Manual and automatic adjustment of room temperature from modern heating sources is carried out using thermostats or thermostats.

They are mechanical and electronic. Each of them has its own pros and cons.

Among electronic models, three types are most widespread:

- thermostat for water heating

- for electric underfloor heating

- for gas boilers or boilers

In appearance, they are all very similar to each other, but their circuitry is different.

Let's take a closer look at the features of connecting a thermostat to a gas boiler, its diagram, errors and possible problems when operating such devices.

Areas of application of thermostats

Thermostats are widely used in various fields, both in industry and in everyday life.

Most often, these devices can be found in underfloor heating systems with a heating element in the form of a heating cable, which is located in the screed. When power is supplied to the electrodes, the wires heat up and give off heat to all surrounding layers; for proper operation, the system is equipped with a temperature sensor built into the screed. The controller can be used for electric or water heated floors, the principle of its operation does not change. Thermostat with sensor for heated floors

The thermostat is also used in heating or heating boilers to automatically adjust the heating level of the internal environment. Many manufacturers equip heating devices with these devices already at the manufacturing stage, but even if the boiler design does not provide for this, you can install the controller on the line yourself.

Global Tool

Price on the website: 4108 rub.

Overall rating: 4.6

This model is suitable for those who are looking for a thermostat with a large display. Modern design with touch screen combined with simple operation. The device synchronizes with applications. Allows centralized management with support for device sharing. Displayed parameters of weather, ultraviolet index and humidity will help you decide on your choice of clothes for the next day. Built-in IP20 protection class. Data memory and locking functions also add convenience. The seller offers different versions of the model.

buy on aliexpress

Types of room thermostats

There are three types of thermostats for residential premises:

- The electronic device consists of a temperature sensor, a signal transmitter and a thermal relay. The advantage of this device is the accurate determination and subsequent change in the temperature in the room. At the same time, remote control is quite easy and the thermostat can be used in the Smart House system.

- An electromechanical thermostat has a more simplified internal structure than an electronic one. The relay is the main element in the design, shaped like a tube, the cavity of which is filled with a substance that reacts to changes in temperature conditions. During heating of boiler equipment, this substance expands; during cooling, on the contrary, it contracts. All surges are experienced by the drive, which regulates the temperature through an electrical circuit.

- The mechanical unit does not contain electronics. The basis of the operation of this thermostat is a change in the properties of the material under the influence of temperature conditions. Changes in the temperature of the substance filling the gas membrane provoke the closure or opening of the electrical circuit, thereby triggering the thermostat mechanisms.

How to connect a room thermostat

The thermostat is installed in strict accordance with the operating instructions supplied by the manufacturer. Violation of installation rules can lead to thermostat failure. Depending on the design, the installation method of the product differs.

Connection diagram

Depending on the technical characteristics, a 220-volt household network or a DC power source can be used as a battery.

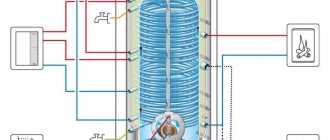

Schematic connection of the regulator to a boiler with a boiler

To connect to the electrical circuit, you must follow the operating instructions. To properly connect an electrical appliance to the network, it is better to contact specialists.

Selection of installation location

It is recommended to install the device in places with average room temperature. Installing the product near window or door openings, ventilation shafts and air conditioners may negatively affect the correct determination of the temperature indicator. The installation height on vertical surfaces plays an important role when choosing a mounting location. Cold air sinks down, the upper layers have a higher temperature. The product should be mounted at a height of 1.5 to 2 m. When choosing an installation location, it is necessary to take into account that for normal operation there must be unobstructed access to the device.

Installation and connection

Before connecting the room thermostat to the gas boiler, you must carefully study the operating instructions. Wireless models are easy to install. It is necessary to connect the receiver to the boiler automation, and install the transmitter on a vertical surface of the room.

Installation of wire structures is carried out in several stages:

- Open the gas boiler panel, which blocks access to the automation.

- In accordance with the operating instructions, connect the wire to the boiler control board.

- Install wiring in an open or closed way to the installation location of the room thermostat.

- Attach the regulator to the wall.

- Connect the wires coming from the gas boiler to the device.

- Connect the thermostat to a household power supply.

After startup, you need to check the functionality of the product and set the required operating mode. The setting of the room regulator differs depending on the design of the device. Connecting a room thermostat to a gas boiler reduces the degree of human participation in the operation of the heating system. The ability to adjust allows you to maintain a comfortable room temperature and save fuel.

Conclusions and useful video on the topic

How to connect a thermostat to a gas boiler:

Room thermostats for regulating the heating system:

Installing the device yourself should not cause any difficulties. But do not forget, when connecting the thermostat to a gas boiler, to study the instructions that come with the device and the technical documentation for the heating equipment.

Tell us about your own experience in choosing and connecting a thermostat to a gas boiler. Share useful information that may be useful to site visitors. Please leave comments in the block form below, ask questions, post photos on the topic of the article.

Saving electricity and gas, a stable comfortable temperature, a minimum of time spent on adjusting heating equipment - all these are not whims, but well-founded requirements for a properly organized heating process.

Therefore, connecting a room thermostat to a gas boiler, to ensure all of the above conditions, becomes an obvious necessity. We will talk about the principle of operation of the thermostat and the types of the device. Let's look at the differences in functionality of different models.

The article describes in detail the principles of connecting a temperature controller. Rules for installing different versions of the device are given. By following our recommendations, you can complete the installation yourself, without the help of heating engineers.

General principles for connecting a thermostat

The method and diagrams for connecting the thermostat to the heating equipment itself can be found in the technical data sheet of the gas boiler. Modern equipment, regardless of manufacturer, requires connection points for the thermostat. The connection is made using the terminals on the boiler or the thermostat cable included in the delivery package.

If you are using a wireless thermostat, place the measuring unit only in a residential area. This may be the coldest room or the room where the largest number of people often gathers, the children's room.

It is not advisable to install a thermostat unit in the kitchen, hall or boiler room, where the temperature regime is unstable.

The thermostat should not be exposed to sunlight, it should not be located in a draft, near heating devices and electrical equipment that emit a large amount of heat - thermal interference has a bad effect on the operation of the device

Connecting different types and models of thermostats may have their own characteristics; installation is carried out in accordance with the manufacturer's instructions, which are included with the device.

Recommendations include a comprehensive description of the regulator's operation, connection method and diagrams. Next, we will tell you how to properly connect a thermostat to a gas boiler and about the installation features of the most typical regulator models.

Connecting a mechanical thermostat

The mechanical type thermostat is distinguished by its reliability and simplicity of design, low cost, and long-term operation.

However, it supports only one temperature mode, which is set by changing the position of the handle on the temperature scale mark. Most thermostats operate in the temperature range from 10 to 30°C.

To connect a mechanical thermostat to an air conditioner, use the NC terminal; to gas or any other heating equipment, use the NO terminal

The mechanical thermostat has the simplest principle of operation and is activated through an opening and breaking circuit, which occurs using a bimetallic strip. The thermostat is connected to the boiler through the terminal box on the boiler control board.

When connecting the thermostat, pay attention to the markings - they are present on almost all models. If there are no markings, use a tester: pressing one probe to the middle terminal, check the side terminals with the second and identify a pair of open contacts

Installation of an electronic thermostat

The design of an electronic thermostat requires the presence of an electronic board that is responsible for controlling the device.

The control signal is potential - voltage is transmitted to the boiler input, which leads to the closing or opening of the contact. A voltage of 220 or 24 volts must be supplied to the thermostat.

Electronic thermostats allow for more complex settings of the heating system. When connecting an electronic thermostat, the power wire and neutral are connected to it. The device transmits voltage to the boiler input, which starts the operation of the equipment

An electronically controlled thermostat is used to organize the operation of complex climate systems. It will help in controlling not only an atmospheric or turbine gas boiler, but also a pump, air conditioner, and servo drive in the heating system.

How to connect a wireless thermostat?

The wireless thermostat consists of two blocks, one of which is installed in a living room and acts as a transmitter. The second unit is mounted near the heating boiler and connected to its valve or controller.

Data transmission from one block to another is carried out over a radio channel. To control the device, the control unit is equipped with an LCD display and a small keyboard. To connect the thermostat, set the sensor address and install the unit at a point with a stable signal.

Thermostat connection diagram for an open circuit - the equipment turns on at the moment the current appears. A similar circuit is used when connecting a mechanical thermostat

The main disadvantage of a wireless thermostat is that the remote unit is powered by batteries, which have a limited resource and therefore require frequent replacement. To ensure uninterrupted operation, the device is equipped with an alarm function that warns when the battery needs to be replaced.

Room thermometer with liquid

Until now, filled thermometers are considered one of the most accessible temperature measurement sensors. A liquid is added to the tube that is sensitive to changes in temperature, most often colored alcohol or mercury. As the temperature level outside the tube changes, the liquid expands and rises; using the dial table, you can determine what temperature level is currently in the room. This method is good if high accuracy is not required, because when using such a meter, an error of almost a degree is possible, in addition, alcohol models very quickly lose their readings with a sharp change in temperature, they are difficult to record.

Photo - Room thermometer with liquid

The liquid must have a relatively large coefficient of thermal expansion, so that small changes in temperature will result in detectable changes in volume. The tube material is glass, sometimes tempered, but always transparent so that the marked table can be seen. Mercury used to be more common, but its toxicity levels are too high to cause irreparable damage in household use.

Although filled regulators are the simplest and cheapest options for measuring temperature, they are also not durable due to their fragility. They are also rarely used in even small production processes, because there is no way to regulate their operation automatically.

The best choice

The selection of a thermostat for a heating boiler is based on the personal preferences of the room owners. When choosing, you should consider what characteristics are required when using a particular boiler.

Wired or Wireless

The communication between the control unit and the sensors and the boiler for different models is carried out wired or wirelessly. In the first case, you will need to lay a wire. The cable length reaches 20 m. This allows the control unit to be mounted at a great distance from the room in which the boiler room is installed.

Wireless thermostats for heating boilers are designed as a receiver and transmitter. A distinctive feature of products of this type is that there is no need for wiring. The transmitter signal can be received at a distance of 20-30 m. This allows you to install the control panel in any room.

Temperature setting accuracy

Depending on the design of the room thermostat, the room temperature setting differs. Inexpensive models have mechanical control. The disadvantage of cheap thermostats is the error reaches 4 degrees. In this case, the temperature adjustment step is one degree. Products with electronic control have an error of 0.5 - 0.8 degrees and an adjustment step of 0.5o. This design allows you to accurately set the required power of the boiler equipment and maintain the temperature in the room in a certain range.

Ability to set the hysteresis value

The room thermostat for a gas boiler has a difference between the switch-on and switch-off temperatures. It is necessary to maintain optimal heat levels in the room.

Hystersis principle

For mechanical products, the hysteresis value does not change and is one degree. This means that after switching off, the boiler will start working after the air temperature in the room drops by one degree. Electromechanical and electronic models have the ability to set hysteresis. The adjustment allows you to change the value up to 0.1 degrees. Thanks to this design, it is possible to constantly maintain the room temperature in the desired range.

Programmable

The function is only available for electronic or electromechanical thermostats. It is possible to program the control unit to set the temperature according to the clock. Depending on the model, thermostats are programmed for up to 7 days. This makes it possible to make the heating system with the gas boiler turned on autonomous. At a certain time, the thermostat turns on or off the boiler unit or changes the intensity of its operation. With weekly programming, gas consumption can be reduced by up to 30 percent.

Wi-fi or GSM

Thermostats with built-in wi-fi and gsm module connect to the internet. Gadgets with installed applications are used to control heating. This is how remote shutdown, connection of the boiler and adjustment of temperature indicators in the heated room are carried out. Using the GSM standard, the room thermostat transmits information about the occurrence of malfunctions in the heating system to the owner’s phone. It is possible to remotely turn on or off the gas boiler.

Safety

When choosing a thermostat for gas boiler equipment, you should pay attention to the presence of safety systems. Functions are available to prevent the circulation pump from stopping, protect against freezing or exceeding the maximum temperature in the heating system, etc.

The presence of such options allows you to safely use boiler equipment in autonomous mode.

Settings

To enter the programming menu, press and hold the “SET” button (about 5 seconds).

You will enter the main settings menu. To switch modes P0…P8, press + or -. To change modes P0 ... P8, press the “SET” button again, then + or -. Long press SET (about 5 seconds) or within 10 seconds if no button is pressed, the menu will be memorized and exited. P0

- Cooling / Heating - C / H

(Set H, for heating) P1

- hysteresis settings - 0.1 - 30

(Set optimally 0.3) P2

- setting the upper limit +110 ° C (110 did not touch)

P3

- setting the lower limit - 50 ° C (-50 did not touch)

P4

- Temperature error correction -7 ... +7 ° C (did not touch, there is no point, the temperature is set by feeling once, and what it will be shown on the screen does not matter)

P5

- Delay start time - 0 ... 600 sec

(Different versions have different values, I have a maximum of 300, you need to set the maximum, which is 10 minutes) P6

- Alarm signal (did not change)

P7

- Upper alarm temperature threshold - 0 ... 110 ° C (OFF) (did not change)

P8

- Reset to factory settings - S/N (when switching the parameter, all settings are reset)

The boiler is set to a slightly higher coolant temperature than usual. This setting acts as a reserve in case of extreme cold. Or, for example, after peeling potatoes and showering, quickly heat the room and not overheat it. Parameter P5

I intentionally push it to the maximum. since the hysteresis is small, 0.3 degrees, so that the boiler does not twitch constantly. This gives him a pause to rest the pump and the ignition relay. This increases the life of the boiler. For a boiler, such pauses are the norm. Remember how often you use hot water. These are the same pauses.

How to connect a thermostat to a gas boiler

If you have an old or simply too simple model of gas appliances, you may need to connect the thermostat yourself. This is not difficult to do, the main thing is to follow the instructions and check the documents for the gas boiler itself and the equipment connected to it.

Required tools and materials

One of the main advantages of connecting a thermostat to a gas boiler is that it does not require any special tools or special skills. Everything that is needed to install a thermostat on a gas boiler is part of the basic equipment set. You will need a technical passport of the gas boiler and documents for the thermostat to check the diagrams and make sure they are compatible. You will also need a regular screwdriver, a tester to determine the voltage in the electrical network, as well as tools for installing the device on a wall indoors. In some cases

Important! The complete set of tools depends on the equipment model and installation location. which one you choose

Important connection points

The most important point is choosing the sensor model you need. Thermostats come in three types: mechanical, electromechanical and electronic. The first two types are installed directly into the system and measure the temperature of the coolant. Older models of gas equipment can be equipped with such devices. Their installation is not only difficult, but also impractical. If you want to install a thermostat for your heating system, it is better to choose a modern electronic model. It connects to the boiler and determines the temperature not of the water in the system, but of the air in the heated rooms. The comfortable temperature in such devices can be set through the settings. If the set threshold is exceeded, the device gives a signal to the boiler and turns off its operation.

In order for the thermostat to measure the actual temperature and humidity in the room, you must adhere to the following rules when installing it:

- The installation height of the regulator should be slightly less than a person’s height, from one and a half meters to 1.7 meters.

- The device must be installed at a distance of at least a meter from heating devices and any equipment that heats up during operation, as well as from fans and air conditioners - all this will distort the readings of the device.

- The effect of drafts or ventilation on the regulator should be minimized.

- The sensor must be located in a heated room - otherwise its readings will be underestimated.

Important! If you have heated floors in your house, it is best to purchase a model of a temperature control device that has an additional temperature sensor installed near the floor. It detects the air temperature in the lower zone and provides more accurate readings

Price range

The cost of a thermostat depends on its design and set of functions. Conventional mechanical devices are relatively inexpensive - from 1000 rubles .

Electronic devices with programming, remote control and other functions can cost up to 10,000 rubles and more. There are many price options, which allows you to choose an affordable device and be able to more accurately set the temperature in the house.

Main types of boilers and temperature control

There are several types of boilers: solid fuel, gas, electric and liquid fuel.

Boilers have become widespread throughout the world. There are domestic samples, and there are also imported boilers. Material of manufacture: steel or cast iron. Easy to use, economical, with the function of adjusting the coolant temperature. In cheaper models, this function is implemented using a special device - a thermoelement.

Structurally, a thermoelement is a metal product, the geometric dimensions of which decrease or increase under the influence of temperatures (depending on the degree of heating). And this, in turn, changes the position of a special lever that closes and opens the draft damper. The photo shows an example of such a regulator:

Photo: thermostat sample

The more the damper is open, the stronger the combustion process, and vice versa. Thus, the volume of air that enters the closed combustion chamber is completely controlled by the thermostat, and if necessary, its supply is stopped and the combustion process is extinguished. More modern models are equipped with controllers that, depending on the specified thermal conditions, control the air flow, turning on (or off) a special fan (see photo below):

Boiler with temperature controller

Gas boilers are the most common and cheapest units to operate. Boilers are single-circuit and double-circuit. Single-circuit boilers have one heat exchanger and are intended for heating only. The connection diagram is shown in the figure below:

Switching diagram for a single-circuit boiler

Double-circuit boilers have two heat exchangers and are designed for heating and producing hot water. The boiler switching diagram is presented below:

Switching diagram for a double-circuit boiler

Some boilers have separate controls for heating and hot water temperatures.

Thermostatic control valves

The thermostatic valve is a simple solution to the problem of obtaining a coolant at a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to a heating system

Piping diagram for a solid fuel boiler using a thermostatic three-way valve:

Piping diagram for a solid fuel boiler using a thermostatic three-way valve

Piping diagram for a gas boiler using a thermostatic three-way valve:

Piping diagram for a gas boiler using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the temperature in the room by varying the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed to adjust the temperature needed in each individual room.

This idea should be considered as an addition to the thermal control installation. Also, such devices require periodic readjustment and regular performance checks (every six months when changing operating modes).

Homemade external thermostat for the boiler: instructions

Below is a diagram of a homemade thermostat for a boiler, which is assembled using Atmega-8 and 566 series microcircuits, a liquid crystal display, a photocell and several temperature sensors. The Atmega-8 programmable microcircuit is responsible for compliance with the specified parameters of the thermostat settings.

Scheme of a homemade external thermostat for a boilerStrictly speaking, this circuit turns the heating boiler on or off when the outside air temperature decreases (increases) (sensor U2), and also performs these actions when the temperature in the room changes (sensor U1). It is possible to adjust the operation of two timers, which allow you to adjust the time of these processes. A piece of circuitry with a photoresistor affects the process of turning on the boiler depending on the time of day.

Sensor U1 is located directly in the room, and sensor U2 is located on the street. It is connected to the boiler and installed next to it. If necessary, you can add an electrical part of the circuit that allows you to turn on and off high-power units:

The electrical part of the circuit allows you to turn on and off high-power units

Another thermostat circuit with one control parameter based on the K561LA7 chip:

Thermostat circuit with one control parameter based on the K561LA7 microcircuit

The thermostat is assembled on the basis of the K651LA7 microcircuit and is simple and easy to adjust. Our thermostat is a special thermistor that significantly reduces resistance when heating. This resistor is connected to the electricity voltage divider network. This circuit also contains resistor R2, with which we can set the required temperature. Based on this scheme, you can make a thermostat for any boiler: Baxi, Ariston, Evp, Don.

Another circuit for a microcontroller-based thermostat:

Circuit diagram for a thermostat based on a microcontroller

The device is assembled on the basis of a PIC16F84A microcontroller. The role of the sensor is performed by a digital thermometer DS18B20. A small relay controls the load. Microswitches set the temperature, which is displayed on the indicators. Before assembly, you will need to program the microcontroller. First, erase everything from the chip and then reprogram it, and then reassemble it and use it to your health. The device is not capricious and works fine.

The cost of parts is 300-400 rubles. A similar regulator model costs five times more.

A few final tips:

- although different thermostat options are suitable for most models, it is still desirable that the thermostat for the boiler and the boiler itself be made by the same manufacturer, this will greatly simplify the installation and operation process itself;

- before purchasing such equipment, you need to calculate the area of the room and the required temperature in order to avoid “downtime” of equipment and changes in wiring due to connecting devices of higher power;

- before installing the equipment, you need to take care of the thermal insulation of the room, otherwise high heat losses will be inevitable, and this is an additional cost item;

- if you are not sure that you need to purchase expensive equipment, then you can conduct a consumer experiment. Buy a cheaper mechanical thermostat, adjust it and see the result.

The electronic thermostat can be programmed in any order.

Any modern heating boiler, regardless of the type of energy carrier used, must meet a number of requirements. This includes functionality, ergonomics, safety and the last quality, the relevance of which is growing every year - energy efficiency. When choosing a boiler, the buyer thinks about how much the equipment will help save his budget. Reducing energy costs for heating a house will allow not only the high efficiency of the heating element, but also additional components of the heating system. This is a thermostat and thermostat for an electric heating boiler, which control the operation of the boiler depending on the ambient temperature.

In addition, when it comes to electrical equipment, you need to think about purchasing a voltage stabilizer. It will not affect the energy efficiency of the heating device, but will also help save your budget by maintaining the operation of the electric boiler during power surges in the network.

Connecting a thermostat with a thermostat

Many models of modern thermostats are a set of a control unit and a thermostat. Thermostat is a device for remote control of a heating device, placed in any convenient place. The temperature selection is transmitted to the control unit connected directly to the boiler. There should be no issues with connecting a simple thermostat; What do you need to know about installing a room thermostat?

The first step is to choose not the device itself, but the location for its installation. It should be located:

- at a sufficient height from the floor - about one and a half meters. The point here is not about convenience, but about physics - the sensors of a low-lying thermostat will capture the heat of the heated floor and set a low temperature;

- at a distance from possible sources of heat, be it sunlight, heaters or stoves. The logic is the same;

- on the inner wall of a room where there is enough open space - and again not for reasons of comfortable control of the device. For correct operation, the device must have access to air flow - circulation makes it possible to evaluate temperature changes and adjust the operation of the boiler. A thermostat covered with a curtain for reasons of aesthetics will not bring the expected result.

The method of connecting the thermostat to the unit can be wired or wireless. The former are distinguished by their affordable price and the absence of signal problems; wireless ones are more expensive, but eliminate the need to lay another cable.

The advantage of a device with a thermostat is its expanded functionality. Installation of modern models in terms of labor costs is quite comparable to a conventional thermostat, but in the end it gives more advantages:

- customizable temperature modes;

- clear interface with date and time display;

- minimum number of boiler starts;

- the most precise calibration of sensor operation;

- high reliability.

The main thing is that the thermostat eliminates the need to manually regulate the operation of the boiler, allows you to configure the device remotely and significantly reduces the amount indicated in the bills for paying for electricity.

The right approach to choosing a thermostat will allow you to completely forget about the problem of heating your home.

Installation Rules

Room regulator

Installation of central thermostats is simple. But it is necessary to adhere to several rules in order not to interfere with the efficiency of the system in the future:

- The regulator is mounted in such a way as to ensure free air flow.

- There should be no household electrical appliances, lamps, touch switches, additional heaters, etc. nearby.

- The thermostat must be freely accessible.

Piping an open gravity system in a private house

It consists of a single device - an open expansion tank, the functions of which are as follows:

- Compensation for excess heated water.

- Protection against pressure surges in the system.

- Removal of air and steam in case of boiling of the coolant.

When selecting the tank volume, the already familiar 10% of the total volume of water in the system is used, with a small margin.

The most optimal point for installing the tank is the top of the heating circuit. An accelerating manifold is installed immediately behind the tank: this is the name given to the vertical spill area after the boiler. So that air accumulations can easily escape into the atmosphere, and water flows by gravity, the section of the system between the tank and the heat exchanger is given a slight slope. For the convenience of replenishing the constantly evaporating coolant, the tank is often equipped with a cold water supply. Date: September 25, 2021