When any owner of a plot of land chooses SIP as the material for building a house, sooner or later the question arises: how to make a roof? Choose the classic option with a rafter system or still make it from the same material as the whole house. Each method has its own disadvantages and advantages. For example, the roof on the rafter system must be additionally insulated if the top floor is intended to be an attic. And in the case of SIP panels, the roof needs a ventilation system, but even with this nuance, this option is several times better than the traditional one.

In the case of a rafter roof, there is a possibility of poor installation or selection of poor materials. In the case of SIP panels, this cannot happen, as in the construction of houses, this installation method is simple but effective.

Roof installation from SIP panels

The main distinguishing feature is the design of the mauerat. Unlike traditional methods, in this case it is also a connecting beam, and its upper part is made at an angle that corresponds to the slope of the roof.

Before installation begins, it is worth correctly assessing the house and choosing a method for attaching the panels. There can be three of them in total:

No runs

In this case, the parts of the rafter system will be the ridge and connecting beams, and the mauerlat. This option is suitable for small houses in which the distance between the ridge and the Mauerlat will not exceed four meters. If the length is longer, it is necessary to make intermediate runs.

With intermediate runs

This is a way to increase the load-bearing capacity of the roof, as well as the strength of the roof. The top edge of all beams, including the ridge beams, in this case should also be beveled to the angle of the roof. This option is suitable for large houses, as well as for attic floors.

With rafter system

A rafter system is most often necessary as a kind of insurance or if the attic area is divided into two zones: cold and warm. It is in this case that it is easiest to organize them correctly. But in the case of SIP, everything is different. Using this material, there is no need to build rafters along the entire length and width of the roof, but you can limit yourself only to the living area or even use the option with intermediate purlins. Since a large number of beams that will be used in the construction of rafters will only increase the final cost of the house.

Conditions for planning the construction of a roof

When arranging, the following is taken into account:

- Slope.

- Load created by snow.

- Wind pressure.

- Probable directions of air flows.

Atmospheric loads must be considered taking into account the region of residence and probable deviations from average climatic norms. From this data you can determine what roof slope is required.

Required Tools

The installation of the roof involves the following work:

- Configuring the panels, giving them a shape that ensures a tight fit.

- Transportation to the installation site.

- Sealing gaps.

- Preparation of technological holes.

- Installation of mechanical fasteners.

The following tool is required:

- Hacksaw. An alternative is electric scissors or a circular saw.

- Vacuum or mechanical type gripper.

- Screwdriver, drill with a set of attachments.

- Mallet made of polymer material.

- Hand tool for measurements.

- Mounting gun.

Load calculation

When the slopes and dimensions of the slopes are known, you can understand the wind and snow loads that will affect the roof.

- The snow load is determined by multiplying the standard mass of snow precipitation by an indicator that takes into account the roof slope. This indicator is equal to one if the angle is not more than 25 degrees, 0.7 - from 25 to 60 and 0 if more than 60. You can determine the area in which the construction site is located by evaluating the climate map prepared by the meteorological service.

- Determination of wind load. Strong winds can cause serious damage: from tearing off individual roof segments to overturning the entire structure. The reason for such destruction is the separation of wind flows horizontally and vertically, the formation of force applied along different vectors. Wind load can be determined by multiplying the following indicators:

- Ripple factor.

- An aerodynamic indicator determined by the geometry of an object.

- The standard value of wind pressure determined for the area.

You can understand in which wind region a building is located by looking at the wind map of the country.

After calculations, it is possible to determine the positions of intermediate runs that help maximize the load-bearing capacity of SIP panels.

What weather can you work in?

SIP is characterized by a minimum weight, but a large windage, due to which installation is unacceptable if the wind speed exceeds 9 meters per second. Negative temperatures are not a hindrance, however, when sealing joints with sealant, temperatures below +4 degrees are unacceptable.

If it is raining, the fog has thickened, the surfaces have become slippery, you cannot lay the roof, this is a safety requirement.

Roof installation

The problem with installing a roof from SIP panels is that if, for example, a house can be built by two people, then laying the slabs will require 4 people, or even heavy equipment to lift the slabs to a height. Which complicates construction somewhat. But if you choose professional companies, you won’t notice any problems. All professional teams consist of a sufficient number of installers.

There are also standards that are used in the construction of roofs from SIP panels:

- The beam pitch should be 625 mm;

- The optimal thickness of one panel is 224 mm, 174 mm is allowed.

In this case, the following will be considered defective: slabs thinner than the specified width, OSB thickness less than 12 mm.

The consequences of violating standards are varied. There may also be minor shortcomings, such as sagging ceilings, or complete destruction of the structure.

SIP panels can be mounted in different ways:

- perpendicular to the ridge beam;

- parallel to maeurat.

There are panels on the market designed specifically for laying roofs - with built-in stiffeners. This option allows you to do installation in different ways without losing quality.

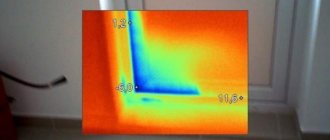

Reducing home heating costs

Comparing the heat-shielding characteristics of SIP panels with similar properties of other materials, it is easy to see that no insulation layer that was once installed as part of the roof can compare in its heat-shielding qualities with the energy efficiency of SIP panels. If their installation is done efficiently, then there are no joints between the panels, turning the roofing pie into a single whole and reliably protecting the rooms inside the house from the penetration of cold air masses. Therefore, heating a house requires less heat energy than houses with roofs made of traditional materials.

Choosing a roof from SIP panels

For roofs made of SIP panels, you can use different roofing options. But it should be chosen before work begins. After all, many of the materials require a certain roof slope. For example, a soft roof will require at least 12 degrees. For metal tiles, a steeper slope is required, which is fully explained by its characteristics - snow and other precipitation simply do not linger on it.

In Europe, roofing made from solar panels is common. This is a way not only to protect SIP panels from precipitation and, accordingly, damage, but also to make already economical houses more autonomous.

Roof insulation and vapor barrier

The design of SIP panels includes two OSB sheets with a layer of insulation laid between them. Thus, the insulation appears on the roof along with the installation of the panels. The exceptionally low thermal conductivity of SIP panels is an excellent protection for warm air inside the house from contact with cold outside air. And the high degree of air permeability of the insulation does not prevent heated air from leaking out, allowing you to save on the vapor barrier device.

Do you dream of your own home, a holiday home or for permanent residence? There is nothing easier than doing this at TechnoSip.

Look at our catalog of projects, the prices will pleasantly surprise you.

up to 100 sq. m. from 100-200 sq. m. from 200-250 sq. m

Our recommendations

It is worth making a roof from SIP panels only if an attic floor is needed or is planned in the future. In the case where the attic is planned to be used as an additional storage room, then, of course, there is no point in making it warm.

When choosing a rafter system and roofing, you should consult with professionals before starting installation work. After all, it depends on what materials to use and how quickly the roof will be erected. Be sure to trust the installation of the roof of a house from SIP panels only to trusted companies. Improper installation or non-compliance with standards will lead to water getting inside the roof and, accordingly, to deterioration of the quality of the panels and possible destruction of the entire structure. Protect yourself by choosing only trusted builders.

From us you can buy a house made of SIP panels and discuss the possibility of making a roof from the same material. We have professional installation teams who do their work efficiently and on time. And to check the compliance of the house with the design documentation, we have a technical control department that closely monitors the progress of work - from the start of construction to the handing over of the keys.

7. Basic layout schemes for a cold rafter roof

Gable roof

Hip roof

Hip roof with cuckoo

Note:

The pitch of the rafters is taken according to calculation.

Roof covering is one of the most important types of work. The roof is the face of the house. If the roof is done carefully, then the house already looks great, and vice versa.

The first glance is always at the roof. And only later do they begin to look at the walls made of SIP panels and the quality of their assembly.

Meanwhile, Customers who choose SIP technology often underestimate the role of foundation and roofing work. This is easy to understand - SIP technology is not directly related to these works. That is why at many SIP construction sites, the piles are screwed in by migrant workers, and the roofs are covered by unskilled laborers. What is the demand, what is the supply:

Sloppy installation of the roof covering, visible to the naked eye, is unpleasant. But gross violations of installation instructions are even worse. They lead to a sharp decrease in the service life of the roof, and deprive you of decades of manufacturer’s warranty.

Almost every person starting to build their own home is limited in funds. You need to be careful and pay close attention to the origin of roofing materials! “Cheap” construction sites are being infiltrated by cheap counterfeits and substandard products. This is wasted money. Material that should last for decades will have to be changed after 6 - 8 years:

To ensure that your costs meet your expectations in terms of service life, reliability and appearance of the house, contact only official representatives of well-known brands who are ready to fulfill warranty obligations upon the client’s first request.

It is best to purchase roofing materials from well-known manufacturers directly or from their large official dealers. This guarantees a quick solution to any problems, or rather their absence for the entire service life. Anything bought cheaply on the market results in frayed nerves and additional expenses.

In the photographs presented above, it is not only the roofing material that is to blame. This includes violation of roof installation instructions - cutting metal tiles with a grinder and improper installation of under-roof ventilation, which led to overheating of the roofing material on the sunny side. High quality material would have lasted longer, but also not the entire period allotted to it. Violation of installation instructions will void your manufacturer's warranty!

Roofing and foundation are the main types of work in the construction of any house. In order for the foundation and roof to be reliable, strong and durable, special knowledge of an engineer and designer is needed. And high-quality roofing comes from the experienced hands of a qualified roofer.

Foundations in Hotwell are handled by a separate unit with its own special teams (more details).

Hotwell pays increased attention to the theoretical and practical training of employees in the roofing business. Everyone is learning, both engineers and builders, including those who have been making roofs for decades.

Professional tournaments

Roofing Marathon 2015 (more details):

Roofing Tournament 2017 (more details):

Video 2021:

Roofing Tournament 2018 . Prize 2nd place in the nomination “Flexible tiles”:

3rd place in the nomination “Metal tiles” and 2nd place in the nomination “Underroofing layers of pitched roofing”:

Victory in the Roofing Tournament 2019 in the “Metall Tiles” category:

Below we give a brief overview of the roofs that Hotwell makes for SIP houses.

Metal tiles

One of the most popular types of roofing. Can be installed in any weather, including any frost. Long service life if installed correctly. A huge number of colors, textures, coatings. Selections from samples can be made at the Hotwell office. The company's roofing specialists will advise and help you make the right choice.

Most often we use premium metal tiles made from RUUKKI steel (Finland) 0.5 mm thick with enhanced protection (first class galvanizing).

High-quality steel ensures the durability of the roof. Warranty period up to 25 (!) years. For reference: with proper installation, the actual service life of roofing materials is usually 2-3 times longer than the warranty.

The ability to custom cut sheets of metal tiles at the factory for a specific project often allows us to cover roof slopes without joints of metal tile sheets along the length. In difficult cases and on complex roofs, metal tiles are cut according to the manufacturer’s instructions using special electric shears for metal tiles. All teams are fully equipped with the necessary tools for roofing work.

Flexible bitumen shingles

One of the most popular types of roofing. The service life of high-quality bitumen shingles, like metal tiles, is very long. The only “disadvantage” is that laying bitumen shingles requires positive temperatures and weather without precipitation. In winter, if the choice of flexible bitumen shingles is important, we preserve the roof before the onset of warm weather, i.e. until spring:

There have never been any problems. While time passes, in the SIP box at home you can do interior decoration and wiring of utility networks.

Flexible tiles are a convenient material for complex roofs. Large selection of manufacturers. Variety of shapes and colors. Hotwell specialists will help you choose bituminous shingles.

Autonomous gas roofing drum nailer PASLODE CR175C (USA):

Composite tiles

Composite tiles add a touch of luxury to your roof. The price corresponds to the high quality - composite tiles are several times more expensive than conventional metal tiles.

The multilayer structure of composite tiles is based on a steel sheet, which is coated on both sides with an aluminum-zinc alloy and a protective material. Basalt chips and a layer of acrylate are applied to the outer side, which serve as additional protection from external influences and allow you to imitate ceramic tiles.

This structure reliably protects the steel from corrosion, which increases the service life of the roof to 70 years. Manufacturer's warranty is 30-35 years.

Attaching composite tiles to sheathing differs from attaching metal tiles. Hotwell crews are trained and experienced in installing composite tile roofs:

Natural and cement-sand tiles

Natural (ceramic) tiles are among the elite and most durable roofing coverings. Cement-sand tiles (CSCH) are cheaper than ceramic tiles, but look no worse. BRAAS factory

, built in Russia, cement-sand tiles have become widespread in individual construction:

Other types of roofs

Soft roof

We make roll waterproofing materials on slopes with a small slope (flat roofs):

Polymer membrane roofs are also designed for waterproofing flat roofs and roofs with a slight slope. This type of roofing is indispensable when installing roofs of houses in the High-Tech style used as terraces.

Polymer (PVC) membranes are a modern waterproofing material. Today, PVC membrane is in great demand all over the world. In Europe, more than a quarter of all roofs are protected by PVC membranes (according to AMI Consulting). In 2014, the Hotwell company mastered the thermowelded method of installing this type of roofing:

Hotwell has trained specialists, workers and special equipment from the world's leading manufacturers at your service. In the photo below is an automatic welding machine Leister Varimat V2 (Switzerland), designed for overlapping PVC membranes and other roofing materials:

Cellular (cellular) polycarbonate

We use the following for installing canopy roofs when it is necessary to improve the illumination and insolation of windows facing the terrace:

Ondulin

- inexpensive, practical roofing material. It has been produced by the famous company Onduline for more than fifty years. Previously, we ordered more often for SIP houses. Now less often, although this is not the worst budget option:

Profiled sheet

- an analogue of metal tiles. Different colors, different profiles. Easier to install than metal tiles, since the corrugated sheet is not so demanding on the pitch of the sheathing:

Next stage >>>

What to pay attention to

When installing a panel roof, it is very important to ensure proper protection of the ends of the pie. For wooden panels, this is done using OSB sheathing: the slab is cut into boards as wide as the thickness of the panel, and then secured with self-tapping screws and bitumen mastic. It is necessary to ensure that the shell is absolutely airtight, for which it will also not be superfluous to coat all longitudinal and transverse seams with mastic.

For metal panels, the top and side ends are sealed with L-shaped or U-shaped wind strips made of roofing iron. Transverse joints often have an overhang of the metal coating, but it is important to ensure that the length of the overlap is not less than that allowed for the existing slope. The lower joint is closed with a U-shaped strip, one of the edges of which is not rolled: it inserts the overlay into the body of the panel close to the upper metal shell to a depth of 100–150 mm. From below, the strip is adjacent to the outer plane of the shell and is attached to it with self-tapping screws with a sealing washer.

As a rule, the upper and longitudinal ends of the panels are slightly shifted inward relative to the outer plane of the walls. At the same time, a straight parapet is erected on the sides and top, which will ensure the integrity of the facade and additional protection of the roof pie. But at the same time, it is imperative to cover the junctions of the panels with the roof flanging with drip strips.

Which SIP to choose

Purchasing the right type of panels is the first point in the instructions for installing a composite roof. Depending on the properties of the material, different installation schemes can be used, and the set of technical solutions also differs. The required panels are called roofing panels; only two types are suitable for the purposes under consideration.

If the roof is going to be covered with weld-on insulation, bitumen shingles, seam sheets and other materials suitable for use at low slopes, it is better to give preference to panels with a double-sided shell made of OSB 3 or 4 classes. It is very important that the binder of the inner shell of the panels is synthetic wax, while the outer shells must be impregnated with urea-formaldehyde resins. This is the best option, but other variations are possible; you just need to remember that the inside of the panels should not emit volatile substances.

Metal panels form an almost finished surface of the rough ceiling and a completely completed roof covering. The main difference between such materials is the type of protective coating (the most preferred are Pural, Plastisol, PVDF) and the design of the connecting lock. The latter must have a counter bead that prevents moisture from seeping into the joint, or be designed for rolling. Many imported panels use a system of sealing tapes instead of a mechanical valve, but there are few high-quality materials sold using this scheme on the domestic market.

Hip and half-hip

They are characterized by the presence of two slopes in the shape of a triangle and four in the form of a trapezoid. The first slopes are called hips, they are located on the side of the gables. To implement such a structure, high professionalism of builders is required. The design is difficult to implement, repair, and maintain.

With a half-hip design, all 4 slopes, having the shape of a triangle, converge at 1 point. In fact, they form a figure similar to a pyramid. Such varieties can be found in regions where there are strong winds.

Flat roof structure

It is generally accepted that the construction of walls and ceilings is the only purpose of SIP. However, the strength and load-bearing properties of this building material are sufficient to withstand not only snow, but also limited operational loads. The structure of incompressible filler in a double-sided rigid shell has almost the same mechanical model of load perception as a reinforced concrete product. This greatly facilitates the calculation of the strength of the structure.

There are two methods for installing a flat composite roof. The first involves the use of panels in a shell made of wood-based materials filled with mineral wool. The panels are laid on a frame support system, and waterproofing, spacer sheathing and roof covering are successively installed on top. Technologically, this option is more complex; the influence of the human factor is too great, but the quality of the materials used has minimal impact on the final result. As a rule, roofing of this design is cheaper.

The second type of flat roof consists of metal-clad panels. Roofing galvanized iron is covered with decorative and protective polymer layers; in fact, the outer shell is a profiled sheet. Such panels are much longer and allow covering spans up to 6 m long. With such a roof structure, a lot depends on the quality of the protective and decorative coating, the correct profile of the locks, and the availability of adequate sealing means.

Roof surface care

To increase the service life of your roof, you should regularly perform the following activities:

- inspect the roof for scratches; if damage is found to the protective surface, it should be restored;

- Debris removal should be done carefully, avoiding damage to the coating;

- use a wooden shovel to remove snow;

- When cleaning dirt, you should not use chemicals. It is necessary to wash the surface with clean water or soapy water, and then thoroughly rinse with plenty of water. Cleaning with a small amount of white spirit is possible. After washing, wipe with a cotton cloth;

- clean the drainage system from debris and fallen leaves.