In order to effectively solve problems such as pumping from great depths and supplying water to an autonomous water supply system, it is necessary to understand the design of a submersible pump for a well. The use of such pumps makes it possible to pump water from wells whose depth reaches 80 meters. In this article we will look at how a submersible pump works, what categories it is divided into and how to choose the right device.

The pump for the well is selected taking into account certain features of its future operation

Pump components, operating principle

A screw or screw pump intended for a well has a cone- or cylinder-shaped body and a motor that is attached to the flange using washers for sealing. The casing contains a shaft for operation, which has a screw configuration.

When the working part rotates, the liquid flows to the outlet; the sealing elements prevent water from flowing in the opposite direction. This way the device maintains constant pressure. The twist angle of the screw mechanism affects the level of performance, as well as the frequency with which the rotor rotates in the electric motor.

There are pumps that have a motor built into the housing. The drive goes through a sealed channel and reaches the stator windings. The product is equipped with an oil tank, which automatically lubricates the auger bearings and the rotor inside the engine.

Water enters the housing by passing through a grate that goes around the auger. A flexible rubber hose can be connected to the pressure fitting, which is also connected to the storage tank of the water supply system.

Before operation, the pump is immersed in liquid. Pumps can be used in wells and wells. When the pump absorbs air, it wears out, and with the help of automation the drive is turned off.

Using pumps, you can pump water, oil products, and solutions with aggressive compounds. In this case, the pump must be made of a material that resists the negative effects of chemicals. Using a pump, you can pump out liquid containing sand and silt. Small fractions from the pressure hose go to the settling tank, where they are separated, and part of the sand settles in filters. Filter devices are installed at the inlet of the pump for rough cleaning. They prevent large stones and algae from getting inside.

Attention! Auger devices correspond in size to the diameter of the well. If you reduce the dimensions, you can improve the performance of the pumps.

This is interesting: Replacing a well pump: problems when lifting a deep well pump from a well and their solution

Rodless deep well pumps

In recent years, we can conclude that rodless deep-well pumps have begun to be used more and more often in fields. In most cases, they are used to work with a well after a deep-rod pump has already worked with this well. And this happens because rodless types can pump oil from greater depths, thereby significantly increasing the level of production of this liquid. But the full operation of these devices has not yet been fully implemented, since they are complex in their design and internal composition of parts. There are two varieties of this type:

- Electrically immersed. This type is actively used for working with oil wells.

- Hydropiston.

Purpose and features of screw pumps

The borehole pump is of the submersible type. Unlike surface equipment, which works directly on the ground, this structure is lowered into the well. The installation is distinguished by its high power, capable of overcoming the pressure of a water column above 50 m.

Such equipment is called screw or auger, since its main unit is a screw. A distinctive feature of the installation is the ability to pump water from deep reservoirs with a high degree of pollution. This is due to the design feature of the screw, which stops the flow of sand and small particles into the mechanical part of the device.

Construction of a screw pump for a well.

The screw has different lengths. Depending on this value, the performance of the equipment changes, while the pressure always remains constant. Thanks to this quality, it becomes possible to pump viscous liquids.

The operating principle of screw pumps for wells is as follows:

- Through the supply hole located below, water enters the working chamber.

- Here it is picked up by the auger and fed further into the main hose.

Characteristics and types

Depending on the ability to work at different depths, pumps are divided into types:

- Standard. Used for working in shallow wells.

- Deep. Capable of lifting water from artesian wells. They have high performance.

The average characteristics of the screw mechanism have the following parameters:

- productivity is 1500-2000 l/hour;

- head 40-60 m;

- the working environment temperature is +5…+40°С;

- the screw distills water with microparticles reaching a diameter of 2 mm;

- engine power is 1-1.5 kW;

- operating voltage 220 V.

The equipment body is made of stainless steel. The mechanism is unpretentious in operation and rarely needs repair.

Popular manufacturers

A number of companies whose products are of high quality are engaged in the production of auger equipment.

These include:

- Aquarius. The Kharkov manufacturer produces pumps of the BTsPE series. A distinctive feature is their compactness. Installation can be carried out in wells with a diameter of 110 mm.

- Belamos. Belarusian company. Produces high quality products at an affordable price. The equipment is capable of pumping water both from wells and from open reservoirs with a degree of contamination of up to 80 g/m³.

- Unipump. A foreign manufacturer that ensures reliable operation of its products. The screw has a spiral shape with a productivity of 1.2 m³/hour. The degree of environmental pollution can reach 1500 g/m³. The disadvantages include the high price.

Pump "Aquarius".

Rod pumps

Deep (well) rod pumps are the most common type, which are designed to lift oil from wells. They can often be seen at various oil wells around the world.

Rod pumps are:

- Non-insertable

- Plug-in

Non-insertable - the cylinder of this device is lowered into the oil well without a plunger.

Inserted - a cylinder with a plunger is lowered into an oil well on rods.

A plunger is a cylindrical displacer that is used in deep-well pumps of the rod type.

Types and main technical characteristics

Among screw pumps, there are two categories. The fundamental parameter of this separation is the working depth at which these hydraulic machines are capable of operating. So, depending on this characteristic, they distinguish:

- standard screw pumps;

- deep category devices.

A screw pump, belonging to the standard category, is used for pumping water from wells or boreholes whose depth does not exceed 20–25 meters. Such pumps are often used to service wells with low flow rates, drilled in sandy aquifers (sand wells). Since using a screw pump it is possible to pump out a liquid medium with different capacities, while maintaining a stable pressure of the created flow and not paying attention to the content of sand inclusions in the water, this equipment is optimally suited for servicing wells of this type.

Monoblock screw pump with top-mounted water intake

The deep-grade screw well pump is equipped with an extended auger, which determines the impressive technical capabilities of such a hydraulic machine. Possessing high power and reliability, it can successfully service artesian wells, the water in which is located at a depth of up to one hundred meters. Of course, the price of such models is significantly higher than the cost of devices of the standard category, but in many cases, when it is necessary to ensure water supply from wells of considerable depth, such equipment simply cannot be done without.

- productivity, showing how much liquid medium the pump is capable of pumping per unit time, is 1500–2000 l/hour;

- the pressure of the created liquid flow is 40–60 meters of water column;

- the temperature that the pumped liquid medium may have is from +5 to +40°C;

- the size of particles of insoluble solid inclusions that may be contained in the pumped water is 2–2.5 mm;

- The power of the electric motor driving the rotor and auger is 1–1.5 kW.

Sprut range of screw pumps

Most models of mid-price screw pumps, which are often used to equip household autonomous water supply systems, can operate from a 220 V electrical network.

Screw pumps for industrial use have more impressive technical characteristics. In particular, such devices, without compromising their technical condition, can successfully pump liquid media whose temperature significantly exceeds the above values. In addition, industrial screw-type pumps are able to work with liquid media containing insoluble solid inclusions, the particle size of which exceeds 2–2.5 mm.

Borehole screw pump for artesian water intakes

The main part of the body parts of screw-type well pumps is made of stainless steel, individual elements are made of durable plastic. To seal the internal structural elements of such hydraulic machines, gaskets made of rubber and silicone are used.

Since the moving elements of the internal structure of screw pumps are constantly in contact with the pumped liquid medium, they do not require additional cooling.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Operating principle

Today it is known that all deep-well pumps have a huge number of different characteristics. Each of them differs from the other in some special feature or nuance. Undoubtedly, the entire installation of this device is located below the surface of the water. And it is from the pump itself that the wire and pipe for supplying water run in a dense insulated winding. In the standard assembly of any device you can usually see a motor and a filter. And the liquid suction itself is carried out from below or from above the installation. A mechanism with bottom suction can easily filter sand or silt from the waters of an underwater river. Deep well pumps consist of two components:

- Pumping part with several stages;

- Motor part. It can be either built-in or external.

Types of screw structures

The main working body of auger equipment is a screw pair, consisting of a stationary stator and a movable rotor. The design of the device and the shape of the working shaft of the mechanism determine the name and capabilities of the devices.

Design of a screw submersible pump.

Screw pumps are a screw design with internal gearing. A mobile single-throw rotor (“Archimedes screw”) performs planetary motion in a helical stator. Being in constant engagement, the cage and the screw form several autonomous cavities among themselves.

When the moving part rotates, the sinuses on the suction side increase in volume, thereby creating a vacuum, as a result of which the cavities are filled with the transported liquid. Further movement of the rotor causes the resource to move towards the pressure line.

Screw eccentric pumps are positive displacement units. The mechanism casing itself acts as a container that facilitates the movement of the resource. The principle of operation is to pump liquid due to the translational movement of an eccentric shaft. When it rotates, vacuum cavities are created between the stator and the rotor.

As a result of the resulting vacuum, liquid is taken from the well and then supplied to the pressure pipeline. The working shaft is driven by an electric motor cooled by the flow of transported liquid.

Centrifugal deep well pumps

Devices of this type are usually used to lift water for quite a long time without seasonal breaks. Such a jaw mechanism has two components - a hydraulic device and an electric motor. They are good for summer residents to use on their plots, since they do not take up much space, are convenient and easy to use, are also simple in structure, and most importantly, they are affordable to many from a financial point of view.

Rules for operating a screw pump

Reliable operation of the purchased equipment is guaranteed in case of strict compliance with the norms and operating rules reflected in the device passport:

- Power supply parameters: 220 V ± 5-8%, 50 Hz. If the value changes exceed the recommended interval, the installation should be connected to the source only through a voltage regulator.

- Temperature of the pumped liquid: +35…+40°С.

- Permissible content of solid inclusions: 150 g/m³. Exceeding the norm will lead to premature wear of the equipment or jamming of the working mechanism.

- Immersion depth, depending on the manufacturer, is 50-80 m.

- The speed of the coolant flowing around the engine body should not be lower than 0.08 m/s.

- It is not allowed to operate the unit without water.

- The distance from the bottom of the well is no higher than 1.0 m.

- The operation of a pipeline with a diameter below 25 mm is not permitted.

- The number of operating starts of the installation is no more than 15 times per hour.

- To reduce the frequency of switching on the unit, it is recommended to add a storage tank and a pressure switch to the equipment set.

- Do not suspend the pump from an electrical cable.

- The installation cannot be operated with the shut-off valve closed, since at this moment the engine will not cool. As a result, the stator winding will overheat and the equipment will fail.

- Repair of the device and replacement of spare parts should only be carried out at a specialized service center.

This is interesting: Pumping stations for water: choosing a household automatic pumping station for your home and garden

How to choose a deep-well pump yourself

Of course, choosing a deep-well pump for your site is a serious matter that requires care and concentration. It’s safest to entrust this matter to specialists who can easily select the right device based on the customer’s preferences and be able to install it correctly. But if you choose such a pump yourself, then you should take into account all the features, all the pros and cons of each type, compare prices and calculate which type would be more appropriate to buy from a financial point of view. You can contact consultants directly in the store itself, or you can buy this device, guided and relying only on yourself and your preferences. In this matter, you should not listen to neighbors, friends and comrades, since this device is selected completely individually for each site.

Disadvantages of screw pumps

When analyzing screw pumps, you need to take a differentiated approach to this issue, since some advantages and disadvantages depend on the chosen model and operating conditions.

Screw pump for well.

In total, for all screw structures, the following remarks should be noted:

- Inability to idle. This problem only appears when the well budget is reduced.

- Low efficiency. Indicators for different models range from 50-70%.

- Unregulated volume of resource supply.

- High or low price. It is difficult to take an unambiguous view of these indicators. Budget devices are characterized by increased wear of contacting surfaces, overheating and a short service life. Powerful, good quality equipment will cost comparatively more.

Average prices of deep-well pumps

- The price of centrifugal deep-well pumps varies from 9 thousand rubles to 13 thousand rubles. This is explained by the fact that this type is intended for summer cottages, and there is no point in putting a high price on this product, since it will not be in demand, which already causes damage directly to the manufacturer.

- Screw deep-well pumps can be purchased at an average price of 3 thousand rubles to 12 thousand rubles.

- The price of rod pumps starts from 6 thousand rubles and reaches quite high prices.

- Rodless deep-well pumps have a price approximately the same as sucker-rod pumps.

Of course, these prices are written in average values; the price for each device depends on many indicators, namely: the type, cable length, the company that manufactures the device, suppliers, the country where the purchase is made, the mechanism and many others.

Review of popular models

Judging by the reviews, the most purchased in our country are the Russian screw-type submersible pumps Aquarobot and Unipump ECO VINT, the Ukrainian Aquarius and the Belarusian Belamos.

So:

- The Aquarius submersible screw pump can be used to supply water from open reservoirs, wells and wells with an internal casing diameter of more than 100 mm. And also for cleaning wells and wells, pumping contaminated water from flooded basements and containers, watering and irrigation. It is secured in an underground source using the included synthetic cable. It is easy to install, operate and repair.

Submersible pump Aquarius NVP

- Unipump ECO VINT - these pumps are assembled in Russia and China. They provide decent pressure, but do not have very high productivity, which is unlikely to be enough to provide water to a large farm. However, for a summer cottage or a small country house it is quite enough. Its advantages include compact size and lack of vibration during operation.

Photo of a pump from the ECO VINT series

- Among the many models of pumps from a well-known Belarusian manufacturer, screw units include the Belamos SP series units (see Belamos borehole pump: model review). They belong to high-pressure devices designed for work in wells and mine wells. The instructions also allow you to use them in tanks and open water bodies. Their main advantages are a reliable stainless steel case and the presence of built-in thermal protection that turns off the device when the engine overheats critically.

Screw well pump Belamos SP 70/6

Installation of a submersible pump

Once the user has decided on the choice of the device he needs, then after purchase he will need to install the pump. In principle, you can involve specialists, but it is quite possible to carry out the installation yourself.

Before installing the equipment, a thorough check of all elements of the equipment's current insulation . It is imperative to check the entire length of the electrical cable, as well as the location of its connection to the device.

To install a submersible pump, you will need a hose (this is if the pump will later be used for watering and irrigation activities), a cable, a pipe, couplings, brackets and a safety rope. Then installation is carried out according to the following instructions:

- First, attach a pressure pipe or hose to the pump. Couplings are used for this.

- Next, to the pipe, which was previously secured with couplings to the device, you need to fix the cable using the existing brackets. Please remember that the pump must never be lifted by the cable. For this, another structural element is already used, called a safety cable.

- After the above operations and checking all fastenings, you now need to lower the pump to the desired depth.

- After immersing the device, you need to check the grounding and insulation

The engine must be started for the first time without any load. Then you should wait an hour. This is done in order to identify the presence of possible deficiencies and malfunctions in the operation of the engine. If, after idling, no shortcomings were found in the engine, then you can already connect the load and start using it.

Advantages and disadvantages of technology

Advantages of screw type well pumps:

- increased productivity;

- the absence of complex components in the design simplifies routine maintenance;

- there is no increased noise during equipment operation;

- small geometric dimensions;

- Pumping of liquids with different chemical compositions is allowed.

The disadvantages of a submersible pump for a screw-type well include increased cost and the inability to regulate the water supply. When installing the product, it should be taken into account that the device does not allow operation without a liquid supply.

The average price of an imported pump is 8-10 thousand rubles. Domestic equipment will cost slightly less. You can purchase submersible pumps in Moscow in specialized stores that supply components for water supply systems.

Conclusions and useful video on the topic

Video tips from professionals will help you cope with the calculations and make the right choice.

The author explains in detail how to choose a suitable well pump. You will also learn how to make correct calculations of important technical indicators of equipment:

From the video you will learn how a pump with a centrifugal mechanism works and how to choose the best option for specific living conditions:

Finding a good well pump with a centrifugal mechanism is not difficult. First of all, use our advice and do the calculations. Then, consult with experts and make your final choice.

Sources

- https://stankidarom.ru/prochee/ustrojstvo-glubinnogo-nasosa-dlya-skvazhiny-printsip-raboty-pogruzhnogo-skvazhinnogo-nasosa.html

- https://www.calc.ru/Ustroystvo-Skvazhinnogo-Nasosa.html

- https://remont-book.com/glubinnye-nasosy-dlya-skvazhin-do-50-metrov/

- https://met-all.org/nasosy/ustrojstvo-glubinnogo-nasosa-dlya-skvazhiny-printsip-raboty-pogruzhnogo-sskvazhinnogo.html

- https://nasosovnet.ru/centr/tsentrobezhnye-nasosy-dlya-skvazhiny.html

- https://www.nektonnasos.ru/article/skvazhinnyj/glubinnyi-nasos/

- https://sovet-ingenera.com/vodosnab/nasosy/centrobezhnye-nasosy-dlya-skvazhiny.html

Scope of application of screw units

An important point is that the screw pump is designed to pump not only water, but also steam, gas and other liquids. The water that rises from the well serves a variety of purposes:

- Drinking and solving various household problems.

- Filling tanks, fountains and pools.

- For powering irrigation and drip irrigation systems.

- For the accumulation of various containers, for example, boilers and heating boilers.

To use screw units, all design features of such a device should be taken into account. The most commonly installed screw pumps are:

- Water supply of a suburban area. Many summer cottages are located at a great distance from the central water supply network.

- Some models are characterized by the fact that they can carry out complete or partial water purification.

- Liquid supply from wells. Design features determine that the device can be operated even if the container is severely clogged. The screw pump device provides the required pressure in the pipeline.

- Some models are installed during construction work to pump out groundwater or melt water. An example is also the pumping of paints and other similar substances.

The main operational characteristics determine the widespread use of screw units in a wide variety of industries. The screw pump can last for a long period, but the choice must be made depending on the operating conditions.

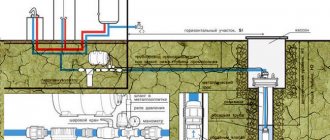

How to install water pipes

It’s worth noting right away that it is most convenient to install both the pump and pipes at once. At the same time, all the necessary calculations should be done in advance, otherwise you may encounter a lot of difficulties. The descent of the pump into the well should be smooth. Moreover, if the preliminary preparation is not carried out correctly, then you can receive an insufficient amount of water that is required to supply the house. The lack of pressure will affect the comfort of residents. As a result, they will have to choose between doing laundry, using the shower, or watering the garden. Carrying out side procedures simultaneously will become impossible.

Modern pumps are most often equipped with a flanged or threaded version for connecting a pipe. Although sometimes a coupling type of connection is used. Experts recommend first connecting the water-lifting element on one side, and only after that proceeding with the installation of the second part of the pipe. Lowering the structure to the ground is strongly discouraged. This may cause damage to important components or displacement of certain parts.

How best to use

When purchasing a screw pump for an equipped source, you will have to take into account certain operating rules. By following simple recommendations, the homeowner will be able to significantly extend the life of the device.

To operate a screw pump in a well, it is advisable to select a pump that can be well mounted on the wall of the shaft. It is advisable to install the device at an optimal depth so that the likelihood of the water level dropping to a critical level is minimal. This will prevent the device from running dry.

It is advisable to maintain a distance of at least 1 meter from the bottom so that liquid mixed with sand is not pumped through the water supply. When purchasing a screw unit, you don’t have to worry about the reliability of the operation of such equipment. The design of the product and the basic principle of operation were specially developed in such a way that the water intake hole was located above the engine itself. The working unit, thanks to this design, can be cooled naturally. The probability of fire in this case is practically zero.

Features of water intake are decisive in the selection of functional characteristics of equipment. Before selecting a suitable pump, be sure to take into account all the required control parameters.

Pump motors

Built-in motors are usually located at the bottom to maximize protection of the device from corrosion due to constant contact with moisture.

The upper part of the structure is occupied by the drive shaft device and certain blade outlets.

Vibration pumps have a special glass and housing. There is a built-in vibrator that creates the necessary traction to create a flow of water, and there is also an electric motor. The vibrator is a rather complex structure, but it plays a major role in performing the work. It consists of an anchor, a rubber shock absorber and adjusting washers.

Where is the easiest place to buy a deep well pump?

Firstly, these are cities in Russia, such as Moscow, Kazan, St. Petersburg, Ryazan, Ufa and many others.

You can also order a deep-well pump online. In the world of high technology, there are a huge number of Internet resources on which the buyer is provided with an endless assortment of this product. You can find sites where prices are lower, you can find free delivery, or quite the opposite, everyone decides for themselves.

Pumping station vs. deep well pump

A pumping station is a kind of mechanism in which there is a storage tank. And the most important task of this structure is to fill the tank to a certain level, and only then supply water to the house’s pipeline. Often this is not entirely convenient, since this device is used in country houses, and water is needed there quite often, and there is no desire to wait until the tank is filled. In principle, the operation of a deep-well pump and a pumping station does not have any special differences, it’s just that everyone must choose for themselves what suits them best for use. Among the advantages of the pumping station is a long service life, but among the disadvantages are large dimensions. In a deep-well pump it is quite the opposite. It is impossible to say with certainty what is better and what is worse.

Carrying out installation

Features of installing pipes and pumps largely depend on the type of well. In some cases, installation of conventional devices will be very difficult. In such situations, it is possible to use flexible hoses that can replace water-lifting pipes. The main thing is that these elements are strong enough and safe for humans. Under no circumstances should they release harmful chemical compounds into the water. In addition, you should make sure that the pipes are reliable enough and that all fasteners are of high quality. Otherwise, the water supply will have to be repaired immediately after its first use.

Experts strongly recommend using only those options that have been developed and manufactured for these purposes as water-lifting pipes. You should not take nylon hoses or fire pipes, as they will quickly fail and may even damage the pump. As a result, you will have to spend money on purchasing a new set of expensive equipment.

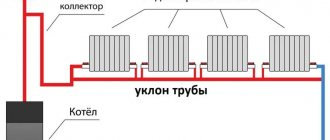

Selecting a well pump

The choice of pump for a well is made according to a set of indicators. There are scientific calculation methods, but a larger calculation can also be carried out.

The main indicators in the operation of the selected pump are:

- Pressure (pressure created), m of water column;

- Productivity, m3/hour.

The pressure characteristic consists of several components of the sum:

- The height (depth) of the well to the zero level of entry into the building;

- Resistance of the horizontal section of pipelines;

- Height to the upper water point;

- Minimum pressure in the home network;

- Power reserve – from 5 to 10%.

Moreover, the calculation should be carried out without taking into account the presence of a hydraulic accumulator at the station. It is designed to reduce the start-up frequency and smooth out pulsations. It is recommended to purchase and install a separate hydraulic accumulator of larger volume. The use of this device is mandatory for any type of pumping equipment.

Let's consider a special case - the well has a depth of 20 meters, the horizontal section is 8 meters long, the upper point of water intake (mixer) is located at a height of 2 meters. The minimum pressure for operating household equipment (washing machine, dishwasher, etc.) is from 1 to 1.5 kgf/cm2 (according to the product data sheet), that is, from 10 to 15 meters of water column.

The resistance of the horizontal section will be 8 x 0.3 = 2.4 meters. The final pressure is:

(20 + 2.4 + 2 + 15) x 1.1 = 43.34 meters (where 1.1 is the power reserve correction factor).

Next, the second value is determined - productivity. It is determined by the average water consumption per person per day - 200 liters. For a family of 4 people, the required volume of water will be 0.8 m3/day.

The constant period of water consumption is approximately 12 hours. The required pump capacity will be 800 l / 12 hours = 66.7 = 70 liters per hour. To account for peak loads, a correction factor of 1.25 should be applied. Then the final value will be 70 x 1.25 = 87.5 = 90 liters per hour (2.16 m3/day).

The calculated productivity value should not exceed the daily water limit of the well. Excess may cause clogging of the well and damage to the channels at its base.

The last stage of pump selection is selection according to the flow-pressure diagram. This diagram is present in the passport of each pump. Along the axes of pressure and flow (productivity) we mark the calculated values.

The intersection of points on the curve of the diagram will be real indicators of the operation of the unit under design conditions. The intersection point should be located in the middle part (middle third) of the graph.

Choosing a pump for a well is an important undertaking. Knowledge of the types of equipment and calculation methods allows you to select the necessary pump for a well without difficulty. You can involve specialists in the store in selecting a pump - as a rule, experienced managers know the selection methodology. At the same time, you can check your calculations - trust, but verify.

( , 1 today)

Possible malfunctions and methods for eliminating them

Despite prevention, cases of breakdown are possible, so we will consider the most common of them.

Preventative cleaning must be carried out every 1-2 years, but emergency unscheduled repairs are also possible if parts are worn out or the suction pipe is filled with sand ahead of time

If the pump does not turn on, perform the following actions:

- check the presence of contacts in the socket;

- inspect the pump for clogging with sand;

- We measure the voltage, if there is a deficiency, we connect a stabilizer.

If productivity suddenly decreases, we check whether there is a leak in the pipeline. At the same time, we inspect and clean the filters. When the voltage decreases, we use a stabilizer.

The pump will sooner or later become clogged with sand, so we clean it: remove the mesh and protective chute, separate the pump part and the electric motor, check the operation of the shaft, and wash all the elements. We assemble the device in reverse order.