Living in a cottage or having a dacha with a house and a bathhouse, many people set up a shop on the premises or in the yard. If in a bathhouse it is used only for its intended purpose - for sitting, an outdoor one can also decorate the landscape.

The height of the bench is selected individually. For a tall person or a child, it will not be the same, but there is an average size that is comfortable for most. The appearance, depending on the material and the creative imagination of the manufacturer, can be very diverse.

Garden furniture set

Optimal sizes

Benches come in both stationary and transformable versions, which allows you to put them under a roof for the winter. True, folding ones are not so varied in design, and may not be combined with anything, but they have traditional sizes.

Corrugated pipe and glued wood panel – what could be simpler?

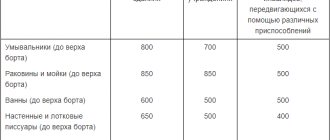

Parameters of benches that are considered comfortable:

- The width of the bench - in a gazebo or in a bathhouse (unless it is a shelf for a steam room) varies between 370-500 mm.

- The standard bench (seat) height is 400-500 mm.

- The height of the backrest is 450-550 mm with an inclination of no more than 45 and no less than 15 degrees.

- The height of the side armrests is 180-220 mm.

- The average length of the product is 2.2 m.

If you convert inches into centimeters, you get 44.5 * 37.5 * 160 (height * width * length)

These parameters are the most optimal, the size of the bench for a bath or sauna also corresponds to them.

Dimensions of the bench and board for it

In the garden, in the bathhouse, and especially in the gazebo, you can install a semicircular bench. Apart from the radius of curvature, all other dimensions are the same.

Almost round bench

Product made from cinder blocks and timber

An unusual bench without a back can be built in a few minutes.

The bench will be collapsible. It can be used as a sleeping place (if you add a mattress) or for sitting. The legs will be half-solid cinder blocks with holes made through them. How many cinder blocks you need depends on the width of the bench. You will need 8 blocks if the seat consists of 4 bars, 6 blocks for 3 bars. It is necessary to select the bars with a cross-section so that they can be inserted into the through holes of the cinder blocks. If necessary, cut off the ends (if they do not go through). To give the bench an aesthetic appearance, you can paint the cinder blocks with multi-colored façade water-based emulsion. Paint material in a can is suitable for this. Place multi-colored blocks opposite each other in a vertical position. Place the ends of the bars inside the windows. To make the bench more stable, you can tighten the cinder blocks of each support with a belt.

Seat width

The comfort of sitting on a bench directly depends on the width of the seat. For an adult, the minimum width is about 410 mm, and the standard is 500-600 mm. Of course, there are many other options, benches with dimensions of 900 mm. For example, on a 110 cm bench you can sit on both sides at once quite comfortably, without disturbing the people relaxing nearby. It is impossible to say which width is better: it all depends on personal preferences and the place where this or that product will be located.

Metal and wood

The simplest benches on a metal frame use a square profile.

You can weld two sidewalls in the shape of the letter “H” from a profile pipe, and a solid wooden seat will also serve as a “stiffener.”

The following example also uses solid wood as a stiffening element, but the supports are made in the form of a square with a cross member for attaching the seat.

And this is the simplest self-supporting structure made of a square profile, the strength and rigidity of the welded base is sufficient for the seat to be made from a wooden block.

The following photo shows a factory-made bench.

rmnt.ru

Beautiful examples

Let's look at a few examples of how metal benches decorate areas.

- A metal bench in an antique style, without the use of wood parts, will look gorgeous in the local area. The seat and backrest of the structure can be decorated with metal rosebuds. This product will look especially impressive against the background of stone walls or a fence.

- A frame welded from metal under a wooden seat does not necessarily have to have perfectly straight and regular lines. The legs of the structure can be thin, with slight bends. The metal back can be entirely decorated with floral or plant patterns. To give the bench a more interesting look, the metal components can be painted dark green.

- A vintage bench with a metal base made up of openwork sides and the same back, painted white, will look great in the garden. A seat made of dark natural wood will stand out well against the background of graceful lines and carved patterns.

Bath bench - drawings

A bench for a bath is an indispensable piece of furniture:

- relax after the steam room in the relaxation room

- wash yourself, placing the basin on the bench next to you

- as a footrest

- and so on.

Depending on the purpose, the bench is made narrower or wider. If it’s for the legs, then it’s a very small height.

The steam room requires a small bench, but a larger one can be placed in the relaxation room. And so on.

How can you make it yourself?

Of course, made of wood.

First option.

Bath bench 1.5 mm long and seat width 300 mm

All elements of the bench are taken from a solid board. Preferably.

- If there is no 300mm wide board for the seat, then you can join the seat from two 150mm wide boards or three 90-120-90mm wide boards

- The legs (sidewalls) must be made from a solid board 260mm wide, according to the drawing: cut in three places along a radius of 160-140-160mm. You can adjust the drawing of the sidewalls up to 250mm wide (10mm will not play any role).

- A crossbar made of a 200mm wide board (the beam in the drawing) is designed to give stability to the bench, since it connects all the elements: the legs are connected to each other and the seat acquires an additional, third point of support (see “Unit B”). If you take a board with a width of 150mm, then, naturally, you need to change the dimensions in Node “B”: 75mm of crossbar height instead of 100mm. 75 mm will be enough, especially if all the elements are made from 50 mm thick boards.

- All parts according to the drawing are made from 30mm thick boards, but you can change the thickness by using 50mm boards. The bench will be stronger, but the weight will increase.

- The connection of the seat with the legs (sidewalls) is provided on dowels, and the sidewalls with the transverse board (beam) are provided with self-tapping screws.

This version of a bench for a bath is good because the transverse board is a stiffening rib for the seat, therefore it will not bend under any weight.

If the bench according to this drawing needs to be made longer, then boards thicker than 30mm should be used.

This bench is suitable for both a rest room and a washing room, because its height of 450mm is the optimal size for a sitting person.

Second option.

Drawing of a bench for a bath with a length of 390-500m and a seat width of 160mm

The second version of the bench drawing is very similar to the first. Only the crossbar is not made of a board, but of a block that cuts into the middle of the sides.

You can connect the parts using dowels or wood screws.

The bench is small: 390-500mm long, seat width 160mm and height only 200mm. This bench is most suitable as:

- footrests

- shelf step

- basin bench

Third option.

Perhaps you will prefer the option of making a bench from 50x50mm bars:

- smaller area for processing parts: sanding, painting, etc.

- there is no need to cut out the parts of the sidewalls (legs) along the radius from the board

- simpler joints for connecting wooden parts made from bars of the same cross-section. Without insert. On self-tapping screws.

Bench for a bath made of bars:

- 2 parts of the sidewalls are assembled from two legs and two crossbars

- two assembled sidewalls are connected by two crossbars at the level of the lower transverse bar on the sidewalls: they are placed with their ends directly on the transverse bars of the sidewalls and attached to them with self-tapping screws.

- the seat is assembled from three to four bars (depending on the desired width of the seat) with small gaps between each other

This is exactly the option discussed in the video when assembling the bench:

Decorating the space on the side of the bench

Flower beds that are laid out on both sides of the garden bench should not be too high. But their volume and choice of plants are selected based on personal preferences. Most often, a design style is chosen that will be in harmony with the rest of the green spaces.

When planting plants, you need to take into account the changing seasons. The surroundings of the bench should always look attractive, both in spring and autumn.

Flower beds that are too low will not look very interesting. In this case, to add splendor, you need to dilute the flower beds with flowering shrubs and decorative trees of original shape.

Paniculata or ash hydrangea, spirea or rhododendrons look great planted on the side of the bench. If the place is not too shady, you can plant rose bushes.

Undemanding perennials are also suitable for decoration.

- black cohosh;

- chrysanthemums;

- delphiniums;

- garden geranium;

- lupins;

- penstemons;

- asters;

- astilbe.

It is better to plant flowers in small groups so that the colored spots are clearly visible. Multi-colored fragments create a harmonious single canvas of the flower garden and look very beautiful.

To make the seasonal colors look great, you can plant summer trees in front, which will emphasize the overall style of the composition. To do this, you need to allocate a special place where you plant different types of annual flowers every year. If you want to emphasize the spring mood, plant small “nests” of bulbous plants between perennial plants.

- hyacinths;

- tulips;

- snowdrops;

- daffodils.

The greenery of later perennials will hide their withering, while in early spring they will give the charm of awakening nature and give the awakening garden a festive look.

If you are creating your own nook in the garden from scratch, first plant plants behind the back of the bench, and then plant flower beds on the side of it. It is not necessary to plant all the plants at once. You can start with larger ones and when they grow well, start decorating the “sidewalls”.

Flowerpots installed on the sides of the bench look very beautiful and advantageous. Such interesting decor gives the recreation area a unique stylistic expressiveness.

You can plant different plants in large pots every year to create a unique flower arrangement around the bench. In this case, it is easy to experiment with colors, change plants every season, choose the top perennials and annuals to decorate the overall ensemble.

Manufacturing options

You can make a wooden bench with your own hands. The simplest outdoor design is two posts and a crossbar for sitting, but you can also add a backrest, armrests and even a canopy. In addition, wood can be easily combined with other materials, and it can also be processed in different ways, for example, adding an antique finish. Making beautiful garden furniture is not difficult if you use ready-made drawings and diagrams, following the instructions step by step. There are many projects on the Internet to suit every taste.

It is important to ensure that the dimensions of the elements correspond to those specified, otherwise the product may turn out crooked and unstable. Also use quality wood, it should be dried and pre-treated to protect it from moisture. If you decide to make a bench for the hallway, make sure that the impregnation or primer is suitable for indoor use and does not contain toxic substances

If you decide to make a bench for the hallway, make sure that the impregnation or primer is suitable for indoor use and does not contain toxic substances.

To assemble your garden furniture yourself, you will need some tools. These include a saw, a jigsaw, a drill, a plane, and a hacksaw. You will also need a grinding machine, a hammer, pliers, and a screwdriver. For measurements - a ruler or tape measure, a square. If you have the appropriate skills, you can make any types of benches - with a curved back, corner or those presented below.

From logs

Tree trunks left over after clearing a site are a good material for garden furniture. You can also purchase logs specifically for this purpose:

- pine is an affordable material that does not deform from heat;

- linden - easy to process, interesting shapes can be cut from it;

- oak is strong and durable.

The design of the bench can be any, but first you need to prepare the logs. If the wood is not very dry, you should leave it for a while to get rid of moisture. The log is then stripped of its bark and dried again. Coniferous varieties must be additionally treated with an acetone solution to remove the resin. The log is sawn, the necessary parts and grooves are cut out, depending on the selected drawing. It is necessary to remove all knots and carefully sand the surfaces of the seat and back so that they are smooth.

You can make a simple bench on two supports or an original bench - it all depends on your imagination. Another interesting method is when a seat is cut out of a solid log and a place for sitting is cut out, without using additional parts and fasteners. This option looks unusual, but requires skill when working. From logs you can make not only a bench, but also a table, as well as several small chairs, assembling a garden set for your cottage.

Double

The simplest option is a bench designed for two people. It will not be too long and bulky, so if necessary, it can be moved to another place, if you do not fix the product in the ground. For the base you will need to prepare four legs, as well as beams to form the frame. To make the seat and back, you can use 2-3 boards, depending on their thickness. All elements are fixed together using nails or screws. If desired, you can add armrests to the bench - to do this, you need to make the side parts of the frame longer and install sanded boards on them.

From the kitchen set

If you have old chairs, don't rush to throw them away. You can use them to make an original bench with a beautiful back, and you won’t need much time. First you need to remove the chair seats. The remaining frames are processed: they should be sanded, the remaining varnish should be removed, a protective primer should be applied, and then decorative paint. You will also need two boards that will become the new seat. You can use one, but a wider one; it will also need to be pre-processed and painted in a suitable color.

Briefly about the main thing

To summarize all of the above, it should be noted that despite the apparent simplicity of choosing garden benches, it should be noted that in fact this is not a simple matter. The range of garden furniture is huge, there are plenty of offers on the market. That's why consumers are stunned when they have the opportunity to choose from a wide variety. This means that you must first decide what you want, and then go shopping. The best option is to consult with professional designers who will sort out the landscape design, where there is always a place for wooden benches.

Source

Bench made of concrete slabs and boards with backrest

By looking at the drawings of the bench, you can find out the features of its structure. You can make such a design with your own hands relatively easily, quickly and without high financial costs.

Making a bench with a backrest with your own hands is described in great detail in step-by-step instructions.

Assembly: initial stage

After the preparatory work, it’s time to process the wood. In order for a hand-made bench with a back to serve for a long time and decorate the area, the materials must be pre-treated.

Wood is coated with antiseptic compounds

and let it dry.

After this you can start assembling the back.

On one of the two-meter boards, fifty centimeters are measured from the edges. The edges of the concrete slabs will be located at this level. From this mark another fifteen centimeters are measured towards the center of the board. This is where the first boards will be attached. From the resulting marks we measure seventeen and a half centimeters - the gap between the back boards. Next, we measure fifteen centimeters for two more boards. There should be a gap of five centimeters between them. All this can be seen in the drawing.

Wood glue is applied to fifteen centimeter sections. They are attached to boards, the length of which is sixty-five centimeters. Additionally, they are secured with self-tapping screws.

On top, between the boards of the back, pieces of seventeen and a half centimeters are glued. To ensure that the parts stick together well, they are clamped and held until the glue sets. After gluing is completed, the back is covered with an antiseptic.

All wooden parts can be varnished

. This will give them additional stability and attractiveness.

Assembly of the main part

It is better to assemble the main part of the bench from both sides. Concrete slabs are placed between the boards, and M16 threaded rods fifty-five centimeters long are inserted into the drilled holes. You will need four of them.

The rods are fastened with M16 nuts and washers. They are twisted simultaneously from different sides to make the bench level.

Varieties

Benches with tables cannot be classified unambiguously; they can be divided by purpose, materials, designs, and location of the table within the bench itself. Products can be stationary, wall-mounted, portable, transportable on wheels, transformable and foldable into a suitcase. It’s easier to understand the abundance of models using examples, a selection of which we have prepared for you.

By table location

First, let's figure out where the table can be located in the product.

An elegant wooden bench with two seats and a common surface in the middle, complemented by wheels. This equipment allows you to transport the structure in the shade if the sun interferes with daytime rest.

According to transformative properties

The table is not always permanently attached to the bench; it is much more convenient if it appears for a while and disappears when there is no need for it.

Thanks to a simple transformation, the bench can easily be converted into a two-seater or three-seater.

Unusual designs

The rich imagination of designers gives the world amazing, extraordinary products.

The bench is similar to a table with two chairs.

Options and types

The meaning of wooden benches and benches is approximately the same - to seat people on a flat surface to make it comfortable and safe. Depending on your desire, you can add a backrest to the design of the bench, then the sitting will be more comfortable (although this is not always appropriate).

Below you will see photographs of options for arranging gazebos with benches. Examples with and without backrests will be shown, as well as from a combination of materials - wood and metal.

Bench without back

The simplest, cheapest and most reliable option is a bench. It fits perfectly into any interior, does not take up additional space and allows you to seat the maximum number of people at the table.

As with any seating furniture, one of the most important indicators is its stability.

You will be surprised when you start checking the garden furniture of your friends or even your own, and you will not find practically a single item that would ideally stand on the surface (if you have not taken up this issue before).

The bench may be level, but the floor surface is no longer there. A number of questions immediately arise: change the floor, sit on an unstable bench, or modify it to accommodate the unevenness of the floor?

These are the problems that summer residents face when it comes to organizing a recreation area. Therefore, buying or making a good bench yourself may turn out to be more difficult than you originally expected.

Bench with backrest

The option with a backrest is more convenient and aesthetically pleasing. Its design is noticeably more complex compared to the bench. To install it, you may need a support on the wall or a “dead” mount to the floor.

Therefore, before looking at anything, you need to take the dimensions of the internal area of the gazebo and ask yourself the question - what is the optimal size of the bench and how to place it.

In terms of appearance and quality, they can be completely different.

It could be a thick solid oak that will last another 50 years, or it could be a structure made of boards that will rot, become deformed and require additional maintenance.

There are many ideas (I've seen over 30) on how to make a bench out of old furniture - chairs, beds, chests of drawers and the like. If you approach this issue creatively, the result will not be as “collective farm” as it seems at first glance. A couple of examples are below.

Made of wood and metal

You could see similar pairs of tables and benches on city streets, parks and squares. Most often this is a metal base and a wooden tabletop (if we are talking about a table) or a wooden seat and back (if we are talking about a bench)

This design allows you to reduce the size of the furniture, which is extremely important in the limited space of the gazebo

Folding

A convenient option for a summer house is a folding bench. Thanks to its design, it is very easy to move from place to place - this is especially true for those who will constantly carry this bench from home to the gazebo and vice versa.

If this option solves your problems of this kind, then for 1850 rubles you can buy it in the Wooden-World store.

Set of table, benches and chairs

I would also like to introduce you to them; it is likely that one of the examples will hook you and in the future will decorate the interior of your gazebo.

Materials for a garden bench

garden bench

Plastic

Light plastic furniture has many advantages: it is easy to move from place to place, easy to care for, and has an affordable price range. You can choose any color option that fits perfectly into your landscape design. Disadvantages of plastic furniture: it quickly becomes scratched, fades in the sun, looks cheap.

If you have at least a little idea about soldering PVC pipes, make light and practical garden furniture from them

Pipe scraps can be joined with liquid nails. You will get a very unusual bench

Or even a chair. By the way, the chair cushions are foam chips in plastic bags. Warm, cozy, extravagant

Another option for bright children's garden chairs

Tree

Wooden bench without backrest

Scheme of a simple bench

This material is ideal for creating furniture: it absorbs heat, looks noble, and is easy to process. Any type of wood is suitable for making a bench, the main thing is that the material is sufficiently well dried and has no external defects.

Garden bench with backrest

Scheme of a wooden bench with armrests

Stone

Garden benches made of stone

Garden benches made of stone

This natural and beautiful material fits perfectly into any stylistic direction of landscape design. Stone compositions look solid, noble and unusual. But, despite many advantages, natural stone has several disadvantages. Sitting on a stone bench is not very comfortable, and it is also unsafe for health. Therefore, it is imperative to make warm covers or pads along with the bench. Stone compositions are installed permanently; they cannot be moved from place to place.

Metal

Metal garden bench

Garden benches, made by hot or cold forging, are a real decoration for a garden or a place to relax. The designs look beautiful and stylish, especially if additional decorative elements were used. Metal is most often combined with wood, glass or other material.

Standard sizes of structures

For outdoor benches, certification and declaration of conformity according to the GOST R system are not required. Therefore, there are no regulatory parameters - length, width, height - for this type of furniture. There are only standard, generally accepted sizes. Calculation of the standard sizes of bench designs is made based on what parameters the average person has. As for seats for overweight people or children, the calculations for them are completely different.

A typical park bench is between 1.5 and 1.8 m long, enough to seat three or four people. The height of the backrest on a standard bench is 0.9 m, which is the most common for Russian residents. As for the typical height, the minimum is 0.4 m.

To choose a suitable bench, you need to take into account a number of parameters.

- Dimensions. If the product will be placed on a garden or summer cottage, you definitely need to know how many people can fit on it comfortably and without harm to themselves, what kind of build these people will have. For example, an overweight married couple or four people with a standard body type. Of course, not only the length is important, but also the depth of the seat, the height of the backrest (as well as its presence in principle), as well as whether the bench will be equipped with armrests or not.

- Purpose of operation. A garden bench for a summer residence in a recreation area with a barbecue is not at all like its park “sister” with standard dimensions. Outdoor furniture in parks and squares is installed in such a way that it cannot be moved or carried away, while garden furniture is often light and mobile. In the alleys and boulevards, previously only standard options could be found, but now, even for public places, original furniture of fantasy design with inscriptions or drawings is often made. As for garden benches, they can be absolutely anything - in accordance with the general idea of landscape design and the wishes of the owner.

- Material of manufacture. The first requirement is strength, the second is long service life and immunity to environmental influences. If wood is used, it must be treated with compounds against fungus and mold, and the steel for the frame must be galvanized. If the product has forged parts (or simply metal), they must be coated with anti-corrosion agents and painted with special paint. For park benches, concrete is often used as a base material - such a product cannot be moved even if there is a strong desire to do so.

Rules for caring for benches

45 interesting and unusual ideas for decorating your home with your own hands

It is clear that the main thing that wooden products need to be protected from is moisture. That is why it is recommended to purchase mobile products for your dacha. It is easier to move them to a dry place, thereby preserving them longer. Of course, there are protection options for stationary structures as well. They, for example, can be covered with waterproof polymer or rubberized film.

And yet, when buying benches, you need to pay attention to the material from which they are made. Ideally, it will be wood that absorbs water in minimal quantities.

The latter causes wood to rot.

In the factory, benches are coated with protective compounds, varnishes or paints. If a piece of garden furniture was purchased on the market from a private entrepreneur, then all protective operations will have to be carried out independently. It should also be noted that garden benches made of wood will have to be periodically cleaned of old coatings and new ones applied. You need to be prepared for this.

Wooden benches require constant maintenance Source cdn.pixabay.com

The sun also has a negative effect on wood. Therefore, wooden benches should be moved to the shade in summer. For stationary models, umbrellas are installed.

The next recommendation is to periodically tighten the fasteners. During operation they will weaken, and this will reduce operational safety.

Dimensions and drawings

Before creating a bench, it is recommended to draw up a drawing; it will be much more convenient to build the structure using it. The size should be determined so that a person feels comfortable sitting on the bench. The distance from the ground to the seating element is about 45-50 cm: based on this indicator, choose the length of the supports. If the bench is installed motionless and stable, the legs should be longer so that they can be secured in the ground.

To make it as comfortable as possible, you can tilt the seat slightly (up to 20 degrees). Its optimal width is approximately 45 cm. The height of the back is from 50 to 60 cm. In this case, you can also tilt it at a slight angle or leave it straight. If the bench is intended for many people and is designed for a large number of seats, it is recommended to choose material 100x100 mm, 150x150 mm. It is possible to use a rectangular section: for example, 150x100 mm. For children's benches, wooden blocks of smaller cross-section are used.

Required bench dimensions for a comfortable seat

Let's start, perhaps, with determining the depth

In this aspect, it is important to provide a small gap, which will be formed from the distance between the border of the bench and the part of the legs of the person sitting on it. To do this, it is recommended to adhere to measurements equal to about 400 millimeters (+-25). To achieve the ideal width, it is advisable to be guided by your preferences

However, the most commonly used dimensions are 410–510 mm. In addition, you can use your imagination and make, for example, a narrowing towards the back side. This will allow users to freely place not only their legs, but also their elbows. If in use there is upholstered furniture-pillow, then a slight tilt in the construction of the structure is possible. Its value should be from 5 to 8 degrees.

Bench height

As for the named parameter, it is the relationship between its location and the condition for comfortable sitting of people. First, let's consider the second point: for a winning pose, it is necessary that the person's knees are at an angle of 90 to 100 degrees. Moreover, his feet should be close to the surface. To do this, the bench must be placed so that the distance from the floor to the product is approximately 405–455 millimeters. If the structure is used with padding material, for example, a pillow, additional convenience should be taken into account

In such a situation, when determining the height, you need to pay attention to the thickness, namely, in a compressed form. This indicator should be subtracted from the total elevation

Wooden benches: design features

Let's first talk a little about terms. The fact is that we somehow naturally manage to make words interchangeable - “bench”, “bench”, and then “shelves” (some write “canopy”, but in this writing it’s already something like tents over the bed?). We still need to differentiate somehow.

Of course, there are stationary and portable benches. But let's agree that in a bathhouse, a bench is a portable seat, a bench is, well, if not attached to the wall, then at least a seat adjacent to it, and a shelf is a lounger or seat intended for steaming or being steamed exclusively in the steam room. The shelves can be stationary, removable, folding, folding, tiered. Even if a bench or a bench is used as a shelf, if people are steaming on it, we will call it a shelf or shelf.

By and large, there is no difference - if you took the shelves outside, they became a bench?

Now let's move on from philology to carpentry. The simplest bench is not a board with two wide legs. You need to understand that a board with two legs will not last long. Those sitting will rock it, so sooner or later it will collapse - the fastening is not so large that this will not happen. Therefore, the simplest bench is a seat board, a couple of four legs and braces, or a transverse brace between the legs in the middle of the height of the legs or close to the floor.

The second important point is sustainability. Do it in such a way that the person who sits on the edge does not tip over along with the bench. A heavy structure, low or with a wide seat will not tip over.

ADVICE! However, there is such a nuance: it is better to make such pieces of furniture from not too massive boards, because the more massive the board, the longer it will take to dry after gaining moisture. Take this fact into account!

There is one more rule regarding what a seat in a steam room should be like: gaps must be left between the bars. The optimal gap width is 1-1.5 cm. It is clear that they are needed to drain water and speed up drying.

Ergonomics

Ergonomics is the science of how to make things and processes comfortable for humans. In this case, we are talking about ensuring that the seats in the bathhouse do not cause inconvenience due to their size.

Of course, much when choosing sizes will be dictated by the size of the rooms themselves for which you are planning to make benches for a wooden sauna with your own hands. But the height of the seat is a point that is of great importance, but depends little on the size of the room.

It is preferable that the seated person's knees are not raised relative to the pelvis, so the seat should not be too low. However, too high is also uncomfortable - your legs will dangle in the air without support, which increases pressure on the vessels under the knees and in the hips. Therefore, we can proceed from the height from the floor to the knee bend of adults.

Various ergonomics manuals advise making the height from 30 to 50 cm. We believe that it is easier to derive the arithmetic average from the measurements of the people who will most often use this bathhouse.

The width of the seat depends on how they will sit on it - if they sit as usual, then 30-40 cm is enough, and if reclining, then 60 cm.

Those benches on which the steamer will lie must be long enough to accommodate him at full height, and also wide enough so that he can freely place his arms along his body. It is also better to measure such things on specific people.

BY THE WAY! Adherents of the Russian bath should remember that the height of the upper shelf on which the steamer lies is about 85 cm, and the shelves cannot be covered with clapboard to the floor, because the steamer’s feet are located under the bench or shelf.

Before introducing you to the drawings, we recommend that you take a look at our other material, which describes in detail all possible types of benches.

Traditions and recommendations

Useful things for the home with your own hands

Despite the lack of a uniform standard, there are traditional ways to determine ceiling height. Typically, a Russian bathhouse was built individually, for the family living in the house. Therefore, to determine the required parameter, the tallest member of the family stood on the floor and raised a broom upward.

Standard arrangement of shelves in a bathhouse

Height of the product from the floor

These are the parameters that are considered optimal:

- the steam room warms up quickly enough, and the consumption of firewood does not exceed the normal amount;

- with a height of up to 2.4 m, even an electric oven does not require a lot of electricity consumption to properly warm up the workspace;

- if there is a tall person in the family, you can use his arm extended upward as a standard - this will ensure that those taking a steam bath will not experience discomfort in any position;

- sometimes you can find advice to add half a meter from the tip of the middle finger of an outstretched hand, but if the height is greater than 5 m, then more fuel will be required and the steam will go to the ceiling;

- 200 cm will already lead to the accumulation of steam almost at the level of the respiratory organs, in such an atmosphere it will be difficult to breathe;

- in a compact structure, a ceiling of 20 m is sufficient, but if a structure is being built for commercial use, with a large number of visitors and steam volumes, the ceiling should be at least 3 m.

Steam room at the dacha

Experts say that the construction of a bathhouse should certainly begin with agreeing on the size of the steam room. In this case, all dimensions are proportional to the calculated number of visitors. The ceiling height can be 220 cm or 230.

There are several varieties, which need to be arranged according to a pre-selected pattern. The subject of preference can only be the modification that ideally fits the dimensions of the room.

Bathhouse at the dacha

It is not recommended to cover furniture for bath rooms with paints and varnishes, as substances harmful to human health will be released under the influence of high temperatures.

All components of the structure should be carefully sanded, paying special attention to the edges. This will help avoid injuries and splinters.

To connect parts, it is necessary to give preference to nails made of wood. Regular ventilation and drying of the bathhouse after visiting will help prevent the appearance and proliferation of mold and mildew, and will also significantly increase the service life of furniture and premises. For better ventilation and drying, you need to leave space between the floor covering and the bottom shelf.

These measures will help avoid the appearance of rot, mold and destruction of wood. With some effort and a little imagination and ingenuity, you can make beautiful, durable, high-quality pieces of furniture for the bathhouse and more with your own hands.

To learn how to make a bench for a bathhouse with your own hands, see the following video.

How to make a bench with your own hands for a bathhouse

To make a regular portable bench for a bathhouse, there is no need to assemble a special frame. This design option is distinguished by its simplicity and ease of use.

Material selection

Only a certain type of wood is used to make bath benches. Due to the high resin content in pine, which begins to actively release under the influence of high temperatures, this type of material loses its relevance. Iron hornbeam is also not used, although it has a high level of resistance to water and moisture. Its significant disadvantage is the strong heating, which leads to burns on the skin.

Among all types of wood, it is better to give preference to:

- Linden. It practically does not heat up even in a sauna and is resistant to steam. The material has a pleasant smell, but after a while it begins to darken.

- Aspen. Its resistance to steam and water is an order of magnitude higher than that of linden, but it is inferior in smell. This variety is the most mediocre in terms of attractive appearance. Aspen is valued for its resistance to mold.

- Larch. It is noteworthy that wood under the influence of steam and water only becomes stronger and can last for ten years without changing color or texture. The disadvantage of the material is its high cost.

- Cedar. This representative of coniferous species releases resin in minimal quantities when heated. It is chosen for finishing steam rooms and making benches due to its positive effect on the lungs and the entire human respiratory system. Cedar is especially useful for people suffering from asthma, bronchitis, and lung diseases.

- Oak. This type of wood has proven itself well when used as a material for making bathhouse benches. Oak has increased resistance to water and steam, and has high decorative qualities, but products made from it are best used for dressing room equipment. Given its density, it gets very hot in the steam room.

- Birch. It is used to make benches for bathhouses because of the medicinal tar released when heated. Thanks to its healing properties, it is possible to treat even the most contagious skin diseases.

To make a bench you will need:

- wooden beam with a section of 6×7 cm;

- slats 2-2.5 cm thick and 6 cm wide (for the seat structure) in the amount of 9 pieces;

- fasteners made of wood or metal.

When decorating a bathhouse, it is not necessary to use the same material for finishing the walls and making the bench. But the option in one style looks more impressive, although playing in contrast also has its own originality.

Required Tools

To carry out the work you need to prepare the following set of tools:

- saw;

- hammer, mallet;

- pliers;

- screwdriver;

- sander;

- roulette;

- level.

Advice! It is important to prepare all the tools in advance so that you don’t get distracted when making a bath bench.

Bench manufacturing technology

Step-by-step instructions for a do-it-yourself wooden bench for a bath include the following steps:

- Cutting the timber into 4 fragments, each 40 cm long.

- Assembling U-shaped racks. Two pieces of timber 60 cm long need to be knocked down to form transverse jumpers.

- Cutting according to the specific length of slats for making a seat. It is optimal to use slats with a length of 160-170 cm.

- Assembling the bench. The prepared slats need to be stuffed onto the jumpers, avoiding a gap of less than 1 cm between them. This is necessary to remove excess moisture and to expand/contract the natural material when exposed to temperature changes and high humidity. In addition, it is recommended to retreat 20 cm from the edge in order to achieve increased stability of the structure.

- Bench strapping. To create a strong bench, the legs and stands need to be connected using the remaining slats, 10-15 cm away from the floor. Special corners are also suitable for these purposes, but it is advisable to attach them from the inside of the product, otherwise a burn will appear on the skin at the point of contact. That is why it is advisable to recess the fittings used in the manufacture of the bench by 2-3 mm.

Finishing and decor

The finished bath bench must be treated with a natural-based antiseptic composition. If you want to make it in country style, then you need to adhere to the following algorithm of actions:

- Sand the surface along the grain with a brush.

- Clean with a grinder until a relief pattern is formed.

- Apply translucent glaze in two batches.

- Wipe the surface with a dry sponge; when it dries, remove the glaze.

- Cover the bench with varnish.

Making and giving the bench the desired appearance is quite simple if you follow all the recommendations regarding assembly and finishing.

Advantages and disadvantages

A bench made of metal is the most reliable and durable thing. Today, you can find similar products in many country and garden plots. They are in many ways superior to standard wooden options, demonstrating higher practicality and unpretentiousness.

The popularity of metal benches is explained by the many positive characteristics that are inherent in them.

- The main advantage of the products under consideration lies in their strength and resistance to mechanical damage. It is incredibly difficult to spoil, break or deform such a structure. Under the influence of precipitation and temperature changes, a metal bench will not lose its visual appeal and become less strong. Of course, we are talking about well-maintained options, manufactured according to all the rules.

- A metal bench can last for many years. This material itself is designed to last for many years of use. In this regard, it is not advisable to compare wooden options with metal structures.

- Metal can be easily combined with other materials. Most often there are models that have a metal frame, and the back and seat are made of wood. The result is reliable, beautiful, and very comfortable designs.

- Metal benches can have a very unusual, elegant design. In dachas and local areas you can often find truly amazing structures that are difficult to take your eyes off. A metal bench can have various kinds of decorative elements, graceful lines and sophisticated features. Such a detail will effectively complement the local area.

- Garden and home furniture made from any type of metal is environmentally friendly. You can use such products without worrying about your health. Metal structures do not emit pungent odors and do not cause allergic reactions.

- The metal bench is an absolutely fireproof design. Moreover, in the event of ignition, the metal will not support the flame, actively spreading it. The same cannot be said about models constructed from wood.

As you can see, metal benches have many advantages. However, it is not without its shortcomings, some of which are quite serious. Let's get acquainted with them.

- Metal benches are more difficult and capricious to manufacture. It is much easier to work with the same wood, and it takes less time. When making a bench from metal, the master must competently use a welding machine, and not all users have such skills.

- Often metal benches turn out to be very heavy. It can be difficult to move such structures from one place to another. If you do not plan to carry or transport a similar product in the future, then this will not be a problem.

- Sitting on a bench made entirely of metal is not always comfortable. This is especially true during the hot summer season. During such periods, the metal seat heats up very quickly and strongly, which leads to very unpleasant sensations. In cool seasons, sitting on such a bench can also be uncomfortable, because the seat becomes too cold.

- Making your own or purchasing a finished metal bench can cost a pretty penny. This is especially true in cases where people select a very beautiful, original model, decorated with artistic forging. The same wooden or plastic varieties of benches are several times cheaper.

- A metal bench will have to be regularly treated with special compounds that will protect it from corrosion. The only exceptions are stainless steel products.

↑ What to make a bench from

Before selecting material for assembling a bench, look at what the gazebo itself is made of. When racks, walls and gratings were welded from metal profiles or corners, then metal elements should be present in the furniture. If the pergola (canopy) is made of wood, then the benches should also be made of wood.

The best material for a bench is wood. Wood goes well with metal, stone, polycarbonate. To create a bench, you don’t have to be a carpenter or own a plane. It is enough to know how to use a hammer and a hacksaw.

Today on the construction market you can buy wood that has already been processed and sanded. Boards of different thicknesses and lengths can be purchased and cut to size. And then, according to your drawing, assemble the frame of the bench.

Choosing a bench style and design

Design development is a multivariate and complex stage of creating a project.

Every person can draw simple models on paper; others will require considerable imagination and artistic ability. The Internet can be of great help, where there are a large number of photographs of finished products made from different materials and in one style or another. As a rule, site owners create recreation areas in the same style with all other landscaping elements, forming a harmonious image of the site. There are no restrictions in this matter; the criteria are only your own taste, sense of proportion and preferences.

Stylishly designed bench

You can also find ready-made drawings of garden benches online, with dimensions and other useful information. The use of ready-made images gives a tangible impetus to imagination and saves time and effort for those who find it difficult to independently design an original and attractive product design.

Choosing a place to install the bench

Let's start being original

Not everyone is capable of grasping the “mechanical” sciences to the point of accurate calculations and numerical modeling. But even the basic information from them gives enough freedom to fantasize about the theme of benches. For example, is the triangle rigid? And a 3-sided pyramid and its base - a triple angle - then, probably, even stronger? Right. So now you can create a bench-chair from waste wood materials, see fig. left. You can get cable drum cheeks for nothing, because... It is very difficult to disassemble them, and the boards come out unmeasured, more suitable for fuel. You just need to make the seat and back not shields, but frames.

Garden bench-chair made from waste wood

The supporting frame is the embryo of modern honeycomb materials: many flat boxes with common low sides. The ratio of the frame's load-bearing capacity to its weight is very large; covering the frame with rigid material increases it even more. An airplane wing is essentially the same frame. Therefore, swing benches are made on the basis of frame structures, see fig. on right. The backrest only seems weak at first glance: in fact, it is strengthened by a triangle of rigidity, which “turns on” under load, shown by the arrow in pos. 3. If the suspension is not chain, but rope, instead of sotv. its branches need to be braced from timber from 50x50, steel strip from 40x4 or rod from 8 mm - a triangle with at least one soft elastic side, of course, will not be rigid.

Bench swing on a chain suspension

From flat boxes you can assemble not only a frame, but also a package, connecting them with their wide sides. It will look like one box, but much more rigid. By putting many frames into a package, we get honeycomb material, but that’s not what we’re talking about here. Sheets of material can also be folded into a bag, and it will be much stronger than its components in total. The broom principle – remember? The reason is friction between the sheets of the bag. And if you reduce it, the elasticity increases, you get a spring. Although this is not about her either.

Bench made of wood and concrete

The author of the shop in Fig. on the right, it seems, there were extra slabs left from paving the paths, so he put them to use. Otherwise, it is difficult to explain the appearance of such a bench: it is unsightly, low-tech (drilling concrete is not a job done with pleasure), heavy - assembled at its location, inconvenient, and the back is clearly flimsy. But the design is interesting, because... at the connection of the flooring with the legs, a package is formed, tightly bound inside. Its load-bearing capacity in this case is monstrously excessive. The work of the flooring made of beams on the edge for bending and torsion is fully ensured by the sidewalls in the form of box-shaped packages from the same 150x30 boards.

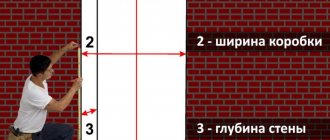

Note: the wide long side of the board is the face. Long narrow edge. Short narrow - end or cut (cut, edging). The joints of faces, edges and edges are the edges of the board.

To properly assemble the bags, you will need 2 (even better - 4) large squares. Carpenter's squares of half a meter or more are not always found on sale and cost a lot. However, we only need an angle of 90 degrees without marking the sides, so let’s remember, also from school geometry: it is given by a triangle with a ratio of side lengths of 3:4:5. And also - that angles with parallel sides are equal to each other. Based on this, we make as many squares of any size as needed:

- We mark the required dimensions on flat pieces of wood (in brackets in item 1 of the figure - for making a bench).

How to make your own 90 degree square

- Drill holes for the bolts according to the marks.

- We attach the rest to the short bar.

- We turn the longest bar (hypotenuse) until the holes in it coincide with the middle length (long leg), pos. 1 in Fig.

- We insert a boss, also with a hole for fasteners, between the hypotenuse and the leg (item 2); The thickness of the boss is the same as the short leg strip.

- We fasten everything tightly, cut off unnecessary ends - the exact 90-degree square is ready, pos. 3.

Boards for packages of legs and seats are processed using a square with periodic checking by others, pos. 1 on next rice.:

How to use squares to make an even package from many boards

It is better to assemble the package (item 2) using a pair of squares attached to a solid base at a distance of the width of the board minus 2 thicknesses of the square (in our case - approximately 130 mm from each other). It’s even better to assemble the entire base of the bench at once, using 4 squares. Fastening - with diagonal pairs of self-tapping screws, oriented mutually perpendicular to adjacent tiers, pos. 2a. Then only a couple of fastener heads will be visible from the back side, in contrast to, excuse me, the shameful bolts of the concrete-wooden bench.

The assembled bench is already standing and you can sit on it, but for full strength (equal to or greater than wood-concrete), this bench needs to be strengthened and at the same time refined:

Making a bench from packages of boards

- Board soles are attached to the lower ends of the legs, pos. 1 in Fig.

- Stiffeners from laths from 20x20 to 40, pos. 2. If the bench is without a back, the ties are placed in pairs, outside and inside.

- If desired, select a seat according to the profile, manually or with a grinder, pos. 3.

- If the bench has a back, after selecting the profile, its supports are cut in, also pos. 3 (do you see the stiffness triangle?). In this case, you need one tie on the leg from the inside.

- For a bench with armrests along one of the boards, the packages of legs need to be placed longer; they are processed outside the package and adjusted to the location.

- For the support beams of the armrests, boards are cut to the same profile as the rest.

- The armrest beams are attached to the backrest posts from the inside with an overlay, and the boards protruding from the packages are cut into, pos. 4.

- The bed (flooring) of the armrests is made of simple plywood 4-6 mm thick. To avoid transverse warping during drying, the blanks are cut so that the fibers of the outer layers run along the armrest.

- Armrest flooring blanks are generously impregnated on both sides with a water-polymer emulsion until thoroughly wet (see also at the end).

- The blanks for the armrest floorings are damp and still soaked, placed on the beams and secured with self-tapping screws at intervals of 50-70 mm. Fasteners are carried out starting from the root (adjacent to the back) ends.

- Dry the bench for 3-5 days under a canopy (you can use temporary film).

- The holes above the fastener heads are puttied and the bench is finished clean.

Note: during work, all parts are impregnated, as described at the end.

The same, but with flowers

The voluminous legs of the bench may not be set, but simply box-shaped; this works well for a bench with flowerpots. In this case, for proper strength, the seat should not be made in the form of a series of beams on the edge, but framed.

Drawings of a garden bench made of wood with flowerpots for flowerpots are given in Fig. (Dimensions - in inches):

Drawings of a wooden bench with flowerpots

Before impregnation with a water-repellent agent, flowerpots are soaked in a 5% solution of ferrous sulfate (see below); copper sulfate or borax - under no circumstances! However, you can’t adapt the backrest to this bench: there is nowhere to attach it so that it is secure. A possible solution is to place this bench in a pergola, gazebo or under a canopy so that there is somewhere to recline besides it.

Originally the old fashioned way

Rustic benches, i.e., enjoy great success, and deservedly so. antediluvian-wild-primitive appearance. Some examples of these are shown in Fig. from the beginning. Unfortunately, the selection of materials alone, taking into account all operating conditions, requires, in addition to enormous (if not unique) experience and knowledge, a lot of time and, in addition, a lot of luck. And to put everything together so that the fruits of labor do not disappear in 3-5 years is an engineering task more complicated than a design one. But for beginners in rustic design there is also a welcome window - a bench made of wild logs.

Benches made of wild logs and wooden blocks and blocks

There is no need to think about the choice of power circuit here: the oakiness (without quotes) of the material helps, so we take a cantilever one. The simplest log bench (on the left in the figure) will still require a lot of work. But it will give you the opportunity to acquire the skills of sawing logs lengthwise and cutting shaped grooves in them. They will be very useful if you decide to build a log house; for example, a real Russian bathhouse is built only using chopped ones. How to adapt a rustic backrest (in the center) to a bench made of logs, see below, and how to simplify its manufacture - on the right in Fig. All the work is to cut 2 ridges of the same length from a log, cut grooves into them for the seat board and put everything together. If, instead of an edged board, you cut an unedged block from a log with a thickness of 60 mm or more, then such a bench will have a completely rustic look.

It’s also easy to attach a rustic backrest to a log bench. If the workpiece is of normal thickness, then it is sawn lengthwise into 1/3:2/3 or 1/4:3/4 and the trim is placed on racks made of boards (on the left in the next figure), beams, or, for the sake of appearance, from poles or stakes. If there is a log more than half a meter thick, then the blocks of the seat and back are placed in the grooves of ridges made from it without a single nail. It turns out – it doesn’t get any more rustic, on the right in Fig.

Log benches with backs

Note: for more options for making rustic benches, see the video below:

Video: rustic benches with back (1) and without (2)

Same old stuff

Original and tasteful benches up to 1.5 m long are made from old chairs. They are connected in pairs with their front sides facing each other with an insert that extends the seat.

How to make a bench from four old chairs

It’s best if you find 4 unnecessary “Vienna style” chairs, with backs curved in a horizontal plane; this in this case is important to ensure the overall strength of the structure. What follows is clear from the figure: 2 chairs go to waste - the front drawers are cut out of them. They use dowels and glue to connect the remaining 2 chairs, lay the seat, and finish it. To make the bench suitable for gatherings not only one-on-one, but also waddle, a pair of upper corners of the backs can be connected with a support beam under the flooring of the common back (shown in green in position 5. A curved beam for such an improvement is assembled from several plywood blanks with glue and small nails or screws.

You will only need a couple of chairs with straight horizontal backs for a bench, because... a straight composite seat box will not be strong enough. One solid frame for the seat (on the left in the next figure) does not solve the problem, nor does tying the upper ends of the backs of chairs with a beam: reclining them on a common back will only rather weaken the structure. An additional bottom frame is needed (center and right in the picture) to form a solid straight box.

How to make a bench from a pair of old chairs

The limits of originality

Everything has a limit. Originality too. In terms of the ratio of benefits to convenience and labor intensity, the limits of originality of benches can be divided into upper and lower.

An example of the top one is a puzzle bench made of stools with shaped seats, see figure:

Puzzle bench made from stools

This is an ideal solution for a weekend home: if you need it, put everything in a bench. It was necessary - they took it apart and gave each seat to the guests. We’re leaving - at least the children will take it apart and bring it into the house, but burglary and “borrowed it for a while before the owners arrived and forgot to return it” are such different articles.

An example of the opposite kind is a transforming bench, see next. rice.:

Design and dimensions of a transformable garden bench

Transformable furniture often helps out in everyday life, but, firstly, only when there is an acute lack of space, and in itself it is always less convenient, reliable and durable than unchanged furniture. Even in a 6-acre dacha there is always room for a table with benches. Secondly, it’s simply inconvenient both to sit on the folded one and to get out and climb into the unfolded one. Gatherings outside are organized not only for playing chess (excuse the deliberately redundant expression). Thirdly, the hinges in the open air deteriorate many times faster than in a house or apartment, and an all-wood transforming bench has to be strengthened with braces to the point that even at the computer you wonder: is the cure better than the disease itself?

What is

In appearance, the bench press bench resembles an ordinary bench. This equipment was specially created for strength sports. In terms of design and construction, this equipment can be produced in several versions. Often there are models with several adjustable parts, special horns that hold the barbell. Also popular are benches in which the level of backrest can be independently adjusted.

By and large, a power bench or, as it is also called, a bench press bench is a unique exercise machine that combines the functionality of several sports equipment. Thanks to the use of such equipment, you can perform various strength exercises, pump up your abs and train various muscle groups using a barbell or dumbbell.

Dimensions

Device