Hoods can operate in various modes and provide productivity reaching 1000 m3 of air per hour. Thanks to the use of high-quality engines, these figures are achieved without significant energy consumption. The user can choose models that fit the size of his room. Models with a capacity of up to 600 m3/hour are suitable for small kitchens, and for larger ones - up to 1000 m3/hour. In this case, the owner can choose the fan rotation speed, of which there can be 3. Also, some devices are equipped with an intensive mode, which is used to quickly remove air from the room or eliminate smoke that has formed due to improper cooking.

If you use a hob, oven, steamer or microwave oven, installing a hood will be a very important factor in ensuring a comfortable stay in the room. The fact is that during cooking, the temperature in the kitchen rises. If you don't provide proper ventilation, cooking will become a real nightmare. A good hood is an excellent solution that replaces natural ventilation and makes the atmosphere in the kitchen pleasant for everyone.

Installing a carbon filter in the hood. Operating principle

There are two main types of kitchen hoods.

The first are flow-through, providing for the removal of polluted air to the outside through an external ventilation system. As for the latter, these are recirculating kitchen hoods that use carbon filters to clean air masses. The air passing through them does not leave the premises, and therefore they can function without an air duct pipe - unless we are talking about combined hoods that combine the functions of both types of these devices. Which option is better - flow-through or with a filter without outlet? In many ways, the answer to this question depends on your preferences, but if the compactness and ergonomics of equipment capable of excellent air purification is of fundamental importance to you, opt for the second option. In addition, it is cheaper and easier to install it, and we will tell you below what the filter elements necessary for the operation of these devices are.

As you might guess, the carbon filter for exhaust hood uses activated carbon as an active substance - a highly effective absorbent that is needed in many sectors of the economy and is successfully used in them. The air passing through it is thoroughly cleaned, as a result of which the undesirable components included in its composition remain inside the filter - without a chance to escape outside.

You should also remember that a good carbon filter for a kitchen hood can purify the air at different rates. This is due to several key factors, namely:

The carbon filter purifies the air at different rates

- filler quality;

- degree of wear;

- operating mode of the device.

The installation of a carbon filter in the hood is carried out behind the fat barrier.

As for determining the degree of wear of a given cleaning device, some of them provide for the presence of built-in indicators that signal that the life of the filter in the hood has been exhausted. In other cases, the need to replace the purifier in a coal kitchen hood can be determined purely empirically - as mentioned above, a worn-out cleaning element works much more slowly, not fully coping with the responsibilities assigned to it.

Replacement instructions

As we found out above, disposable fat, combined and carbon cassettes cannot be regenerated by washing or rinsing. A contaminated element should be replaced if the following signs are detected:

- the indicator mark or the inscription on the thin grease filter, applied by the manufacturer, has changed color (usually turns red);

- the thrust has decreased significantly, the noise of the fan has noticeably increased;

- The carbon cartridge has expired;

- Some brands of hoods are equipped with differential pressure sensors, which indicate that the filter fabric or carbon cassette is completely clogged.

To remove the outer fat pad, simply unlock the 2 latches located at the edges (some models use one lock)

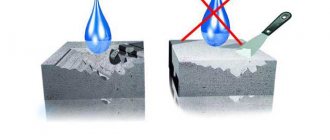

Attempts to wash a clogged disposable filter have, of course, been made by many users. The result is negative; it is impossible to remove absorbed fat from the fibers. Washed synthetic filler gets clogged up again quite quickly.

First you need to buy an air purification element for a specific hood. It is better to give preference to original filters of the same brand as your household appliances. In other cases, the manufacturer does not play a special role. If you cannot find a product of the required size, take a universal grease-absorbing filter - it fits most exhaust devices.

The universal aluminum mesh can be cut to the desired size and placed in an old frame

How to remove and install a new filter that captures grease vapors:

- Disconnect the device from the household power supply by unplugging the plug from the socket. It’s a good idea to be careful – during disassembly of some models you may accidentally hit the fan start button.

- Pull the built-in panel towards you until it stops.

- At the bottom, find the latches or plastic clips that hold the frame with the filter insert. Unlock them and remove the part.

- Disconnect the used filter and install a fresh one. The frame should be pre-washed with kitchen detergent and dried. Let's watch the replacement procedure in the video:

Cassettes filled with activated carbon are usually located behind the grease trap. To get to the carbon filter, the latter must be removed. The cartridge itself is secured with clamps or a Phillips screwdriver.

Before servicing a wall-mounted tilting hood, fold down the front protective shield. How to install a carbon filter on a similar household appliance is shown in a short video:

How to remove the filter from the hood. Coal

If we are talking about recirculation models that purify the air in the kitchen and send it back into the room, then a carbon filter for the hood is mandatory. Indeed, in such models it is important not only to remove soot and grease, but also to cleanse the air of foreign odors.

The installation of a coal “catcher” is provided behind the grease catcher. This element is based on a high-quality adsorbent, activated carbon. It perfectly absorbs all odors.

It should be remembered that in recirculation mode, the throughput of the hood drops by 15-20%, and the installation of an absorbent product reduces it even more. If the carbon adsorbent accumulates contaminants, then the air through it will pass worse and worse.

A carbon filter for hoods is often not included in the basic package and must be purchased additionally. In addition, this is a replaceable element that will have to be purchased regularly as it wears out.

Externally, such an element may look like a rectangular cassette or a circle. The body of the product is plastic, and the coal is held in place by a special mesh. Activated carbon is here in the form of powder or granules.

The larger the total area of absorbing particles, the better the “catcher” works.

Due to coal compacted in one place, the efficiency of the hood decreases. The process for replacing the carbon filter is as follows:

- The hood is disconnected from the network (this is necessary for safety);

- The anti-grease filter is removable;

- The carbon filter is removed from the cassette;

- A new carbon filter is being installed - a click indicates that the operation was carried out correctly;

- The hood is turned on and checked for vibrations and extraneous noise, which could be caused by improper installation of the filter elements.

How to clean greasy metal mesh

It is recommended to wash grease and soot from mesh filters made of stainless steel or aluminum at least once a month. The ideal option is weekly washing, then the grille does not have time to become overgrown with plaque and is easy to clean.

The easiest way to remove deposits, recommended by manufacturers, is to remove and place the catch screen in the dishwasher. This option is not suitable in case of heavy soiling, and not every home has a dishwasher.

To clean the grates, use any alkaline-based household products that dissolve fats:

- regular baking soda;

- laundry soap;

- gel intended for washing dishes and plumbing;

- cleaning fluids for ovens, gas and electric stoves (some come in a spray bottle).

Advice. In particularly advanced cases, when the hood has not been washed for years, the listed chemicals will not help. Buy a powder or gel for breaking through clogs in sewer pipes like “Mole” or a caustic liquid that clears soot from pots (for example, “Milam”). Be sure to wear rubber gloves while working!

If the contamination is minor, there is no point in purchasing household chemicals - just wash the mesh with soda. How to clean a metal filter using this method:

- Remove the dirty hood grate and place it in a wide iron container (bowl).

- Prepare a cleaning solution consisting of 3-5 liters of water and 1-2 packs of soda. Pour the liquid into a bowl with a wire rack.

- Heat the container on the stove and boil over low heat for 10-15 minutes. If the dirt does not come off, continue boiling. After rinsing and drying the filter, replace it.

Important point. Before installing the cleaned mesh, carefully inspect the internal cavity of the hood and the fan housing - you will probably find drops of grease on the surfaces. We mentioned the reason above - mesh elements do not retain 100% of vapors. It is better to remove plaque immediately - once it has accumulated it is much more difficult to clean.

Gels and special cleaning liquids are used according to the instructions on the packaging. Typically, the product is applied to the filter grid and left for the specified time. It doesn’t hurt to additionally rub the mesh cells with a hard plastic brush or brush, then wash with running water and dry. The technology for using various means is shown in the next video:

How to install a carbon filter in a grow box. Growbox ventilation

Ventilation is a very important component of any grow box. It allows not only to renew the air inside the structure, providing an influx of carbon dioxide, but also to remove hot air that occurs due to the heating of lighting fixtures during operation. This makes life much easier for the grower, because it becomes much easier for him to maintain a favorable temperature inside. Also, do not forget that with the help of ventilation you can regulate the humidity inside the grow box, a favorable indicator of which is the key to effective fight against mold. Lastly, ventilation allows the grower to eliminate various types of odors and pollen. To do this, a carbon filter is installed in it, which does not allow aromatic compounds to escape.

How to calculate ventilation in a grow box?

Ventilation in the grow box is calculated based on the volume of the internal space. To prevent odor from being heard outside the structure, the air inside it must be completely renewed within 3-10 minutes. The volume is calculated by multiplying the height, length and width of the structure. Next, it is calculated how many times within an hour the fan will have to refresh the air inside. To do this, 60 minutes are divided into the selected interval. Depending on the resulting number, we calculate the required fan power by multiplying it by the volume of the grow box. We add 20% to the new number, thus taking into account losses due to air movement. We choose a carbon filter with the same or increased performance. We remind you that the outlet of the ventilation system should be at the top of the grow box, since hotter air always rises.

Components of the ventilation system

First of all, the basis of any ventilation system is a fan, which is installed to exhaust air outside the grow box, attached to the outside of its wall. As an example, I would like to give the duct fan model TD-MIXVENT 160/100.

Its productivity of 160 m3/hour will be quite enough for a stealth box and a small full-fledged grow box. It works almost silently. Its engine is protected from the negative influence of external factors in accordance with protection class IP 44, which provides it with a long service life. In case of overload, the fan can turn off on its own. The grower can also regulate the voltage supplied to it, which allows you to change the operating speed.

The MagicAir 160/100 m3 carbon filter will work perfectly in tandem with this fan, allowing you to clean the air inside the grow box.

All thanks to a cartridge with high-quality activated carbon, which is recommended to be changed only once a year. The model is equipped with a replaceable fabric pre-filter, which can significantly extend the working life of the cartridge by trapping dust, pollen and other small particles. It lasts for 3 months of work, after which it is enough to simply wash it. The material does not lose its qualities within 3 washes.

The last element of the ventilation system is the air duct. For the ventilation elements already mentioned above, an Aludec DA3 air duct with a channel diameter of 102 mm would be suitable.

It has a layered structure consisting of aluminum foil and polyester, which is based on steel spirals. The corrugated surface provides the air duct with ideal flexibility. Its total length is 10 m. It is secured using ordinary clamps.

Grease filters

Any kitchen air purifier must have a grease filter. It is designed to clean the air flow passing through the device from small suspended fatty particles. If it had not been there, then less than a month would have passed before the internal surfaces of the hood, including the engine, were covered with a layer of oil suspension.

The grease filter can be disposable or reusable - it is clear that the latter type is better and more practical. Disposable models are made from padding polyester, acrylic or non-woven fabric and are most often installed in budget flat-type structures. Such “rugs” made of synthetic fabrics are thrown away as soon as they become dirty.

Disposable fat “catchers” cannot be washed; when washed, they lose all their properties. That's why they are disposable.

Using an “updated” product in this way is fraught with engine damage.

But a metal grease filter will last as long as the hood itself - it is distinguished by its quality, safety, reliability and durability. Such designs are better because they do not need to be replaced, but only require periodic washing.

A traditional grease filter is a cassette in the form of a metal frame and a mesh element made of foil (in the form of a mesh or with perforation). The perforation here can be uniform or asymmetrical, and the provided cells are necessary to change the direction of air flow. This allows fat particles to be retained on the surface.

The metal grease filter can be made of aluminum, galvanized steel or thin stainless steel. In high-quality technology, aluminum is additionally anodized, which protects the product from oxidation. Such structures can have several layers or be made in the form of several modules. Two or three separate cassettes are easier to maintain - they are easy to remove, wash and return to their place.

A stainless steel grease filter is considered better than an aluminum one, since this material has a longer service life. In addition, products of this type purify the air more effectively.

Carbon filter for cata hood. Carbon filters

Dear customers, we offer you several opportunities to save money when purchasing carbon and grease filters:

— 4 sets of carbon or grease filters for the price of 3!

This is a simple, convenient and profitable solution for all connoisseurs of clean air in the home, protecting expensive kitchen furniture from settling fat and protecting the hood motor (extending service life). After all, 4 sets are a supply that allows you to not have to worry about buying a new carbon filter to replace a used one for 1 or even 1.5 years (the service life depends on the frequency of use of the hood and the intensity of cooking).

— 3 sets of carbon filters for ELIKOR hoods for the price of 2!

The promotion applies to filters - an analogue of the F-03 filter (F-03) and an analogue of the F-00 filter (F-00). You place an order for 2 sets and receive another one as a gift!

— 3 sets of carbon filters for KRONA hoods for the price of 2!

The offer applies to filters - analogue of filter type K5, type K5 new, art.971.1190.05 and - analogue of filter type KU, type KU new, art.971.1000.03. You place an order for 2 sets and receive another one as a gift!

About the need to use carbon filters:

Working in the kitchen involves not only the process of preparing delicious dishes, but also associated fumes, odors (and not always pleasant ones), combustion products, flour dust and many other things that are not visible to the naked eye, but “successfully” settle on the walls, furniture, ceilings and in our bodies. All this can be countered by a kitchen hood, which, depending on the power, will clean the polluted air in a short time, preventing it from spreading throughout the apartment.

One of the most important elements of a ventilation device are filters for hoods, which carry a significant functional load. There are two types of filters for hoods - carbon and grease. At the same time, despite the prevailing opinion that carbon filters are used only in hoods that have a recirculation mode, they are also necessary for units that operate in exhaust mode.

Thanks to carbon filters for kitchen hoods, various types of odors that accumulate in excess in this room are effectively removed. Such filters include adsorbent substances: chemically treated sludge and activated carbon, which purify the incoming air, while absorbing all odors and firmly retaining them. There may be one or two such filters depending on the power and number of motors. It is necessary to take into account that they are not included in the package of hoods, as a result of which a carbon filter for further replacement should be purchased separately.

Timely replacement and quality of filters have a serious impact on the operation of the kitchen hood, because... depending on the degree of filling of the filter, air begins to circulate more slowly, and therefore its cleaning is significantly reduced.

Accordingly, replacing the filter is a necessary operation that must be performed after a certain time period of 2-6 months. There is a dependence of the service life on the intensity of use of the hood, as well as the manufacturer - the instructions for use contain all the necessary information.

We recommend Zeman filters, they are made specifically for hoods CATA, Krona, Jet Air, Apelson, NODOR, ELIKOR and will provide minimal power loss and double protection against odors and grease, which means additional protection of the motor and extension of the life of the hood. High quality workmanship guarantees accurate dimensions and convenient, quick replacement. In addition to the cardboard box, Zeman filters are additionally packaged in a bag with a zip lock fastener for quick and clean disposal.

You can buy filters for CATA, Krona, Jet Air, Apelson, NODOR, ELIKOR hoods on the company’s website, where they are presented in a wide range.

Types of kitchen hoods

The hood is an important element in ensuring normal ventilation in the kitchen. The speed at which odors are removed from the room depends on its effectiveness.

Carbon filters are a mandatory component not for all types of hoods, but only for recirculating ones, so let’s first remember what types of air purification devices there are in the kitchen.

According to the method of air flow, all hoods can be divided into three categories:

- flow-through;

- circulation (recirculation);

- combined.

Flow hoods are connected to the ventilation duct using a rigid or flexible air duct.

The air containing kitchen fumes enters the hood and then into the ventilation. Various types of flow-through devices are also equipped with filters, but their function is slightly different - to protect the motor from an aggressive environment.

Recirculation devices do not require air ducts.

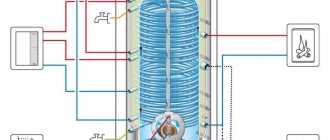

The air flow in the circulation model comes from the stove into the housing, passes through 2 cleaning stages (2 types of filters - anti-grease and carbon), and then returns to the kitchen space.

Combined models have an additional recirculation function. That is, you can insert carbon filters and start the recirculation mode, or you can connect an air duct and use the flow function.

Do-it-yourself carbon filter for extractor hood. DIY carbon filter for grow box

The “crazy hands” section is gaining momentum and today we have prepared instructions on how to make a carbon filter for a grow box with your own hands. But first, some useful information to broaden your horizons

Properties of coal for eliminating odor

The basis of any carbon filter, which is basically clear from the name, is activated carbon. 97% activated carbon consists of carbon and contains practically no foreign impurities. The structure of coal is made up of amorphous carbon crystals and graphite, making it highly porous and ideal for filtering polluted air. Thanks to the chemisorption process, pollutant molecules are absorbed on the surface of activated carbon and this process is irreversible.

We wrote more about why you need a filter when growing indoors and how to choose a ready-made one in this article. If you still plan to assemble your grow box filter yourself, use our step-by-step instructions below.

Required parts and tools

What you will need to assemble the carbon filter:

- air filter from a car (we use a filter for a GAZ car);

- Activated carbon;

- galvanized flange with a diameter of 100 mm;

- washers, nuts, rivets;

- drill with 4 mm drill bit;

- jigsaw, soldering iron, metal scissors.

The choice of an air filter for a car is due to the fact that it already contains the mesh we need, which greatly simplifies the task of creating a carbon filter.

Assembly steps

The first stage is to get rid of the filter paper.

It is held in place by foam and comes off easily with normal heating. However, you should not use a lighter to heat it - it will take too much time. A hotplate is perfect for this manipulation. Place the filter cover on the burner and wait a little, when everything heats up, carefully remove the filter (don't forget to wear gloves!) and remove the paper.

The second stage is to reduce the diameter of the internal mesh.

Since our flange is 100 mm, the internal mesh must be reduced using metal scissors.

The third stage is to rivet the outer mesh.

In the place where you placed the flange, you need to connect the cover to the flange itself and the external mesh. You should end up with something like this.

The fourth stage is to solder the nuts.

On the back side of the filter we solder the nuts into which the screws will be screwed. This is necessary so that you can replace the used coal.

The fifth stage is the final one.

Finally, we spray the entire structure with activated carbon. It is advisable to do this on a vibration stand for good compaction and close the lid. Don’t forget to seal the foam rubber around the ends of the filter; it is necessary to compensate for the free space after compacting the coal.

Bottom line

You get a carbon filter with a length of 22 cm, a diameter of 18 cm, a flange with a diameter of 100 mm protrudes 6 cm, if the flange protrusion is in the way, an angle grinder will help you.

For those who are not particularly “mom’s engineer,” we suggest that you familiarize yourself with a large assortment of ready-made carbon filters here. Wishing you great harvests!

Interesting facts about activated carbon

This is not a medical page, but it will be interesting to know about the component. Extraction comes from ordinary charcoal. By combining positively charged electrons with carbon in the formula, we get the finished product. It is used in different areas of life. Carbon filters are made from a natural component obtained after burning hardwood, walnut or coconut shells and other carbon materials.

Carbon is subjected to special chemical treatment and, as a result, the product becomes porous, subject to adsorption and other reactions.

Did you know that the specific surface area of one gram of activated carbon is approximately 500 m²? This figure can be compared to a tenth of a football field. The cassettes are filled with this activated sorbent and closed on the outside with a fine mesh. It traps mechanical contaminants. Such filters are not used in industry. They are more efficient in the home. In small rooms and kitchens, filters reveal their usefulness, uniqueness and productivity.

Charcoal filter in package

Many buyers are thinking about buying a universal filter. It's comfortable. There is no need to look for a suitable model, which may not be available in the nearest store. Elikor carbon filters are in particular demand. In addition to the fact that they fit most hoods, they are also inexpensive. Of course, universal models will be inferior to the original filters, but if you urgently need to replace an element and don’t spend a lot of money, this one will do just fine.

Advantages of a recirculating hood

The question immediately arises: why buy a hood with filters (and this is an additional expense), when you can simply install a model with an air duct that does not require annual investments?

In fact, recirculating hoods are very popular due to the following advantages:

- Autonomy . The device does not require a ventilation system to operate. If the exit to the ventilation shaft is in the opposite corner, you don’t have to worry about the design of the air duct, but simply install a model with a carbon filter.

- Compactness. The housing takes up a minimum of usable space above the stove, and its “working” part easily fits in a small cabinet. With sliders, the surface does not protrude beyond the border of the cabinet until it is time to turn on the device by sliding the panel over the stove.

- Heat retention. In winter, when the outside temperature is below zero, frequent ventilation threatens heat loss in the apartment. When using a hood with filters, there is no need to open the vents (unlike flow-through models, which require air flow).

- Easy to install. The hood is inserted into a cabinet suspended above the stove or simply attached to the wall. There is no need to create either an air duct or hanging structures to disguise it.

- Easy care. To ensure that the functionality of the device does not suffer, you need to change the carbon filters on time and periodically clean the anti-grease filters.

The cost of recirculation models can also be considered an advantage, since it fits well within a modest budget - on average from 2,200 rubles. up to 5000 rub. Plus, about once every six months you need to purchase a carbon filter, which will cost 350-900 rubles.

Additional information about recirculating hoods, their application and installation features is provided in the articles: