Despite the variety of wood-burning bathhouse heaters made of metal and cast iron offered on the market, the traditional design of a brick stove remains relevant and in demand. This is not surprising, because it warms up the steam room well, retains heat for a long time and provides it with dry steam. Also, in addition to the steam room, a brick stove can also heat 2-3 adjacent rooms (washing room, dressing room). In this article we will tell you how to properly build a brick sauna stove with your own hands, and share our experience in terms of preparatory work and foundation construction.

Types of stoves for baths

First of all, you need to select a suitable ready-made stove design. Experienced stove craftsmen are able to develop their own schemes in relation to masonry and operating conditions. This means that you need to take advantage of their experience and take a ready-made diagram, and for this you need to understand what kind of brick stoves for a bath there are.

It is very difficult to clearly classify heaters by type, there are too many of them, but conditionally all developments can be divided into groups according to the following criteria:

- method of transferring heat into the room;

- location of the heater;

- method of heating water.

The efficiency of heat transfer largely depends on the design and operating principle of the heater. According to this criterion, existing types of furnaces can be divided into:

- duct: the name indicates that the stove has one or many channels (gas ducts) for flue gases. The latter, passing through these channels, give off heat to the brick walls. Gas ducts can pass through the furnace body both vertically and horizontally;

- bell-type stoves by I.V. Kuznetsov: here the principle of heat transfer is different, combustion products give off heat, accumulating in the space under a specially made bell. Moreover, they can come out of there only after cooling, so the oven turns out to be very heat-intensive.

Advice. Bell furnaces are very complex to construct; a home craftsman without experience is unlikely to be able to build one. Therefore, it is better for a beginner to start mastering the laying of channel-type brick ovens.

The backfill of stones (heater) can be located either inside the stove or open. This criterion does not particularly affect the quality of work. But the method of heating water can affect the duration of heating the steam room. Here are the following technical solutions:

- a register made of steel pipes or a stainless steel tank built into the body of the furnace, or rather, into the flue;

- hob: water is heated on it in large containers.

It is necessary to take into account that a good brick stove with a hob will warm up the steam room faster, but the inconvenience with hot water in pans cannot be compared with a flow-through heat exchanger inside a flue connected to a storage tank.

Similarities and differences

When deciding which stove is better, the first thing you need to do is determine its functional tasks, because it will depend on them what is more suitable for the homeowner in each specific case.

All designs operating on solid fuel have a number of identical parameters:

- Both metal and brick products will have an open flame inside the firebox.

- At the moment when the structure body heats up, the room is filled with warm air and a comfortable temperature is created in the rooms.

- Products of fuel combustion are discharged through the chimney pipe.

- The chimney pipe must have the correct draft, otherwise the stove will not work properly.

- The combustion process is possible only if oxygen is supplied.

A metal and brick oven has a number of differences that are worth paying attention to. First of all, the difference lies in the material used to make the heater body.

In the first case, it can be cast iron or steel, and in the second - exclusively brick.

Nice cast iron stove

Many people wonder why iron stoves heat a room faster than brick stoves. The answer to this is quite simple and lies in the thickness of the housing walls: the smaller it is, the faster the structure warms up. Steel or metal can be very hot, while brick is an inert material and due to its greater thickness it does not heat up as much.

However, metal stoves have a significant advantage - their fireboxes have a clear system for regulating the fuel combustion process, which makes it possible not to overuse the material, and accordingly, the cost of maintaining the house during the heating season is reduced.

Good to know: How to prepare fireclay clay for laying a stove, how to mix the solution

A brick heating device has a significant mass, so it can only be erected after the foundation has been poured. Metal structures do not require this, which simplifies the installation process, and to save space, such a stove can even be hung on the wall.

Bath stove projects

As already mentioned, there are a great many different designs of brick kilns. We will offer several standard schemes, you can use them or find something suitable in the technical literature. So, the first is a diagram of a brick sauna stove with an open heater and a built-in tank for heating water:

Note. In this diagram and in what follows, the following symbols are used:

To build this furnace you will need 415 pcs. bricks and components such as:

- firebox door 210 x 250 mm and blower door – 140 x 140 mm;

- cleaning doors 140 x 70 mm – 2 pcs.;

- stainless steel tank 200 x 300 x 490 mm;

- cast iron plate 410 x 410 mm;

- grate 175 x 255 mm;

- valve 120 x 230 mm and 2 valves 130 x 130 mm.

The following diagram shows the order of the sauna stove:

How to finish the stove depending on its type

External decoration will help to give the sauna stove individuality. It can be done in various ways - from simple jointing of brickwork to cladding with marble or granite slabs. It all depends on the taste and financial capabilities of the owner.

Photo gallery: examples of finishing stone and iron stoves of different sizes

The stove, lined with glossy slabs, looks like a fireplace

Finishing with natural stone can be very unusual

The firebox in the form of a fireplace portal looks unusual

Granite is ideal for lining a sauna stove

Flat stone can be used to decorate not only the stove itself, but also the adjacent wall

A wooden fence, although not a full-fledged finish, can protect against burns

A large structure can be built from facing bricks and simply unstitched seams

Stove-heater with heating plate

This sauna heater, instead of a built-in tank, is equipped with a 2-burner stove, and the heater is located in the body of the stove, directly above the firebox. Although the design provides for the possibility of installing an internal hot water boiler, this is reflected in the corresponding diagrams for laying stoves for baths:

The construction of the heater will require 650 bricks, as well as stove fittings:

- firebox door 210 x 250 mm and blower door – 140 x 140 mm;

- cleaning doors 140 x 70 mm – 4 pcs.;

- cast iron plate 410 x 710 mm;

- grate 175 x 255 mm;

- steel circle Ø20 mm – 3 m;

- stainless steel water tank 220 x 380 x 630 mm – if necessary.

In this option, the order of the masonry for the stoves is as follows:

Work on insulating flammable materials

A modern bathhouse is most often built of wood, and sometimes even a brick bathhouse has wooden partitions. Therefore, the partition opening where the heating device is located must be insulated.

This opening, as well as the section of the wall near the opening, is sheathed on both sides with asbestos cardboard and a sheet of metal 4 mm thick is placed on top of it. In this case, the distances from the stove body to the walls and partitions must be maintained: 32 cm to unprotected ones and 26 cm to protected ones.

Places where insulation is required

Sauna stove with bottom heating

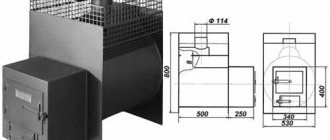

This is a small brick stove, which, due to its design, requires a good foundation. In fact, it will take more time to install it than to complete the masonry itself. Here is a sectional diagram of the heater:

In addition to 260 pcs. You will still need bricks for construction:

- firebox door 210 x 250 mm and blower door – 140 x 140 mm;

- cleaning doors 140 x 140 mm – 2 pcs.;

- chamber doors for stones 210 x 250 mm – 2 pcs.;

- cast iron plate 410 x 410 mm;

- grate 175 x 255 mm;

- valves 130 x 240 mm and 130 x 130 mm.

How to choose the right baking stone

A few simple rules to help you make your choice:

a stone for baking bread must have a porous structure; the longer the baking time, the thicker the plate should be; It is better to bake baked goods, sweet and meat buns, cheesecakes or rolls on stones made of dense materials; when choosing a baking stone for pizza, pay attention to models with a thickness of no more than 1-1.5 centimeters to reduce heating time; thin baking plates are ideal for baking pita bread, khachapuri, plachinda and other pies made from unleavened or puff pastry; all other things being equal, give preference to porous materials; the rectangular shape is more spacious and ergonomic; models with angular or longitudinal legs are less susceptible to thermal shock; Before purchasing, measure the internal dimensions of the oven so that the stone is not too large or small.

Before purchasing, look at the safety certificates; it is important that the raw materials for production are environmentally friendly

Preparing for the construction of a furnace

Before you start building a brick stove in a bathhouse, you need to prepare the necessary tools and materials. The set of tools required for the job is shown in the figure:

As can be seen from the figure, the set should contain tools for splitting and shrinking bricks (pick, hammer), for working with mortar (trowel, grater) and various measuring devices (tape measure, level).

For reference. Modern stove makers, instead of chopping stones with a pick, often use cutting machines - machines, grinders.

In addition to the tools, some devices will help you build a stove:

- a sieve to sift sand;

- a small container for soaking bricks in;

- various scaffolds or trestles.

A few words about the features of cast iron models

Scheme of the structure and operation of "Buleryan"

Easy to install. The brick oven is installed on the foundation. It has to be taken into account in the house design, otherwise difficulties in organizing heating cannot be avoided. Cast iron models are not so heavy that they require a strong base. The stove is mounted next to the chimney, and the floor is protected with a metal sheet or other non-combustible material.

Ready for use immediately after installation. Models are sold ready to use. Additional cladding is desirable, but not at all required. Unlike cast iron structures, brick structures are not immediately put into operation after construction, because they need finishing.

There is temperature control. This function is not provided in all designs, but expensive models from well-known manufacturers are equipped with fuel combustion control systems. If a gas generator stove is chosen for a home, then the owner will not have to wake up at night to add wood to the firebox.

Cast iron model with decor

Attention! Care must be taken when operating cast iron stoves. In the event of a sudden temperature change, the housing may burst. This is possible if the hot surface is doused with cold water.

This is possible if the hot surface is doused with cold water.

Long-burning stove-fireplace

What brick to use for a sauna stove?

You must understand that a stove in a bathhouse will operate in more extreme conditions than a conventional stove for heating a house. This means that masonry bricks should be selected of good quality, without damage, chips and cracks, best of all - with smooth spoon edges (see figure below). For the construction of furnaces, 2 types of bricks are used: red solid ceramic and refractory (fireclay). Dimensions of a standard brick are 250 x 120 x 65 mm, approximate weight is 3.5 kg.

1 m3 of standard ceramic brick contains approximately 480 stones with a total weight of 1700 kg. However, some brick kiln designs may involve the use of non-standard size stones, as shown in the figure below:

Advice. When buying a brick, take it with some margin for rejection. The amount of reserve depends on the quality of the material, and also on the skill of the craftsman to accurately and correctly chop or cut it. An inexperienced stove maker needs more stock.

Conclusion

Heater in the steam room - both spirit and temperature

Currently, a large number of methods for heating a bath are offered, but only a stone stove lasts longer and brings more benefits. Our portal offers you additional information on this topic, and the video in this article will examine in detail all the nuances that we discussed in this material.

Did you like the article? Subscribe to our Yandex.Zen channel

Masonry mortar

Kiln brick laying up to the chimney is done exclusively with clay mortar, without cement. To prepare it, you need to take the same amount of sifted sand and clay purified from impurities (that is, the proportion is 1: 1), mix and add water. A good consistency is when the solution slides off the shovel easily, but there is no excess water in it.

Advice. It is better for a novice master to purchase a ready-made building mixture for laying stoves.

You can also take clay from a nearby ravine and prepare it yourself. It will need to be soaked in a trough for 2-3 days, and then mixed thoroughly and manually pushing the mixture through a sieve, separating stones and other foreign fractions. The amount of water for soaking is taken in a ratio of 1: 1 to clay. As for laying a firebox made of fireclay bricks, you will need an equally fire-resistant mortar. To prepare it, instead of sand, chamotte chamotte is added to the clay in the same proportion.

What is better - buy ready-made or fold it yourself?

The construction of a heating structure for a steam room is one of the most crucial moments in the construction of a bathhouse.

And a real Russian stove can only be made of brick. No modern design can compare with it in terms of the quality of steam and the aroma that comes from burning wood. However, its installation requires a lot of time and money. Such work can be done when you have certain stove-maker skills and experience, only in this case the design will meet all the necessary requirements.

If the listed difficulties do not frighten you, then you can start laying the stove yourself or by inviting a professional stove builder. But today there is an easier way - purchasing ready-made equipment. Its cost is comparable to paying a professional. At the same time, installation of such a stove is much simpler and can be completed much faster, so it makes sense to think about which option you should choose.

If you decide to build your own bathhouse on the site, then the first question will be the choice of stove equipment. There are two options - buy a metal structure or build it yourself. Everyone chooses the most optimal option for themselves.

However, no matter what advantages ready-made sauna apparatus have, they cannot compete with stone ones made by hand.

Among the advantages of the latter, one of the main ones is the absence of the need for additional heating of the stove during the procedures, since brick models have a large heater, the temperature in which reaches a very high level and allows maintaining the necessary heat in the bathhouse for a long period of time.

Perhaps it is this factor that becomes decisive when choosing, or maybe it’s just a matter of habit, because stone samples are classic and the most familiar for a Russian bath.

Construction of a sauna stove

Any, even the simplest sauna stove requires a reliable foundation. As a rule, the foundation is the foundation, although in some cases its construction is not required; the stove is placed directly on the floor, laying a sheet of asbestos and metal. This is allowed when the total weight of the structure with the pipe does not exceed 750 kg or the foundation of the building itself is a monolithic slab. In other cases, a separate foundation is needed, located no closer than 50 (or better, 150 mm) from the foundation of the building.

Advice. Even before laying the foundation, keep in mind that all wood-burning stoves must be located at a certain distance from building structures to avoid fire, as shown in the figure:

The easiest way is to pour the same concrete slab to the size of the furnace, evenly distributing its entire load on the ground. To do this, a hole no more than 30 cm deep is dug, its bottom is compacted, and then crushed stone is poured to a height of 100 mm. Next, a concrete base up to 7 cm thick is poured from cement-sand mortar, and after it hardens, formwork and reinforcement cage are installed. Then concrete is placed into the resulting form to the remaining height. Complete hardening of concrete - 3 weeks.

Next, to lay out a brick oven, you must adhere to the following rules:

- soak each brick in a container of water before laying;

- apply the solution not to the stone, but to the previous row;

- lay the brick with its smooth side facing the smoke duct;

- First lay out each row without mortar to fit the stones;

- the remaining solution is removed, and the inner surface is washed off and wiped dry every 3-4 rows;

- horizontal and vertical checks are performed on each row.

Important! If small-sized stoves have a firebox made of refractory bricks, do not bind fireclay and ordinary masonry! A gap is left between them, filled with a solution of ground mineral wool.

After finishing the masonry, it is allowed to dry for a couple of days, after which a test kindling is done with a small amount of firewood. When the dampness is completely gone, the stove can be fully heated.

Reflective trims

You can assemble this version of protective casing yourself. To do this, you will need a non-flammable thermal insulation material, which will be discussed in more detail below, as well as a sheet of stainless steel.

Stainless steel can be replaced with a cheaper option - galvanization, however, when heated, it can release harmful substances, so we strongly do not recommend using it. When starting work, secure the insulation to the wall, and then cover it with a metal sheet.

To ensure that such thermal insulation for a sauna stove is as productive as possible, polish the metal surface. This will allow IR rays to be better reflected back into the steam room, and the reflected rays will be better perceived by humans.

You can use the following materials as thermal insulation:

- Basalt wool is absolutely safe for baths. It retains heat well, in addition, it is highly hygroscopic and does not burn at all;

- Basalt cardboard is a good option for a bathhouse. It consists of thin sheets of basalt fiber that retain heat well and do not burn;

- Asbestos cardboard is a strong and durable heat insulator, which is also suitable for a bathhouse;

- Minerite for baths is also an excellent material. Non-combustible plates are specially manufactured for shielding hot surfaces in baths and saunas;

Before covering the wall near the stove in the bathhouse, familiarize yourself with the correct technology for its construction

The most important thing is the installation order and compliance with the gaps

The ideal design has the following structure:

- Wall;

- The ventilation gap is 2-3 cm;

- Insulation 1-2 cm;

- Stainless steel sheet.

Metal finishes along with thermal insulation are widely popular. First, thermal insulation sheathing is attached to the wooden walls, and then the partition is completed with a sheet of metal. Between them you can place an additional layer of insulation made of basalt wool, basalt cardboard, asbestos board, mineralite, and so on.