In the article we will tell you how to choose lining for your home, which lining to choose, and talk about the types, characteristics and grades of lining. Lining manufacturing technology, advantages and installation methods.

The most successful and cost-effective solution for covering the internal walls of building structures can be called lining. We will consider all types of this unique coating, as well as the features of the selection of materials and installation itself. We also note that there are many materials for “dry cladding” on the market, but wood is a classic that will look great in a room with almost any style, and will also ensure its environmental safety. So, let's talk about how to choose lining , as well as which lining to choose in order to avoid buying low-quality material.

What is a lining?

Factories engaged in the production of construction wood, in addition to classic timber, logs and boards, also produce “profiled moldings”, which includes lining. It is a cut board with a thickness of 7 to 20 mm with a planed surface, used for covering the walls of premises. The average width of one plank is from 90 to 150 mm, which allows the use of lining in the most non-standard rooms.

All modern profiled moldings have two distinctive features: the presence of a groove and a ridge on each lamella, which facilitates the sheathing process. Therefore, panels made of plastic, MDF and even aluminum can be called lining, but initially this name was given to cladding materials made from various types of wood. types of lining in Russia are made of pine, oak, larch, alder and linden.

How is the lining made?

The pre-prepared log is lowered onto an edged board, where a cross cut is made. Elite grades of lining are made by radial sawing, due to which they have the same texture, tone, geometric stability and increased strength. Both types of lining are sent to drying chambers, where they are kept at high temperatures for 8–12 days. Thanks to the effect of heat, the workpieces become lighter, stronger, and their resistance to various types of fungus increases significantly. During the drying process, the moisture content of the boards is adjusted to 8–10%, and after that it may increase slightly due to the influence of external factors, but not more than 15%.

At the third stage, planing is carried out, during which machines with cutters working on four sides at once create the profile of the product, form the front surface of the lining, and cut the tongue and groove. Longitudinal grooves are cut on the back side, acting as compensators for thermal expansion, and also necessary for removing moisture and ventilating the rear surface of the lining.

After this, the products are trimmed and sorted - depending on the defects (see board defects), they are divided into several stacks. Some manufacturers also cut out defective areas from damaged panels to obtain a premium product. That is why there are linings on sale even with a length of 30 centimeters. Long panels are used for cladding ceilings and walls, while short ones are used for filing small structural elements.

To maintain low humidity of products, it is customary to pack them in shrink film, thus forming packs of 8-9 lamellas. To ensure ventilation, the ends of such packaging are not closed.

General overview

The specific domestic name for wood slats has been preserved since the time they covered freight cars. For a long time, freight rail transport has been designed differently, and the name is firmly rooted in the spoken language.

Nowadays, lining is called planks with grooves and tenon-like protrusions, which make it possible to make cladding quickly and efficiently. In Europe there is no such term; the product is classified as profiled boards and is produced according to the relevant standards, which contain more stringent requirements than domestic GOSTs.

The lining, manufactured according to European standards, has noticeable advantages:

- a variety of patterns, allowing you to choose products for any interior;

- wide, easy-to-connect spikes;

- good ratio of thickness and other sizes of planks;

- perfectly polished surface;

- humidity indicators (no more than 15%) ensuring long-term preservation.

Products are classified depending on the quality of the wood, the method of its processing, and consumer characteristics. Lining for the exterior finishing of outbuildings and residential buildings is exposed to a high load of atmospheric factors, so it is additionally processed - primed, painted, varnished or other protective coating is applied. In this regard, the requirements for its appearance are less stringent than for the type of lining for interior decoration.

Advantages of classic lining

First of all, the positive qualities of the wood itself should be noted: good heat and sound insulation; low coefficient of thermal expansion; high degree of plasticity.

The lining itself has even more advantages, largely due to its configuration. The weight of the cladding is positively influenced by the piece nature of the products, the minimum width and thickness of individual lamellas, as a result of which one craftsman can easily handle the installation of the lining. Due to the low weight, there is no overload of the building’s load-bearing structures, so there is no need to further strengthen the foundation.

The lamellas are joined to a depth of 5–8 mm, thanks to which it is possible to assemble a skin in which there are no gaps or joints. Moreover, they also do not appear during temperature changes. That is why lining is often used for cladding bathhouses, as well as in buildings without heating.

Free fastening is another undeniable advantage of the lining, during which the panels are fixed using clamps that press the lower flange of the lock to the base. This guarantees the unhindered expansion of each cladding element along its entire length, resulting in no gaps, deformations or cracks forming on the surface. All fastening elements are hidden - each metal clamp is covered by the next panel, so there is no need for finishing work.

Why is it worth choosing wide lining for finishing?

The properties of the material directly depend on the nuances of production. It is made from solid wood. This is, in fact, a wooden (edged) board of different sizes. The raw material for production is any type of wood. Which means she:

- Endowed with good sound and thermal insulation properties;

- Has a low thermal expansion rate;

- It is light in weight, which means it does not bear a large load on the walls, and is easy to transport;

- The appearance of the finished coating allows you to bring comfort and a pleasant atmosphere to the interior.

The wide lining, thanks to the presence of special locks, is assembled without cracks or seams, creating a single fabric.

The healing properties of natural wood are known to many, so each user can choose for himself which aroma is closer to his spirit and taste.

Strength, reliability and durability, with proper installation and maintenance, are guaranteed to everyone who plans to use lining in home decoration.

The material is considered environmentally friendly. Raw materials (solids) undergo minimal processing at the enterprise.

If we talk about shortcomings, then they exist, albeit few. The lining is subject to combustion. But, subject to basic fire safety rules, nothing can threaten either people or the coating.

The cost of a wooden lining is higher than that of its plastic counterpart, but it is stronger than it.

Which lining is better?

So, which lining is better ? Since lining can be made from any type of wood, and each of them, in turn, has its own advantages and disadvantages, it is quite logical that lamellas made from different types of wood differ from each other in both external qualities and technical characteristics. Since the issue of aesthetics is very subjective, it is better to touch upon the second aspect, with the help of which you can choose the lining that is optimal for specific conditions.

The most radical differences are between panels made from coniferous and deciduous trees. The lining, made from pine, spruce and other conifers, contains a lot of resins and essential oils, which prevent the formation of fungus. In turn, pine lining has a beautiful texture, is easy to process and lasts a long time. Spruce products have high thermal insulation characteristics, but can release resin for a long time at high temperatures, so they are rarely used for cladding in bathhouses. True, you can choose deresined lining.

In Russia, alder, linden and larch linings are used for finishing baths and saunas, since this wood does not emit any resins after processing. Even though these species are less durable than pine, they are still popular due to their high porosity, which allows the paneling to withstand very high temperatures. The most durable and expensive material from which lining is made is oak. Birch products will also cost a pretty penny, but they are practically not common, as they behave poorly in damp rooms.

MDF sheets - a promising alternative

First, it’s worth explaining what MDF is. When processing wood, waste accounts for almost 50% of the total weight of raw materials. In order to avoid large financial losses, sawdust is used in factories to create new material. Large sawdust is mixed with glue and pressed into chipboard sheets at high temperatures. Fine waste is used to form MDF sheets (mixed with wax and pressed at a temperature of 700-800º. At the same time, the wood releases lingin - a natural binder that replaces the role of glue or epoxy resin).

MDF is an environmentally friendly material that in the future will become a serious competitor to conventional wood boards. In addition, MDF is easier to process, cut, and attach (you can use regular nails). However, the main problem is its inaccessibility - this material is very expensive. It is practically not produced anywhere in Russia. At the moment, it is easier and cheaper to purchase wooden lining.

Advantages of MDF:

- Ease of processing (cutting, drilling, impregnation with antiseptic);

- Various designs (the outer side of the slab can be covered with a special pattern);

- Speed of installation (installation can be done both with staples and galvanized nails);

- Environmentally friendly (this material does not emit harmful substances even with temperature changes).

Flaws:

- High cost, problems with availability even in large warehouses.

Various lining profiles

There are products with different section profiles, in which the shape of the edges, the size of the elements and the configuration of the lock, the nature of the back and front surfaces may differ. These factors have the main influence on the appearance of the lamellas, however, the areas of application of linings with different profiles differ. For example, a regular eurolining with an enlarged “tenon” on the front side forms seams. The edges of such a lamella can be rounded - this type is often used for baths - or standard. All eurolining must have ventilation grooves on the back side.

If the lamellas are implemented without a shelf-recess, such lining does not form seams after installation. If the product has rounded edges, the shape is called “calm”. A classic with an angular edge will allow you to create walls that look like natural profiled timber. If the thickness of such lining is no more than 25 mm, it is often called “imitation timber”. It is considered the best option for cladding building facades.

Another common type of lining is double-sided lining, in which the groove and tenon are located in the center of the end faces, and both planes can be used as facing ones. This means that during the cladding process the master can choose a more successful texture or simply a surface without defects. Double-sided lining has only one, but significant, drawback: it does not have ventilation grooves, so such slats cannot be installed in rooms with high humidity.

It is interesting that the front side of the lining is not always made in the form of a plane. Expensive products are sometimes subjected to a figure milling procedure, which is called “landhaus”. At the same time, the texture of the front surface can either simply have several panels or be part of complex spatial solutions. They also produce lining with threads made using hot stamping. The most interesting types of products are “blockhouse” with an imitation of a log house and “American”, made to look like siding.

Types of lining

When manufacturing lining, manufacturers determine the grade in accordance with domestic GOSTs or European DIN standards. But now, quite often, companies are guided by their own criteria in determining the quality of finished products. At the same time, lining of various quality levels is produced on the same equipment, using absolutely identical technologies. The division of products into classes and grades occurs after the trimming procedure, immediately before packaging and sale. Based on the presence of cracks and knots, resin pockets, blueness and roughness, lining is usually divided into four grades.

The most expensive and high-quality lining is called “extra”, “premium” or simply “knot-free”, its front side is absolutely smooth, however, roughness and irregularities can be found on the back surface, as well as color unevenness. Class “A” lining, in turn, may, among other things, also have knots up to a centimeter in diameter, but not more than one per meter of product. Cracks occasionally occur, but not through ones, and minor processing defects can only be on the back side.

On class “B” lining there are sometimes dark knots, the diameter of which can reach a third of the width of the lamella. Products may have small cracks through them, as well as open pockets and traces of the core. Class “C” lining is, as a rule, everything that is not included in other classes due to quality. It may have long through cracks, blue discoloration, protruding and through cracks, and imperfections on the front side. Most often used for rough cladding, as it does not have the most aesthetic external characteristics. You may also encounter “D”-class products, which certainly have no place in a residential area.

In general, despite external differences, even “premium” and “C” do not differ too much from each other in terms of durability. Everything else is purely a matter of your taste, since not everyone likes a perfectly smooth surface. To some it may seem “lifeless”.

Care Tips

Remember that if you use the lining outdoors, then it must be primed, painted or varnished, otherwise within a few years the boards will begin to rot, mold and collapse. Renew the protective layer every few years to prevent your siding from deteriorating. Don't forget about the ends, which are especially vulnerable to weather influences due to their rougher surface - treat them with sealant. Other means will not work, since fibers from the end absorb liquid 250 times faster than they are sawn lengthwise, and your protection will simply go deeper and stop working.

Also remember that you need to protect the board from all sides, including the one with which it is attached to the house. Otherwise, the condensed water will quickly ruin everything.

It is recommended to prime the lining before painting, as this provides an additional protective layer and the paint will adhere better.

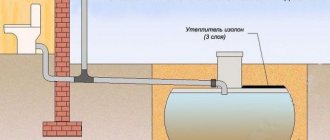

If a liquid leak occurs (from a hole in the roof during rain or during a water supply and sewerage accident), do not forget to check the condition of the siding. In addition to direct water damage, mold may develop on the lining.

How does eurolining differ from regular lining?

Of course, Soviet-style lining - the same one that brought the popular name to modern-type products - with its 25% humidity, tiny lock and 20 mm thickness is no longer suitable for anyone. Its main problem is quality, but the configuration of the Soviet lining leaves much to be desired. That is why the first appearance of eurolining in Russia was a kind of triumph: contractors, developers and ordinary people renovating their homes began to buy tons of it.

Since lining marked “euro” is produced according to the European standard DIN 68–126, which most of our manufacturers still ignore, it differs from domestic ones in almost all respects. The tenon of the eurolining is larger than that of a regular one and reaches 8–10 mm in size, due to which cracks do not form in the lining even in damp rooms. There are always ventilation grooves on the back side of such lining, and the standard thickness of the panels does not exceed 12.5 mm. But the main advantage is the several profile options that Europeans offer.

The requirements of the DIN 68–126 standard are much stricter than those of domestic GOST standards. The treatment of the front surface of the lamella is much better, and if there are live knots on the surface, they are additionally processed. The groove and tongue fit perfectly together, and eurolining of any type is subjected to forced drying to 10–15% humidity, which eliminates the appearance of deformations on the finished lining. When sorting eurolining by quality, not only defects of the wood itself are taken into account, but also “industrial injuries” of the products.

Common questions and answers

- How can you reduce the cost of fasteners and materials without losing the quality of the lining itself? Installation in a checkerboard pattern (the first sheet is attached to the 1st, 3rd, 5th level of the frame, the second - to 2nd and 4th) will reduce the number of hidden staples - clamps by half. Purchasing a short-length lining (up to 1.5 meters) will reduce the cost of material by 25-40%, depending on the raw material. For durable wooden lining, you can save on the frame - install not 5, but 3 levels from the floor level.

- Oil, wood varnish or stain. For different types of wood it is better to use the appropriate chemicals. Thus, oak absorbs wood very slowly, and pine practically does not change its color (it may become blacker, but not lighter).

- Yes, installation of insulation, sound insulation, and additional communications is possible. However, you should not install batteries or other sources of strong heat under plastic lining - it may melt.

- The described scheme can be used to simulate future home renovations. You can read more in the corresponding article. (heperlink)

- Yes, but only in wooden ones. This is another advantage of natural material over artificial. Sheets can be processed like an ordinary board - drilled, cut, etc. Wooden lining can easily support a medium-sized shelf, you can screw a sconce or chandelier to it, and install a socket without any problems. It will not be possible to install it on plastic or MDF - the material will not withstand the load and will crack in a couple of weeks, leaving an ugly hole in the middle of the wall.

- There is, however, in terms of its properties, ease of installation and ease of maintenance, the lining leaves its competitors far behind.

How to choose the optimal size lining?

To determine the length of the lamellas, you need to pay attention to the dimensions of the plane being sheathed in order to reduce waste during the installation process to a minimum. Since the lining can be from 30 centimeters to 6 meters long, and one step is only 10 centimeters, choosing the best option is extremely simple. Please note: trimming the edges may be necessary even for the highest quality lining.

It’s also easy to determine the width of the products, because the narrower they are, the more stable they are, since lining that is too wide is more prone to deformation. Sometimes, for an additional decorative effect, slats of various widths are used for cladding. The optimal thickness of lining for indoors is considered to be European 12.5 mm. If the lining will be mounted on a thick layer of insulation or on a facade, it is better to purchase thicker panels - 15–20 mm is just right. Such lamellas are stronger and more reliable, but also more expensive.

A separate topic is lining, joined along the length. It is milled from a board consisting of several sections, adjusted to each other according to the type of sawing and pattern, and not having the same length. The elements are connected using glue. The main advantage of such a lining is its stability over a length of up to 6 meters, since there is almost no stress on the board. Most often, it corresponds to the “Extra” grade in all respects, but it still has a minus: the minimum thickness is 15 mm. Its use for lining a bathhouse is also not advisable due to the fact that its design uses glue, which theoretically can produce harmful fumes.

Selection by profile shape

Both wooden and plastic lining have many designs in terms of the shape and decorative design of the panels, as well as the method of fastening them together. Next, we will look at the main types of finishing materials used in modern construction, which differ in profile shape:

Lining - “Panel”

Panel-type lumber has a classic shape that imitates a standard wooden beam. It can be produced in both plastic and wooden versions (most plastic lining models are made in the simplest and most convenient version for assembly).

Eurolining

A widespread version of the lining - “eurolining”, unlike the classic one, has a deeper joint with an elongated tenon size, which improves its ventilation and drainage properties. Eurolining is the most suitable solution for finishing the facades of country buildings and houses.

Lining - "Calm"

“Calm” lining (pine), also called “Peasant” or “Collective Farmer” lining. Its main purpose is to cover walls and ceilings of premises. The “Kolkhoznitsa” lining is good because it has a perfectly flat surface, on which traces of the grooves are absolutely invisible. This is achieved due to the absence of a special shelf in the lumber (recesses on the front side of the panels).

American

“American” lining, which has special recesses on the inside with imitation of overlapping laying. Due to the installation features, such lumber is most often used for cladding the facades of houses. American lining is made exclusively from wood.

Block house

The so-called “Block House” lining, produced in the form of semicircular and slightly convex boards (panels) on the outside, imitating a structure made of logs. Like timber lining, this type of cladding has a wide, flat inner surface and is equipped with tongue-and-groove grooves along the edges. This type of board can be used for both external and internal finishing work.

When considering the profile of the panels, we should also mention such a variety as quarter lining, used to create optimal conditions for moisture removal. Quarter paneling is a board with a quarter selected at the edges, which can only be mounted overlapping and only horizontally.

With this method of installation, condensation will certainly accumulate in the joints of the quarter panel. This is why, for example, a quarter panel cannot be used in a bathhouse, since it does not provide conditions for moisture removal.

In conclusion, we note that facade lining can be used for covering almost any external surfaces of a house - simply wooden, plastered or framed.

Both wooden and plastic products (American lining, for example) are easily processed with simple carpentry tools. And their fastening to the frame or sheathing of the house can be done using ordinary nails or self-tapping screws with dowels.

From a short video you will learn about the properties and characteristics of lining, and also find out what types it comes in.

Which lining should you choose and avoid purchasing low quality material?

There are several hundred lining manufacturers represented on the Russian market, and the quality of their products does not always correspond to the declared grade. Therefore, the only way to buy a normal lining is to carefully inspect it, paying attention to every little detail. And it starts with packaging. If products are sold in film, this is the first “bell” that may indicate low quality. Since the seller is unlikely to allow you to tear the packaging to remove the panel from its center, only the two outer slats may be ideal. By the way, if a manufacturer covers the ends with stretch film, this can affect even the condition of very good products - due to the lack of ventilation, their humidity increases.

If possible, inspect the panel carefully. Quite often it can be slightly bent, which indicates a broken production technology or improper storage. You cannot purchase such a lining, as it will be difficult to install, and due to stress, over time it will still pop out of the lock. If the panel looks smooth, carefully feel the front surface and inspect it under side lighting. Waves may appear across the board.

Pay special attention to the groove and ridge - there should be no cracks, knots or chips on them. When inspecting the product, it is advisable to have a clamp with you, which can be immediately inserted into the groove shelf. Sometimes waves are found in it, due to which the clamper cannot be placed in the desired position. Try connecting several slats together, making sure that they are not bunched together too tightly. If the retail outlet has a device for measuring the moisture content of the lining, be sure to use it!

How to avoid defects during installation

Sometimes the number of boards is taken end to end, and then you have to go to the store again because part of the siding has deteriorated during fastening. How to reduce such marriage to a minimum?

- Use fasteners of sufficient length. The most common reason why lining cracks at the fastening points when used over insulation is that the nails are too short. Over time, they weaken due to thermal and water influences, and the entire structure begins to loosen, compromising the integrity of the connection.

- Make sure that the waterproofing is done correctly so that water will not spoil the siding. The second most common reason for defects is condensation, ice freezing or rainwater between the wall and the lining.

- Make sure that the boards have been stored properly , that is, they are well dried and do not have a lot of sapwood on them (the layer of wood directly under the bark - in this case, the risk of twisting the boards is high). Boards that are too thin and too wide are subject to greater loads and are more likely to be damaged during installation.

Features of installation and scope of application of lining

On the main surface for installing the lining, wooden frames are usually assembled, in which the distance between the supporting profiles should be from 40 to 60 cm. Sometimes the frame is made of galvanized profiles, but in this case, to secure the clamps, you need to use rivets or small self-tapping screws rather than nails metal.

The lamellas can be laid both vertically and horizontally - it all depends on the design idea. But the first option is optimal for wet rooms, since when positioned vertically, the compensation grooves do an excellent job of removing condensate. The horizontal type of cladding prevents moisture from entering the lamella lock, which is excellent for cladding facades. Also, the second type of installation is often used for sewing wooden and metal partitions. An interesting decorative effect comes out when installing the lining diagonally, but in this case problems may arise with economical installation.

It is recommended to install the lining with a gap to the enclosing structure of up to 10 mm, and after installation, it is better to cover the external and internal corners with wooden additional products. To do this, you can use linen, jute or hemp rope, which go well with wood and help seal gaps, following any curved surfaces. It is best to choose a rope if the lining is adjacent to a blockhouse or a real log house. more about how to cover walls with clapboard in our other article.

Calculation of the cost of finishing

Let's consider a simple option:

- To decorate a 4x5x2m room, you need (5x2x2+4x2x2) m2 of a certain type of lining (take, for example, wooden). 36m2 of heavy lining requires a strong frame made of timber 3x3cm or more long, 5m x 4m x 5 horizontal frame levels (every 40cm from the floor level) = 100 m of timber.

In addition, fasteners: dowels plus self-tapping screws for timber (at least 100 pairs per 100m), plus fastening of the lining to the frame (number of sheets, depending on the width, for example, 10 cm) x 5 levels of the frame. A wall 5m long and 2m high will require (5/0.1) x 5 levels of frame = 250 mounting brackets. For all walls of the room this quantity will be equal to 250x2+200x2 = 900 pieces.

By studying prices on the trading platform, you can calculate the estimated cost of repairs. Added to this is the cost of hiring workers if necessary. If the resulting number does not match the budget, you should think about choosing a different type of raw material. MDF boards are 30-50% cheaper than wood boards. Plastic lining is also 40% more profitable. A metal frame can cost more than a wooden beam; the method of fastening the lining also varies from cheap, but short-lived, to durable, but with a frankly extortionate price.

An additional price will have to be paid for varnishes, antiseptics for the lining, leveling, and finishing primer of the walls. For more complex types of repairs (with insulation, installation of sound insulation, etc.), the price will include preparatory work, material, installation of these structures.

Prices for lining

Despite the fact that materials of this type are considered molded, lining is often sold by square meters. If you choose a domestic manufacturer, they mainly offer lining made from local types of wood, but it is possible to make an exotic and incredibly expensive option to order - for example, from mahogany. The price of the lining is affected by its grade, type of wood, width and length, thickness.

The most economical lining is pine, its price starts at 170 rubles per square. Larch is the second most expensive, but the difference is noticeable, because it will cost 400 rubles. Linden is even more expensive - from 500 rubles, and only if inexpensive varieties are used. Alder lining class “A” will cost at least 700 rubles per square, and oak lining – from one and a half thousand!

Since the lining of classes “A” and “B” most often do not differ too much in external data, the difference in price for them is approximately 20-25%, while products of class “C” usually cost several times cheaper. By purchasing short slats of 0.3–1 meter for narrow structures, you can save money, since they are on average 25% cheaper than full-size ones. And remember: the thicker the lining, the more expensive it is.

Conclusions and recommendations

So which lining to choose for repairing the interior decoration of a private house? Of course, environmentally friendly, pleasing to the eye and durable. MDF and wood are much more profitable than their plastic counterpart. Natural materials will create comfort, will not harm the health or well-being of residents, and can be reused for finishing other rooms or self-construction.

Also consider the operating conditions: for a summer house or other living space where you rarely visit, MDF and plastic are not suitable. They need care and constant temperature conditions. Plastic often deforms and bends at high temperatures; MDF quickly absorbs moisture and swells without proper care. Wood was and is the most preferred material.

However, for finishing ceilings, MDF and plastic sheets are best suited as they are lighter. For rooms with low requirements (niche, pantry, corridor), plastic is preferable. It is easier to clean, its sheets are thin enough, which saves space, and you don’t mind throwing it away during the next repair.

And one more piece of advice: when choosing materials, be guided by their availability in the nearest warehouse. In cities with a population of over a million, you can find almost anything, but outside large regions, only wooden (2-3 varieties of several types of wood) and plastic (1-2) types of lining are available.