Laminate is a universal floor covering. Despite all its attractive qualities, laminated parquet “suffers” from a significant drawback - high sound conductivity. The noise of footsteps from high heels, the ringing and sharp sound from the fall of any objects on the parquet causes irritation and negative emotions of others. Soundproofing the floor in an apartment under laminate is the first necessity for maintaining a comfortable environment in the home. The floating laminated parquet floor has a drum effect. To cope with these phenomena, noise-absorbing substrates are placed under the laminate.

Video description

Soundproofing floors under laminate.

Texound

The material consists of natural aragonite stone and elastic polymers. The thickness of the roll type is 3.7 mm. The dense product absorbs sounds of any type well. Moisture-resistant raw materials do not rot, are not afraid of mold and temperature changes. The only drawback of Texound is that it cannot be placed on a bare floor. The product is used in combination with thin insulation.

Thin backing for the board Source t-solutions.com.ua

Schumanet 100

The rating of soundproofing substrates is completed by fiberglass. The material has a high noise absorption index of 29 dB. “Shumanet 100” consists of fiberglass impregnated with bitumen and organic resins. The thickness of the raw material is 4 mm, produced in the form of convenient rolls.

The substrate simultaneously performs the functions of sound and water protection, preventing water from passing through for 120 minutes. The canvas does not crumble and does not lift the screed under the laminate. The material is easy to install yourself. The only drawback is the very high cost, which is why they are used when arranging luxury buildings.

Types of sound-absorbing coatings for laminate

The building materials market offers a wide range of soundproofing substrates:

- Polyethylene foam.

- Cork.

- Combined substrate.

- Insulation boards.

- Cardboard with felt.

Polyethylene foam

Standard cheap coating in rolls, 25 and 50 m long, is made with a thickness of 0.8 to 6 mm. The roll width is 1 m. It has low soundproofing qualities. The main purpose is to level out micro-differences in the height of the floor base.

Cork

The crushed bark of the cork tree is pressed with a binder. Cork is produced in rolls. Cork is the only soundproofing material of natural origin. The sheets are covered with plywood before laying the parquet.

Combined substrate

The structure of the coating consists of two outer layers of polyethylene with a lining of polystyrene foam granules. Sound waves passing through polyethylene get stuck in it and lose their energy.

Insulation boards

The boards are made from natural wood fiber raw materials. They have low resistance to structural noise, but they perfectly muffle sounds from neighboring acoustic devices.

Cardboard with felt

The material belongs to the professional group. The coating is intended for sound insulation of laminated floors in residential areas.

Along with these types of coatings, the building materials industry produces a number of highly effective noise-absorbing substrates for laminate:

- Akuflex.

- Akuflex-Super.

- Akuflex-Combi.

- Isonoise 3 mm.

- Schumanet 100.

- Vibroisotex Laminate.

Akuflex

Roll covering consists of a polyethylene base covered with polyester fiber. Due to its increased elasticity, it successfully “copes” with footstep noise and impact sounds. The underlay is designed for sound insulation of floating laminate floors in service areas.

Article on the topic: Soundproofing of interior partitions made of plasterboard and other materials

Specifications:

- Sound insulation indices - under laminated parquet - 20 dB, under cement-sand screed - 27 dB.

- Purpose - reducing the level of impact noise.

- Roll dimensions (L x W x H) - 1500 × 100 × 0.4 cm.

Akuflex-Super

The canvas has a fiberglass base coated with a bitumen-polymer binder. Akuflex-Super underlay is used for sound insulation of floating laminate floors. The coating effectively suppresses shock waves. At the same time, the substrate has a waterproofing property.

Specifications:

- service life - 25 years;

- purpose - maximum reduction of impact noise level;

- sound insulation index - 25 dB;

- water absorption - about 2% during the day;

- roll dimensions (L x W x H) - 1000 × 100 × 0.5 cm;

- weight - 34 kg.

The covering is laid both under the laminate and under the screed.

Akuflex-Combi

The product is a reinforced bitumen base covered with synthetic fiber fabric. The material is highly resistant to impact noise.

The technical characteristics of the coating are similar to those of Akuflex-Super. A distinctive feature is that sound insulation is laid only under a cement-sand screed.

Isonoise 3 mm

The insulation material is extruded polystyrene foam, which, in addition to high sound insulation properties, has excellent thermal and waterproofing properties. Microscopic polymer cells form a closed system. The substrate is much superior to materials such as mineral wool and polystyrene foam.

The product practically does not absorb moisture and is resistant to bacterial and mold formations. Withstands loads up to 6 tons/m2. Rolls measuring 1000×100×0.3 m are used for sound insulation and insulation of floors and walls.

Schumanet 100

The soundproofing substrate under the laminate is a fiberglass sheet with a polymer bitumen coating. Supplied to the retail chain in rolls measuring 1500×100×0.5 mm.

The insulation is laid on the base of the floor - under a cement-sand screed. When installing laminated parquet flooring, sound insulation is laid directly under the parquet board - with the bitumen layer facing up.

Vibroisotex Laminate

The backing is made of polyester fiber using Vit pet technology. The main purpose of the coating is to insulate impact noise.

The material is used in various building structures, and is especially effective as a substrate for floating laminate floors. Supplied in rolls measuring 1500×100×0.4 mm. Vibroisotex Laminate is an environmentally friendly material that has high sound insulation qualities.

Article on the topic: Green Board fiberboard panels for sound insulation and construction

Features of the work

The principle of creating a protective layer under the floor covering is the same for all types of raw materials. Soundproofing substrates that are mounted on the screed are pre-protected with thin polyethylene. The material is folded in strips, making overlaps of 20 cm and overlaps of 2 cm on the walls. All seams are taped. The raw materials are placed perpendicular to the laminate.

The protection must not be installed on a subfloor made of wood. The product is placed on boards or plywood installed on top of the problematic base. The noise-absorbing agent is placed under the flooring between the joists.

Cross-sectional multilayer screed Source acousticstime.com

What does soundproofing and soundproofing of a floor mean?

Returning from work to their apartment, everyone dreams of spending the evening in silence and relaxing. But due to the insufficient thickness of the walls, annoying sounds come from all sides. A person sleeps poorly and does not feel rested. As a result of living in uncomfortable conditions, health is undermined, weakness appears, and nerves fail. You can stay healthy and ensure comfortable living in your home if you improve sound insulation.

Soundproofing the floor in an apartment under laminate is necessary to prevent sounds that impair the quality of life. Moreover, almost all materials used for sound insulation conduct heat poorly, which means your home will become warmer.

In what cases is it recommended to soundproof the floor in an apartment under laminate:

- There are noisy neighbors under your apartment. Of course, if no one lives below you or your apartment is on the first floor, then extraneous sounds will not bother you.

- The multi-storey building is made of materials that allow noise to pass through. If the flooring material does not absorb all kinds of sounds well, then soundproofing the floor in an apartment under laminate is mandatory.

- You live in a new panel building. The older the house, the lower the noise level. The fact is that earlier the walls of buildings were thicker, and the material from which the slabs were made had a different composition. The principle is this: as the rigidity of the floor increases, the noise level increases.

In addition, you will have to soundproof the floor in the apartment under the laminate if the finishing coating is poorly laid. The problem is that you have to re-lay the laminate, but using the correct technology.

Not all apartments require sound insulation. However, if extraneous sounds disturb you: the voices of neighbors, footsteps, then, most likely, the sound insulation in the house is poor, and you will have to improve it. Do not forget that laminate used as a finishing floor covering will amplify noise, transmitting it along the floor slabs.

Although the sound insulation was initially good, once the topcoat is installed the noise level will increase.

It is generally accepted that the concepts of “sound insulation” and “noise insulation” are one and the same. But this opinion is wrong, and in fact there are differences:

- A sound wave is created by one source. It has frequency and amplitude.

- Noise is a variety of sounds combined together.

Sounds and noises are sometimes perceived in the same way, so it is impossible to determine exactly what you hear.

What kind of noises are there?

- Airborne. For example, the speech of a person behind a wall, the noise from car tires.

- Structural - when the sound wave is transmitted by the structure of the house. Moreover, the sound source is far away, and the material simply picks it up.

- Drums. For example, when the door slams, a drill, a hammer drill, a hammer knocks, and the like works.

The most difficult thing to eliminate is structural or impact noise. There is only one effective method: to separate the structural elements of the building, and then fill the gaps with a special soundproofing material. Obviously this won't be possible. This means that noise must be eliminated in other ways.

The listed 3 types of noise differ from each other in the type of carrier: it can be air or something solid. Thus, the sound that is transmitted through the air instantly disappears; it is easy to eliminate. However, if the sound wave is transmitted by, for example, a wall, it will be more difficult to create silence.

It is necessary either to ensure that the material does not come into contact with the sound source, or to prevent the sound from spreading. Unfortunately, this is not always possible to implement in practice. For this reason, eliminating absolutely all sounds is an impossible task. However, soundproofing the floor in an apartment under laminate will drown them out. The easiest way to do this is with the help of a substrate that is laid under the finishing floor covering.

The substrate will muffle extraneous noise coming from below. Do not forget that if the high-rise building is panel or monolithic, the sound will penetrate more strongly. Therefore, sound insulation will be more effective, the better the material of the soundproofing board.

Useful tips from experts

In order for the installation to be of high quality, it would not hurt for a novice master to familiarize himself with the norms and rules of the work. Just knowing the process of laying sheets will not be enough.

It is equally important to take into account the recommendations of professional builders with many years of experience, and their recommendations relate to the following nuances:

1. Before unwinding the roll, you need to remove the tape that secures the material. 2. The material is laid with an overlap. 3. For air to circulate, a gap of at least 1 cm is required. 4. The material should be cut using carpet scissors or a construction knife. 5. When installing soundproofing slabs, it is important to avoid hard contact between the structures and the material. 6. Before unwinding the roll, you need to give it time to stand in the room being repaired for a day. 7. Construction work is permissible within the range of +15 degrees, and humidity should be from 65%. 8. The coating must be laid on a clean, perfectly smooth and even work surface. 9. It is imperative to reinforce the screed with mesh. 10. The surface of the mixture must be adjusted and leveled to the building level. 11. In the area of corners and doorways, you should carefully cut out the canvas in order to then apply the material to the columns and walls. 12. Cutting should be carried out exclusively according to the planned measurements. 13. To level the base, use dry construction mixtures. 14. Parquet boards should be laid on Schumanet in accordance with technological regulations and standards. 15. During construction work, be sure to follow safety regulations and do not neglect the use of personal protective equipment.

According to customer reviews, the sound and waterproofing of Shumanet 100 is of high quality. Professionals often use this material when treating rooms with a high level of sound and noise insulation requirements. A wide range of products makes it possible to choose the optimal type of material that is suitable for a particular case in accordance with the technical properties and premises. To learn how to make sound insulation in an apartment yourself, see the following video.

Topic: Soundproofing

+ Reply to topic Shown 21 to 30 of 43

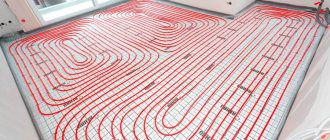

- 05/26/2016 16:41 #21 Junior Member Registration 05/26/2016 Messages 3 Thanked 0 Thanked 0 times in messages Message from Tehnik-san I will share photos of proper fastening of heating pipes, taking into account the requirements to preserve all the technical soundproofing parameters of the proposed sound insulation systems. Those. Even if you install the “Shumka” according to ALL the rules, you can cross out the recommendations and “screw” the system by mediocrely fastening the pipelines with self-tapping screws directly to the screed. I’ll show you my “secret” - how to do it right. We heat the bitumen layer with a hand torch and simply glue, rather than drill, the pipe fastenings to the concrete floor slab. And we glue it to mounting tape (gray), even this way it holds tightly and saves time. By the way, why do you use Schumanet? The quality has become poor: you roll out a roll, and the bitumen layer is already in cracks. In some places you can even see the light. If you often make floor noise, take a look at Maxforte-ShumoIzol, now we use it on sites. The quality is much better!05/26/2016 16:41 # ADS Registration Always Lots of Messages

- 05/26/2016 23:47 #22 Senior Member Registration 07/16/2012 Address Yubileyny, 63 Messages 1,178 Said thanks 119 Thanked 237 times in messages Message from Jenkins_Dog By the way, why do you use Schumanet? The quality has become poor: you roll out a roll, and the bitumen layer is already in cracks. In some places you can even see the light. If you often make floor noise, take a look at Maxforte-ShumoIzol, now we use it on sites. The quality is much better! I just installed Schumanet and didn’t see any cracks. All of these substrates are essentially the same. And Maxforte is simply 1.5 times more expensive.

- 05/27/2016 00:31 #23 Junior Member Registration 05/26/2016 Messages 3 Thanked 0 Thanked 0 times in messages Message from Brim I just installed Schumanet and didn’t see any cracks. All of these substrates are essentially the same. And Maxforte is simply 1.5 times more expensive. No, you are confusing! Shumanet-100 and MaxForte-ShumoIzol cost the same, 290 rubles/m2. But at the same time, ShumoIzol has 4 dB higher sound insulation performance. As for quality, let everyone have their own opinion. We don't use it anymore, but work on construction sites every day. If you bought it for yourself, I hope everything goes well for you! The main thing is that the Schumanet is not torn anywhere (and it breaks easily), otherwise when you fill the screed there will be sound bridges - this will reduce the sound insulation!

- 05/27/2016 08:28 #24 Senior Member Registration 07/16/2012 Address Yubileyny, 63 Messages 1,178 Said thanks 119 Thanked 237 times in messages Message from Jenkins_Dog No, you're confusing! Shumanet-100 and MaxForte-ShumoIzol cost the same, 290 rubles/m2. But at the same time, ShumoIzol has 4 dB higher sound insulation performance. As for quality, let everyone have their own opinion. We don't use it anymore, but work on construction sites every day. If you bought it for yourself, I hope everything goes well for you! The main thing is that the Schumanet is not torn anywhere (and it breaks easily), otherwise when you fill the screed there will be sound bridges - this will reduce the sound insulation! Why use Schumanet-100 when there is Schumanet-100Combi for 215 rubles per meter? And a lot of analogues. Moreover, Shumanet-100Combi (formerly Akuflex-Combi) has a reduced impact noise level reduction index of 25 dB, while Shumanet-100 has 23 dB. The Schumanet-100 Super has 27 dB, but all this is essentially a measurement error. For comparison, MaxForte-ShumoIzol has 27 dB. At the same time, a “bare” floor slab with a thickness of 140 mm shows an index of the reduced impact noise level in the region Ln,w = 80 dB, 180 mm - 76 dB (yes, it seems that a significant increase in thickness does not give much). Moreover, according to SNiP standards, it should be no more than Ln,w = 60 dB! 80 - 60 = 20 dB 76 - 60 = 16 dB That is. We need no more than 20 dB from the substrate to bring the level of GI to compliance with sanitary standards. Those. - any substrate is suitable. And 27 dB does not have significant advantages over 23 dB. The main thing is that there is a substrate. And a screed with a thickness of at least 60 mm was made on it, otherwise the characteristics are significantly reduced. At the same time, we must understand that the substrate only protects our neighbors below from our impact noise. Therefore, there is no point in chasing indicators significantly higher than SNiP standards. To insulate airborne noise, mineral boards with a thickness of 20mm or more must be used. Here they will reduce airborne noise by 8-10 dB, and in terms of impact they will go very far from the substrates, because reduce the level of impact noise by 32 - 39 dB per layer. Moreover, Shumostop-K2/C2 costs 245 rubles per meter, i.e. a little more expensive than Shumanet-100Combi and cheaper than MaxForte-ShumoIzol.

- 07/12/2016 15:13 #25 Junior Member Registration 05/26/2016 Messages 3 Said thanks 0 Thanked 0 times in messages I doubt about this Combi.. Even if Schumanet-100 for 290 rubles. I was disappointed, I'm afraid to imagine the quality of the Combi. It seems to me that in this case the low price is more of a minus than a plus. A material costing 215 rubles cannot have normal bitumen with plasticizers and a damping substrate. I judge by Soundproof, which is in the same price category. There's a general darkness there... In any case, I'll take a look and report back. As for your dB, it’s all theory. In practice, the more, the better, taking into account possible installation errors and defects from the developer. According to certificates, for example, 25 dB, but in fact, if the substrate is thin 2-3 mm, as is the case with Schumanet, it will pinch it somewhere due to unevenness and a sound bridge will appear... The substrate should be strong and 4-5 mm thick minimum. Don’t even tell me about Shumostop, they won’t fill the screed. The slabs are pressed down from walking while doing work, and the screed may shrink over time. Already discussed on specialized forums. If I use slabs, I use Rockwool floor butts (or analogues with a density of 110-130 kg/m3).

- 07/13/2016 09:39 #26 Senior Member Registration 07/16/2012 Address Yubileyny, 63 Messages 1,178 Said thanks 119 Thanked 237 times in messages Message from Jenkins_Dog Don’t even tell me about Shumostop, they won’t fill the screed. The slabs are pressed down from walking while doing work, and the screed may shrink over time. Already discussed on specialized forums. If I use slabs, I use Rockwool floor butts (or analogues with a density of 110-130 kg/m3). Well, take the flag, as they say. I made myself a Shumostop K-2. There are no particular problems observed. Floor butts are, of course, cheaper. But they are thicker (and this is often a minus) and most importantly, they have repeated reviews about the drum effect. I haven’t seen anything like this on Shumostop.

- 04.11.2016 14:26 #27 Junior Member Registration 04.11.2016 Messages 3 Thanked 0 Thanked 0 times in messages Who used the new Shumoplast coating? I was told that it is very convenient to install when there are communications and wiring on the floor. Shumoplast can be placed directly on communications, as it is liquid and this is very convenient. The effect is said to be better than that of rolled materials

- 11/04/2016 15:08 #28 Senior Member Registration 12/24/2013 Address Yubileiny Avenue 49 Messages 336 Said thanks 100 Thanked 56 times in messages Message from Vladimir Ivanovich Who used the new Shumoplast coating? I was told that it is very convenient to install when there are communications and wiring on the floor. Shumoplast can be placed directly on communications, as it is liquid and this is very convenient. The effect is said to be better than from rolled materials. Then you want to pour self-leveling flooring on it? I poured semi-dry on a huge cottage, right on the noise-plaster. Balls are falling all over the place. Soft... you need to walk carefully. And you need to mix it vigorously. The Tajiks didn’t mix it well there.

- 11/04/2016 22:16 #29 Senior Member Registration 07/16/2012 Address Yubileyny, 63 Messages 1,178 Said thanks 119 Thanked 237 times in messages Message from Vladimir Ivanovich Who used the new Shumoplast coating? I was told that it is very convenient to install when there are communications and wiring on the floor. Shumoplast can be placed directly on communications, as it is liquid and this is very convenient. The effect is said to be better than that of rolled materials. What's the point? Take a noise stop + any roll type, pass everything around the communications with a noise stop, over the pipes - with a roll type. The thickness of the pipes in the corrugation is already 2-3 cm. Where else should I put noise-plastic on top of them? Well, when the pipes are on the floor, I can hardly imagine how electricity can also be on the floor. When the pipes overlap, it’s already a disaster, but if you add electricity, the screed will be 15 centimeters wide.

- 11/04/2016 22:23 #30 Senior Member Registration 07/16/2012 Address Yubileyny, 63 Messages 1,178 Said thanks 119 Thanked 237 times in messages Message from sibert Then you want to pour self-leveling floor on it? Poured semi-dry onto a huge one cottage, right on the shumoplast. Balls are falling all around. Soft... you need to walk carefully. And you need to mix it strongly. The Tajiks didn’t mix it well there. Yes, what kind of liquid is there? “A leveling screed with a thickness of at least 50 mm is laid directly on the SHUMOPLAST coating, and must be reinforced with metal structures to give it increased mechanical strength.” But in good terms, this is at least 60mm of M-300 sand concrete.

Social bookmarks

Social bookmarks

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- Cork underlay for linoleum Underlay for linoleum: is it necessary or not? Everyone knows that for laying such flooring as…

Production technology

The synthetic fiber base is treated with a mixture of bitumen-polymer binder on both sides, onto one of which a layer of sound insulation made of polyester fibers is glued. To prevent the layers in the roll from sticking, a polymer film is applied to the surface of the bitumen layer. To give the material the necessary elasticity, special additives based on butadiene styrene are introduced into the bitumen mixture.

The higher price of Shumanet-100Hydro compared to conventional Akuflex is justified by the presence of a waterproofing layer.