The role of underfloor heating in a residential or office space can hardly be overestimated. In winter, when there is frost outside the window, it is not very pleasant to walk on a cold surface both at home and at work. If you are faced with a similar problem, it means that the floors require insulation. The material used for this purpose must conduct heat poorly, be resistant to moisture, be lightweight and have good strength properties. It is recommended to use natural materials for thermal insulation of floors. Wood is considered one of the best. Sheets of plywood are placed on top of the wooden beams from which the logs are made, securing them with ordinary self-tapping screws. Not only high-quality timber is quite suitable for arranging the logs themselves. You can also use second-grade wood and even third-grade material. Different grades of plywood contain different marking options.

Expert opinion

Konstantin Alexandrovich

When insulating floors with plywood with a backing in premises intended for residential use, it is recommended to use plywood under the MK brand. It is resistant to moisture and does not contain compounds toxic to humans.

What is plywood

First, let's figure out what plywood is. This is a sheet construction and finishing material in which thin cuts of wood (veneer) - a millimeter or so thick - are glued together using a synthetic binder (glue). The number of veneer layers is three or more. The more layers, the greater the thickness of the sheet and the higher the strength of the material. But the strength characteristics also depend on the type of wood (deciduous or coniferous) and the type of glue used to glue the layers of wood together.

Plywood is a sheet construction and finishing material that consists of sheets of wood veneer glued together.

In wood, the fibers are arranged in a certain direction. When producing plywood, layers of wood are arranged so that the direction of the fibers in adjacent layers does not coincide. Moreover, on the outer layers the wood fibers are directed along the long side of the sheet (as a rule). The number of layers and layered structure are clearly visible on the side sections of the material.

Sheet sizes and thickness, scope of application

As already mentioned, plywood is a sheet material that has a rectangular shape. The size of the plywood sheet can be height/length from 120 cm to 360 cm. Plywood thickness - from 4-5 mm to 36 mm. The most popular is 10-14 mm. The sheet size is selected so that waste is minimal. It is often more convenient to work with small-format sheets - they are easier to transport. But when installing small plywood, more fasteners are required. But such a floor is less susceptible to thermal and humidity deformations (more seams, which compensate for changes in size).

The dimensions of the plywood sheet are chosen so that it is easier to work with them and there is less waste

In general, plywood is a popular material. It is used in construction - in the construction of panel houses, for leveling floors and walls, and for constructing floors. It is also used in the production of furniture, in the construction of passenger cars, in the finishing of ships, and in aviation. Cheaper varieties are used to make containers, packaging, and removable formwork for concrete or reinforced concrete products. So the scope of application of plywood is very wide.

Laying plywood on the floor began in the last century

Although there are cheaper sheet materials available, plywood is still one of the most popular options for flooring. Moreover, there are several ways to make a plywood floor:

- laying plywood directly on the joists;

- lay on top of the subfloor made of boards;

- level the old wooden floor;

- level the concrete floor.

Laying plywood over an old plank floor is the best choice. Due to rigidity and elasticity, differences in height are compensated, which, when using other materials, must first be sealed. Repairing an old wooden floor is done this way. And it is plywood (as a base) that is recommended by almost all manufacturers of finishing floor coverings - laminate, linoleum, carpet, etc.

Tools required for work

All of the above work can be done with your own hands. And everyone can do this, the main thing is to prepare the materials and tools for the work in advance.

Here is a list of tools that will be required for the job:

- jigsaw or hand circular saw;

- electric drill;

- screwdriver;

- hacksaw;

- tape measure or ruler;

- level or rule;

- plane;

- axe;

- hammer;

- countersink;

- putty knife;

- sanding block with sandpaper (grain 240, 320) for sanding.

When using power tools, do not forget about safety precautions. In addition, do not neglect the arrangement of floor ventilation.

After all the finishing work has been carried out and the plinth has been installed, you need to drill holes in it with a diameter of 10 mm at a certain distance. This is done to ventilate the wooden floor.

Ventilation of the underground space will protect the floor from dampness, the appearance of fungus, mold, and therefore extend its service life.

What kind of plywood is used on the floor?

In addition to the thickness and size of the sheet, you will also have to choose the type and grade of plywood. First, let's look at the type. If you plan to lay plywood on the floor under some kind of coating, you can use unsanded sheets. Under a hard finishing coating, such as parquet or parquet boards, grades 1 and 2 will be used. For a soft surface - such as carpet - you will have to use only the first one with a minimum number of knots.

The grade of plywood is determined by the number of knots, their condition and the presence of other defects. The best is first/highest, but some factories also produce “luxury” or “elite”. They use veneer for the outer layer(s) without any flaws at all.

If you plan to use the plywood floor as a finishing floor, that is, “for painting,” you need one sanded on one side and of the highest grade. If your budget is strictly limited, you can take a lower grade. But the defects will have to be puttied and sanded. This is an additional waste of time without guaranteeing an ideal result.

You need to choose the type of plywood depending on the planned finish coating

Types of moisture-resistant plywood

In general, it is advisable to use moisture-resistant material for the floor. There are the following types of moisture-resistant plywood:

- FC. Suitable for rooms with normal humidity. Urea glue is used in production. It is environmentally friendly, but the water resistance of the material is average.

- FKM. It is also safe, and has higher water resistance, since melamine glue is used. But the price is more expensive. It makes sense to use it when installing floors in the kitchen and hallway.

The most popular types of plywood - FSF. Cheap, waterproof. But the layers are glued together using a phenolic binder. So for use in residential premises, a hygienic certificate indicating the formaldehyde emission class is required. A material with a formaldehyde emission class no higher than E1 is considered safe. Can be used for installing floors on an open balcony or loggia, in a bathroom or toilet.

- FB. Plywood with bakelite binder. Lightweight, highly moisture resistant, safe. But darling. Used in the construction of aircraft, often called aviation.

- BS. Alcohol-soluble glue is used for gluing veneer. Plywood is moisture resistant, durable, expensive. Does not withstand exposure to some chemicals. It is used with caution when laying ceramic tiles - modern tile adhesive may contain various additives that can cause destruction of the adhesive layer.

So, when laying plywood in residential premises, the optimal choice is FC plywood. For the kitchen, bathroom and corridor in a private house, it is better to take FKM or FSF (but check its safety).

Installation algorithm

Laying engineered boards, regardless of the type of subfloor base, requires adherence to several fundamental principles:

- The presence of a deformation gap between the walls and the floor structure.

- Continuity of the installation process, minimizing the risk of unevenness, or “steps”, due to uneven curing of the adhesive.

- Mandatory compliance with the minimum (72 hours) period required for all structural elements, primarily the adhesive composition, to acquire physical properties that form optimal performance characteristics.

Laying plywood on the floor on joists: sequence of actions

In general, it is quite difficult to fully describe the technology - there may be too many details. We will describe only the main steps and stages. This is the order in which you need to lay the plywood floor along the joists.

- Removing the old floor to a solid base. Removing debris, cleaning the base with a vacuum cleaner.

- Assembling the grille and leveling it.

- Attaching the joists/grids to the base.

- Installation of plywood on joists.

In general, that's all. But there can be many particulars. For example, if there are significant differences in the foundation (holes or humps), then it is better to seal them. It will be easier to set according to the log level. Second point. In high-rise buildings, it is often recommended to spread film over concrete tiles as waterproofing.

How to attach plywood to a wood floor. Through self-tapping screws, but you can also pre-apply a layer of mastic for gluing wood

This can be done, but this is not a guarantee that in the event of a flood you will not flood your neighbors below. You will have to violate the integrity of the film when attaching the sheathing. And water, as you know, will find a hole. If you are really concerned about this issue, it is better to cover the concrete slab with liquid waterproofing. But then it must be applied to the walls - exactly to the level of the finished floor. That's right - using coating waterproofing, it is better to treat the flooring in the kitchen or bathroom. It's more reliable.

Technical nuances

Sometimes laying the floor with plywood on joists is the best solution. If wood is expensive in the region, it is cheaper to lay plywood directly on the joists - without a rough wooden floor. The height of the log depends on how much the finished floor level needs/can be raised. If the floor does not need to be raised to a significant height, you can save money and use a board with a thickness of 28 mm or more as a joist. If the floor needs to be raised to a greater height (from 50-60 mm), we take a beam of a suitable cross-section.

The minimum board thickness for joists under a plywood floor is 28 mm

If 50-60 cm is not enough, a small “shortage” (5-8 cm) can be “added” using spacers - cuttings of timber of the required size. All the same, a perfectly level base is very rare, and spacers are used under the logs to bring them “to the horizon” (as in the photo above). If you need to raise the finished floor even higher, then take 150*50 mm timber (for example). If this height is not enough, a sheathing of edged boards is made on top (perpendicularly), achieving the desired height.

How to lay plywood on joists: with edged board sheathing

In any case, we use chamber-dried lumber, first or highest grade. They are usually coated with bacterial protection. It can also be impregnated with compounds that reduce flammability. Before laying, it is advisable to keep the wood indoors for a week. Then there will be a guarantee that the floor will not creak.

Chamber drying boards and timber are very expensive. To save money, you can buy regular lumber (but not raw) and keep it for about a year in a well-ventilated area (in an attic, in a shed) or in a stack outside, covered on top (but not hermetically sealed) from rain. But during the drying process, some of the material will crack, some will twist, etc. So the source material must be purchased with a reserve for rejection. The amount of the reserve depends on the initial state of the forest. The more raw lumber you use, the more waste there will be.

Lag pitch and plywood thickness

The lag laying step is calculated from the center of the beam or board. The beam width is at least 50 mm, the pitch is from 300 mm to 900 mm. The greater the distance between the supports, the thicker the flooring required. That is, the thickness of the plywood for the floor along the joists depends on the distance at which the joists are installed from each other. So when installing a plywood floor, there are options:

- Lay joists less often and use thicker plywood.

- Install the joists with a small gap, use a smaller thickness of the flooring.

Which is more profitable? You will have to count for each region. In some places the first option will be cheaper, in others the second. If you also need to raise the floor to a considerable height, you can get out of this situation by installing joists, nailing the sheathing across them across the battens, and then placing plywood sheets on them.

Table for choosing plywood thickness depending on the joist installation pitch

Laying plywood on a wooden floor under laminate, linoleum is included in the technological map. It is recommended to lay plywood under parquet and parquet boards. In this case, long-term operation of the finishing coating is guaranteed. So, covering the floor with plywood is a justified decision in many cases. It's just expensive. Currently there is cheaper sheet OSB. But plywood has a more stable quality, and with OSB - depending on your luck.

Plywood thickness for floor joists

The thickness of the plywood is selected depending on the selected floor design. The specific thickness depends on the distance between the lags:

- logs every 300 mm, plywood needed 9 mm;

- supports every 600 mm - sheet plywood is required no thinner than 12 mm;

- the logs are installed at 900 mm intervals - we put 18 mm plywood and no less.

Which plywood for the floor to choose?

Coniferous, birch or combined? Birch is better, but coniferous is optimal for the price. When laying on joists, two layers are usually laid. The total thickness should be no less than recommended. Two layers are done to get the most stable floor at minimal cost. Because the material for two layers of 12 mm will cost less than one layer of 21 mm. But when laying two layers of plywood, the installation time will increase and the consumption of fasteners will increase. This is also worth taking into account.

Thickness of plywood on old floor

When laying on any hard base (rough or old plank floor, concrete), one layer of plywood may be sufficient. Moreover, it is possible to level it in this way even on an uneven base. But in this case, two layers will be required and we take their total thickness from the table above. Due to its high degree of elasticity, such flooring can compensate for unevenness.

The thickness of plywood for floor boards is 10-12 mm

Provided there are no significant differences (only a few millimeters are acceptable), the thickness of plywood for laying on an old floor is 10-12 mm (in one layer). This will be more than enough even for coatings that require stability of the base.

How do you attach the joists to the base?

If the sheathing is attached to a concrete base, studs are used. In wood and concrete, a hole is pre-drilled with a drill whose diameter is 1.5-2 mm smaller than the fastener. The length of the fastener must be such that at least half the length of the stud/bolt enters the base.

How to attach joists under plywood to the base

If for leveling you use several shims made of materials of different thicknesses, then you need to drill the hole so that the pin/bolt catches them too. This is a guarantee that the gaskets will be secured and the floor will not sag or begin to creak.

Soundproofing and thermal insulation

In a multi-storey building, you should take care of soundproofing your floor - there will be fewer problems with your neighbors. To do this, it is better to use materials that do not conduct sounds well as leveling pads - rubber, fiberboard, pieces of linoleum. You can also install special vibration damping pads.

You can insulate a plywood floor with any of the materials

For thermal insulation, mineral wool is placed between the joists. In high-rise buildings (second floor and above) this is the best choice. The material dampens sounds and has good thermal insulation properties. Expanded clay should not be used as thermal insulation. Compared to modern materials, it is less effective (the characteristics are 4-7 times worse). You can use polystyrene foam or extruded polystyrene foam. But this choice may be justified if there is an unheated room below or the floor of the first floor in a private house. In this case, foam glass may have even better properties. 100% harmless, excellent thermal insulation characteristics, does not burn. But the price is high.

Please note that on the ground floor of a high-rise building or in a private house, waterproofing is spread over the joists. And it’s better if it’s a membrane rather than a film. The canvas is spread over the joists, the edges are placed on the walls, securing them there no lower than the level of the finished floor.

Laying plywood on the floor: rules

To prevent the plywood floor from sagging and playing underfoot, the first layer is laid so that the fibers of the outer veneer layer are perpendicular to the joists. In this case, the dimensions of the sheet and the pitch of the lag must be selected so that the joint of the sheets falls in the middle of the beam/board.

The junction of two sheets should be in the middle of the board or beam

If the lag pitch is large (50 cm or more), an additional beam is installed under the connection along the short side so that the joint does not hang in the air.

Rules for laying plywood on the floor

When laying out sheets, remember the following rules:

- A gap of 20-30 mm is left between the edge of the sheet and the wall. This way the plywood will not rest against the walls. When temperature and humidity change, it changes size. And this gap compensates for this expansion, otherwise warping will begin and the joints may rise.

- The sheets do not fit together tightly. Leave a gap of 3-5 mm. This is also to compensate for thermal and humidity expansion.

- The second layer is placed so that the seams do not coincide. This is necessary to ensure that cracks do not form in the floor. It also makes the floor more durable and stable.

With a large pitch, transverse bars are added on which the joints of the sheets will rest.

A few words about installing the fasteners. Lay out the plywood sheet and adjust it the way it should lie. Next, mark the position of the joist (middle) and jumpers on it - then it will be easier to install the fasteners.

Plywood fasteners

You can attach plywood to the joists with nails or self-tapping screws. Self-tapping screws are not hardened (they break less often). The length of the fastener is not less than three times the thickness of the sheet. That is, for fastening plywood with a thickness of 12 mm, a length of 35 mm or more is suitable. The fastener installation step when laying plywood is 15 cm.

When laying plywood, do not forget about the gaps

The second layer of plywood is often fixed with glue. They usually use construction PVA, but any type that can be used to glue wood is suitable. “For reliability” they also add screws. To get into the logs when attaching the sheets of the second layer, the position of the supports is marked not only on the plywood, but also on the walls. But, even if the fasteners only connect sheets, this will be enough.

The rules for laying the second layer are the same: compensation gaps are needed. And the seams should not coincide with the seams of the bottom layer. They must be offset by at least 30 cm.

Additional insulation

If you need to insulate the floor in a house on screw piles, you should take into account the features of such a housing structure. Typically, houses on stilts are built in swampy areas with high levels of moisture, and they always have basements or basements. On the one hand, this is a plus, because such an elevation provides maximum opportunity for dryness, but the lower part of the house is always blown by the wind, which contributes to strong heat loss. Therefore, it is better to use reliable solid materials such as mineral wool or penoplex as insulation, especially if you plan to live in the house permanently.

Any house on screw piles requires additional insulation due to the high level of heat loss due to the design features. In order to equip the base in advance and eliminate the blowing, you need to either make masonry or build a frame. The masonry is constructed by digging a shallow trench around the entire perimeter of the house. A reinforcing network is laid in the trench, then a concrete screed of the required height is made.

The frame is built by installing sheathing around the entire building - it can be wooden or metal. It is on this sheathing that the heat-insulating material is attached. As a rule, this is EPS or extruded polystyrene foam. The final cosmetic stage is covering the structure with plaster and sheathing with corrugated board.

Laying plywood on a wooden floor

Repairing an old wooden floor is not easy at all. It's easier to lay plywood on top. Before this, it is necessary to carry out an inspection, eliminate the creaking, and install, if necessary, additional fasteners. If there are large differences in height, it is better to eliminate them too. Cut off the humps, fill the cracks and sand them. There is no point in achieving perfect smoothness, but large differences can also cause problems in the future. How to repair differences in a wooden floor before laying plywood? There are several options:

- Use a mixture of wood chips and varnish or paint. Fill the depressions and cracks with this mixture and level it out. After drying, use sanding to bring it level with the surface. This method is good if there are depressions.

- If the boards are bent over, a different technology is needed. We need to cut off our humps. Planing paint is long and difficult. In this case, it is better to remove the old paint with a blowtorch, and then level out the differences using: a sanding machine (rent);

- electric plane;

- belt sanding machine.

You can attach plywood to a wooden floor using nails or self-tapping screws.

They also use wood mastic or wood glue. Plywood can already be laid on a relatively level floor. But in the case of a wooden floor, it is necessary to use two layers, because the first layer has some unevenness. They are several times smaller than those of wood, but they still exist. The second layer of plywood is laid with overlapping seams so that the seams of the second layer do not coincide with the joints of the first. Then the second layer is leveling. It will be almost perfectly smooth.

Laying plywood on a wooden floor under linoleum, laminate - a requirement of flooring manufacturers

When choosing materials, keep in mind that plywood thickness may have certain deviations. For the second layer, choose sheets that differ minimally in thickness. Moreover, to level out differences in the first layer, you can use linings - thin strips of fiberboard of different thicknesses, strips of plywood, etc.

Before work, be sure to remove all construction debris and dust. It is a good idea to vacuum your wooden floor. Debris can cause squeaking. So don't ignore this step.

How to make your own electric heated floor

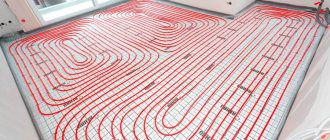

Cable and film floors vary significantly in thickness, so their installation has a number of nuances. But to imagine the scope of the work ahead, let’s consider the main stages of installation of both systems.

Cable system installation instructions

The installation of a structure made of conductive cables is carried out by analogy with the installation of a water floor, with the difference that such spacious niches are not required for the wiring, so instead of slats, you can get by with small recesses.

If the size of the room requires a large heating area, it makes sense to make several electrical circuits and connect each to a separate thermostat so as not to overload the network (+)

The sequence of work looks like this:

- The gaps between the beams are insulated with a layer of thermal insulation (for example, mineral wool, ecowool or perlite).

- Then a heat-reflecting layer of foil material is laid, on top of which a mesh with a cell of 50*50 or 40*40 mm is attached.

- Small recesses are made in the subfloor joists where the cable turns, and metal insulation is applied to each cut.

- Then the electrical cable is laid, fixed to the grid with special clamps.

- A temperature sensor is installed between the wires, enclosed in a corrugated tube and connected to the thermostat.

The power cable is supplied in a metal sleeve to the socket and connected through a thermostat, after which the structure is checked for functionality.

After this, you can lay the subfloor for laying the laminate.

Installation of film infrared floor

As already mentioned, the simplest and most accessible option for arranging heated floors for beginners in the renovation business is an infrared system.

To install infrared floors, do not use nails or other fasteners that damage the film - this may cause a short circuit

Work algorithm:

- A heat-reflecting substrate (4 mm thick) with a lavsan coating, which does not conduct electric current, is laid over the entire area of the room. The joints between layers of material are glued together with mounting tape.

- The heated area is marked.

- The heating film is cut at the cut locations according to the layout plan.

- Then the film is spread on the floor, the sections are connected to each other in parallel using grommets. After connecting and crimping the wiring, the connection point is sealed with bitumen insulation, and the film strips are fastened end to end with tape.

- To prevent the wires from being deformed, small grooves are cut in the insulating layer with a stationery knife, the cable is placed there and secured with tape.

- Now installs the heating sensor (its wire is also hidden in the foil material).

- A hole is made on the wall (usually at a height of 50-100 cm from the floor) for the thermostat, and a groove is drawn to it for wiring the sensor and power supply.

During the installation process, try not to bend or crease the film so as not to damage its integrity, because the performance of the entire heated floor system depends on this