator is lost, and the engine stops due to the lack of an electromagnetic field. EP is necessary to create the driving force of the electric motor.

These motor brushes are nothing more than consumables, so such a breakdown is not unusual. With intensive washing, the brushes are worn down to the ground in 2-12 months. Replacing brushes in Bosch washing machines is easy, although you have to disassemble the motor. It’s easy to understand that the time has come to replace them; before the drum stops completely, these brushes will spark. The next photo shows the brushes worn down to nothing.

Engine doesn't work

If the engine is faulty, the drum will not rotate, but if you try to turn it manually, you can do this without problems. Electric motors in Bosch washing machines are installed original, from Bosch himself. That is why they break very rarely, and most often it is one element that fails, and not the engine itself.

The motor consists of small bearings, windings, electronic components, a rotor, and other components. That is, in essence, this is a real engine, only it is driven by the drum, not the car.

It is very rare that an engine replacement is required; in other cases, repair is always possible. Surprisingly, modern technical means allow such complex repairs to be done at home, without loss of quality.

A foreign object has entered the space between the drum and the inner wall of the tank

If, when trying to spin the drum, a slight movement is felt, half or a quarter of a turn, then it is most likely blocked by a foreign object. Most often this is a bra wire.

Bra wire in drum

You need to carefully remove it with pliers. At the same time, do not swing from side to side, so as not to break off.

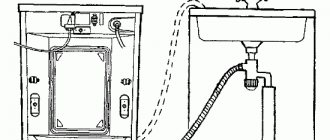

If a foreign object is not visible inside, it means it is stuck between the drum and the tank. To remove it from the bottom of the washing machine, perform the following steps:

- We unfold the washing machine so that we have access to the back wall.

- Unscrew the screws (bolts) holding the top cover and back panel. We remove these body elements.

- We find the heating element, disconnect the wires from it and unscrew the lock nut. We remove the heating element.

Removing the heating element

We illuminate the hole with a flashlight. If a foreign object is found, remove it using pliers, bent wire or your hands.

IMPORTANT!

When installing the heating element back, we pay special attention to the tightness of the cuff fit.

If a blocking object is stuck at the top of the tank and it is not possible to rotate the drum so that it falls down, you must perform the following steps:

- We immobilize the pulley by wedging it with a wooden block.

- Unscrew the bolt from the shaft and remove the pulley.

- We hit the shaft with a wooden or rubber hammer. If you don’t have this in your tools, you can substitute a piece of wood to avoid damaging the thread.

- After the shaft and drum are pulled out, they will move a little, and the object that is jammed will fall down.

- Remove it through the mounting hole of the heating element.

When washing, the drum does not spin, but it rotates manually

- If the drum rotates stably under the influence of the hand, then the reason for its inoperability in automatic mode may be a critical weight, that is, an overload of the contents inside the washing machine.

Initially, you can try to remove at least half of the entire contents and start the washing machine.

- Perhaps there was no breakdown, and you really overloaded your machine. Many models of washing machines, especially new models, have a special weight sensor, which, under heavy load, blocks the operation of the drum. Modern models can provide relevant information on the screen or in the form of an audible signal indicating that it is necessary to reduce the weight of the contents.

If the model is not very new, then the drum is simply in a “dead” state and refuses to fulfill its main task.

- By the way, if after unloading the laundry the machine starts working again, then you can exhale calmly, since there is no breakdown. In order for the machine to last as long as possible, it is necessary to strictly follow the manufacturer’s recommendations.

If reducing the load does not help, then most likely some component of the washing machine has failed.

There are several main problems that are associated with a faulty washing machine drum. Fortunately, repairing washing machines and replacing the drum today will not cost much, since there are quite a lot of repair offers and you can choose the most optimal option, the price of which will fully meet your expectations.

What can you do right away?

We calm down, turn off the machine with the button on the panel and unplug the cord from the outlet. We cover the floor with rags, find the drain filter on the front panel below, place a container (scoop, suitable container) under it, open it and drain the water. We take the laundry out of the machine and figure it out further.

We determine when the drum stopped. If during the spin cycle, the laundry will remain simply wet, without any signs of soapiness. If you wash it, things will be powdery.

You need to try to spin the drum by hand. Did not work out? Rotation is physically interfered with by a foreign body or a failed part. When the drum spins while the machine is turned off, the reason is hidden in the electronics.

The drain filter plug is unscrewed counterclockwise, and if you can’t pull it out by hand, you can use pliers

And one moment. A common consequence of drum immobility is the usual overload. Try splitting the laundry in half and restarting the wash with less “work.”

Modern washing machines are equipped with special sensors that monitor the weight: if it is exceeded, they stop the process. On some models this information is displayed on the display.

Don't forget to check the external conditions that affect the operation of the machine. Some washing machines are equipped with sensors that are sensitive to water pressure parameters.

While the user is disassembling the device and changing parts, a pinched hose, a burst gasket or a dirty filter will not alert you to attention.

The main causes of washing machine malfunction

- Belt failure. The belt may not only weaken, but also fray or even break. It is this belt that is responsible for transmitting torque from the electric motor to the washing machine tank. Rapid wear of the belt occurs from frequent use of the washing machine, or, conversely, from very rare use. In this case, the belt may simply dry out and begin to crack. Today, such repairs in Moscow will cost 800-1200 rubles, depending on which washing machine repair company you use;

- Failure of electric motor brushes. The reason may also be worn brushes that do not create the necessary electromagnetic field to rotate the motor rotor. The more often you use the washing machine, the more the brushes will burn, thereby becoming shorter and shorter. When the brushes become so short that they simply do not touch the commutator, the washing machine motor simply stops rotating. In this case, it is necessary to carry out a comprehensive replacement of the brushes. Such repairs will cost from a thousand rubles and more;

- Failure of the electronic module or programmer. The electronic module is used in washing machines with electronic control, and the programmer is used in models with electromechanical control. People who are faced with the problem of repairing washing machines that the drum does not spin should pay special attention to this point. The control board, which is responsible for all processes of the washing machine, is the “brain” of the entire system. If this “brain” does not send the necessary signal to the drum, then it will not spin. Most often, the cause of failure of this board is frequent power surges or natural wear and tear. In this case, you will have to reset the program, “reflash” this board, or completely replace it. This should be done by a specialist, and his services will cost 1,200 rubles and more;

- Motor malfunction. The motor may simply burn out. Even though the electric motor of a washing machine breaks down the least often, it can also fail, and the main reasons for this can be the same power surges or an ordinary leak that causes a short circuit. If, for example, an interturn short circuit of the winding occurs, then when the machine is empty the drum can rotate normally, but when the machine is filled, then when you try to start it, the meter plugs may simply “fly out”. If a break in the rotor or stator winding occurs, this leads to the fact that the drum does not rotate at all. In this case, it will be necessary to completely disassemble the machine in order to carry out the necessary diagnostics and repair the engine. This repair option will be the most expensive of those listed above and starts from one and a half thousand and above;

- You may also need to repair the washing machine drum cross. It is she who is responsible for rotating the drum in an automatic washing machine. Fortunately, such repairs will cost much less than replacing the entire engine.

Methods to prevent future problems

Empty pockets thoroughly before washing. Place all small items (baby socks, handkerchiefs) and bras in special mesh bags.

It is important not to overfill the tank - follow the manufacturer’s recommendations for the maximum weight of laundry, do not fill the machine to the limit

Connect the washing machine through an uninterruptible power supply or at least an extension cord with a surge blocker if you live outside the city or simply have problems with power surges.

This is especially true for models with many programs and an overly smart “brain”. Pay attention to the correct grounding of the machine.

In addition, it is necessary to regularly carry out preventative cleaning of the drum - this will protect the washing machine from breakdowns and the occurrence of unpleasant odors.