It is quite difficult to disassemble an Electrolux washing machine for spare parts or for repair purposes without having the skills and experience of such work.

Errors made during the disassembly process can become the final verdict for the further operation of the household appliance.

For those who are faced with such work for the first time, detailed step-by-step instructions on how to disassemble an Electrolux washing machine will come to the rescue.

By adhering to it, disassembling and reassembling the washing machine will be done as quickly as possible and without any problems.

Is it possible to remove the lid of a washing machine?

To remove the lid from the washing machine, you first need to move it away from the wall so that you can access the back wall of the washer. ... After the lid is unscrewed, it must be removed; to do this, you need to move the lid back relative to the washing machine, then lift it up and put it to the side.

Interesting materials:

Do I need to cover clematis for the winter? Do I need to cover strawberries? Do lilies need to be covered for the winter? Do I need to cover Honeysuckle for the winter? Do you need to cook moss mushrooms? Do you need to boil saffron milk caps before salting? Do you need to cook fresh champignons? Do you need to cook russula? Do I need to drain the water from the steam generator? Do I need to soak dry milk mushrooms?

Preparing for disassembly

To make the process of disassembling the washing machine go as quickly as possible, you need to prepare the following set of tools in advance:

- wrenches;

- slotted and Phillips screwdrivers (a good option is screwdrivers with a magnetized tip that holds very small fasteners);

- pliers (when working with household appliances, it is better to choose a tool with rubberized lining on the handles);

- WD-40 liquid (an irreplaceable assistant in situations where it is necessary to unscrew scale-covered and rust-covered bolts).

In addition to tools, you should always have rags and a basin at hand (necessary for collecting the remaining water in the tank, drain hose).

Having prepared the necessary tools, household appliances are disconnected from the water supply, sewerage, electricity, and placed in an open, free space so that nothing interferes with the disassembly process.

Tools

First of all, it is necessary to provide sufficient space and good lighting. You won't be able to disassemble the car without tools. It should be noted that manufacturers use different solutions in manufacturing.

Set of tools

Do you wash your shoes in the machine?

Oh yes! No

Therefore, let's consider a universal set. It will allow you to disassemble any car. List:

- Socket wrench with ratchet. Size - 10 and 13.

- Screwdrivers - T10, T15, T20, RN1, RN2, slotted SL 2-20.

- Set of socket heads with ratchet - from 5.5 to 13.

- Flashlight.

- Pliers.

- Round nose pliers.

- Wire cutters.

Tools needed

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! We recommend taking photographs of all stages of work, as well as the fastening of parts.

Electrolux washing machine diagram

Understanding what the main elements of a washing machine look like and where they are located will help you quickly diagnose and repair household appliances.

So: all elements of the internal structure are hidden behind the metal panels of the case (front, rear, side) and the lid. To extend the life of the washing machine in conditions of high humidity, the panels are coated with a special protective enamel.

Depending on the location of the hatch, there are Electrolux washing machines with vertical loading (laundry is loaded by opening the lid) and front loading (the hatch is located on the front panel).

The internal structure (a certain set of parts and mechanisms that ensure uninterrupted, high-quality operation of the washing machine) includes:

- The control module is one of the main elements that controls and controls the functioning of all mechanisms of the washing machine.

- The control panel helps you select the desired program, start or pause the washing process.

- Pressure switch and inlet valve (provide control of the process of water intake into the tank).

- The motor is the driving force that ensures the rotation of the drum.

- Tach sensor (controls the rotation speed of the drum).

- A tubular electric heater (TEH) is located in the lower part of the washing machine body, under the tank, and heats the water to a set temperature.

- Thermistor (built into the heating element, determines the degree of water heating).

- Damper and springs are elements that reduce vibration of the washing machine drum during the washing, rinsing or spinning process.

- Heavy concrete or plastic blocks are counterweights (they help dampen the vibration that occurs during operation of the washing machine).

- The rubber seal around the hatch is a cuff (ensures the door fits as tightly as possible and prevents water from leaking).

- Hatch blocking device (protects the washing machine from leaks).

- The drain pump, filter, and pipes are the main elements of the system for draining waste water from the drum.

On the rear panel there are: power cord, drain and inlet hoses.

What difficulties might arise?

The main difficulty that arises in the process of disassembling a washing machine is soured, rust-covered fasteners and mechanism components.

As a rule, it is very difficult (almost impossible) to unscrew or dismantle such parts the first time.

A special product will help solve the problem - WD-40 . It is enough to treat the soured element, wait from five to thirty minutes (the length of the wait depends on the density of limescale or rust), and then, with a little effort, unscrew the desired element.

Cleaning

Soap scum, lint and hair remaining on perforated walls after washing, mold and mildew that actively multiply in a humid environment are not only a source of unpleasant odors, but can also cause serious damage to household appliances.

Regular cleaning of the drum will maximize the period of uninterrupted operation of your LG washing machine.

Modern models of washing machines are equipped with a “drum cleaning” mode. Launching the program is simple:

- press the “Start” button and wait for the sound signal;

- We find two buttons with the “*” icon on the control panel and press them for a few seconds (at this moment the washing machine stops responding to any other commands);

- Press the “Start” button again (the self-cleaning program starts).

Cleaning lasts 90 minutes. A sound signal will indicate the end of the program.

The “drum cleaning” mode is started with an empty tank, without using any detergents. As soon as the self-cleaning process is completed, the hatch door is opened to allow the inner surface to dry thoroughly.

Expert advice

- When disassembling the washing machine, take into account that some parts are made of plastic, so work is carried out as carefully as possible so as not to damage the parts.

- When repairing a machine with your own hands for the first time, it is advisable to photograph each stage of the process so that after replacing parts there will be no doubt about the order in which the elements are installed.

- During disassembly of the unit, the parts are marked with multi-colored markers - this will help to perform assembly correctly and significantly reduce its time.

- When starting work, be sure to make sure that the device is disconnected from the network and that there is no residual current in the parts. To do this, use a multimeter.

When disassembling household appliances yourself, do not forget to follow safety precautions. Having studied the operating instructions, armed with the necessary tools, and following the steps described in the article, even a technician without experience can perform disassembly.

How to replace a damaged part

For almost any reason that arises, you can repair this unit yourself. In most cases, this part is located at the back and top - near the lid.

Method for replacing a failed unit

Close the water supply valve.- Disconnect the supply hose.

- Remove the top cover. The solenoid valve must be accessible.

- Disconnect the electrical wiring.

- Disconnect the connecting hose of the valve and the fitting.

- Remove fasteners.

- Install fasteners (latches or screws).

- Dismantle the part that has become unusable.

- Change the valve.

The unit is assembled in the reverse order of disassembly, following a strict sequence of actions. After installation, the functionality of the entire mechanism is checked.

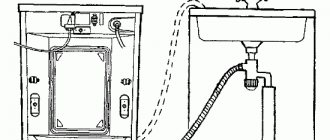

Features of replacing a unit in a SMA with vertical loading of laundry

On top-loading machines, the inlet may be located in the plinth area of the rear wall. Replacing the inlet valve on this type of washing machine may require removing the side wall.

On the Internet you can find detailed video tutorials on the repair procedure. SMA LG, Indesit and other brands have some repair features, but the principle of replacing a damaged part is almost the same for all models.

If replacing spare parts yourself is not possible, you should contact a reliable service center that services this brand of unit.

When choosing a service center, you must carefully study the experience and user reviews of the service provider. Public opinion, expressed in impartial customer reviews regarding the competence of the craftsmen, is sometimes much more valuable and objective than numerous certificates displayed for public viewing on the official website of the service center.

Source

Probable malfunctions and their diagnosis

Replacing the filling valve of a washing machine may be necessary when the water supply is disrupted or stopped.

Procedure for diagnosing a malfunction

- Check the filter mesh, clogging of which prevents the normal flow of water.

- Dismantle the part, connect the inlet hose, lower it into the container, apply voltage to the coils one by one. In good condition, when voltage is applied, the valve is open, when disconnected, it is closed. If it stays closed, the coil is probably burned out. There will be no water inlet.

- If water flows in, but after shutting off it continues to flow out, the membrane has become unusable or the rod spring has been completely weakened. Here it is necessary to replace the water supply valve in the washing machine.

You should also check the presence of inserts pressed into the fittings. If they are missing, the compartment overflows and disrupts the proper order of program execution. In such a situation, the solenoid valve should be replaced.

In almost all situations, in the event of pressure disturbances during supply/no flow, the failed unit should be replaced.

Algorithm of actions

For each type of Electrolux washing machine (depending on the loading method), a specific parsing algorithm is prescribed.

Horizontal loading household appliance

The body of a front-loading washing machine consists of two halves (back and front, connected by fasteners along the side line).

Taking into account this design feature, the Electrolux washing machine is disassembled as follows:

- We find two screws located on the back wall of the case and unscrew them. We slightly push the cover towards the back wall, lift it and remove it from the body.

- On the left and right side panels, unscrew the two screws that secure the rear panel.

- At the bottom of the rear panel, unscrew the two fasteners.

- On the sides, after opening the plugs, unscrew the fixing bolts.

- Unclench and lift the plastic holders that secure the panel in the upper part of the case.

- Remove the back panel.

- Inside the powder receptacle we find a plastic tab, press it, and carefully pull the dispenser out of the washing machine body.

- We unscrew the fastening bolts and remove the hatch door along with the hinge.

- Carefully prying up the clamp spring with a slotted screwdriver, pull the metal ring off the cuff. We put the rubber seal inside the drum.

- We unscrew the screws located on the left side of the control panel, carefully use a screwdriver to open the latches on the top and sides of the panel, without disconnecting the wiring, remove the control unit.

- We unscrew the screws located around the hatch lock, under the control panel and around the drain filter, and remove the front panel from the body.

- Hold the pulley with one hand and remove the drive belt with the other.

- We unscrew the fasteners holding the motor, disconnect the terminals of the power wires, move the motor slightly toward itself, and remove the mechanism from the housing.

- Disconnect the wires from the drain pump, unscrew the fasteners, carefully turning clockwise, and remove the pump from the housing.

- We disconnect the wiring from the heating element, unscrew the central bolt (located between the contacts) and, using gentle rocking movements, remove the heating element from its seat.

- Having unscrewed the central bolts, we dismantle the counterweights.

- Using pliers, pull out the pin holding the shock absorbers and remove the paired elements from the bottom of the tank and the body of the washing machine.

- In the upper part of the housing, we disconnect the powder receiver pipes, the wiring of the filling valve, the springs, after first disconnecting the tube, we dismantle the pressure switch.

- Carefully lifting it, remove the tank from the springs and remove it from the housing.

At this stage, the analysis of the Electrolux front-loading washing machine is completed.

From vertical

Algorithm of actions:

Carefully prying the latches on the right and left sides, lift the control panel, disconnect the wiring from the board connectors, and remove the panel from the case.

Before you disconnect any wires, you need to take a photo of their connection diagram.- Disconnect the wires, unscrew the fasteners, and remove the electronic board.

- Having previously disconnected the pipes and wiring, we dismantle the fill valve.

- Having unscrewed the fixing elements located on the rear panel and one at the bottom of the front panel, we dismantle the side walls of the case.

- From the opened space we pull out the engine, drain pump and water level sensor (all elements are located under the tank). To do this, unscrew the fasteners, remove the wiring, and pull the mechanisms out of the housing.

- We block the pulley wheel with a wooden block. Carefully remove the drive belt.

- Raise the top panel (cover), take out the powder receptacle (fixed with latches).

- Unscrew the bolts holding the cover.

- We pull back the rubber cuff, under which we have access to the screws that secure the plastic strip. They also need to be unscrewed. Remove the top panel.

- We unscrew the hardware holding the shaft, close the tank doors, and remove the tank from the housing.

At this stage, the disassembly of a top-loading washing machine can be considered complete.