Wood and plastic are well-known and widely used materials, and each of them has its own pros and cons. Until recently, the disadvantages of using plastic and wood were minimized with the help of special additives and impregnations, but modern technologies make it possible to create completely new, revolutionary materials. One of them is called wood-polymer composite (WPC), or simply liquid wood.

Facade board made of wood-polymer composite

Types and features of facade boards

There are several options for facade boards.

Unedged timber

The most budget option , but despite this, the finishing does not look cheap. Larch is most often used for these purposes:

- resistant to temperature changes;

- moisture resistant;

- has strong antiseptic properties;

- has low weight;

- does not age;

- the price will be cheaper than beech/fir.

Of the exotic species, preference is given to teak and meranti - they have a high density. They are used not only for cladding facades, but also for finishing floors (parquet is often made from teak) and roofs of cottages.

Pine wood is also relevant - durable, moisture-resistant, and does not fade. They will be an excellent solution for buildings located in areas with high humidity.

Ash, linden, walnut and beech are chosen less frequently than other species. This is due to the presence of low density, which leads to changes in the size of the boards over time.

When choosing wood, consider its type:

- extra - absence of cracks and knots on the surface of the board;

- prima - minor defects, 1-3 knots and small cracks are acceptable;

- A, B - there may be an unlimited number of knots and cracks.

Planken

This type is a processed board , which is characterized by the presence of various types of joints:

- corner - the edges are sawn at an angle, installation is carried out “overlapping” (it can prevent precipitation from getting under the facade);

- clapboard - tongue-and-groove connection;

- rounded - planks are installed butt-to-butt.

For treated boards, the materials chosen are the same as for unedged timber - coniferous and exotic species, as well as larch and oak. As for the last option, it is the most durable of all the listed wood species.

Wood-polymer composite

WPC is a material made from crushed wood with the addition of polymers. The majority is wood - it can be up to 90%. Under the influence of high temperature and pressure, the mass is given the desired shape.

The advantages of facade boards made of WPC include:

- resistance to negative factors - the material is not susceptible to rotting, pest attacks and corrosion, and is not a favorable environment for the proliferation of microorganisms;

- moisture resistance;

- resistance to mechanical stress and chemical and aggressive substances;

- frost resistance - therefore suitable for northern regions;

- fire safety - if all installation work was carried out correctly, the risk of accidental fire is eliminated;

- the presence of excellent soundproofing and heat-saving characteristics;

- excellent aesthetics;

- ease of processing;

- wear resistance.

Thermal board

This is more likely not the name of the material, but a method of processing wood. For its production, larch is mainly used, which is processed under high temperatures.

The advantages of this type include:

- presence of increased density;

- moisture resistance;

- no need to additionally treat the surface with protective compounds.

Disadvantages of the solution

The main disadvantage of wooden structures will always remain poor fire resistance and ability to maintain combustion. However, the modern chemical industry offers quite a lot of means for treating wood, after which it burns much worse. There is another option - burnt planks. It is extremely difficult to set wood on fire after firing if its processing was carried out by professionals. The combination of impregnation and firing will create a virtually non-combustible façade.

At the same time, the material ceases to be of interest to various pests. If the finishing of external walls is done with other materials, for example, decking, then it can also be protected from pests using various primers and impregnations. In general, protection from various external factors is easy and does not cause any difficulties.

If we talk about other disadvantages, then the only point worthy of attention will be the need to regularly carry out surface maintenance. This procedure consists of reapplying protective layers or painting the structure. If there is damage, it can be removed by sanding, using wood putty, or simply painting over it.

Classification by section shape

The board for finishing the facade of a house may also differ in cross-sectional shape:

- Block house. The panels are installed close to each other.

- American. The fastening is carried out with an overlap, which provides reliable protection to the building wall from the penetration of steam and moisture.

- EVRO. Wide panels have several protrusions and grooves, with the help of which the panels are mounted.

- Decking. The surface is absolutely smooth. More often used for flooring, less often for building cladding.

Shingles. Chopped or sawn

Shingles, shingles, shingles. There can be many names, but the essence is the same - wooden tiles used for decorative finishing of the walls and roof of a house. We will further call this material shingles; after all, this name is more familiar to the Russian ear. The shingles can be chipped or sawn. Below you can clearly see how their textures differ - sawn looks more neat, while chopped gives the impression of unprocessed natural material.

- Sawn

- chipped shingles

Table 1 shows the comparative characteristics (advantages) of each of the cladding materials, provided that the shingles are made from the same type of wood.

For their manufacture, larch, oak, red cedar, beech, and ash wood are used. Covering the walls of the facade with such tiles means ensuring its safety for 50-60 years. Budget materials are our spruce and pine.

chipped shingles

Sawn shingles

There is no need to impregnate with drying oil and varnishes. The service life is 10-15 years longer, due to the greater thickness and manufacturing technology than sawn shingles. Since all the tiles are slightly different from each other, the finished facade looks non-standard and attracts attention

Any type of wood can be used. The cost is lower than split wood (due to the mechanization of the manufacturing process). Due to the small thickness of the shingles, the overall weight of the structure will be less, so you can save on the cross-section of the leveling sheathing. Cladding work is completed faster when you work with standard sawn tiles

For wall cladding, both chipped and sawn shingles 20-25 cm long are used. During installation, a two-layer coating is used, which is shown in the figure

Counting the material yourself

The amount of material that you will need for wall cladding can be calculated using the formula: L = S: a where: L is the amount of shingles, linear meters. S - wall area, m2 a - shingle installation step. Accepted 0.09...0.115 meters. Don't forget to add 7-10% for trimming at the end.

Installation instructions

Preliminary work:

- Façade measurement.

- Cutting wood material.

- Treatment of planks with protective compounds.

- If you plan to mount the boards on a wooden base, you must first apply a layer of primer to it. If the wall is brick/concrete, this is not necessary.

Frame installation

What the frame step width will be depends on the thermal insulation material. The width of mineral wool and expanded polystyrene is 600 mm. The thickness of the frame depends on the thickness of the insulation. Another 20-25 mm should be added to this indicator to create a ventilation gap.

Vertical guides (metal bends or wooden beams are suitable) are attached to the corners of the walls and in the center. To do this, use nails and screws.

If the walls of the building are not insulated enough, you should take care of this at the current stage - cotton wool, as it “breathes” and helps create a cozy microclimate indoors.

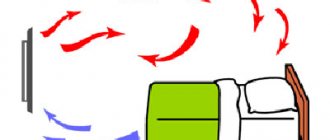

Air membrane

This layer is necessary to prevent moisture from entering the insulating material. The membrane is laid on top of the thermal insulation, thereby allowing condensation from the insulation side to evaporate.

A second frame is necessary if there is no ventilation gap between the insulation and the façade board.

Working with façade boards

The method of installing the planks depends on their type. So, for untreated boards with uneven edges, the “overlapping” method is suitable. But for planken, the best solution would be to fasten it joint to joint.

To compensate for the geometric expansion of the wood, a treated board with a beveled profile should be used. To improve the appearance of the cladding, it is recommended to install the planks using hidden fasteners.

Work after covering

When the installation of the boards is completed, all joints should be treated with protective compounds. If necessary, the finish is primed and painted.

The cost of facade boards may vary depending on the manufacturer and region. Let’s look at the example of “extra” class larch.

The average price of untreated timber is 1300−1600 rubles. for 1 sq./m3, and WPC - 3500 rub. for 1 sq./m3. The cost of a thermal board ranges from 2700−3000 rubles. for 1 sq./m3, and the price for a plank with an oblique cut is 2000 rubles. for 1 sq./m3.

General information

To give the house a certain appearance, the house is clad with overlapping boards. This is one of the finishing options.

Relevant for country styles. The finishing is done with an overlap or a herringbone pattern.

Here the board sits one on top of the other and goes from bottom to top. This allows you to get a sloping Christmas tree. Yes, from an economical standpoint, this is not the cheapest option. But reliable and durable.

Edged and unedged boards are used in the work.

The first is distinguished by perfectly smooth sides with a rectangular cross-section. The thickness is the same along the entire length. After finishing, it is covered with varnish and paint.

Unedged boards are called boards made from solid logs. It is sawn along the grain into lamellas and also has untreated end sides. Bark, sapwood, etc. remain along the edges.

To recreate the effect of a Texas house from a bygone era, you can use unedged boards. But it may take a lot of wood putty to remove all the defects. And you already know how to fix the flaws from the article at the link. The choice is yours.

Block house

To sheathe the walls and create a complete imitation of a wooden log house, a block house is used.

Advice from the “façade designer”

For exterior decoration, it is better to buy panels made of coniferous wood. Due to the high resin content, such a block house will not absorb moisture and rot.

Larch and cedar are remarkable in this regard with their hard wood and low knotiness. After vacuum heat treatment, thermo-ash and thermo-pine become resistant to high humidity. This, and an affordable price, make these materials favorites in the block house sales market.

There are panels of varieties: Extra, A, B, AB, C.

- Their width depends on the diameter of the log (determined by manufacturing technology) and ranges from 14 to 20 cm.

- The thickness of the block house used for external wall decoration can reach (due to the arcuate profile) 4 cm.

- The length is usually measured - 3 and 6 meters. You can order a different length, but such material will cost more.

Example of calculating the number of block houses

Let's calculate how many panels need to be purchased to finish the facade. P is the area of the facade. We take, for example, equal to 20 m2 F - the area of one 6-meter board, with a working (width of the panel excluding the tenon) width of 15 cm. It is not difficult to calculate it. F = 0.15*6 = 0.9 m2 N - number of boards needed for wall cladding N = 20/0.9 = 22.2 pcs. We round up, and we get that we will need 23 six-meter or 46 three-meter panels. How to decorate the facade of a wooden house? Which design should you prefer? The question is purely individual, because everyone’s financial capabilities are different. But how to buy high-quality material and not ruin the owners - these tips will be useful to everyone.