Nowadays, buying an apartment or a house is not a cheap pleasure. Therefore, those who own a plot of land try to use these precious square meters to the maximum. Apartment owners turn their balconies into bedrooms, kitchens, recreation rooms and other rooms that are needed. But residents of private houses use their attic. After all, you will agree that having a warehouse for unnecessary things is good, but it is even better to use this space more rationally. Many people make an attic in which they organize a living room, bedroom, children's room or recreation room. But to bring your ideas to life, you need to take care of some nuances. One of them is insulation or thermal insulation of the attic.

The attic needs insulation, as it may not be heated by anything and is constantly exposed to bad weather. Many different materials are used to insulate the attic, but the best of them is considered to be polyurethane foam, also known as polyurethane foam. The process is not complicated, but there are some nuances. Let's look at the advantages of using polyurethane foam and the method of insulating an attic space.

Characteristics of polyurethane foam as insulation

First of all, we invite you to get to know this insulation material a little. It is completely different from the mineral wool or polystyrene foam we are used to. Why? It's all about the composition and appearance. PUF is in a liquid state and when its components are mixed and sprayed onto the surface, it begins to increase in size. And if you lay ordinary wool in slabs, then polyurethane foam must be applied using special equipment.

Nowadays, much attention is paid to the environmental component of materials. If we talk about polyurethane foam, it can be called one of the best in terms of safety and environmental friendliness. During operation, it does not emit harmful substances. This is very important for the attic, since it is exposed to the sun and heats up, and the insulation itself is applied from the inside.

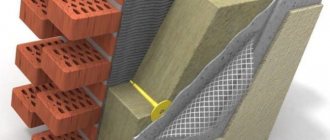

Another important point is the adhesion of the material, i.e. its adhesion to the surface. When applied, it adheres perfectly to almost any type of coating: wood, metal surface, reinforced concrete. The only exceptions are the slippery polyethylene surface and fluoroplastic. But, when arranging an attic room, such materials are not used. There are many advantages regarding the method of applying polyurethane foam. The fact is that rigid insulation cannot penetrate into cracks and hard-to-reach places. But polyurethane foam penetrates everywhere, leaving no cold bridges. Moreover, after processing the coating becomes monolithic, without seams. These same seams can also act as cold bridges. This is not observed with PPU.

Insulating the attic with polyurethane foam occurs quite quickly. The structure of the material is porous, due to which there is air inside. Due to its characteristics, polyurethane foam is the best material for thermal conductivity. This is shown in the photo below.

Here are some more advantages of the material:

- moisture resistance;

- excellent property to make the room soundproof;

- PPU does not burn, which is very important in operation and for the safety of residents;

- it is not afraid of the influence of fungus, mold and microorganisms. And rodents do not damage it, since the composition does not contain substances that attract them;

- the material is quite light and does not load the attic rafter system.

Types of polyurethane foam

Polyurethane comes in three main types with very different properties:

- Open cell foam;

- Closed cell foam;

- Closed cell foams.

The first two are applied by spraying using a special filler, the last is applied by insulating materials made from expanded polystyrene or rigid mineral wool. The difference is therefore important in terms of performance, the way it works and the effect achieved.

Spray foam is a material that expands in volume as it is applied, similar to foam used to seal windows and doors, for example. Consequently, it adapts to the shape of the insulated areas.

This is especially useful where the roof or wall has a complex structure: many bends, intersecting elements, etc. In other words, anywhere where other insulating material must be cut into irregularly shaped segments.

In practice, this often ends with the quality of filling such places leaving much to be desired. It should also be noted that stuffing soft types of mineral wool here is also not the best solution. The insulation will still be clearly worse.

Using expanded polystyrene for attic insulation

To summarize, we can identify many factors that speak in favor of using polyurethane foam in the attic. Let's look at these factors point by point:

- Application to any surface.

- Excellent adhesion.

- With a small thickness, you can achieve high-quality insulation, since the thermal conductivity is the lowest.

- The material can enhance the rigidity of the roof.

- When insulating, the free space of the attic is not lost.

- The composition can be applied to the most inaccessible places.

- Excellent sound insulation is achieved.

- The material will not deform during operation.

- You are guaranteed to get a long service life. This is 25-50 years.

- The layer is seamless.

As you can see, there are quite a lot of advantages, but along with this there are some disadvantages. They relate to the insulation process itself and the equipment for this. It is clear that you have to pay for quality. And if we talk about the best method of insulation, it is clear that the cost will be quite high.

The second nuance is that application requires special equipment, thanks to which the polyurethane foam is applied to the surface. It is not so easy to get it, since the units can be used by professional workers. And the installation price may kill your desire to do this. So it turns out that it is cheaper to hire workers or a company that specializes in such work. In the photo you can see the system for applying polyurethane foam.

Why is there such a price difference in the market?

Reasons for the low price

Poor quality components

The main cost item is spraying components. Most often they save on them. Characterized by the following properties:

- Components of low concentration (bodied with solvent)

- Low flammability class G4 - low fire safety

- Expired component expiration date

Low pressure equipment

A strong sprayed layer is the result of mixing two components of the material. The better the mixing, the better the quality of the sprayed layer.

Better mixing is achieved with high pressure equipment. You can save money by assembling your own sprayer. But the pressure in it will be 30 times less than necessary! The components will be poorly mixed and the spray layer will become unusable very quickly.

Inappropriate material parameters

The easiest way to save money is to spray the thinnest layer of material possible. But the thinner the layer, the lower the effect. You will receive a spraying service, but this service will be of little use since the technological process is not followed.

To maximize the effect of spraying, it is important to spray a layer of the required thickness. The parameters depend on where and under what conditions the spraying will take place!

Unskilled personnel

Cheap labor in the form of guest workers or students is an excellent opportunity to do things cheaply. Allegedly, trained employees will be able to correctly select the pressure, material, and distance from the material to the gun. Let's tell you a secret - there is no training!

There is only the experience of a mentor, which is transmitted in the process of work between the student and the teacher.

Warehouse and company expenses

Some private craftsmen mislead clients by calculating company expenses. Allegedly, the costs of maintaining a warehouse, accounting department, and crew are the main ones in the final cost of the work.

In fact, the cost of work of the same quality by a private master is an order of magnitude higher than the cost of work by an organization. The quality that the organization guarantees a private master cannot fulfill.

Average price and above

Certified components

80% of the quality of the spray layer depends on the materials used. We use only certified factory components. Modern innovative materials significantly improve the quality of sprayed coating.

The sprayed layer is strong. Meets all declared characteristics!

High pressure equipment

The higher the pressure created by the equipment, the more technologically advanced the process of mixing the components, the better the quality of the sprayed layer.

We work on high pressure equipment. Hybrid heaters and heated hose bring materials to the correct viscosity before spraying.

Correctly selected material

Depending on the material being sprayed on and the surrounding environment, we select components, set the viscosity and spray force. We control the layer thickness and fragility. We strictly follow the technological process.

This approach is more expensive, but the effect of the work will be significant. It is cheaper to spray once and for a long time (>50 years).

Experienced team

As a company, we have been in the spraying market for more than 10 years. Our team was formed even before the opening of the company, undergoing training abroad.

In total, over the entire period of work, we insulated and waterproofed more than 27,000 m2 of surfaces. There is no type of object on which we have not yet sprayed polyurethane foam or polyurea.

We transfer work experience from the senior master to the younger ones and strictly control the quality. We are responsible to the customer with the ruble and the company’s reputation!

Guarantees under the contract

We are dealers of PU foam and polyurea components. We often purchase components at good discounts. We service the equipment ourselves; we have a base and a warehouse. Therefore, we can offer good discounts even during the season!

In addition, we enter into a legal contract for spraying services and provide guarantees for the work performed!

We prepare the room before insulating polyurethane foam

This is the first step from which the attic insulation with polyurethane foam begins. Without preparation, it will be difficult for you to do anything. Such work is simple, but requires some time. Let's look at the steps that go into preparing a room:

Remove everything unnecessary from the attic: things, furniture and anything else that might get in the way. Your task is to create an empty room in which work will be carried out.

In addition, you need to protect the glass surfaces of the attic and windows, because if polyurethane foam gets in, you can ruin the appearance. It will be quite difficult to tear off the insulation without damaging the glass. Therefore, use cloth or film for protection.

The same needs to be done with the door.

The walls and ceiling of the attic must be cleaned of the old coating, if any. If you are just building an attic, then you need to clean the rafters and the space between them from dust and dirt. After all, this is where the polyurethane foam will be sprayed.

Now everything is ready to start working. They only forgot the necessary tools and materials. Let's find out what is required for the job.

Preparing the attic roof for insulation with penoplex

Attic floors with different layouts also have different insulation laying patterns. For example, an inhabited attic is insulated according to the same scheme as the roof. The material is placed in the space between the rafters and attached to the sheathing. In the classic version of the attic, which has both vertical and inclined sections of walls, the process becomes somewhat more complicated.

Putting up the frame

First of all, you will need to assemble the frame of a vertical section of the wall, on which, in fact, the insulation and cladding of the room will be attached. It can be made from a steel profile, but a regular wooden beam is best suited. Initially, a horizontal cross member is attached at the level of the future upper edge. It is stuffed from pediment to pediment along the entire length of the slope. Vertical posts are attached to the crossbar in 0.6 m increments.

Advice! The transverse size of the beam is chosen equal to the thickness of the first layer of future insulation.

According to reviews, it happens that craftsmen tend to simplify the process and lay sheets of polystyrene foam directly on the rafters, directly on the roof lining. You can't do this. According to the execution technology, in order to insulate the attic with penoplex, it is necessary to sew additional sheathing on the inside of the slope. Thus, an air channel will appear between the roof structure and the attic insulation. This will remove water vapor from the space between the attic insulation and the roof frame.

Vapor barrier for future attic

The next step is to stretch a vapor barrier film over the rafters and the assembled frame. If penoplex is laid directly between the rafters of a cold roof, then the sheathing is sewn end-to-end with a board, or moisture-resistant plywood is used, and the film is sewn directly to the sheathing.

The fabric is stretched overlapping and glued with tape. The film is needed primarily to protect the wooden frame parts from moisture.

Preparation of tools and materials

If you have hired specialists who will do everything quickly, efficiently and without your efforts, then you don’t need to do anything, since they have everything you need. All you need to do is prepare the premises and pay the workers for their labor and materials. Otherwise, to insulate the attic with polyurethane foam you will need:

- two separate containers that will contain liquid polyurethane foam and water;

- hose system and spray gun;

- pump or compressor to create pressure inside;

- special clothing for work: gloves, respirator, thick shoes and glasses;

- a spatula or rag to clean the inside surface of the attic;

- tool for removing excess polyurethane foam.

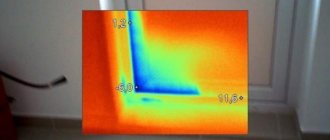

Where does the heat go?

Before insulating the attic, it is important to determine where the heated air goes, and why is it so difficult to maintain the optimal temperature?

Walls, ceilings, floors, windows and doors – through all these elements of the room’s structure there is a fairly active exchange of air with the outside space. And if the first floor of the house is fully insulated, leisure time in the attic will be more comfortable. But to make the atmosphere as pleasant as possible, you need to pay attention to the entire room.

Heat escapes through cracks in doors and windows, walls and roofs. Cladding with insulation, steam and wind insulation materials will allow you to maintain a comfortable temperature for relaxation and active pastime, and save on heating system resources. Next, we will talk about the nuances of insulating the attic roof, walls, floors and ceilings, recommend materials and demonstrate some expert advice, which will allow you to make the room warmer on your own.

Technology for performing polyurethane foam insulation work

So, now everything is ready for you to insulate your attic. But before starting work, decide how thick your insulation layer will be. When performing thermal calculations, it is important to take into account the temperature of your environment and the thickness of the walls, as well as the material from which they are made.

On average, a thickness of 10-15 cm of polyurethane foam will be sufficient for an attic. The spraying process itself is simple, the principle is similar to painting surfaces with a spray gun. You just need to make sure that the spraying is done in one even layer. And to make the layer thicker, you need to spray polyurethane foam in several stages.

There is an important condition to create an ideal insulation layer: the surface must be dry and clean. As for temperature, it is recommended to work at 10 to 15 degrees Celsius.

Now let’s take a closer look at the principle of spraying polyurethane foam onto an attic roof:

- work starts from a certain edge. You need to move from right to left or vice versa;

- the voids themselves between the rafters are filled by moving the gun from bottom to top;

- it is important to ensure that you apply an even layer, avoiding differences;

- work is carried out until the entire surface is filled with insulation.

If you have excess, you can trim it. And the fact that polyurethane foam is afraid of the influence of ultraviolet rays forces us to cover the surface with a special paint for polyurethane foam in order to protect the material.

To clearly see the process of insulating an attic with polyurethane foam, we suggest you watch this video.

2.1 Characteristics and advantages of the insulator

First of all, you need to pay attention to the quality characteristics of polyurethane foam. The parameters are as follows:

- thermal conductivity coefficient like PSB S 35: about 0.025-0.03 W/mK (about one and a half times lower than that of mineral wool and foam insulation); density: from 30 to 200 kg/m³; service life: up to 40 years (this figure can differ - different companies promise different durability).

In fact, it is now difficult to say exactly how long sprayed polyurethane foam will effectively last - since it began to be used in our country relatively recently, and the “age” of most objects insulated with it does not exceed 4-5 years. However, the conditions carried out in laboratories prove that it actually begins to lose its properties after more than a dozen years.

The process of insulating the attic from the inside using polyurethane foam

Typically, the density of the material for insulating residential buildings is about 60-80 kg/m³, however, if necessary, this indicator can be changed. This is done by changing the proportions when creating the polyurethane foam itself - the material is prepared right at the work site, by mixing two components.

It goes without saying that the higher the density, the more effective the insulator and the higher its price. You can save money in the following way: initially, a layer of dense polyurethane foam is applied to the surface of the roof from the inside - it will better protect the structure from possible contact with moisture. Then, a less dense (but cheap) composition is sprayed onto it.

Another – third – layer of glass wool and mineral wool is sprayed on top of it, with the same density as the first. Thus, a kind of “pie” is obtained: with a denser insulator around the edges and a less dense one inside.

Regarding flammability: the material is classified as non-flammable.

When in contact with an open fire, it smolders, but does not spread the flame. However, there is a downside: when the threshold of +500 degrees is exceeded, it begins to release compounds dangerous to humans. However, this is typical for most other heat insulators, so this point cannot be called a significant drawback.

But among the significant advantages of polyurethane foam are the following properties:

- resistance to moisture, and absolute - even with frequent exposure to water, the material will not react in any way, will not begin to deteriorate or mold; the material is not interesting to rodents or insects; in normal condition, the material does not harm humans in any way (unlike, for example, mineral wool) ;lightness - which is very important for both the roof and the attic floor; in addition to retaining heat, polyurethane foam also insulates sounds quite well - which is very important for the roof (for example, this will reduce the noise from rain drumming on the roof).

If necessary, the properties of the insulator can be further improved, as when insulating a house with mineral wool under siding - for this, components can be added to its composition during preparation that will increase the resistance of the material to high temperatures.

Some nuances when insulating

I would like to highlight some points that some do not consider necessary to take into account. But they are important because they guarantee your safety and the best quality of insulation. It all starts with the little things, so we recommend that you stick to what is written below.

Firstly, we are talking about overalls for insulating the attic. The worker performing insulation with polyurethane foam must protect himself from contact with the skin, eyes or respiratory organs of the chemical. To do this, use a special suit, gloves, a respirator and safety glasses. If there is no special suit, then you can use another type of clothing with the same qualities.

Secondly, it concerns the mixing of polyurethane foam components. You need to adjust everything so that the two components of polyurethane foam are mixed in an ideal 1:1 ratio. In addition, thorough mixing is important. If the ratio is not observed, the performance of the insulation is reduced.

These rules for attic insulation are simple, but quite important. Don’t neglect them, and then you will fully feel the beauty of polyurethane foam insulation.

2.5About the advantages and disadvantages of technology

The technology for applying insulation discussed above may seem unfamiliar to the reader. Not surprising - after all, for those who have not encountered thermal insulation work, the idea is probably limited to gluing foam plastic or unwinding a roll of mineral wool.

In fact, this method is many times simpler, but at the same time more effective and convenient than the same polystyrene foam or mineral wool. The list of obvious advantages of the technology includes:

- the use of a thin layer of insulation (due to minimal thermal conductivity) - which is very important from the inside; no need to level the surface being treated; no need to create a complex multi-layer “pie”; minimal time for surface treatment (on average, in 6-8 working hours, 1 person can cover about 100 m²); monolithic insulation (that is, the absence of any seams); covering structures of any shape.

The first point is a fairly significant advantage. Indeed, when working from the inside, the main problem is the loss of free space, which can reach considerable values. For example, if you insulate the floor using expanded clay, be prepared to raise it by about 20-30 cm, thereby making the room smaller.

When insulating walls with polystyrene foam, you will have to lose about another 10-15 cm. Polyurethane foam is much more economical in this regard - the effective insulation layer is approximately 3-5 cm.

The second and third points will be appreciated by those who have tried to independently insulate any surface using polystyrene foam or mineral wool. Compared to spraying, this is a much more labor-intensive and lengthy process that requires not only time, but also attention.

If there is even a slight difference in height, the foam will no longer lie flat. Well, you have to work with mineral wool wearing gloves, a respirator and goggles.

It goes without saying that saving time is also a significant advantage. When creating a floor screed, you would have to wait several days until it hardens. And simply creating a heat-insulating “pie” is also not a quick procedure.

When it is necessary to insulate the attic from the inside, most homeowners choose mineral wool or expanded polystyrene (foam). The fact is that these are the most common types of insulation in Russia and, moreover, they can be installed independently.

At any construction market or Do-It-Yourself format store (Obi, Leroy Merlin, etc.) they will always offer to buy both mineral wool and polystyrene foam. But this does not mean at all that mineral wool and sheet insulation made from foam polystyrene are the best and most effective for attic insulation. Polyurethane foam is superior to them in terms of characteristics, and even more so in terms of manufacturability.

Expert's answer to the question: “What are the characteristics of polyurethane foam?”

- fill all spaces of a room with a complex configuration;

- obtain a hard coating of surfaces without seams, voids, or cold bridges;

- normalize temperature, humidity, sound insulation;

- make the roofing system stronger.

PUF is environmentally friendly, suitable for covering surfaces made of various materials, does not allow moisture to pass through and does not support combustion. There is no need for fastenings before coating; the thickness of the layer is adjusted during the spraying process.

When choosing insulation for the attic, it is necessary to take into account the disadvantages of polyurethane foam. It does not tolerate ultraviolet radiation at all, so interior finishing is required. When exposed to fire, it can smolder. To carry out insulation work, special equipment is required, which increases the overall cost of insulation.

Polyurethane foam parameters

It is worth knowing the basic parameters of polystyrene foam. The lambda coefficient (λ) of open cell polyurethane is similar to that of mineral wool and is 0.035-0.037 W/(m K). This means that to ensure the same thermal insulation of the roof, the same thickness of the material layer is required.

In practice, foam may be a little better as it can fill any space very tightly. After all, even small gaps and cavities become bridges of cold. Open cell foam cannot be confused with closed cell foam, which has a much lower lambda of about 0.023 W/(m K).

- The diffusion resistance (μ) of open-cell varieties, that is, the degree to which they impede the flow of water vapor contained in the air, is low and is usually around 3-4. This is not much, because, for example, the very popular cellular concrete has similar properties.

- The vapor permeability of mineral wool is greater, and the vapor permeability of, for example, polystyrene is several tens of times lower. At the same time, neither high nor low diffusion resistance in itself is either harmful or particularly desirable.

Open cell foam is also a flexible and very lightweight material with a density of less than 10 kg/m3. This is less than polystyrene. In practice, the load on the roof from its use is negligible. A layer of 20 cm is less than 2 kg/m2 of roofing.

Foam is a self-extinguishing material. Like polystyrene, it is not resistant to fire - it melts and carbonizes, but after the flame is removed it automatically goes out.

The answer to the question: “Is it possible to insulate the attic with polyurethane foam?”

There are no walls in the attic, so thermal insulation can be considered zero. If this room is simply heated, the heat will rise, heating the roof and contributing to the formation of ice in the winter. Attic insulation should cover all cracks and prevent the formation of excess moisture . Thermal insulation of the attic room with polyurethane foam ensures all this one hundred percent .

Insulating the top floor of a house with polyurethane foam by applying it to the ceiling is an almost ideal option if the attic space is not planned to be used as a living space. It is enough to spray polyurethane foam in several layers to save up to 30% of heat.

Comparison of polyurethane foam with analogues

| PPU | Styrofoam | Ecowool | Minvata | |

| Life time | More than 50 years | No more than 20 years | No more than 15 years | About 30 years |

| Environmental friendliness | 100% eco-friendly | Chemical | Eco-friendly | Chemical |

| Installation | Spraying without installation work | Additional materials and tools required | It is necessary to create a frame | It is necessary to create a frame |

| Thermal conductivity | 0.02 W/mK | 0,03 — 0,045 | 0,03 — 0,037 | 0.03 - 0.042 W/mK |

| Density | from 9 to 45 kg/m3 | from 11 to 40 kg/m3 | from 26 to 95 kg/m3 | from 20 to 200 kg/m3 |

| Hygroscopicity | Low vapor permeability | Does not allow moisture to pass through | Low vapor permeability | Low moisture resistance |

| Fire resistance | High | Fire hazardous | Doesn't burn, but smolders | Eat |

| Flaws | Destroyed by ultraviolet radiation (but a layer of regular paint will protect against exposure) | Fragile, increased flammability, low sound insulation | Absorbs moisture and cannot be used in wet areas. Decreases in volume over time | Absorbs moisture, favored by rodents, susceptible to the development of fungi and bacteria |

| Expenses | Only for material | Low cost, expensive delivery, long installation, requires polyurethane foam | Inexpensive material, requires frames, professional installation with wet application | For delivery, material, frames and fasteners, installation |

| Pest resistance | Yes | Yes | Yes | No |

How to do everything in practice?

There are 3 types of this insulation, with three levels of rigidity. This must be taken into account when choosing technology, which can be classical or complex . When using the first, a material of the same hardness is taken and one or several layers are applied. If the second technology is chosen, then first a layer of high-hardness polyurethane foam (3-5 cm) is applied, then a softer layer (5-8 cm).

If the attic was uninhabited before treatment, before starting work it is necessary to empty it of unnecessary things and clean all surfaces of the remnants of the old coating and dust.

The next step is preparing workwear, tools and material . You will need 2 containers (for liquid insulation and water), a sprayer, a pump with a compressor, hoses, thick clothing, a respirator, goggles, and a tool for cutting off excess frozen material.

The PU foam components should be mixed according to the instructions and mixed thoroughly to maintain the positive characteristics. Attic insulation using polyurethane foam is the application of liquid material between the rafters and on the floor, filling all the cracks and hard-to-reach places. If necessary, application of 2 or more layers is allowed.

Upon completion of the work, the roof and floor form a single whole with the insulation. In winter the attic will be warm, in summer it will be cool. If you cover polyurethane foam with finishing material, it can last up to 30 years.

Increasingly, owners of private houses are using the attic as a living space, significantly expanding the total area of the building.

For many, the attic, which has become a full-fledged room, becomes a way to save the family budget.

The construction of another floor in the house requires a significant investment in its construction, and to build an attic, you only need to prepare a roofing project of a special design.

If the home owners plan to use the attic for living in the winter, then care must be taken to include it in the general heating system of the building. However, the first thing that owners should take care of is the insulation of this room. Only after complete insulation can the attic be included in the number of residential premises.

Why is thermal insulation necessary?

If you neglect thermal insulation and limit yourself only to heating the attic, then the following situation may arise:

- In winter, warm air will quickly leave the room, which will entail significant financial costs.

- When warm air comes into contact with the roof, the snow on it will melt and form ice and icicles, which can lead to damage to the roofing.

- In cold weather, condensation will form on the inner surface of the roof, leading to rotting of the elements of the rafter system.

- In the summer, the room will heat up intensely to such an extent that living in it may simply become impossible.

Insulating an attic from the inside is a more difficult task than insulating ordinary rooms:

- The need to apply insulation not only to vertical surfaces, but also to roofs that have a negative angle of inclination.

- There is a high probability of moisture from the roof getting onto the insulation and getting it wet.

- Possibility of carrying out work only in the warm season.

*

All these problems are eliminated by insulating the attic space with polyurethane foam.

Applying insulation to the roof from the inside

*

Attic insulation technologies

The main task when insulating an attic is to simultaneously keep the room warm, without leaving gaps and cold bridges, but at the same time do it in such a way that the attic does not become a place where it is impossible to breathe.

Since the most vulnerable place from which heat escapes in the attic structure is the roof, special attention is paid to its insulation.

The ideal option is to install a roofing pie before installing the roof itself. This procedure will allow you to carry out waterproofing of insulation more quickly and efficiently.

However, most often, work on attic insulation is carried out later than the roof covering is installed, but the order in which the “roofing cake” does not change:

- First of all, a waterproofing material is installed to protect the insulation from moisture.

- The next layer of the “pie” is insulation.

- To prevent moisture from entering the insulation from inside the room, a vapor barrier layer is installed.

- The work is completed with a finish made of plasterboard or lining.

The method of insulating attic walls depends on the material from which they are made. Typically, the walls that require a special approach to their insulation are the gables of the building. It is more advisable to carry out this procedure from the outside.

However, if external insulation is impossible for good reasons (for example, the façade finishing has already been completed), then the gables have to be insulated from the inside.

How to choose penoplex for insulating an attic roof

Several types of extruded polystyrene foam are used for construction work. The most famous and affordable is brand “C” penoplex. It is used for exterior finishing of walls without cladding or for insulation of vertical surfaces in non-residential premises. It can be used to insulate the gable walls of the attic. For the interior space of the attic floor “C”, penoplex is usually not used due to the high content of chromium salts. According to reviews, “C” - expanded polystyrene is excellent for floor insulation and sometimes attic ventilation.

In addition to expanded polystyrene “C”, material of grades “A” and “K” is produced. In the first case, “A” - penoplex is used in road construction and foundation insulation. The second - penoplex "K" is used to insulate walls and interior space. Material density 33 kg/m2, heat resistance up to 75°C. The main thing is that pressed polystyrene foam does not have unsafe additives and additives, and the mechanical and heat-insulating qualities, according to reviews, are not inferior to other brands.

It is believed that the insulation layer made of "K" grade polystyrene foam provides reliable protection against water vapor and can be used without a vapor barrier, primarily due to the special edge profile that forms a lock. In practice, craftsmen still prefer to play it safe and lay additional vapor barrier on top of the insulation.

Combined attic insulation

If the building is operated in harsh climatic conditions, then experts recommend insulating the attic using a combined method . Using glass wool and foam plastic boards simultaneously for insulation, home owners receive high-quality insulation at a relatively low cost.

The insulation is installed in the following order : initially, glass wool is attached between the rafters, and on top of it there are foam boards that completely cover the rafters.

As always, installation of a waterproofing layer and vapor barrier is provided in the usual manner, and a lathing is mounted on top of the insulating “pie” , which serves as the basis for the finishing material (plywood, lining, plasterboard).

Scope of application

The versatility of polyurethane foam and its performance characteristics provide it with a wide range of applications. For example, in light industry it serves as the basis for the production of synthetic leather and duplicated fabrics. It is used as a filler for upholstered furniture and is used in the automotive industry.

Some of the characteristics of polyurethane foam are its low thermal conductivity, low vapor permeability and waterproofing properties. This allows this material to be used as insulation. In the construction industry, it is used as thermal insulation for construction projects .

With its help, thermal insulation with polyurethane foam is carried out in the following areas:

During the construction of the foundation, polyurethane foam also performs a waterproofing function, and for walls - acoustic insulation. Typically the material is applied by spraying .

In addition to construction projects, polyurethane foam as an insulating material is used for refrigerators, tanks and various containers, cars .

Insulating the attic with foam plastic

The detailed technology for insulating the attic has already been described above. the main stages were indicated in the order required for the correct implementation of insulation work in the attic space. All of the above applies to polystyrene foam.

It is worth noting that the foam boards must be cut to such sizes that they fit tightly into the space between the rafters, where they are placed during the insulation process. Any cracks and gaps that appear during the installation of foam plastic become cold bridges, significantly worsening the quality of insulation.

When creating an insulating “pie,” there is one important condition : the foam plastic should not touch the waterproofing film. There should be a gap of at least 2-3 cm between them.

To comply with this condition, you can use twine secured to the rafters in such a way that the foam cannot “fall” beyond its limits. In the same way, you can secure the insulation after its installation.

For high-quality foam insulation, it is recommended to use a material with a thickness of at least 70 mm, and in harsh climates, at least 100 mm. If laying foam plastic slabs in two layers is used, then their joints should not coincide with each other. Upon completion of installation of the slabs, all seams must be covered with foam.

Insulation of attic rooms is a process that can be easily completed independently. For many home owners, the most difficult step is choosing materials for insulation.

Today, manufacturers offer a sufficient range of insulation materials, which is not easy for an uninitiated person to understand. However, there is also enough information about the quality of insulation. Therefore, everyone is able to choose the most suitable material for insulating the attic, and then do the work independently, strictly following its technology.

As a result of high-quality insulation of all attic structures, a new comfortable living space .

Advice from professionals

To minimize the likelihood of cold bridges, polystyrene foam on the attic roof should be laid in 2 layers. In this case, the arrangement of the plates should be staggered. Additionally, the joints should be filled with polyurethane foam and sealed with plumbing tape with low vapor permeability.

The peculiarity of attic insulation with foam plastic in cold regions is the thickness of the slabs, which can reach 150-200 mm. To reduce space loss, mineral wool with a low thermal conductivity coefficient is often laid on top of thin sheets of polystyrene foam. Such a combination of insulation can total 100-120 mm.

Any gaps between the foam boards and the sheathing are best filled with low-expansion foam. Such a building material will not exert much pressure when drying and will not deform fragile slabs. The mass will prevent heat leakage and condensation formation.

It is not recommended to use polyethylene film to waterproof insulation in the attic. In extreme conditions it lasts less than stated. At the fastening points there is a high risk of rupture when heated and during frosts. Insulating materials should be chosen with similar durability indicators, so that you do not have to repair and dismantle the entire finish.

Any sheathing material can be easily fixed to a wooden sheathing under foam plastic.

Thermal insulation with polyurethane foam, price per m2

The cost of the foam spraying service depends on the consumption of components, area, number of layers applied and the density of the layer itself . If you decide to insulate with polyurethane foam, the price per m2 will be approximately 500 rubles if the layer thickness is 20 mm. As its thickness increases, the cost also increases accordingly: 50 mm will cost from 550 rubles, 100 mm - from 660 rubles.

Of course, insulating a house with polyurethane foam will cost more than with polystyrene foam, but the installation convenience is worth it . You don't need frames or fasteners, you don't need to level the surface, and most importantly, rounded and complex shapes will be covered just as smoothly and densely as classic surfaces.

Source