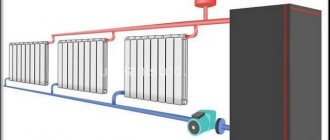

Gas boiler maintenance must be done regularly. During the annual inspection, failures in the operation of automation, the safety of insulating materials, and the tightness of components and pipes are identified. This ensures the safety of the equipment and achieves savings by fine-tuning the gas flow. In this material we will talk about the actions that need to be performed for proper prevention of a gas boiler. Let's look at the example of a wall model. Most often, it is wall-mounted boilers that require detailed maintenance. The following maintenance steps can be defined:

- shutdown of gas, water and electricity

- coolant drain

- turbine maintenance

- cleaning the heat exchanger

- cleaning gas burners and electrodes

- boiler cleaning

- checking the expansion tank

- checking flow sensors and filters

- gas pressure adjustment

- connection and testing

Turbine maintenance

Gas boiler turbine

The exhaust fan ensures proper removal of carbon dioxide, soot and smoke after combustion of the gas mixture. After dismantling the fan, it is worth checking the chimney pipe leading to the street for clogging. The fan must be cleaned of dust and the shafts lubricated. The condensate collector leading to the turbine must be sealed.

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

After removing the cover, clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other coolant and prevents local overheating.

Using a soft copper brush, you need to remove any remaining soot from the ignition electrodes and ionization sensor, which are located in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

Prices

Depending on the type of boiler, its power and placement option, we have a current price list for boiler maintenance. The cost of the work is publicly available and does not include hidden prices, which are sometimes used by unscrupulous companies or private craftsmen.

We try to maintain the minimum acceptable cost of work so that each of our clients can afford boiler maintenance and ensure a long service life of the heating equipment.

Undoubtedly, we are committed to long-term cooperation and when concluding a boiler service agreement with our company, we will be able to offer special conditions and more flexible prices for subsequent repairs, calling a technician and carrying out routine maintenance. You can obtain more accurate information from our engineer by phone or mail indicated in the CONTACTS section.

| Service | Price |

| Maintenance of atmospheric boiler with power up to 30 kW | from 4,500 rub. |

| Maintenance of atmospheric boiler with power from 30 to 60 kW | from 7,500 rub. |

| Maintenance of atmospheric boiler with power from 60 to 110 kW | from 10,500 rub. |

| Maintenance of turbocharged boiler up to 30 kW | from 5,500 rub. |

| Maintenance of turbocharged boiler with power from 30 to 60 kW | from 8,500 rub. |

| Maintenance of turbocharged boiler with power from 60 to 110 kW | from 11,500 rub. |

Maintenance contract cost

Chemical descaling

gas boiler heat exchanger

There are operating conditions (they are indicated at the end of the article) under which it may be necessary to service a gas boiler in the form of cleaning the heat exchanger from scale. In this case, the supply pipes are unscrewed and the entire heat exchanger is dismantled. For chemical cleaning, it must be filled with a solution of hydrochloric acid, which dissolves blockages. After 10-15 minutes, drain and rinse with running water. If during washing there are still difficulties with the passage of water, the cleaning process should be repeated.

Guarantees

We provide a guarantee on behalf of our company for all work performed on boiler maintenance or repair. The warranty applies to absolutely all equipment and is valid from 14 days to 1 year, depending on the brand and complexity of the work.

This guarantee is confirmed by an official certificate of work performed, signed by both the master and the owner of the equipment. All data is entered into the CRM database and has a storage period of 5 years.

In case of replacement of faulty components or assemblies, we use only original spare parts, which are also subject to warranty.

Permitting documentation of our company

In accordance with the legislation of the Russian Federation, we have the right to carry out maintenance of gas equipment. This permit is supported by a License for hazardous gas work, a SRO Certificate, an Agreement with Mosoblgaz, and an Agreement with the housing inspectorate. Each employee of our company is certified, was trained at a training center and received a standard certificate with the right to perform gas-hazardous work.

Order service

Adjusting the pressure of the expansion tank

During the production of a gas boiler, nitrogen is pumped into the expansion tank, but during operation, manufacturers are allowed to pump it with ordinary air. An expansion tank is necessary to compensate for excess pressure that occurs as a result of heating and cooling of the coolant. In addition, it has the function of protecting against water hammer in the heating system.

To completely prevent a gas boiler, you need to measure the pressure in the expansion tank using a pressure gauge. For most wall-mounted boilers, the pressure required for operation is 1 bar. The exact numbers need to be clarified in the documentation for the boiler. In the event that the pressure is insufficient, it is necessary to pump nitrogen or atmospheric air into it using a compressor. In case of excess pressure, it is necessary to bleed off the excess through the valve.

Routine inspection of gas equipment in the apartment

During the term of the contract, gas workers are required to carry out scheduled inspections of equipment and all connecting systems.

The frequency of such inspections may be established by agreement. In this case, the consumer is given a corresponding act. In addition to such visits, they are obliged to respond as soon as possible and go to the owner’s address if he reports a detected malfunction. On-site inspection and work to eliminate it is carried out. If gas appliances are used correctly, one check for the entire term of the agreement is sufficient. If the equipment’s service life has expired, gas workers recommend replacing it or carrying out diagnostics in a specialized organization. If the period is extended in conclusion, its service becomes annual.

Organizations servicing gas equipment prepare documentation for each room indicating all the devices located there, indicating the date of installation and service life.

Cleaning filters

Incoming filtering is necessary. If water is used as a coolant, the flow often contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the operation of the input flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned using ordinary running water and a brush with hard bristles. Next, before reinstallation, to soften the O-rings that prevent leakage, they need to be treated with silicone grease to achieve a tight connection.

Administration of Yemanzhelinsky urban settlement

- Boris Dubrovsky congratulated the residents of Varna on the 175th anniversary of the village 07/18/2018

- Boris Dubrovsky discussed with the investor the implementation of a special investment project to develop a gold deposit 07/17/2018

- In the Chelyabinsk region, the second stage of issuing land plots to large families in the village of Severny has begun 07/16/2018

- Lending volumes to small and medium-sized businesses in the Chelyabinsk region increased by a third 07/18/2018

- Construction of a bypass canal on Sak-Elge began in the Karabash district 07/18/2018

- Repair work was completed at the House of Culture in the village of Yemanzhelinka 07/18/2018

Gas pressure adjustment

Measuring and adjusting the minimum and maximum gas pressure will not only achieve proper operation of the boiler, but also save money. The exact pressure range is indicated in the instructions. For wall-mounted boilers it is at least 2 mbar. The maximum pressure is 13 minibar.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the “chimney sweep” mode and check the pressure in this mode. If necessary, adjust the pressure to the specified values.

What is the difference between cleaning single-circuit and double-circuit boilers?

Mainly by volume: cleaning gas boilers with a primary heating circuit takes less time and effort. It includes maintenance of all components and components, including the firebox and chimney. The last 2 elements are also found in double-circuit boilers. Cleaning the firebox and sectional chimney is not difficult for those who independently service household appliances: contaminants are removed mechanically.

The normal functioning of the unit, or more precisely, its performance and stability of operation, depends on the condition of the chimney. The automation of modern heating boilers necessarily includes a draft control sensor; in its absence, the start of the burners (ignition) is blocked. Therefore, it is very important to keep your chimney clean.

The importance of correct gas pressure setting

When the pressure drops below acceptable values, the boiler automation is not able to accurately regulate the heating temperature and operates at maximum values. The electronics opens the maximum pressure and heats the boiler to the required temperature, but due to insufficient pressure, it is impossible to maintain the desired temperature. The automation shuts off the gas and, after reaching the minimum allowed temperature, again heats the boiler to the maximum in the maximum possible mode.

If the gas pressure exceeds the rated values, the flame height is too high. This can lead to premature burnout of the heat exchanger, which is not designed to operate in this mode.

Compare this with normal operating mode, in which the temperature is gradually brought to the required values, and then maintained at a minimum gas flow. In this case, gas consumption decreases due to the smooth dynamics of heating and cooling.

Why us?

You can completely trust our specialists to repair and service boilers. We have been working in this field since 2003 and pride ourselves on fast and high-quality servicing of heating boilers.

We travel to any district of Moscow and the Moscow region, and also, by agreement, to other regions on the day the application is accepted and work seven days a week.

We are representatives of most manufacturers and can carry out maintenance of all brands of boilers, and we also have all the spare parts for them.

Our company’s specialists are certified and have permits; the entire range of work will be insured and confirmed by a warranty period.

Call us now and you will be satisfied with the price and quality of services!

Is it necessary to chemically clean the inside of the heat exchanger?

Under normal operating conditions, no. The service life of the heat exchanger is about 6-7 years and after this time it is easier to make a preventive replacement. Annual dismantling and reinstallation will only increase the risks associated with possible destruction of connections and the risk of subsequent fluid leakage.

However, there are reasons why annual chemical cleaning may be worthwhile. This is very hard water that contains too many mineral impurities. A layer of scale builds up too quickly in the heat exchanger. Because of this, difficulties arise associated with insufficient heating of water. During prolonged operation under such conditions, the heat exchanger generally stops passing enough liquid, overheats, burns out, and the boiler fails.

Disassembly sequence

Disassembling the boiler to remove a clogged part consists of the following sequence of actions:

- First of all, the boiler is turned off so that its parts cool down. This usually takes 30-40 minutes;

- Next, close the taps responsible for the supply of gas and water;

- remove the front panel;

- drain the water remaining inside the boiler;

- dismantle the heat exchanger;

- we clean it.

See also

Methods and rules for cleaning a toaster inside and outside at home

How often does the boiler need to be serviced? Regularity of prevention

A gas boiler inspection must be carried out at least once a year, before the start of the heating season. Why is regularity necessary when servicing gas boilers? The answer is simple, it is necessary for reliable and uninterrupted provision of hot water. Let's try to figure out what can happen if you don't carry out an annual inspection of your gas boiler.

- Over time, the connections become more and more fragile, the insulating materials exhaust their service life and cannot provide a sufficient degree of sealing. This applies to both coolant and gas.

- Excess dust and fumes on the turbine impeller lead to wear and premature failure.

- Insufficient or excessive pressure in the expansion tank leads to sudden pressure surges, which leads to the destruction of connections, seals and hydraulic units.

- A dirty filter may cause the water supply to stop. Also, poor filtration leads to clogging of thin tubes in the heat exchanger. If dirt gets into the water flow sensor, the boiler will not turn on when the hot water tap is opened.

- Incorrect gas adjustment leads to burnout of the heat exchanger, failure of the Venturi nozzle or excessive gas consumption. Over time, the pressure in the gas pipe changes and only annual pressure adjustment can ensure that the pressure corresponds to the specifications.

Pay attention to your gas boiler, do its maintenance and preventive maintenance, and then it will serve you for a long time

Here you will find a complete description of the Economy gas valve bulkhead for the AOGV Zhukovsky gas boiler. And in all our subsequent work with you regarding the diagnosis of unit malfunctions, we will constantly refer to this article in order to get to the true reason for the malfunction of the boiler and quickly defeat the cold that is creeping into the house.

So! First, let's look at the insides of the valve in the first small diagram, by the way, kindly provided to us by the Zhukovsky plant. It's not entirely comfortable, but still.

How does a gas valve work?

1. Start the igniter. Press the solenoid valve button (22). When pressed, the valve needle will press down through the sealed membrane (25) onto the upper valve stem (24) and gas, through the slots in the seat (the seat is not shown in the diagram) of the upper valve (24), will rush into the hole leading to the igniter. It is immediately worth noting that the position of the upper valve (24) is normally closed. If the button is released, the spring will return it back. And the bottom valve position is normally open. Another spring opens it until it is closed when the boiler is heated by the “accordion” of the thermal balloon bellows, which expands from the temperature. The O-ring (28) is a seal between the upper valve seat and the block body. After the igniter ignited, the thermocouple heated up, and we released the valve button (22), which remained in the pressed position, we can proceed to starting the main burner.

On AOGV Economy gas boilers, a gas valve is embedded into the gas pipeline between the gas block and the burner. When starting the pilot on a cold boiler, this gas valve must be closed. This is necessary to ensure that the gas does not share between the igniter and the burner. To ignite the igniter confidently. We open the tap, the burner lights up. If the boiler starts up hot, then the bottom valve of the block may be closed. It is held in this state by a heated thermal bellows. In this case, the main burner will start when the temperature control knob is turned towards higher temperature.

2. Setting and adjusting the operating temperature. After the burner lights up and the boiler starts working, the question arises, what will happen next? Then the following happens. The bottom valve (23) on a cold boiler is always initially normally open, because it is pressed out by a spring. This valve will close only when the “accordion” of the thermal balloon bellows, having expanded when the set temperature is reached, presses with its rod, which passes inside the valve body, through the seal (27) onto the lever, which begins to close and closes the lower valve (23), and the burner will go out. By rotating the thermostat bellows temperature control knob, you are able to set any temperature within the permitted range, i.e. enable the “accordion” of the thermal balloon bellows to press on the rod and close the lower valve both at +35C and at +90C.

3. Idling. When the lower valve (23) is closed, gas access to the boiler burner is blocked, and the boiler remains operating only on the igniter. Transferring heat to the heating system coolant, the boiler gradually cools down. The “accordion” of the thermal bellows gradually contracts. The spring of the lower valve (23) strives to push it down into the open position and when the force of the spring is higher than the force of the “accordion” of the thermal cylinder bellows, the valve will move and open gas access to the burner, which will “light” from the igniter flame. We're done with the diagram.

22. Magnetic box 23. Bottom valve (for AOGV-11.6) 24. Top valve 25. Membrane 26. Cover gasket 27. Rod seal 28. Ring 29. Valve diaphragm

Now it is. Everything that you will now see here is the foundation on which the correct diagnosis of any malfunction associated with the operation of the AOGV Economy gas valve can be built. All other assumptions not based on this knowledge are usually incorrect. They either involve an absolutely useless waste of time and money, and even if implemented successfully, still do not provide reliability. And the Economy valve is a great and extremely reliable thing. Now make sure.

Functionally, the block consists of two parts. Top and bottom. The first part, the top, is the most difficult. We need two things: attention and accuracy. There is no rush.

Top part. Remove the solenoid valve from above. When separating the valve, hold the needle sticking down so that it does not fall out. (More details here.)

Remove the rubber membrane. It fits quite tightly. We are not afraid! Carefully, so as not to damage it, we pick it out from there.

Under the membrane we see a plastic cap, into which, when pressed, the needle of the solenoid valve rests. We take out the cap.

Next we see the upper inner sleeve. The bushing sits loosely. Let's take it out. When we take it out, we see that the sleeve has a hole for gas to pass inside our gas block.

This is the hole. When reassembling, these holes, of course, must be aligned. Next we see the rubber sealing ring between the block body and the upper valve seat. The top valve, when pressed, allows gas to the igniter. There are slots in the saddle. It is through these slots that the gas passes downwards, and with the top valve open, it goes to the igniter. We take a screwdriver and pry this thing right behind the slots.

The upper valve seat and the upper valve itself are in our hands. If gas flows down through the slots in the seat, we understand that the working surface of the upper valve is in contact with the seat from below. After this, we calmly remove the lower bushing and see the hole in it. Where does it lead? Right. To the igniter. This hole is located clearly opposite the fitting, onto which we then screw the boiler igniter nut.

For a more complete understanding, we give a small layout of the elements in the next photo.

1. Lower valve seat o-ring. It should be located between the block body and the lower valve seat.

2. The hole through which gas initially enters the block. This hole should be aligned with the hole in the top bushing. otherwise the gas simply will not get into the block.

3. These are the holes in the lower valve seat for the passage of gas to the main burner.

4. Bottom valve seat

5. Fitting for supplying gas to the igniter.

6. A hole that allows gas to flow to the igniter. It must be aligned with the hole in the lower bushing of the block.

It should also be noted that at the gas inlet to the block, where the entire block is attached to our boiler, a filter mesh is installed at the inlet.

Now let's move on to the second half of our block.

Bottom part. Remove the valve cover by removing 6 screws.

An amazing picture appears before our eyes, answering the question “What is an Economy gas valve?” Answer: Nothing! The word “Nothing” is meant in an exclusively joyful and positive aspect!!! This means its simplicity, ease of understanding, if you like, even the beauty of the solution!!! And most importantly, the operation of this device is independent of anything! I prove it!

1. This is the gas pipe through which gas flows to the main burner of the boiler when the bottom valve is opened.

2. This is the bottom valve itself. Moreover, it is worth noting that its working surface is on top. That is, when closed, the valve is pressed tightly against the upper seat. Now the bottom valve is open, since we filmed all this on a cold boiler.

3. Lever. We call this thing the bottom valve rocker arm.

4. A very important thing. A pin resembling an ordinary nail.

5. Thermal cylinder bellows rod.

Now let's return once again to the question of how our gas valve works.

1. Start the igniter. The starting and operation of the igniter belongs entirely to the upper part of the gas block. Pressing the button, starting the gas, igniting the igniter, heating the thermocouple and, as a result, fixing the button in the pressed position refers to the operation of the upper valve, thermocouple, solenoid valve and that’s all.

2. Setting and adjusting the operating temperature. As we can see from the photo taken on a cold boiler, the bottom valve is always open. Those. when you press the button and start the gas to the igniter, part of the gas will go to the burner. To prevent this from happening, there is a gas valve between the gas block and the burner. By the way, this tap is present only in boilers of the Zhukovsky plant. And then so on. Do you see that the thermal bellows rod (5) is not enough to reach the rocker arm (3)? When the boiler reaches the set temperature, the “accordion” of the thermal balloon bellows begins to move apart, pressing on the rocker arm, it moves the lower valve (2) until it closes completely. When the gas access to the burner is completely closed by the bottom valve, the boiler remains idling. Only the igniter works. When the boiler cools, the “accordion” contracts, and the bottom valve is slightly opened by a spring installed on the valve stem. The burner starts.

Let's continue. We take pliers and easily remove the rocker pin. By the way, over time it begins to jam. Lubricate it or replace it with any nail that fits the diameter. Use a screwdriver to pull the rocker out towards you. Once we release the rocker arm, the bottom valve will fall down.

We take the bottom valve in our hands. It is no different from the top one, except for the length of the stem. Want to change the aperture? It's easy. We pull off the ring that fixes and at the same time tightens the diaphragm.

In this photo you can clearly see the trace of castor oil to see where the working surface of the valve is in order to evenly tension the diaphragm with the ring.

So. This is what remains. Replacing the rod seal of the bellows-thermal bulb assembly. Use pliers to remove the rod. We pry out the rubber seal with a thin screwdriver. We just pull it out. We see the place where she lies. We install a new one. See also here what to do if the temperature control knob is jammed in the Economy ZhMZ unit

When reassembling, do not forget to align the holes on the bushings with the working holes of the igniter and the gas inlet into the block.

Prologue. There is no device in the world simpler and more reliable than this thing. It’s a pity when we are forced to bring and sell gas valves assemblies, instead of unscrewing 10 screws (4 on the magnetic box and 6 on the valve cover) to sort through, find and see the fault and do everything 10 times cheaper than it costs new at the factory.

Golden Rule. In gas technology, problems cannot be solved with money alone! They are also decided with the head. You can spend money, but the effect will be ZERO. It is clear that it is difficult to adapt to this. Well, in fact, this is what the article was written for. )))))

Promise. A little later, you and I personally, with our own hands, will definitely pick out (and there is no doubt about this) a couple of imported valves. So that some people don’t yell at us about how this valve is more reliable than the valve that we just disassembled.

PS In the Golden Collection of Faults, which we are now slowly forming, there will be a large number of links to this article. After all, only knowing what is inside the block, and not being afraid, considering yourself a man far from all this, can you really understand what is happening with the boiler.

Don't be discouraged everyone! And see you soon!