Updated: 02/19/2021 18:37:13

Expert: Konstantin Borisovich Polyakov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

The most important electrical appliance in the water supply line of a private home or garden irrigation system is a self-priming pump. It allows you to provide water to your kitchen, bathroom and kitchen by pumping it from a well or borehole. Or organize watering of plants in the garden and vegetable garden, supplying water from a reservoir and pool. The device attracts potential buyers with affordable prices and trouble-free operation. There is a wide range of self-priming pumps on the Russian market. To make the right choice, you should listen to the recommendations of our experts.

Surface pumps for wells

Selecting the right type of surface pump for a well is based on hydrogeological characteristics and daily water consumption. Hydraulic characteristics include:

- static level - a constant water level in the well, which can decrease or increase depending on seasonal recharge with groundwater (typical for sand wells);

- dynamic level - the water level in the well after daily consumption;

- well flow rate is the volume of water entering a well from a water layer per unit of time (m3//day).

Daily water consumption should not exceed the flow rate of the well. If you intend to use water for irrigation, and the flow rate of the well is low, then you need to have a spare tank; fill it during the period of minimum consumption. You can find out the flow rate of a well by tapping the level with a float. Before drawing water, the static level is measured. Then water is taken into a measuring container. They record the dialing time, then beat the level a second time and find the difference in levels. Let's say we took 1 m3 of water in 45 minutes , the level in the well dropped by, say, 1 m (dynamic level), which for an internal diameter of 100 mm will be a volume of 8 liters . Let the time period from the start of sampling to the secondary measurement be 1 hour , then the well flow rate: 1000 – 8 = 992 l/h or 23.8 m3/day .

With a static water level of no more than 7.5-8 meters, a surface piston, centrifugal (vortex), or hand pump will be required.

Well parameters and quality

Hand pumps

Hand pump

Well head prices

Well head

Suitable for shallow wells. Country option.

Advantages:

- inexpensive;

- easy to install and maintain;

- saves energy.

Flaws:

- the labor-intensive process of extracting water from a well;

- filling is necessary before pumping;

- difficult to connect to standard home plumbing;

- The deeper the water, the more difficult it is to pump it.

Centrifugal pumps

Theoretically, the maximum depth of the water level that can be lifted from a well using vacuum will not exceed 10.3 m . In fact, normal atmospheric pressure is 76 mm. mercury column, which is equal to 10.3 m of water column . To raise water to this height, an absolute vacuum must be created. The hydraulic resistance when water passes through the pipe is taken into account. So it turns out that the best manufacturers of surface centrifugal pumps indicate a maximum suction depth of 8-9 meters , subject to installation closer to the wellhead to avoid hydraulic losses.

Pumping station

Prices for popular models of pumping stations

Pumping station

The stations include: a hydraulic accumulator, a centrifugal pump, an automatic start pressure switch.

The station is used where the water level does not exceed 10 m , but for this it must be installed in a shaft (caisson) 1.5-2 m . The mine is built from concrete rings, and ready-made plastic and metal caissons are sold. Sometimes the station is installed in the basement, connecting the suction line (water intake) through a trench to a well. Advantages of centrifugal pumps:

- inexpensive;

- easy to select according to the required technical characteristics;

- the kit includes spare parts;

- stainless steel impeller;

- ease of installation, maintenance and repair.

Flaws:

- noisy (problem if installed in a house);

- large starting impulse;

- Stable voltage and frequency are required.

Piston or plunger pumps

Piston pump

Double acting single piston pumps are great for pumping water from shallow wells. The most common are DURO and POMPCO.

Advantages:

- an inexpensive repair kit allows you to independently change worn parts;

- no problems with spare parts;

- low starting splash;

- 20 years of experience with clean water.

Flaws:

- creates noise during operation;

- AC motor models require an inverter.

Video - From what depth can a pumping station lift water?

Surface pump for a 10 meter well

Installed in basements or caissons closer to the wellhead. As a rule, they are part of a pumping station and have an ejector built into the hydraulic part, which creates additional vacuum in the suction pipe.

The use of an external ejector based on the principle of a Venturi tube allows you to extract water at depths of 10 meters or more.

Venturi tube

Principle of operation. There is a narrowing inside the pipe (resembling an hourglass shape). The flow speed passing through the narrowing increases. The laws of dynamics determine that an increase in flow velocity is accompanied by a drop in pressure. As a result, an area of low pressure is formed. The pressure difference inside the pipe and outside draws in the medium (air, liquid, powder) located outside. The Italian scientist G. B. Venturi (1746-1822) was the first to observe this phenomenon, which is also closely related to Bernoulli's theorem. Swiss mathematician Daniel Bernoulli in 1738 obtained the relationship between pressure, speed and other physical properties of a fluid. Most often, a venturi uses this negative pressure to draw a second fluid into the primary flow. This effect has many applications in various industries.

Operating principle of a pump with an internal ejector

Jet pumps consist of three sections: a centrifugal pump, a jet ejector package, and a bottom valve.

Centrifugal jet pump with ejector built into the housing

Rotating the impeller at high speed creates centrifugal force, which circulates the fluid moving through the ejector nozzle. A jet of water passing through the nozzle at high speed creates additional vacuum in the suction system, which allows the water to rise.

There are four main types of jet pumps, which vary depending on application and size:

- Used in large volumes, such as oil wells, the depth of which varies from 2000-5000 meters .

- They are used in cases where water is close to the surface - in autonomous water supply wells. The ejectors are bolted to the front of the pump.

- For water intake where the water level below ground level is 10 m or deeper.

- Miniature devices are used for small applications such as aquariums, swimming pools.

The main characteristics to consider when choosing jet pumps are:

- consumption;

- pressure;

- pressure;

- power;

- rated power;

- outlet diameter;

- working temperature.

Please note: If external and internal pressures exceed material specifications and pressure ratings, the pump neck may rupture and cause damage or reduced flow.

The built-in ejector works effectively for collecting water from a depth of 8-9 meters ; if the depth of the intake is 10 m, then they should be installed 1.5-2 meters below ground level . Selecting a pump for installing an external ejector is quite simple: the hydraulic part will have two holes in the front cover for connecting a two-pipe system. When selecting the injection and lift pipes, it is necessary to ensure that their total cross-section does not exceed the internal diameter of the production string. The discharge line is assembled with a smaller diameter than the elevator pipes. The end of the pipe through which the water rises is equipped with a filter, a check disc or ball valve.

Useful information about deep well pumps in our article. All about the types of deep-well borehole pumps, criteria for choosing a pump.

Surface pump for a 15 meter well

lifting water from a depth of 15 meters , provided that the piston is located closer to the static level. Centrifugal jet pumps with an external ejector will also cope with this task quite successfully. There are two types of ejectors: for production columns with an internal diameter of 100 mm. and more, as well as for diameters of 50 mm . The principle of their operation is the same, the design is slightly different.

Downhole ejector

The design is a combination of a surface centrifugal pump, a downhole nozzle and a Venturi tube arrangement. Piping is used in small-diameter wells to lift water from a depth of 15 meters or more. A pressure pump supplies water to the nozzle. An increase in flow rate causes a decrease in pressure at point A , which in turn draws water through the foot valve into the inlet pipe B. The combined flow then enters the Venturi, where the velocity is gradually reduced and the pressure is restored. Excess flow is diverted to the surface through control valve C , which also maintains the required recirculation flow to the nozzle.

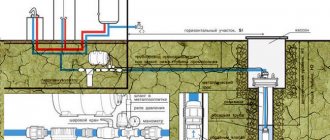

And here is the piping diagram for a production string with a diameter of 50 mm.

Single-pipe ejector

Here the operating principle is the same: water is supplied to the ejector in between the pipe space. Having passed through the ejector nozzle, a vacuum area is created, water flows from the well through the suction pipe, enters the discharge pipe, and then to the consumer.

Benefits of use:

- the design is applicable for tying production columns 50 mm in diameter;

- easy access to all moving parts on the surface of the earth;

- relatively low costs for purchase, installation, maintenance.

The operating efficiency of this scheme is lower compared to conventional centrifugal pump piping. But the use of a borehole ejector allows you to raise water where the level reaches more than 30 meters .

Recommendations for choosing a pump with an external ejector

Pumps DP-81 and DP-100 are ideal for piping wells with a diameter of 100 mm. with a suction depth of up to 21 meters . The kit includes 2 types of ejectors: E 25, E30.

Table 1. Characteristics of a pump with an external ejector.

| Hydraulic characteristics (engine speed 2,800 rpm) | |||||||

| Model | Ejector type | Ejector installation height, m | Allowable values of “discharge pressure”, bar | ||||

| 1.5 | 2 | 2.5 | 3 | 3.5 | |||

| Table consumption, Q l/h | |||||||

| DP-81 | E 25 | 9 | 2130 | 1400 | 720 | ||

| 12 | 1720 | 1000 | 400 | ||||

| 15 | 1210 | 570 | |||||

| E 30 | 9 | 1780 | 1330 | 940 | 610 | 350 | |

| 12 | 1500 | 1090 | 730 | 440 | 240 | ||

| 15 | 1250 | 870 | 560 | 310 | |||

| DP-100 | E 25 | 9 | 2570 | 1860 | 1110 | 460 | |

| 12 | 1980 | 1410 | 710 | ||||

| 15 | 1390 | 940 | 370 | ||||

| E 30 | 12 | 1760 | 1340 | 970 | 640 | 410 | |

| 15 | 1510 | 1110 | 770 | 510 | 270 | ||

| 18 | 1250 | 900 | 610 | 340 | 140 | ||

| 21 | 730 | 440 | 240 | ||||

Warning: Pumps should not be operated below their minimum “discharge pressure” as shown in the table. Otherwise, negative aspects will arise: loss of flow, the appearance of air in the water, an oscillating pressure gauge. Noises are a sign of cavitation, causing damage to pump components, including bearings.

Example: DP-81 with E25 ejector at a suction depth of 9 m should not operate at a pressure below 1.5 bar . DP-100 with E30 ejector at 21 m suction should not be operated at a discharge pressure below 2.0 bar . If cavitation persists, the pressure may need to be increased.

25mm diameter pipe discharge lines , suction (lift) pipes with a diameter of 32 mm . Ideal for production strings with an internal diameter of 100 mm. — pipes with diameters of 40 and 50 mm. respectively . When choosing a pump, calculate the distance from the installation site to the well; if this is a horizontal section, then add another 6% of the distance to the depth of the static level. Let's assume that this distance is 50 m , and the distance to the water level is 15 meters , then the total distance will be 15 + 3 = 18 m . Then you need to choose DP-100 with an E 30 ejector. Please note the difference in productivity Q l/min depending on the installation depth of the ejector: for example, for DP-81 with an E 25 ejector when installed at a depth of 9 m, the maximum flow rate will be 2130 l/min . and when installing the ejector at a depth of 15 m , the flow rate will decrease by almost 2 times - 1210 l/min.

Installation instructions for a surface pump with an external ejector

Piping of the pump occurs in the following sequence:

Step 1. Read the installation instructions.

Instructions

Step 2. Then check the equipment, prepare the fitting: check valve, filter, couplings, 90-degree elbows with a large radius, PVC-U pipes. Unscrew the 2 bolts securing the ejector block and remove the block.

Removing the external ejector

Step 3. We screw a PVC-U pipe into the body of the ejector block from below, and onto it a filter with a check valve. 32 mm fitting . We screw a Venturi tube inside the ejector block. Then we pass a Venturi tube inside the discharge pipe ( diameter 25 mm ) and connect it to the ejector block. We place the connections on the FUM tape.

Downhole ejector assembly

Step 4. We assemble the suction line to the ejector block from above. We lower the assembled structure into the well.

Lowering the ejector into the well

Step 5. We connect the pump to the pipes lowered into the well. The photo shows the operation of a downhole jet ejector.

Pump connection

Step 6. All that remains is to connect the pump to the reservoir, connect the cable to the engine, pour water through the neck to fill the pipes and hydraulics of the pump, then turn on the “start”.

Connecting the pressure line to the tank

Recommendations: determine the depth of descent of the ejector, measure the distances, determine how much material is needed for the strapping. The pipes should not rest on the pump; place a stand and close the well with a plastic plug.

Video - Surface pump for wells | Installation of a surface pump for wells

Instead of an epilogue

When choosing a suction pump, you must always remember that it is complex technical equipment, so before purchasing you should clearly establish the purposes for which it is being purchased. Using a pump that is not suitable for a certain type of work will invariably lead to its failure. You should also pay attention to the warranty period: does it correspond to the type of equipment purchased? As a rule, it is larger for centrifugal ones, and smaller for vortex ones. It is better to buy a pump through online trading platforms, thus saving yourself from unnecessary retail markups.

Surface pump for a 30 meter well

As the depth increases, the pressure increases, so for a static level of 30 m you will need a pump more powerful than the DP-100.

Surface pump with remote ejector LEO AJDm110/4H

The maximum suction height is 40 meters, which guarantees a certain power reserve for lifting water from a depth of 30 meters.

The manufacturer LEO produces a new type of pump with a flexible shaft for deep wells.

It is installed at the wellhead. The flexible shaft is produced in lengths of 25, 45 meters - the depth from which water can be pumped out. This type of pump is more of a semi-submersible pump than a surface pump. They are mounted on a production string with a diameter of 50 mm. Can be an alternative to a hand pump.

The hydraulic part consists of 2 hoses inserted one into the other. A flexible shaft is passed inside, connected to the head of a screw-type pump.

Screw pump

Despite its small size, the maximum productivity is 1.8 m3//h , and the pressure is 90 meters . The hose is lowered into the well to a given depth, and the flexible shaft is connected to the gearbox shaft of the electric motor. The advantage of the pump is that the electric motor is located at the top. If the pump is clogged, disconnect the flexible shaft, pull out the hose, and wash it.

Rules for choosing wisely

Before purchasing, you should read the information contained in the product data sheet. You need to be interested in the following information:

- Power and productivity - this indicator must be compared with the distance of the well from the house, the number of water distribution points and the maximum volume of water required at any given moment. Naturally, this will require precise mathematical calculations. However, by correctly calculating the required pump power, you can extend its service life, as well as avoid premature breakdowns and overheating;

- The minimum output pressure should be 0.3 Bar. Otherwise, household appliances connected to plumbing communications may fail.

- It is also necessary to correlate the capabilities of the pump with the diameter of the casing pipe installed in the well. It is better to contact the specialists who carried out the drilling with this question.

Reviews of surface pumps for wells

Let's create a table of the 10 best surface pumps that are in greatest demand among buyers.

Table 2. Best surface pumps.

| Brand | Type | Pressure, bar | Head, m | Consumption, m 3 / h | Water level depth, m |

| Grundfos MQ 3-35 | multi-stage, self-priming | 7.5 | 44 | 4.1 | 8 |

| AJDm110/4H | with external ejector | 9 | 100 | 2.2 | 30-40 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming with built-in ejector | 7 | 37 | 4.8 | 8,5-9 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming, vortex | 8 | 38 | 8 | |

| APM 100, 150, 200 (Speroni) | with remote ejector | 7 | 64 | 1,8 2,7 | 10-40 |

| BG and BGM (3, 5, 7, 9, 11 (Lowara) | self-priming with built-in ejector | 9 | 46-60 | 2-4 | 8-9 |

| JET 112 T from DAB | self-priming with built-in ejector | 6-8 | 50 | 2-3 | 8-9 |

| Calpeda NGLM 4/A | self-priming with built-in ejector | 8 | 50 | 2-4 | 9 |

| JMC 100 | centrifugal self-priming | 7.5 | 44.5 | 3 | 8 |

| Gilex Jumbo 70/50 N / 3702 | self-priming | 8 | 50 | 4.2 | 9 |

| The best pumping stations for deep water lifting | |||||

| Grundfos JPD 4-54 PT-V | with remote ejector | 6 | 54 | 27 | |

| ELITECH CAB 800/24E | with remote ejector | 6 | 45 | 2.4 | 25 |

| Gilex Jumbo 50/28 Ch-18 | with remote ejector | 3 | 28 | ||

Here we select stations and pumps with a built-in ejector or an external version. To automate the process of extracting water from wells, it is recommended to purchase a hydraulic accumulator with a pressure switch for these pumps. Usually they buy a ready-made pumping station. The manufacturer has calculated the optimal tank volume for this type of pump.

In order for pumping equipment to operate smoothly, you need to choose the right pump. In addition to the static, dynamic level, well flow rate, average consumption per person per day, it is necessary to determine the total height of water rise from the mirror to the highest point of supply. Do not forget the horizontal section, 6%-10% of which must be added to the lifting height. So determine the required pressure.

Self-priming surface pumps without a built-in ejector are best installed in basements or caissons. The shorter the distance to the water surface, the lower the hydraulic losses. Turns and narrowing of water lines also increase hydraulic resistance. Buy a storage tank for irrigation, this way you will create a supply of water if the daily flow rate of the well is low.

Find out what the water supply scheme for a private house with a hydraulic accumulator is, and also familiarize yourself with its design and startup process in a special article on our portal.

Prices for surface well pump

Surface pump