The designs of heating devices operating on solid fuels are constantly changing and improving. New parts are installed, components and mechanisms are added, which makes it possible to achieve greater productivity and efficiency of thermal devices. The grate for the furnace is the part that cannot be dispensed with in any design, regardless of its type and size. The product can be purchased at a retail chain or, if you have the tools and skills, you can make it yourself.

Item for arranging the furnace

Choose the optimal location for the heating stove. As an example, a stove installed in the center of the room will give off heat as efficiently and evenly as possible. However, such placement of the stove is not always convenient.

Stove in the middle of the room

If the stove structure is placed against the wall (this option is the most popular and often used), cold will flow across the floor of the house.

Select in advance the location of the combustion chamber door. Design the stove so that in the future you will not have to carry fuel throughout the room, spreading dirt around the room.

The heating stove is located against the wall

The best option is to install a firebox in a room that is rarely visited.

Recommendations regarding the foundation are standard - an individual concrete foundation is installed. It cannot be connected to the main foundation.

Calculate the design of the foundation in such a way that it is able to withstand the load not only of the furnace itself, but also of the smoke exhaust structure, which is also strongly recommended to be built of brick.

Initial information

Self-made structures made of steel, when compared with their brick counterparts, are distinguished by the speed of construction and increased heat transfer. To carry out the work, it is enough to find a pipe whose diameter will be approximately 50 centimeters. Such products are especially relevant for small objects.

Approximately the following pipe needs to be prepared.

- The heating structure must be located in a place where reliable fire protection is provided for materials that are easily ignited.

- The area occupied by this facility should not exceed 0.15 percent of the usable square footage of the heated room, since it is not very comfortable to carry out water procedures in a cramped environment.

- The side surfaces of the structure must be covered with heat-insulating materials so that the risk of burns is minimized.

- When installing, you should take care of the correct location of the stove, because the heat emanating from it should spread in different directions, thereby ensuring high-quality heating.

Basic elements

Any of the fragments listed below performs some function, so it is important to study all the details in full

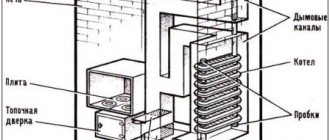

The structure of a sauna stove with water supply.

- The firebox is the main chamber where organic fuel is usually burned to heat the walls and then the surrounding air.

- The ash pit is located below the previous chamber, ensuring the collection of ash, which is formed as a result of the combustion of organic substances.

- The stone container allows you to lay cobblestones of jadeite, gabbro-diabase, crimson quartzite or other high-temperature resistant analogues.

- The pipe is a hollow product that is necessary to remove combustion products from the main chamber.

- The grate is an element inside the firebox that makes it possible to hold a layer of solid substance intended to produce thermal energy.

- Blower and firebox doors allow you to control the flame by covering it, which leads to a decrease or increase in oxygen inside.

- A pipe valve is usually made in the form of a control element that moves perpendicular to the working medium.

Shown is a homemade grate made from rebar.

Why is it needed?

As has already become clear, the grate is a grate that allows the air flow to penetrate directly to the combustion center below, and the ash to be removed through the holes to a specially designated place for it. So why do we need grates in a furnace? Installing a grate in a furnace allows you to solve a number of problems:

- Divides the combustion chamber into two zones - the combustion chamber itself and a niche for ash.

- Used for placing and drying fuel.

- Distributes the air flow from the ash pan.

- Promotes good traction.

- Together with the door it makes it possible to control and regulate the flame.

The grate, which is intended for installation in the stove, cannot be made from any metal. Since it is constantly exposed to high temperatures and oxygen, it can begin to oxidize very quickly. Only cast iron can survive in this environment for a long time

What is needed for production?

It is possible to make a grate with your own hands. What to make a grate for the oven from? It is better to use heat-resistant steel as a material, because it is impossible to work with cast iron at home. To make the grille, you can use any materials that have heat-resistant characteristics. This could be fittings, corners, steel pipes or strips of metal.

To make grate bars you will need:

- the metal from which the grille will be made,

- steel rods for creating partitions;

- ruler, tool for making marks;

- grinder for cutting material;

- welding.

From reinforcement

It is not difficult to make a grate from reinforcement yourself. It is enough to select the desired length of the product and cut the reinforcement with a grinder. It is necessary to determine the number of strips and take into account clearances for ventilation.

When the required amount of material has been prepared, you can begin welding the grate using rods. Do-it-yourself grate bars for the stove made from reinforcement can be seen in the photo below:

Self-installation of the grate

When heated, any metal will expand, therefore, the grate must be installed with a gap of at least 0.5 centimeters on each side. The ledge in the combustion chamber should be cut off (we are talking about the one on which the edges of the grate are laid). If the heating stove is made of brick, then the place for installing the grate should be located below the door at a distance corresponding to the height of one brick. This can be explained very simply: such a rise will prevent burning coals from falling onto the floor.

Also, during installation, you do not need to embed the grille too tightly. The degree of expansion for different materials is also different, therefore, too strong fixation of a cast iron product can cause cracks in the brickwork or deformation of the metal. Upon completion of the installation of the grate, the grooves must be tightly filled with sand (but without using cement!).

On a note! In the case of a triangular cross-section of the grate rods, the product must be laid exclusively with triangles downwards!

Tile grate

One of the most common types of grate is the tiled grate. The main feature of this design is the observance of strictly fixed dimensions. This grille is designed for an installation site of a certain size.

A mandatory condition must be met - the presence of a gap between the outer perimeter of the grate and the walls of the firebox of at least 5 mm. If this size is not maintained, the cast iron grate may expand greatly when heated and damage the firebox.

Specifications

There are many types of stoves, varying in size, type of fuel used, and other characteristics. Therefore, the grate for them will also be different. As for the material of the stove itself, it does not directly affect the choice. Grates are installed in brick, steel, and cast iron devices.

Type of design

There are gratings:

- monolithic;

- typesetting;

- refrigerated.

Monolithic are solid structures. Dimensions are selected depending on the depth and width of the combustion chamber.

Available to fit all standard firebox sizes. This option is the easiest to install.

The typesetting version is made up of individual rod elements. It is used if a standard one cannot be selected, for example, in non-factory-made ovens.

Important! Often the rods are wedge-shaped. When installing, they are positioned with the narrower part down

This increases service life.

Cooled ones are used in systems with heat exchangers. They are made of tubes through which coolant passes. Thus, the grate itself is cooled, and the overall efficiency increases. This option is more often used in solid fuel boilers. The temperature inside the chamber reaches 1000°C. Thanks to cooling, the material can withstand a similar thermal load.

Form

The grate bars differ in the shape of the canvas. Different types are used in different designs. The following types of gratings are available:

- flat;

- basket;

- movable;

- beam

Photo 1. Basket grate made of cast iron. This type of device is usually installed in fireplaces.

Flat (or tiled) - the most common type. They are installed not only in stoves, but also in boilers that burn solid fuel, as well as in fireplaces. They have a rectangular shape. The dimensions are standard, selected depending on the dimensions of the fuel chamber.

Baskets have curved edges, which is why the whole structure resembles a basket. Such structures are placed in open-type ovens intended for cooking. Since such stoves are rare nowadays, and the parts for them are also not very common.

Movable grates are installed in long-burning furnaces, where it is necessary to regulate the air flow. The design allows for the possibility of changing the width of the gaps. They have several sections and a shaft, thanks to which movement occurs. Rotation axes can be horizontal or vertical. An additional advantage is greater ease of cleaning.

Beams consist of individual crossbars (beams), which can be single or double. They are typically used in non-standard sized ovens.

Size

The dimensions of the product depend on two parameters:

- dimensions of the furnace combustion chamber;

- type of fuel used.

In equipment operating on wood, peat and fuel briquettes, a width of 150-350 mm (in increments of 50 mm) is most often used.

The depth is usually 180 or 250 mm. The largest possible dimensions of standard models are 900x800 mm.

When coal burns, more harmful substances are formed. Therefore, the dimensions of the grille should be larger, from 300-350 mm on both sides.

In any case, gaps of at least 5 mm are left at the edges. They serve to compensate for expansion when heated.

Attention! When choosing a size, the weight of one load of fuel is also taken into account. Dimensions, especially thickness, are selected in such a way as to withstand this load

Ways to solve the problem

If the grate is damaged, there are two options: fill the ash chamber with a brick or install a new grate.

The option of filling is acceptable only if the integrity is damaged or there are cracks and it is impossible to eliminate them at the base of the ash pit. At the same time, it would be good to replace the firebox door from a blank door to a door with a grille to regulate the flow of secondary air. But this option will definitely create a lot of unnecessary trouble and reduce the efficiency of the furnace. Therefore, we change the grate.

The grate is usually made of cast iron. Cast iron is very different from brick in terms of CTE - coefficient of thermal expansion. This indicator for iron is much higher than for ceramics. Therefore, the grate is always placed freely with a gap of 5-10 mm around the entire perimeter. Some manuals recommend filling the gaps between the masonry and the grate with sand. But this is very stupid advice. Unnecessary and even harmful. Firstly, the sand from the heat of the coals (and it can reach 1100 degrees Celsius) simply sinteres - vitrifies, tightly welding the grate to the masonry and depriving it of the necessary freedom. Secondly, after the first fire, this gap is filled with ash - a non-flammable and non-caking material. So why make unnecessary movements?

It is important to place the grate correctly - an inverted grate quickly becomes clogged with ash and stops working. Therefore, we remember that the grate slits expand downward, not upward. Sometimes the grate has a thickening in the middle - this is to equalize thermal stress, and not to roll the coals to the edges, as some people think.

The figure shows the correct (bottom) and incorrect (top) position of the grate

Usually the grate is placed in a brick trough or in grooves selected in the brick. If the integrity of these grooves is damaged and it is impossible to restore them, you will have to come up with some kind of supports. Sometimes they try to get out of the situation by driving nails, metal plates, etc. into the seams of the masonry. All this is in vain - the metal is quickly tempered and ceases to hold the grate, and more massive pieces of iron are unacceptable - they will tear the masonry.

Main functions of grate bars

The grate bars are installed in the firebox; as combustion proceeds, the waste is poured into the ash pan.

Any boiler is a structure where each part performs a specific task, ensuring the uninterrupted operation of the entire device.

The grate bars in the furnace perform the following functions:

- Placement of fuel - coal, firewood, briquettes, and other flammable items. Air enters through the blower, ensuring the presence of oxygen necessary for the thermal reaction.

- Removing ash and ash. As the loaded material burns out, it turns into a powder and spills down through the grates. The fuel settles on the surface of the metal, and the flow of oxygen to it improves. This frees up space for loading the next portion of fuel.

The efficiency of the boiler depends on the design of the grates; the correct choice of metal for its manufacture ensures the longevity of the device.

Conclusion

When choosing a high-quality grate, you should take into account the design features of the stove. The choice of a specific design and lattice components depends on the nature of the fuel. A grate for a sauna stove made of cast iron will last longer than the same one made of steel or other metals.

The weight of the fuel itself is also of great importance. Installing gratings does not require special knowledge. You can correctly place the grates in the oven yourself; it is enough to take into account only a few nuances. With the right choice of material and installation, they will last you a very long time.

Hello. I'm inv. is falling apart. There is no money to build a new stove. Pension according to inv. small. How to put the kolsnik? Not started! Zoya

The interpretation of your letter caused some difficulties for our experts, since it allows for dualism of perception, the presence of which does not allow for a correct answer. After much debate, we decided that the following reading can be considered the most accurate:

Hello. I am disabled 2 gr. 5 years ago we had an earthquake in Tuva. Something fell out in the stove and now there is nothing to put the grate on. I try all sorts of things. I put a knife, rasp, scissors, etc. between the side and the masonry. But such a structure quickly falls apart. There is no money to make a new stove. The disability pension is small. How to lay the grate? Zoya.

Based on this, we will try to answer as accurately and clearly as possible. Touching upon, however, the aspect of sealing cracks - this is the most common malfunction after earthquakes and, in general, linear displacements of the foundation and masonry of any etiology - from shrinkage to thermal expansion.

Types of grates for a fireplace or stove

For the manufacture of grate bars, various materials and various designs can be used. In most cases, heat-resistant steel or cast iron is used.

The fact is that the grates are constantly exposed to fire and therefore it is better to choose cast iron. since it has a high strength index. There are two types of grate:

The furnace firebox can have different sizes and shapes, so furnace casting manufacturers make all sorts of configurations. For a firebox with non-standard dimensions, you can also easily select a suitable model. Solid types include monolithic types without the possibility of disassembly. The choice of sizes is quite wide, so the main reference point is the firebox area. The basis of typesetting models is made up of several individual elements. This is something like a constructor. which you can assemble with your own hands and get the desired grille size.

Steel grates for a type-setting stove have the form of a conveyor belt and are called chain grates, and models with the possibility of cooling and made from pipes with your own hands are called pipe grates.

Cast iron grates can be of several types:

- tiled. Rectangular models used for solid fuel boilers, fireplaces and heating stoves. They are universal, the main thing is to determine the standard size;

- basket Ideal for an open hearth. The main purpose is cooking, but today they are used extremely rarely, since the design is morally outdated;

- beam These models owe their name to their resemblance to construction beams. They have the appearance of a stacked structure and consist of double or single elements. The optimal solution if you need to assemble a grate of non-standard size;

- movable. Such gratings have a design feature. allowing you to change the width of the gaps, which is often not enough during installation. In most cases, they are used in long-burning furnaces.

Recommendations for selection

The clearances for coal should be larger, since combustion produces large slag.

When choosing a grate for a boiler, it is necessary to take into account what type of fuel will be used in the operation. Cast iron grates for stoves have different dimensions, but the main criterion is the size of the gap in the grate. It determines the size of the waste that will fall out of the firebox through them.

Recommended clearance:

- for coal - 30x300 mm or 28x205 mm;

- for firewood and briquettes - 140x115 mm or 330x250 mm.

The optimal ratio of the area of the gaps and gratings is 1:1. Deviations in one direction or another lead to a decrease in the efficiency of the device.

Cast iron is more resistant to heat, but is fragile; it is better to use it under coal. It is impossible to break steel alloy products, but they can melt from excessively high temperatures. The optimal solution for them is the use of briquettes and firewood.

Grate design

The size of the grate depends on the fuel that will be used in the future. For everyday use, two designs are recommended - solid and composite.

The first option consists of a cast iron grate, which is selected according to the size of the combustion chamber. The second type is assembled from individual elements.

The size of a composite grate is determined in the same way as a solid one, based on the size of the firebox. In addition to differences in type, devices are also divided by functionality.

The design of the cast iron grate comes in two types: full-rotating and swinging. In the first case, the elements have the ability to rotate horizontally by 180 degrees, which allows you to dump ash and slag.

This design involves grooves in the combustion chamber for additional holes. It is extremely difficult to make a full-circle system at home.

In the second design, the elements have cradle-like movement elements, rotating around at an angle of 30 degrees. This system has the ability to loosen accumulated slag.

By design, the grate can be chain or pipe. In the first case, the model resembles a conveyor belt. In the second, it is made of pipes and has a cooling function.

The cooled grate consists of a cast coil, which is made of cast iron. This type is used in water heating and pipe water supply systems. Coolant circulates inside the cooled grate device. Cooling is used when burning coal, since its temperature is a thousand degrees.

How to make a homemade heat exchanger

A register of several pipes

The shape of a heat exchanger for heating made by yourself can be different. The most common option is a register made of several steel or copper pipes, but plate-type examples are also used.

The temperature in the combustion zone is very high, especially when burning coal. Therefore, increased demands are placed on the metal from which the heat exchanger elements will be made, the rationality of its design and the quality of the welds.

Materials for production

An example of using cast iron radiators as a heat exchanger in a brick oven

The task of water heat exchangers for heating is to ensure optimal heat transfer, and in this process the degree of thermal conductivity of the metal is important. For example, a steel pipe conducts heat 7 times less than a copper pipe. Therefore, with the same pipe diameter, to transfer the same amount of heat, you will need 25 meters of steel pipe instead of 3.5 meters of copper.

Copper heat exchangers are the most economical to operate, but also expensive. Heat exchangers made of steel pipes with a diameter of at least 32 mm are considered more affordable for self-production.

Heat exchanger power calculation

It is quite difficult to calculate in advance the power of the heat exchanger for a heating system. To do this, you need to take into account too many factors: pipe diameter, coil length, thermal conductivity of the metal, fuel combustion temperature, coolant circulation rate, etc. The real ability of the heat exchanger to cope with its functions will become clear only after the heating system starts operating.

When calculating, you can estimate that 1 meter of pipe with a diameter of 50 mm, serving as a heat exchanger, will provide 1 kW of thermal power.

Design Features

A heat exchanger for water heating of a house, welded from smooth-walled pipes, is called a register. It looks like a kind of “grid” and is the most popular form of homemade heat exchanger. In addition to this design, simpler devices are also made in the form of a rectangular or cylindrical tank. The main thing is that the surface area for heat exchange is as large as possible.

When making a heat exchanger with your own hands, several conditions must be observed:

- the width of the internal voids in the heat exchanger must be at least 5 mm, otherwise the water in it may boil;

- the thickness of the pipe walls must be at least 3 mm so that the metal does not burn through;

- a gap of 10–15 mm between the heat exchanger and the walls of the firebox should compensate for the expansion of the metal when heated.

Installation features

The heat exchanger is installed inside the furnace during its laying

The easiest way is to install the heat exchanger simultaneously with the construction of the furnace. If you install it in an old stove, you will have to dismantle part of its brickwork.

Procedure:

- A tubular heat exchanger is installed on the prepared furnace foundation directly into the furnace cavity.

- When further laying rows of bricks, space is left for the inlet and outlet pipes of the device.

- After completing the laying of the stove, connect the heat exchanger to the heating system, fill the system with water and test fire the stove.

The video material offers useful tips for making a heat exchanger yourself:

So far we have only talked about heat exchangers in a water heating system

Let's pay attention to other areas of their application.

Cast iron grate for furnace

Over the centuries, the external and internal design of the stove has been changed and improved in order to increase heat output. Structurally, elements such as the valve, stove, oven could change over time, but an important element of the hearth remains unchanged - the cast-iron grate for the stove.

The configuration, dimensions, and cost of the grate depend on the design features of the furnace, as well as the type of solid fuel. The grate is a grate installed in the firebox, dividing it into two parts: the ash pan and the combustion chamber. It provides the formation of an air flow that supports the combustion process of solid fuel due to natural convection.

Tasks and types

Solid fuel is placed on the stove grate, and the ash formed during its combustion is poured through the grate holes into the ash pan. The resulting slag prevents the grate from overheating. The grate provides high-quality draft from bottom to top, and together with the oven door allows you to regulate the strength and duration of the flame.

Cast iron and steel are used to produce gratings. Cast iron grates are installed in stoves and fireplaces because they do not require special operating conditions and can withstand high temperatures well. Steel grate bars are used primarily in industrial workshops. The dimensions of cast iron grates for a stove, as well as their weight, depend on the type of fuel used.

Depending on the type of construction, there are two types of cast iron grates:

The one-piece type of grates cannot be disassembled; it is selected individually for the stove depending on the size of its firebox.

Prefabricated grate bars consist of a certain number of elements from which a grate of the required dimensions can be assembled.

There are four types of grate shapes:

- Tiled flat model

A universal flat rectangular grille, suitable for most solid fuel fireplaces, boilers, and stoves. To buy one, you need to know exactly the size of the firebox.

Basket

A design of this type was used on open fireplaces; today it is obsolete.

Beam

The design of this type is a kit model consisting of single or double cast iron slats, from which you can assemble a grill of non-standard dimensions. When using a beam grate, the slats must be freely placed in and out of the firebox, while there must be a gap for expansion of at least 5 mm to avoid deformation of the metal and masonry.

Movable

A long-burning stove is usually equipped with a movable grate. This is a structure consisting of a shaft and several moving sections. The vertical and horizontal axis of rotation of the shaft improves the process of fuel combustion and cleaning the grate from ash, while the width of the gaps in it is adjustable. A rotation angle of 30 degrees leads to loosening of the slag and shedding of ash into the ash pan. The angle can also be 180 degrees, but the installation of such a movable grate requires the presence of special recesses in the brick, so it has a high cost and limited use.

A separate type are cooled grates, or KROK, installed in hot water furnaces and water heating boilers. They are made from solid cast iron pipes. Air is supplied through special holes, showering the ash, while maintaining a temperature of up to 1000 degrees of hot solid fuel. Coolant circulates inside the tubes, cooling them.

Selection rules

The selection of the appropriate grate model should be based on the type of fuel used. The size of the grate and the weight it must withstand when loading firewood into the firebox depend on this. Small grates are used for wood stoves and fireplaces, and large grates are used for coal stoves. The minimum grate size is 140x120 mm, the maximum is 800/900x200 mm. The optimal size for burning wood is 140/330x120/252 mm, for coal - 350/300x205 mm.

When installing a grate in the firebox of a fireplace or other stove, it is necessary to make recesses around its perimeter of at least 5 mm, since the metal will expand when heated. The ledge on which it will be installed must be hewn. If the installation is in a brick fireplace, the grate should be placed one brick below the door so that the coals do not fall out of the firebox. After laying, the grooves are filled with sand (without adding cement). Correct installation of the grate is carried out when the grate is placed with expanding gaps between the rods downwards, and not upwards.

It doesn’t matter what shape or cost the grate has. Its quality can only be judged by the material from which it is made, the thickness of the grille bars and the size of the gaps between them.

Price policy

A quality product cannot have a low price. High-quality cast iron parts that will last for many years are expensive. And vice versa, light and cheap ones, made from a mixture of unknown materials, will quickly become unusable.

Approximate prices for furnace grates:

| Size | Price |

| 800x200 mm | 1200-1600 rub. |

| 915x250 mm | 1100-3000 rub. |

| 260x540 mm | 400-500 rub. |

It is better to buy these products in specialized stores. They provide a wide selection of models with different materials and price categories. Consultants will help you make the right choice based on your preferences, the nature of the fuel, and the frequency of operation of the heating device.

What functions do grates for furnaces perform?

This element of stove fittings allows you to achieve high-quality combustion of fuel and maintain it while the stove is burning.

When one portion of firewood or coal burns out, the ash is poured out, and the top layer of fuel is shifted to the grate, where it is better blown by the air coming from the ash pit and burns more intensely. Thanks to the presence of grates, the task of drying wet fuel is simplified.

The efficiency of the furnace depends on the design of the elements, and the durability depends on the material from which they are made.

It is also important to install the grille correctly so that it fully performs its functions.

For the manufacture of stove fittings, cast iron and heat-resistant steel are most often used. The grate bars are constantly exposed to flame, so it is better to give preference to cast iron, because it is more durable.

Furnace fireboxes vary in size and come in different shapes, so manufacturers produce furnace castings of all possible configurations. For non-standard fireboxes, you can also find a suitable model. Grate bars can be:

- Solid. Monolithic models that cannot be disassembled. There are different standard sizes; when choosing, you should focus on the area of the firebox.

- Typesetting. Consist of separate elements. This is a kind of “constructor” that you can assemble yourself and get a grill of the desired size.

Steel grates are made of chain type (reminiscent of conveyor belts) or pipe type (cooled models made of pipes).

There are several types of cast iron:

- Tiled. These are rectangular models that are installed in solid fuel boilers, heating stoves, and fireplaces. They are universal, the main thing is to choose the right size.

- Baskets. A good option for open hearths intended for cooking, but since they are practically not used, the design is obsolete.

- Beam. They got their name because of their external resemblance to construction beams. These are stacked structures consisting of single or double elements. Well suited for assembling grates of non-standard sizes.

- Movable gratings. They are called movable because of the design features that allow you to change the size of the gaps. Grates of this type are most often chosen for long-burning stoves.

Movable grid design. Element numbered 1 is the thrust, 2 is the horizontal axis of rotation, 3 is the grid itself.

The grate must be taken in such a way that the rods can withstand the maximum possible weight of one portion of fuel. You can check with the seller how much a particular model can withstand.

If in doubt, consult a specialist.

In order for the grate to be well cleaned of ash, the gaps must occupy at least 40% of the area of the entire structure. If there are fewer of them, the firebox will work less efficiently, because the amount of incoming air is not enough for intense combustion. If there is insufficient ventilation, gases may accumulate. If the area of the gaps is larger, then unburnt fuel will be poured into the gaps along with the ash.

Metals expand when heated, so grates must be installed with a minimum gap of 5 mm on all sides. In the firebox you need to cut off a ledge on which the grate is laid with its edges. In a brick oven, the location is usually chosen one brick below the firebox door. This is necessary to prevent burning coals from falling onto the floor.

During installation, it is not advisable to tightly bury the grates. Different materials expand to different degrees when heated, so too strong a fixed fixation of a metal element can result in deformation of the metal or cracks in the masonry. Having laid the grate, the grooves are tightly filled with sand without cement.

Let's sum it up

- The best material for grates is cast iron. It is reliable and durable, it can be installed in brick and even steel ovens.

- When choosing a grate, you need to take into account the weight of the fuel and the area of the gaps. Monolithic models are easier to install, while modular models are well suited for assembling gratings of non-standard sizes.

- When installing, be sure to leave gaps for metal expansion and do not fill the grooves with cement.

If you take into account all these nuances, the new grate will last for decades, and you will not need to think about replacing it.

Buying tips

For high-quality combustion, not only the size of the grate is important, but also the weight of the fuel that it can withstand in one laying. The rods should not deform or wear out.

The grate must have a sufficient number of holes - at least 40% of the area of the part itself. If this figure is lower, then there will not be enough oxygen to maintain the fire, and the ash will remain on the grate and clog the stove.

If the gaps in the grate have a large area, then the remaining fuel will fall from the combustion chamber into the ash pan. Fuel consumption will become uneconomical.

Optimal lattice option

A little history

Previously, firewood was burned on a blind hearth - combustion air was supplied through a slightly open fire door. This method has a fire hazard - coals may fall out of the firebox. It is also difficult to accurately select the optimal combustion mode - the regulator is very rough. The ash that covered the coals over time also did not contribute to the normal combustion of fuel - it is an excellent heat insulator (in the combustion chamber of a Russian stove, this is exactly how coals were stored in the ash for the next kindling). Therefore, they began to install a grate - a grate on the hearth through which oxygen enters the combustion zone. The ash is also removed through the grate - nothing interferes with the combustion processes.

The absence of a grate or its damage is not critical - the stove operates without it. True, the efficiency is somewhat lower. And the zone of intense heating of the masonry moves below the hearth - now the base of the ash chamber is also heated. And here you need to be careful if the stove is installed on a wooden base.

Blower

The vent is the first air chamber in the furnace, which usually has a door. The blower chamber is laid out according to the dimensions of the grate. It can be wider than the grate and overlapped by overlap of rows of side walls up to the grate. Through the ash chamber, air enters the firebox through the grate; in addition, it serves to collect ash and other fuel waste.

Blower: 1 - blower chamber; 2 - blower door

The blower door can be of any size, but no larger than the blower door. Through this door it is convenient to remove ash from the wide ash chamber, and as for air, there is enough of it with a door even half as small as shown. Practice has shown that the best place for the blower door is on the second row of the stove masonry. The door is installed in the blower window, which is connected to the blower chamber. When the door is open, air rushes through the window into the ash chamber. The more the door is open, the more air will enter the ash pan and the better the fuel will burn. Air, especially coming from below, is needed to maintain fuel combustion. Hence the name - blower.

Sometimes the door is used to regulate the draft in the oven: the less the door is open, the less draft. It is not necessary to install a blower door, but it is advisable, because without it a draft can occur in devices that do not close tightly, such as valves. And then the heat will go out into the chimney, and the stove will release less heat into the room.

If there is no door, the draft is adjusted using a valve. The more the valve is open, the stronger the draft, and with it more air will enter the stove and the draft will be stronger, which means the fuel will burn better. If there is no door in the ash window, but there is a view, then the fuel will constantly burn with the same intensity, but with this intensity a lot of heat will go into the pipe, which the brick could absorb. The viewer cannot regulate either thrust or fuel combustion.

Let's say that the door is a few millimeters smaller than shown in the figure. In any case, the seams should be no more than 3-5 mm. To do this, the laying must be carried out from the door to the corner of the stove. The last seam turns out thicker than expected, and such a seam cannot be made. To maintain the thickness of the seams, you need to break off a quarter from a whole brick in the corner of the wall where the door is located. You will get a three-quarter and a quarter. Next, you need to break off a larger quarter, taking into account the thickness of the seam. It will seem to lengthen the whole brick. Instead of a whole brick, you need to put the first three-quarter and the second quarter - it will take the place of the thick seam. The masonry of the top row above this quarter will be made of a whole brick - it will block this quarter. If a thick seam is obtained near the door, then you need to do the same in this place.

If, because of the door, the firebox turns out to be several millimeters narrower and the flues are wider, then this will not affect the operation of the stove. In some areas of the country, stoves are installed without a blower at all. In these furnaces, the combustion doors have windows-openings for air intake instead of a blower. In such fireboxes, only wood and peat fuel burns, but the firewood is buried in ash and forms a lot of firebrands. When they burn out, the heat goes into the chimney, so the firebrands have to be pulled out of the firebox and placed in a bucket of water. Such ovens are made due to the lack of grates. If they exist, then they are installed above the blower chamber.

Types of grates

Grate grates are divided into several varieties according to different criteria.

So, they can be divided into monolithic and typesetting.

— Monolithic models of gratings are more common, they are much easier to install - they immediately fit into a nest prepared for them of the required dimensions. The wide range of shapes and sizes of gratings on sale most often allows you to get by with just this option.

Options for monolithic and prefabricated grate

— Prefabricated grate bars are assembled into a single structure directly at the seat. These can be modules with two or three jumpers.

A prefabricated grate is convenient in cases where the bottom of the combustion chamber has a complex geometric shape, that is, it should be narrower in one place and wider in another.

This also includes the so-called beam grate - this is also a stacked version, consisting of individual crossbeams. The elements of the beam grille must pass freely and be removed from the combustion chamber through the open door. Actually, if you look at it, it is precisely such a separate beam that is called a grate.

Stacked and solid options

In different furnaces, the fireboxes may differ not only in size, but also in shape. In this regard, grate manufacturers produce a wide range of products, so you can choose grate bars for even non-standard shaped fireboxes.

By structure they are distinguished:

- Solid cast grate bars . In this case, a product is produced that cannot be disassembled into parts. They are produced in several standard sizes, so when selecting a product you need to rely on the total area of the fuel chamber of the furnace.

- Prefabricated gratings are assembled from several parts. From these components you can assemble a grate for a furnace of the desired shape and size.