Construction mixtures for leveling floors make it possible to quickly and efficiently prepare the base for any coating. In this case, it will take much less time for the surface to dry than for a classic screed. When starting repairs, it is necessary to make correct calculations and find out the approximate consumption of the self-leveling mixture, which will allow you to avoid unnecessary costs.

Self-leveling floor mixtures

Basic properties of self-leveling mixtures

Self-leveling mixtures are distributed over the work surface due to their fluidity and require almost no leveling. They penetrate well even into the smallest cracks and irregularities, firmly adhere to the base and create a horizontal, perfectly even coating.

Self-leveling mixtures

The distinctive features of such mixtures include:

- durability and high strength even with minimal layer thickness;

- fine-grained structure;

- minimal shrinkage;

- quick drying;

- ease of filling;

- resistance to temperature changes.

Types of mixtures for leveling

Leveling mixtures are made based on gypsum and cement; Additionally, the composition includes modified additives and various fillers. Gypsum compositions are intended for use in dry rooms; they dry faster, are lighter in weight, and can be laid in a thicker layer. Cement mixtures are resistant to water, so they are suitable for both dry and wet rooms. Both types are applied to concrete, anhydrite and cement-sand substrates.

Forward Tsemopol and Forward Teplopol are intended for the initial leveling of concrete floors and monolithic cement screeds inside residential buildings

Depending on the fraction of fillers, self-levelers are divided into finishing and coarse. Finishing compositions are characterized by greater fluidity, high penetrating ability, and are applied in a thin layer. Rough levelers are designed for repairing and leveling rough foundations. Such mixtures are applied in a thick layer - from 1 to 8 cm, and contain expanded clay crushed stone, coarse sand, and ground granite. Due to their higher density, coarse levelers do not spread as well as finishing ones, so they need to be distributed over the floor using a rule. The viability of self-leveling mixtures usually does not exceed 30 minutes; for quick-drying compositions it is even less - about 15 minutes.

The dry mixture Forward Cast Concrete is intended for leveling concrete floors and monolithic cement screeds inside residential and office premises with any humidity regime. The Forward Finishfloor leveler is intended for the final leveling of concrete floors.

Basic data for calculations

With an ideally horizontal base, the calculation requires only the area of the room, the thickness of the planned layer and the data offered by the mixture manufacturer on the consumption per square meter of area with a layer thickness of 1 mm (consumption of a bag of self-leveling floor). However, perfectly flat bases usually do not need additional filling. In reality, builders are faced with significant protrusions and depressions on the floor, surface slopes in one or more directions, cracks and other defects. It is not possible to take them all into account, so any calculations will be approximate. To obtain relatively accurate data on the consumption rate of self-leveling flooring, you must:

- check the geometry of the base using a laser plane builder or simpler means - a level and a beacon system. An example of such a check is given in the article on cement screed on beacons in the application to the floor;

- After determining the places with the greatest and smallest depth (in relation to the planned floor level), as well as the slope angle, a sectional drawing of the foundation is drawn up. If the picture is very different in different directions, several drawings are drawn up and the one where the differences in level are maximum is selected for calculations;

- the desired type of self-leveling mixture is selected - mineral or polymer (this depends, among other things, on the required thickness of the fill). The base component of the mixture is also taken into account (for minerals, cement, gypsum, gypsum-cement compositions, for polymers - epoxy resin, polyurethane, methyl methacrylate), since this affects the consumption of the self-leveling floor and the speed of its curing;

- The area of the room is carefully measured, taking into account possible unevenness of the walls.

Based on data on the geometry of the base, the average thickness of the poured layer is calculated.

It is important to understand: for all measurements, the maximum is selected from two values (wall length, level difference). This provides the necessary supply of material in case some nuances are not taken into account

Additionally, 5...10% is added to the calculated value.

The calculations also take into account the presence or absence of filler (usually fine sand). The admissibility of its inclusion in the mixture should be checked with the manufacturer and/or seller of the product.

How to calculate the consumption of self-leveling mixture

Dry self-leveling mixtures are not stored for a long time, and there is no point in taking them in reserve. At the same time, if the mixture is not enough to fill the entire room, there can be no question of the quality of the coating. To correctly calculate the amount of material, you must accurately assess the condition of the base and determine the thickness of the leveling layer. As a rule, the packaging of the dry mixture indicates its consumption per square meter with a layer thickness of 1 millimeter. For a coarse leveler this is approximately 2-2.5 kg, for a finishing leveler 1.5-1.7 kg.

Technical characteristics of leveling mixtures for floors

It is not difficult to calculate the thickness of the base layer: to do this, you need to find the highest point of the floor, from this height measure the depth of the largest recess and add the minimum thickness of the fill.

Calculating the thickness of the base layer is not difficult: to do this, you need to find the highest point of the floor, from this height measure the depth of the largest recess and add the minimum thickness of the fill

If the difference in unevenness is more than 80 mm, all deep recesses must first be sealed with mortar or putty and wait until the surface dries. Now multiply the minimum mixture consumption by the thickness of the layer, and then by the floor area - this way you will find out how much mixture you will need for the job. Since these calculations are approximate, you should add 10% to the resulting number. Levelers are usually packaged in 25 kg packs, so by dividing the found value by 25 and rounding to the nearest whole number, you can calculate how many bags of the mixture will be needed.

Most often, levelers are packaged in 25 kg packs.

The finishing leveler is more expensive than the coarse leveler, and in order to save money, it is recommended to fill the base with minimal differences. Very often, thin-layer mixtures are used together with coarse levelers: first, a base layer is poured, which evens out all defects, then the surface is leveled with the finishing composition. This is due to the fact that coarse levelers, after hardening, form a rough surface due to the large fillers contained in them. This surface is not suitable for laying thin floor coverings, so the floor is filled with a finishing mixture that forms a very smooth base.

Sample of self-leveling mixture

When pouring in this way, the finishing layer can be of minimal thickness, and then it is enough to just multiply the floor area by the specified mixture consumption. If the self-leveler is poured onto a concrete or wooden base, the thickness of the layer depends on the difference in unevenness on the floor. Since the maximum thickness is 5 mm, unevenness should not exceed 3 mm. Having determined the height differences, further calculations are performed using the same formula as for the base mixture.

Consumption table for self-leveling mixtures

| Name | Consumption kg/m2 at a thickness of 1 mm |

| Ceresit CN 69 | 1,8 |

| Ceresit CN 76, 178 | 2,0 |

| Isoflor 707 | 1,5 |

| Uniflor 710 | 1,6 |

| Duraflor 721 | 1,6 |

| Vetonit 3000 | 1,5 |

Which poured floor is better?

It is difficult to give an unambiguous answer to this question, because each of the types of mixtures considered has its own technical characteristics and purpose. If we summarize all the information received, we can come to the following conclusion:

- When installing flooring in rooms that are constantly in contact with moisture, such as a bathroom, kitchen or bathhouse, it is advisable to choose a cement or polymer self-leveling screed. A wide variety of floor coverings, including ceramic tiles, can be laid on such a base.

- If the developer’s goal is to simply level the foundation in a bedroom or children’s room, then a plaster-based leveler may be suitable for such purposes. The usable area of such rooms is much larger than a bathroom or bathroom, but the cost of leveling gypsum mortar is significantly lower than cement mortar.

A self-leveling self-leveling floor made from cement or polymer binders is expensive, but with its help you can level various substrates, even outdoors.

How to reduce the consumption of levelers

The consumption of the building mixture directly depends on the total area of the uneven surfaces and the absorbency of the base itself. It is better to level overly porous and damaged surfaces using a regular cement or dry screed, since filling with a leveling solution will be too expensive. But if the base is dense and the uneven area is small, proper preparation of the floor will help reduce the consumption of the mixture without reducing the quality of the pour.

Elimination of irregularities

The smaller the number of recesses and cracks, the less mortar will be needed for filling. The main defects can be eliminated using available tools and putty.

Putty for concrete floors

To work you will need:

- grinding attachment;

- perforator;

- putty knife;

- primer;

- putty solution.

Concrete floor repair

In order not to miss a single crack, the base must not only be swept, but also vacuumed. The exfoliated concrete is cleaned off, and the tubercles protruding above the floor are knocked down with a hammer drill. Cracks with a width of more than 2 mm should be expanded along their length and removed from dust; on long cracks, perpendicular notches should be made with a grinder. It is convenient to remove roughness and small irregularities using a grinding wheel. After this, the floor is vacuumed again, all recesses and cracks are treated with a primer, dried and filled with polymer putty. When the putty areas have dried, their surface must be sanded.

| Name and packaging | Application base | Consumption kg/m2 | Maximum layer thickness | Drying time | Price RUR/pack |

| PVA-based putty, 4 kg | Plaster, concrete | 0,450 | 3 mm | 5 minutes | 154 |

| Putty stone flower, 25 kg | Concrete, wood, plaster, drywall | 1,4 | 10 mm | 24 hours | 138 |

| Ready putty Sheetrock, 3.5 l | Any | 0,67 | 2 mm | 5 o'clock | 350 |

Padding

Padding

Primers impregnate the top layer of concrete or screed, filling pores and microscopic cracks. Thanks to this, the leveler spreads better over the base and is consumed less. But keep in mind that the primer must match the surface to which it is applied and have high penetrating properties. For porous substrates there is a special strengthening primer, which is not suitable for ordinary floors. Before applying the primer, the floor must be cleaned of dust and oil stains must be removed. As a rule, the base under the self-leveling floor is primed twice; Until the first layer has dried, the surface cannot be treated again.

| Name, weight | Description | Drying time | Consumption kg/m2 | Price |

| Acrylic universal primer, 10 l | Suitable for concrete, cement-sand and gypsum bases; strengthens the surface layer, reduces diffusion capacity | 1 hour | 10 | 151 rub. |

| Soil BOLARS Betonkontakt, 12 kg | Suitable for concrete, stone, plastered surfaces, increases adhesion | 15 o'clock | 0,3 | 712 rub. |

| Primer for absorbent substrates CT17, 5 kg | Suitable for concrete and cement-sand screeds, has antifungal properties and elasticity | 4 hours | 0,2 | 251 rub. |

| Axton concrete contact, 18 kg | For treating smooth concrete substrates, increases adhesion | 2 hours | 0,25-0,3 | 788 rub. |

| Adhesive primer GLIMS BetoContact, 4 kg | For processing smooth concrete substrates, floor tiles | 24 hours | 0,3 | 272 rub. |

Advised by professionals

In order to obtain the highest quality surface at an affordable price, experts use some techniques.

So, if the base base is not too crooked to purchase medium or basic bulk compositions, but not so smooth as to get away with just a finishing coating, the situation can be corrected. You just need to sand the surface using a sanding machine. This will smooth out unevenness and save on materials.

In order not to purchase primer compounds, you can make them yourself from a small amount of dry compounds for self-leveling floors. The mixture is diluted and then applied to the base with a roller. When the product has dried, you can pour the finishing floor.

How to properly mix leveling compounds

How to properly mix leveling compounds

If the mixture is diluted incorrectly, no amount of tricks will help make a high-quality coating. The main mistake beginners make is adding more water than indicated in the instructions. A more liquid composition spreads faster, but the strength and durability of the floor is reduced several times. In addition, peeling, cracks, and other defects may appear on the coating.

To properly prepare the solution, you will need water with a temperature of at least +10 degrees, a convenient container for mixing, a drill with an attachment and a dry mixture. Strictly adhering to the specified proportions, pour the mixture into water and mix for 3-4 minutes with a mixer attachment. Then leave the solution for 3 minutes to ripen and mix again for a minute. The result should be a homogeneous mass without lumps, liquid enough to spread without additional leveling. If the technology is followed, the filling process will not cause difficulties, and the mixture consumption will not exceed the calculated one.

| Name | Drying time | Layer thickness | Consumption kg/m2 | Price RUR/kg |

| Horizon universal | 3-7 days | 2-100 mm | 3-4 | 236/20 |

| BOLARS | 4 hours | 2-100 mm | 3-4 | 239/20 |

| Vetonit 3000 | 4 hours | 1-5 mm | 1,5 | 622/25 |

| Palafloor-303 | 4-6 hours | 2-100 mm | 1,4-1,6 | 308/20 |

| GLIMS-S-Level | 24 hours | 2-5 mm | 3 | 478/20 |

| Perfecta Multilayer | 2-3 hours | 2-200 mm | 7-14 | 312/20 |

| xton | 3-4 hours | 6-100 mm | 14-16 | 256/20 |

| Name. Short description | Packaging kg | Consumption kg/mm/m2 | Price | Strength MPa | Layer thickness in mm |

| ALFAPOL VP - finishing self-leveling self-leveling floor M200 F200 Pk5 W12 on a cement base | 25 | 1,75 | 375-471 | 20 | 2-40 |

| REAL Floor leveler, High-quality dry cement-based mortar | 25 | 1,7 | 360 | 20 | 2-80 |

| Bergauf BODEN ZEMENT MEDIUM, self-leveling floor for the final leveling of horizontal surfaces, ideal for further installation of any floor coverings (ceramic tiles, parquet, carpet, linoleum) | 25 | 2 | 289-324 | 20 | 6-60 |

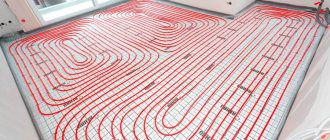

| Forbo Eurobond 915, fast-hardening self-leveling floor, low shrinkage, self-leveling, quick-drying. Suitable for heated floors. For indoor use, incl. in damp areas. Withstands the load from furniture on casters. | 25 | 1,7 | 405 | 20 | 3-50 |

| Petromix PS, for leveling floors on concrete and other hard substrates in dry, damp and damp areas. Serves as a base for floor coverings (parquet, ceramic tiles, textile carpets, plastic coverings, linoleum, etc.) | 25 | 1,5 | 441-471 | 25 | 2-30 |

| The foundation will be T-42 Nipline, a self-leveling, high-strength, moisture-resistant, non-shrinking leveler on a cement-sand base using special chemical additives. | 25 | 1,7 | 342-433 | 25 | 3-30 |

| Ceresit CN 178, for the manufacture of screeds operating under conditions of low and moderate mechanical loads, incl. with constant exposure to moisture (in residential and public premises, on exploited roofs, balconies, terraces, open areas, etc.), during external and internal work, in civil and industrial construction. | 25 | 2 | 370 | 35 | 5-80 |

| Vetonit 4100 cement-based mixture for leveling concrete floors indoors | 25 | 1,6 | 520-537 | 20 | 2-30 |

| vetonit 4150, suitable for quickly leveling concrete floors and creating screeds in residential buildings, offices and public buildings. It is used for repairs and new construction under various types of floor coverings. Used in “Warm Floor” designs | 25 | 1,6 | 520-550 | 20 | 2-30 |

| Berghauf BODEN ZEMENT FINAL, self-leveling cement-based flooring for perfectly smooth surfaces. For rooms with normal and high humidity (bathroom). | 25 | 1,8 | 435-490 | 20 | 0,5-5 |

Useful tips

Before applying almost all Unis/Unis materials, the surface must be primed with a primer, depending on the type of surface. Highly absorbent surfaces, such as foam block, gas block, old plaster, are best treated with a deep penetration primer, or a strengthening or universal primer. This is necessary in order to strengthen the base and increase adhesion (adhesion strength) with the applied material. For weakly absorbent surfaces, such as concrete, ceramic brick, as a rule, a concrete contact primer is used, which creates an adhesive rough (due to quartz particles in its composition) film for the same purposes - increasing the adhesion strength of the material, i.e. in simple terms, so that the material has something to cling to.

When preparing solutions, be careful about the proportions of water and dry mixture. Strictly follow the manufacturer's recommendations for the amount of water per bag. This determines how the material will behave after application.

What are the consequences of not following instructions and why is it important? The most common reason for the appearance of cracks or severe cracking is failure to comply with the proportions of mixing the mortar. To find out how much water you need, use the manufacturer's instructions on the packaging or on the manufacturer's official website

Remember that guarantees of material quality are valid only if the manufacturer’s instructions on the technology of use and the requirements of SNiP and SP are strictly followed.

After applying dry mixtures, avoid drafts; the material should evaporate moisture evenly in a natural way, and drafts accelerate the process of moisture release. Also, after applying Eunice self-leveling floors, do not use heat guns, hair dryers and other heat devices to speed up drying, as this will also disrupt the process of natural moisture release.

And of course, take precautions. Keep away from children

During work, use personal protective equipment. Avoid ingestion. If Eunice self-leveling floor gets into your eyes or skin, rinse thoroughly with plenty of water and, if necessary, consult a doctor.

To summarize, let's summarize what has been said:

prime surfaces before applying materials; after application, avoid drafts; do not use heat devices to speed up drying; strictly follow the proportions of water according to the manufacturer’s instructions; Observe precautions when applying self-leveling flooring;

Preparing a concrete or wood base

During preparation, the room must be cleared of furniture, damage removed, the surface cleaned and primed

Preparation of the base before pouring the self-leveling mortar is mandatory, regardless of the base material and its technical condition.

The general preparation process includes the following steps:

- elimination of severe damage and cracks;

- surface primer;

- waterproofing the base.

In some cases, thermal insulation of the base can be performed with the installation of a reinforcing layer. But it is recommended to carry out these works when installing a cement screed, and only then carry out leveling with a leveling mass.

If the slab is suitable for repair, then technological cuts up to 3 mm thick are made perpendicular to the cracks, every 20-25 cm. The depth of the cut should not exceed 5 cm with a length of 15-20 cm. This method of bridging the crack will distribute the load and reduce destruction grounds. Similar cement compositions are used for sealing.

To eliminate various damages and cracks, your own approach should be used

Waterproofing is required in all cases except zero humidity, which is extremely rare. Polyethylene film can be used to waterproof the base. Be sure to glue a damper tape at the bottom of the wall, which will allow the floor to “breathe”.

Inspection of wooden bases begins with an inspection of the general condition of the surface. The boards or sheets of wood must fit tightly to the floor structure. If there is a so-called “game” of boards, deviations are measured.

To measure, use a homemade sinker, which is attached to the ceiling or tripod. At the lowest point, the load should lightly touch the floor. Place a sheet of paper marked in the form of a cross or circle under the weight.

Then they walk around the room, causing the floor or floor covering to “walk”. That is, they exert a load on the surface to measure deviations. The maximum permissible value is 1.2 mm per 1 sq. m. In case of large deviations, it is necessary to re-examine the existing structure.

Wooden floors require particularly careful inspection - the permissible deviation is only 1.2 mm

If there are no or small deviations, check for moisture. To do this, open one canvas or board. Conduct a visual inspection for damaged structures, joists, fungal colonies and dampness. If they are found, the base is opened and the defects are eliminated.

If everything is in order with the floor or all deviations have been eliminated, seal the gaps between the floorboards, the wall, etc. To do this, use wet sawdust mixed with adhesive mass. Afterwards, along the lower part of the wall, an expansion tape is glued and waterproofing is laid.

Calculation features

- The surface area to be filled. It is not difficult to calculate it. It is enough to measure the sides of the room and multiply the resulting data among themselves.

- The thickness of the poured layer significantly affects the calculation of the self-leveling floor. It is necessary to take into account that the floors must be poured in the same plane in all rooms of the house. To determine the thickness of the material, you need to measure the distance from the rough subfloor to the finished one. The subfloor is usually a concrete slab or a durable previous floor covering. And the finishing surface is the final front finish.

- The area and quality of preparation of the subfloor base significantly affects the consumption of the mixture. The more uneven the floor is and the worse its condition, the greater the amount of mixture needed. In this case, the best option would be a cement or polyurethane screed, which will both help leveling and create an overlap.

Calculation for dry building mixtures

When using a method using dry materials, it must be taken into account that pouring should be done in one step. Initial rough uneven filling and subsequent leveling with a thicker layer are not allowed. Such delamination of the floor will lead to deterioration in quality and loss of its strength and durability properties.

The main point when calculating a self-leveling floor of this type is taking into account the density of materials. Different mixtures have their own density - gypsum, for example, is about 150 kg/m³, and cement - 220 kg/m³. The consumption of gypsum mixture will ultimately be less than cement.

Sometimes you can find calculations for self-leveling floors using calculations of the required materials in liters. One liter of mixture is enough to fill 1 m2 of floor, with a thickness of 1 mm. Using this method is not very convenient, since the mixtures are sold in kilograms.

Carrying out calculations for polymer mixtures

It is necessary to calculate the material consumption for a polymer self-leveling floor taking into account the technology that will be used during installation. The single-layer option involves one fill, and its thickness must be taken into account. Multilayer technology provides from 2 to 5 layers. Most often, two layers are poured - one of them is leveling, and the second is the front layer. Adding layers is provided for the installation of 3D self-leveling floors. They require the use of priming, protective and decorative layers.

Also, when making calculations, it is necessary to take into account several factors:

- If the base of the poured floor is too porous, it will require an additional self-leveling layer.

- Evenness and differences in surface level. If the base is too uneven, additional materials will be required to create a leveling base.

- The quality of the base and the presence of damage, chips and cracks also affects the amount of materials required.

- Different amounts of material will be required to create an absolutely ideal mirror floor surface, or just a flat one.

When taking into account the thickness, it is necessary to take into account the type of room in which the floors will be poured. For a living room, it is enough to use a maximum of 7 mm of self-leveling texture, but not less than 1.5 mm. At production and industrial facilities, floors are subject to greater loads, which affects the increase in the self-leveling layer to 100 mm.

It is important to note that when using polyurethane mixtures. the floor can be 2 mm thick, polymer - at least 8 mm, and epoxy - at least 5 mm