16.01.2020

The thickness of the laminate is an important parameter of this floor covering, which should be taken into account during the floor installation process. There is a wide range of laminated flooring available on the market that differ from each other in size, pattern, design and quality.

The following properties depend on the thickness of the laminate:

- strength - the higher the thickness, the more reliable the floor covering;

- ability to withstand loads - dynamic (jumping, moving on a surface, moving furniture, household appliances) and static (permanently installed heavy objects);

- degree of insulation - the greater the thickness, the lower the thermal conductivity and sound insulation level.

How to choose the optimal laminate thickness for an apartment?

There are several features that determine the thickness of the selected laminate, including:

- Is it planned to have a heated floor under the laminate or not? If you plan, it is better not to choose a laminate no thicker than 10 mm. The thinner the laminate, the better the thermal conductivity and the warmer the floor.

- Are there significant differences in the floor or is the floor perfectly flat? Often, the floor in our apartments is far from ideal, so when installing, we advise you to familiarize yourself with the data on extreme differences, slopes and other floor defects and take them into account. For small differences of up to 2-4 mm per 2 meters (each manufacturer has different values, check on the packaging), it is better not to lay a thin laminate and choose a medium-thick one; for large or sudden differences, it is worth leveling the floor.

- Other features of the room, for example, the distance between the door and the floor.

The size of the floor covering also depends on the intensity of traffic:

- If there is not too much foot traffic in the room, a setting of 6-8 mm is sufficient.

- In more active areas, a material with a thickness of 8 to 10 mm will be required.

Below you will find the features of using laminates of different thicknesses and situations in which it is better to choose one or another thickness.

Brief conclusions

In this article, we tried to figure out how to choose laminate flooring for an apartment based on price and quality. Of course, you want to buy cheap but high-quality flooring. But such miracles do not happen, so you need to try to find a middle ground between the price and quality of the laminate.

There is no need to try to convince yourself that if you buy not very high-quality but cheap laminate today, then in a few years you will be able to replace it.

This way you can only buy wallpaper. Laminate, as practice shows, you will decide to replace in ten years. After all, no one wants to completely remove furniture and create discomfort for themselves for a long time.

Therefore, refresh your memory of everything you read in this article and go to the store to make the right, and most importantly, informed choice.

Good luck to you in this matter, and in life in general!

Best regards, Alexander Tkachenko.

About laminate layers

Classic laminate includes several layers, which ultimately form a durable and easy-to-use floor.

- the top layer is represented by the previously mentioned film of melamine and acrylic, used to prevent mechanical damage and fading of the board, moisture accumulation and the formation of a glossy surface;

- after that there is monotonous foil or paper, often complemented by an original pattern in the form of wood texture, imitation of natural stone or ceramic tiles;

- then comes the base layer (HDF board with high density values), which affects the thickness and ergonomics of the floor covering, the reliability of the locking elements and the quality of installation;

- and the bottom layer, tarred kraft paper, provides the necessary stability and protection from moisture.

The most popular laminate is 8 mm thick. The maximum thickness of the laminate does not exceed 12-13 mm.

Thin laminated coating

The thinner the laminate, the less material is required for its manufacture, and accordingly the cost per square meter will also be less. In the worst case, a thin laminate can serve the owner for up to 5 years. Locks on thin slats quickly break due to careless installation or differences in floor heights, which leads to the appearance of cracks. Therefore, to extend the service life, you need to carefully level and prepare the base. The deadlines for completing work in this situation increase.

The smallest thickness is 7 mm. This is an ideal option for a study or bedroom with low traffic and a relatively flat floor. Thin laminate is ideal for heated floors. Some use thin laminate to decorate walls and even ceilings.

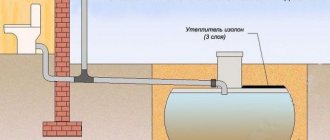

Foiled insulation

There are many manufacturers producing insulation materials. Someone is developing unique technologies that make products more energy efficient. Therefore, relying on average indicators is not always productive.

It is worth noting products supplemented with a layer of aluminum foil on one side. Aluminum reflects heat. Its thin layer allows you to increase the efficiency of the entire “pie” and reduce its thickness.

The foil layer is always located on top.

Foil penoizol

Some polymer insulators and mineral wools also have this addition.

Foiled mineral wool

The use of a foil layer is especially effective when installing heated floors. The reflection of energy will not allow the street or ground to warm up.

Also, structural materials can be supplemented with substrates and slabs made of rigid materials to simplify installation.

Thanks to the textile backing, it was possible to secure low-density mineral wool under the ceiling

Substrates increase the resistance of materials to loads. It is profitable to buy them if the insulation is from below, from the basement or lower floor.

Dense insulation materials, such as extruded polystyrene foam, can serve as a foundation in a wooden house (example in the photo).

The subfloor is assembled from insulation

The combination of mineral wool and expanded polystyrene reduces the overall thickness of the ceiling, making it maximally protected.

Medium thickness laminated coating

The truth lies in the middle. Same with laminate! Average indicators in this case are optimal. A thickness of 8-10 mm is an excellent choice for an apartment: kitchen, corridor, hallway, study, bedroom. Well, again, the thicker the material, the higher its strength, reliability and price.

During the installation process, it is worth remembering that the floor also rises. It turns out that when making calculations, you need to take into account the height of the doorway so that when opening/closing the door does not touch the top layer. Be sure to take into account the location of heavy furniture and draw up a plan indicating areas of intense movement of people.

You can view all 8 mm thick laminate collections in this category. The options presented in the section for classes 33 and 34 with a thickness of 8 mm are one of the most popular categories in the Tetrum store.

Thick laminated coating

Coatings with a thickness of 10-12 mm are intended for offices, but can also be used in apartments, for example, in corridors and living rooms. This is a material with decent strength and sound insulation. It costs more than previous options, but its service life is truly long. A laminate of this thickness is worth choosing if you do not want to spend time leveling the floor or expect that there will be serious loads on the floor in the room.

Corridor

Disputes over whether it is worth putting laminate in the corridor and what thickness to choose there are still ongoing. Still, it is better to think about a more durable coating, such as tiles. However, if the apartment owner decides to put laminate flooring in the hallway at all costs, it is necessary to choose a very durable type. The thickness should be 8 millimeters or even 10. Plus, the class should be at least 32, and preferably 33. And of course, the coating must be moisture resistant. Otherwise there is no point, because with the arrival of autumn and winter with snow and rain, shoes will leave stains on the laminate after walking.

Class and purpose

The choice of room for laying laminate is influenced by the class of flooring. Depending on wear resistance, there are 7 main classes.

- The first and rarest category is represented by classes 21, 22 and 23, which are no longer produced. Their quality is much worse than that of their competitors.

- the second group, which is characterized by high wear resistance, opens from class 31 (service life from 3 to 5 years, intended for rooms with low traffic);

- Class 32 – designed for homes and offices with moderately heavy traffic, service life – up to 15 years;

- Class 33 is produced for places with regular traffic (residential premises, offices, small shops), the service life is from 15 to 20 years;

- Class 34 – premises with active visits, duration of use – up to 20 years.

Class 33 laminate from Tetrum will last up to 30 years in residential premises, and class 34 laminate in an apartment can last up to 50 years!

The existing division into classes is very arbitrary. After all, the degree of strength of the material also depends on the manufacturing technology. But if the class is known, then the thickness can also be known, since these parameters are closely related to each other.

What sizes does lumber come in?

Important indicators when choosing are the height and width of the beam, they are also called thickness or cross-section. The length affects the consumption of building materials; it depends on the size of the house. The following forms of lumber are divided:

- square;

- rectangular;

- multifaceted;

Standard dimensions of timber used for building a house or other buildings:

Click and Lock locks

When purchasing flooring, you should consider the type of lock. The elements of the “lock” category were the first to appear on the market. They are built on the tongue-and-groove principle, where the surfaces are “knocked” together. Here, accuracy and strong adhesion play an important role, for which special notches are used. The coating remains smooth. In case of prolonged use, the comb wears out and gaps form between the floorboards. Over time, laminate with this type of lock has practically disappeared.

Later, laminate with a “click” lock appeared on sale, which quickly became widely in demand. Here the outer tenon is made in the form of a kind of hook, which clicks in a special way during engagement and fixation in the groove. To dismantle, you just need to lift any lamella. Short-term installation and disassembly is what made these locks popular.

We offer an interesting solution - laminate 33 class 8 mm with a click lock.

What it is?

Laminate is now a fashionable word that can be seen in all promotions of construction stores both in Russia and abroad. It appeared a couple of decades ago and became more popular than linoleum. However, not everyone knows what it is. Laminate is essentially a chipboard board (which stands for chipboard), which was first pressed and then laminated. At the bottom it is covered with a special film to avoid squeezing and leakage.

Under the laminated coating is the pattern itself, which makes the laminate look like an expensive wooden coating. Essentially it is a board with a polymer film. It is environmentally friendly and quite easy to install. Plus, this board is quite economical. Installing laminate flooring in one room takes less than a day. This is only provided that it is of high quality and its locks (joints) are professionally waxed. They will be discussed below.

Substrate

Another important factor influencing the quality of flooring installation is the underlay.

Typically, the layer thickness required for proper installation of laminate flooring is in the range from 2 to 5 mm. The underlay allows you to eliminate unnecessary unevenness of the subfloor, without bending the lamellas while walking. In addition, this component contributes to the required thermal and sound insulation of the floor covering.

To achieve the required thermal conductivity and noise protection, foil with a highly reflective effect is usually used. It is expensive, but the result is fully worth the investment.

A good alternative to foil is compressed cork chips, which are environmentally friendly and prevent the formation of mold. The downside is the low ability to withstand static loads. Such a plug can sag as a result of the influence of the significant weight of large furniture.

A budget option is a substrate made from polystyrene or polyethylene foam. Its positive features are the necessary water resistance, chemical inertness, a high degree of safety, and ease of installation. However, during operation, such a material inevitably loses its properties and may collapse and sag, which will contribute to the deformation of the coating.

When choosing a substrate for your home, remember that the stage of laying the laminate is the final one. Using the optimal combination of laminate and underlay thickness, the height of the new floor is adjusted in relation to the door leaf and the adjacent room.

Feature of the material

Modern laminate is a universal finishing material for covering bare floors in rooms of almost any category. The lamellas, produced in accordance with the latest standards, have the following qualities and distinctive features:

- Increased resistance to mechanical loads - the floor surface retains its original aesthetic properties, regardless of the intensity of use.

Rice. 10. Resistance of the coating to mechanical stress

- High degree of thermal conductivity and sound insulation - the lamellas contain heterogeneous layers. Prevents heat transfer and vibration.

- Reliable interlocking - the end faces of the elements are made in such a way that the laminate is joined to each other without the use of any sealants or adhesive compounds.

Rice. 11. Pairing the lamellas “into the lock”

- Anti-slip coating - modern slats are equipped with a special type of finishing on the front surface, which prevents a person from falling and getting injured.

Rice. 12. Matte surface with anti-slip coating

- Workmanship - lamellas from well-known manufacturers do not delaminate, and the protective coating lasts for the entire period stated by the brand.

- Resistance to ultraviolet radiation - regardless of the shade, the color palette of the panels does not fade with prolonged exposure to sunlight.

- Increased moisture resistance. Despite the fact that the material is predominantly made from pressed cardboard, water-repellent additives prevent moisture from entering and swelling of the lamellas.

Rice. 13. Moisture-resistant laminate

- High-quality laminate is made without the use of harmful chemical additives, which significantly increases the level of environmental friendliness of the material. Most products are approved for use in children's, sports or recreational institutions.

- The laminate consists of separate parts, which prevents bending, delamination and geometry disruption due to sudden temperature changes. The coefficient of linear expansion of products tends to zero.

Rice. 14. Swelling of the laminate

The slats have a structure that is as close as possible to natural materials, which significantly increases consumer demand. Despite its high quality, laminate has a lower cost than its natural wood counterparts.

More about choosing thickness

The laminate installation technology is extremely simple. Therefore, almost everyone can master it. You don't need any special education here. To do the job perfectly, just carefully study the appropriate video with the master class and do everything exactly as recommended by a professional.

Now all that remains is to make the final decision about what thickness is needed in a particular case and calculate the costs.

Everyone's wallet size is different. Therefore, reasonable savings never hurt. First, you should create a plan of the premises, where you should note the activity of people moving and the installation location of heavy furniture. Then, based on the specified plan, determine where you need to order class 34 coating with a thickness of 12 mm. And where - class 33 lamellas with a thickness of 8 mm are suitable.

The proposed classes are an ideal choice for an apartment, since they are able to withstand both static and dynamic loads. And if you also level the subfloor well and use a substrate, the service life of the coating will increase by several years.