The Japanese corporation Rinnai has established itself as a global manufacturer of reliable gas boilers. But like any gas-using appliances, for some reason they can malfunction. To identify possible malfunctions, errors in the Rinnai gas boiler are displayed on the display in the form of indicators or numbers and make it possible to accurately identify the causes for quick troubleshooting.

If you think that all this is very difficult, then you are mistaken. In fact, there is nothing complicated in automatic diagnostics, and thanks to these numbers, if you have at least a little technical knowledge base on heating units, you can fix many malfunctions yourself without calling a technician.

And we will help you - we will describe the most common errors of boilers of this company, possible ways to eliminate them, and also post some manuals for the convenience of identifying those codes that are not in our article.

About the manufacturer

The Rinnai company has been manufacturing and selling heating equipment (gas boilers, water heaters, pipes and chimneys) for decades (founded in 1920). In terms of quality of gas boiler units, it is close to leading German manufacturers, while the main models of the brand are 10-30% cheaper.

The company has been operating on the Russian market for more than 10 years, selling products through dealer networks. It has established itself as a manufacturer of boiler units with high technical and operational characteristics, economical resource consumption, and excellent 24-hour service. Installation specialists note the ease of installation and maintenance.

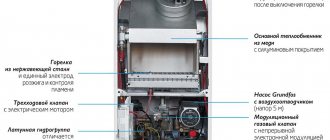

Internals of the Rinnai RB-166 SMF model. The best materials, high-quality assembly and layout were used. The insulation and protection of individual elements is inferior to German boilers, but is quite reliable.

Problems in 98% of cases are noted exclusively in automatic errors, for example, in error 99, which can occur due to icing of the chimney at temperatures of -15°C and below, less often - when the exhaust fan blades are clogged, when the boiler is not serviced completely or not in a timely manner.

Also, a mandatory equipment in the boiler room is a voltage stabilizer; without it, Rinnai gas boilers are vulnerable to voltage surges, which leads to rapid failure of the electrical board.

Subject to the installation and operating conditions, there are no complaints about boilers of this brand; in most cases, the units operate uninterruptedly for more than 8-10 years.

Review of Rinnai gas boilers

The Japanese company Rinnai produces exclusively gas boilers. The manufacturer's technologies are known worldwide, where it occupies one of the leading positions in the production of gas equipment.

In the article we will look at the best models of Rinnai gas boilers, how they behave in practice, what advantages and disadvantages are noted by the owners, as well as what automation errors may occur during the operation of boiler units in domestic conditions.

Conclusions and useful video on the topic

More details about error 99, cleaning the fan:

Basically, malfunctions of most models of Rinnai gas boilers are easy to fix. Knowing the decoding of error codes and having in hand a manual for the operation of a specific device, you can easily diagnose, if not the breakdown itself, then at least the area in which it appeared.

Have you had any problems with Rinnai heating units? Maybe you saw a code that is not in our article? Share your experience and ask questions in the comments.

Device Features

- Two circuits - Rinnai boilers provide not only heat, but also hot water needed for household chores. The built-in instantaneous water heater quickly heats the water so you can shower or wash dishes.

- Two copper heat exchangers provide high performance and efficient heating.

- The magnetic coupling isolates the electrical part of the motor from the water-blade part. Thanks to this, the circulation pump works continuously and is less likely to break down.

- Modulation burner. The power of the boiler is smoothly regulated using a microprocessor from 25% to 100%, depending on the parameters specified by the consumer. According to the manufacturer, unlike equipment with a single-stage burner, which turns off when a given heating level is reached, the fuel consumption of these devices is reduced by 20%.

- Reliable protection against breakdowns due to the presence of temperature sensors, frost protection functions, self-diagnosis functions, forced exhaust gases and air supply to the combustion chamber.

All Rinnai heating boilers have electronic ignition (start heating automatically when a hot water tap is opened or after a temporary stop due to a power outage) and are adapted to Russian conditions, because they can operate properly even with low gas inlet pressure and low network voltage .

The Rinnai boiler can be installed in a private home or in an industrial setting. The equipment operates both from liquefied gas in cylinders and from the central gas main.

The best and most famous models characteristics and prices

The range of Rinnai wall-mounted gas boilers is quite wide and varied. There are models designed to heat rooms of different sizes. They differ in performance, set of built-in functions and price. Therefore, when choosing a boiler, it is necessary to understand exactly for what purposes it will be used. Below are descriptions of some popular models of Rinnai gas equipment.

rb 167 rmf

This model is suitable for use in heating systems of houses up to 180 square meters. m. This boiler is characterized by low noise level and stable operation. Although the efficiency is not the highest, the rb 167 rmf model is one of the most economical units in its price category. Additional features include the presence of a remote control and the ability to synchronize it with a smartphone via a wireless interface. Which is very rare for budget models.

rb 167 emf

This boiler is the predecessor of the model described above. It has less functionality, but is much cheaper. The kit also includes a remote control, but there is no ability to control the operation of the boiler from a mobile device. There is also no function for long-term programming of the device. The main differences of this model are greater efficiency and higher efficiency than the next generation model.

rb 207 rmf br r24

One of the most popular models of gas boilers produced by Rinnai. This boiler has greater power and is capable of efficiently heating a room up to 230 square meters. m. Like most models of the brand, the boiler is equipped with a remote control, which greatly simplifies the operation of the device. It is possible to program the boiler operating modes for several days. The ratio of fuel consumption and performance is considered close to optimal. The boiler design provides protection against freezing and overheating.

br ue30

More powerful, efficient, but at the same time expensive model. The efficiency of the br ue30 boiler exceeds 91%, which is close to the efficiency of boilers from leading European manufacturers. The design of the boiler ensures complete combustion of fuel at any level of installed power. Smooth power adjustment is possible from 25% to 100%. The presence of an additional protective casing ensures virtually silent operation of the device. The disadvantages of this model include the absence of an additional circuit for circulating hot water in the water supply system.

rb 277 cmf

One of the most efficient and high-tech boilers on the world market. Unique developments of the Rinnai company allow the device to provide an efficiency of over 104%. With a maximum power of almost 30 kW, gas consumption is only 1.84 cubic meters. m/hour. The device provides these parameters without interruption in operation. In addition, this model meets all modern environmental standards.

How to identify and eliminate possible errors in the Rinnai boiler

Error code 11

Indicates a faulty ignition system. This is notified by the ionization flame sensor. This sensor-electrode takes into account the presence of a flame and blocks the operation of the Rinnai boiler during insufficient combustion of the main gas burner device or when there are difficulties with the gas supply. Operation pauses after three unsuccessful starts.

To restore functions, it is recommended to keep the Reset button pressed. Gas valve malfunction – The gas valve is controlled electronically. This component is tested by measuring voltage and resistance. If it turns out that the values differ from the standard parameters, it is necessary to replace the valve with a functional one.

There is no gas supply to the device - A valve is installed in the gas distribution circuit that shuts off the gas supply. As a result, a failure to start the device may occur due to a closed tap. Incorrect contact or signal from the flame ionization sensor was not detected. Malfunction of the electronic control board - If the ignition process occurs normally, but the boiler still immediately goes out, then the control board probably does not detect the flame. Therefore, it is necessary to diagnose it.

Error 16

Overheating of the Rinnai boiler heat exchanger. The unit stops working. Overheating safety thermostat has tripped – The temperature sensor and overheating thermostat are mainly located on the outlet pipe of the primary heat exchanger. An important function of the thermostat is to protect the device from excessive temperature increases. An emergency occurs due to problems with the thermostat, temperature sensor, as well as when there is a malfunction in the main circulation circuit.

Code 14 (overheating)

Damage to the temperature sensor – The electronic board receives an incorrect signal or the contact between the sensor and the control board is broken.

Code 15

The overheating thermostat has failed - If it is working properly, but actual overheating of the liquid is detected, then it can be assumed that there is a violation of the coolant circulation in the heating circuit. The main heat exchanger or the filter element of the main circuit is clogged (insufficient circulation results in an increased heating temperature of the liquid). The circulation pump has broken down or there is an air lock in the heating system.

Error 43

Indicates low pressure in the system. Possible reasons why this malfunction appears: low water pressure in the heating circuit. The contact between the pressure sensor and the electronic board is broken. Pressostat malfunction. First of all, we recommend that you check the results of the pressure gauge readings.

Very often, the failure is corrected using a feed tap, which is needed to add coolant to the heating system. When the failure occurs again, there is probably a coolant leak. The circulation pump, main heat exchanger, excess pressure relief valve, worn gaskets, make-up valve and other parts may leak. Leaks can be identified visually in hydraulic units and components.

Error code 99

small chimney size, improper installation, contamination, icing of the inner wall. Narrowing the size of the chimney canal may cause a weakening of draft. Exceeding the maximum length of the chimney pipe You must carefully read the installation instructions for the gas boiler and follow the relevant requirements.

An excessively long straight section of the chimney pipe often causes a lack of draft. Damage to the traction sensor - When a vacuum occurs in the inlet tube, you can hear a characteristic click. The contact between the traction sensor-relay and the electronic board is broken, there is condensation, as well as incorrect connection of the tubes to the sensor-pneumatic relay.

Code 90

There are problems with the fan operation – The fan impeller is clogged. There is not enough lubricant on the fan shaft, which is why it does not develop the required speed. There is no contact between the electronic board and the fan.

Error 34

Problems with determining the temperature by the DHW sensor. This situation indicates a malfunction of the temperature sensor in the hot water supply circuit or the permissible temperature has risen. The main reasons why this malfunction occurs: the hot water supply temperature sensor is broken. Poor contact between the electronic board and the DHW temperature sensor.

Error code 12

Ignition does not take place. This occurs when there is no ignition or the burner flame fades. It is necessary to inspect the contacts between the ignition unit and the flame electrode, and also between the board and the gas valve. The main factor in burner flame extinction is insufficient draft.

Error code 31

The heating system temperature sensor is not working correctly. This circumstance indicates that the temperature sensor of the heating system is broken or the required temperature is too high. Damage to the heating circuit temperature sensor circuit – This problem occurs when the connection between the temperature sensor and the electronic board is broken, or the temperature is lower than recommended.

Five seconds after detecting a malfunction, the Rinnai boiler will restore trouble-free operation if the malfunction occurred accidentally. You should make sure that there is no moisture on the temperature sensor connector and the electronic board connector. If there is no moisture, you need to change the temperature sensor. There is a short circuit in the temperature sensor in the heating circuit - This failure most often occurs after a short circuit in the temperature sensor circuit or the temperature value of the coolant is much higher than the required one.

The Rinnai boiler is in operation. Over the past month, the ignition error code 11-42 has been flashing almost every day. After rebooting with the reset key, the device sometimes turns on satisfactorily, but this does not happen often. Just yesterday I removed the air intake plug and it started functioning better. What's wrong?

When an error related to smoke exhaust is displayed, the protection covers must be opened. This will help draw air from the room. Then check the chimney pipe for ice and, if necessary, remove it. If the accident is related to combustion, you should find out whether gas is entering the room.

The unit itself interrupted operation and issued code 43-62. What to do?

There is no coolant in the unit or the pressure switch sensor is broken. First fill the heating system.

The gas appliance stops working and displays error 99. I cleaned and purged it - the result was zero. What could it be?

This code indicates unsatisfactory traction, and we advise you to check the exhaust gas exhaust system. It is likely that the membrane is stuck. In another case, we advise you to call a specialist for a detailed inspection of the gas boiler with further inspection.

There is a Rinnai boiler. Error 34 began to appear. The unit itself is functioning, the water temperature level is set manually. When it was installed, it probably overheated, since the automatic temperature mode was turned on. We do not have an external air temperature sensor. What is the reason?

Presumably, the DHW temperature sensor is damaged. Sometimes the electronics board is faulty.

Error 31 is constantly visible on the gas boiler. Help me figure out what it indicates?

This code indicates problems with the heating temperature sensor. It probably needs to be replaced.

The following problem occurred. When igniting, the device displays error code 12 (flame failure). When restarted, it turns on, but as soon as the burner lights up, strange clicks are heard, and then an error is displayed. I replaced the ignition electrode, cleaned the water flow sensor and removed the ground from the plug, but no result. Has anyone encountered this?

This malfunction can occur for several reasons. Broken ignition electrode. Gas flow is incorrect. The electronics board is damaged.

For what reason can the Rinnai boiler not start? It also regularly produces error 14. How to fix it?

This fault is usually issued due to some problems in the thermostat, temperature sensor, as well as problems in the operation of the main circulation circuit. It can be assumed that there is overheating of the water in the heat exchanger. If the thermostat and temperature sensor are OK, then the problem is in the control board. It needs to be replaced.

Why does the unit not start and displays error code 43? The pressure in the system is normal, no leaks are observed. I tried to turn it off from the mains, but the problem did not go away. What is the cause of the problem?

This situation usually appears when the coolant pressure in the heating circuit is reduced. In such a situation, it is recommended to check the pressure switch. It is possible that it is faulty.

The problem with the device is as follows: the hot water supply is set to 40 degrees. If you open a hot water tap, the burner ignites and goes out almost immediately. This process occurs frequently. Either warm water flows out of the tap, but not hot, or cold. Sometimes it displays error code 16. What is the reason?

This code is a sign of overheating of the hot water coolant. Most likely, the heat exchanger is clogged with debris, or the thermostat has settings different from those recommended.

The unit performs its functions for approximately 4-5 minutes, then the burner stops working and error 99 is displayed. It blinks for no more than a minute, the burner device is turned on again for ignition, and the device functions normally for another three to four minutes, and so on continuously. This code, based on the operating instructions, means that the draft sensor has tripped, but the chimney is not clogged and combustion products come out normally. Help me figure out what is causing the problem?

Closing the exhaust

- Restart the boiler: depending on the boiler model, restarting is carried out in different ways, most often: press the Power button on the front panel; if there is no button, you can turn off the power through the Stabilizer or socket.

- Problems in the boiler electrical network : a common cause of many errors.

strictly recommended to connect heating boilers through a stabilizer (for the boiler) or a UPS; this will save you from unnecessary costs for replacing the control board.

- Checking the polarity in a plug-socket connection : turn the plug 90 degrees and insert it back into the socket or stabilizer.

Check the grounding: in the private sector, circuit testing is carried out with a device - a megger; when measuring resistance, R should show no more than 4 ohms.

- Check the potential on the metal part of the boiler

: the error may be due to interference (stray currents). They appear for various reasons (a power line is located nearby, a powerful source of radiation, the insulation of a power cable is damaged, or something else), but the result is the same: where there should not be potential, it is present. We also do not forget about installing a dielectric coupling on the gas pipe.

- Check the chimney: blockage that reduces the exhaust channel of flue gases, icing of the tip. In relation to boilers with an open combustion chamber (air is taken from the room), it is necessary to ensure a good flow of air into the room.

- Check the operation of the fan a: make sure the fan is working; when turned on, the impeller should spin and create pressure in the system. The error also appears when the turbine is running, when the fan does not reach the required speed and the thrust is lower than the calculated one.

- Performance is assessed in dynamics (~220 per terminal).

- The presence of U coming from the ED is checked. If there is an error, the multimeter will show zero - no fan control.

- Cleaning the burner: flame separation occurs when the nozzles are clogged with dust, there is enough oxygen, but no gas. Clean with a vacuum cleaner and toothbrush.

- Electronic board is faulty : a fault in the electronic circuit also causes an error to appear in the boiler.

Defects are identified by inspection for deformation, melting, breaks, condensation, etc.

The new board may not be configured correctly.

If the cause of equipment failure is the board, contact the service center indicating the alphanumeric marking of the node.

Error codes for Rinnai gas boilers - meaning and troubleshooting

The Rinnai gas boiler stopped and displayed error code 14. What should I do?

This error means that the temperature fuse is faulty or the safety circuit of the electronic module is broken. You need to check the temperature fuse for a short circuit. The wires in the terminal may be broken.

The Renai boiler was turned off for a week, and after turning it on it started for a minute and went into trouble with error 14. At the time it was turned on, the pressure was 0.5, and I added a little water. How can I get the boiler back into working order now?

Error 14 can be fixed by you yourself. It means that the STB emergency button was triggered by a signal from the coolant overheating sensor. This happens if the pump is jammed or the heating system is air-filled.

A system pressure of 0.5 clearly indicates a lack of water in the system and a lack of circulation. You should add water to the system to the required level and return the STB button to its place. It is located below, under the screw cap.

My Rinnai RB 206 boiler gives error 18. I unplugged it for a day, then turned it on and it started working, but not for long. Same error again. What does this mean?

Error 18 for this model means a ground fault has been detected and a voltage offset of more than 5 V. You need to check the voltage between the boiler electronic module and the ground line. Then inspect the cables for integrity, especially for the control panel cable.

The Rinnai RB 206 device began to provide hot water intermittently - hot for 2 minutes, then cold and hot again. What is the reason for this failure?

First of all, you should check the serviceability of the flow sensor - see if it is a stepper or an impeller, provoke it to work. Then make sure that the primary and secondary heat exchanger are not clogged.

The Renai boiler began to leak slightly. We opened the front cover, and there was corrosion everywhere. What can be done?

If it comes to the corrosion of the lid, then the leak has existed for a long time. It is necessary to replace gaskets or clean contacts and components.

When turning on hot water, the Rinnai boiler often began to show error 16, although this does not happen when only the heating circuit is operating. What could this mean?

This error means the heat exchanger is overheating. It is necessary to periodically carry out maintenance of the unit, which includes cleaning the heat exchanger, checking the operation of the pump and 3-way valve, cleaning contacts and checking sensors, adjusting electronics, tightening connections.

The Rinnai gas boiler does not operate in hot water supply mode, and the heating system is already turned off. Shows error 16. What can I do?

In this case, the error means overheating. The 3-way switching valve in the boiler is clearly faulty, since the automation does not see that the heating circuit is no longer active.

The Rinnai 307 unit stopped with error 14 displayed. Why did this happen, and how can I fix it myself?

The error indicates circulation safety problems. Most likely, the dirt filter is clogged or the pump is jammed. This happens when the boiler has not been started for a long time. Another possible reason is a malfunction of the temperature sensors.

The Renai gas boiler stopped with error 14 displayed. What to do in this case?

The error code indicates that the automation has blown the fuse for the coolant, that is, the boiler has overheated. The fuse can be returned to its place independently using the button under the cover on the outside of the case. The procedure is described in the boiler manual.

The Rinnai boiler stopped with error code 16. What does this mean and how can I fix it?

The error indicates overheating (boiling) of the coolant. First of all, you need to check whether all heating distribution valves are open and whether the pipeline is clogged or whether there is air in the pipes. It may be a pump or a clogged filter, or the 3-way valve may also be faulty. The boiling sensor may have failed.

The Renai gas boiler stopped with error code 99. Allegedly problems with draft. But the chimney is clean. I need help!

The error code indicates a dirty chimney. But if you claim that the chimney is free, then the reason is a clogged heat exchanger. The presence of potential between 0 and ground can also interfere - it “deceives” the sensor, and it gives an error signal. The sensor itself very rarely fails.

The Rinnai RB-166 stopped at the dacha. It gives error 14. What can you advise?

Error 14 means problems with the safety of fluid circulation, that is, either the dirt filter is clogged or the coolant temperature sensor is faulty.

I have a Rinnai GMF-206 boiler in its second year of operation, but before that it had been sitting for a long time. After setting the pressure to 1.5 atm in 3 places, the gaskets immediately leaked. I had to turn off the boiler. Why didn't the valve work?

Since the valve did not work, it means that there was no critical pressure for this. But rubber gaskets have their own service life, apparently they need to be changed.

The Rinai 40 kW gas boiler operates for no more than 15 minutes and turns off. It gives error code 99. How to fix this?

Judging by the error code, the tightness of the exhaust system is broken. There may be several reasons: problems with the chimney, the heat exchanger is clogged, the fan does not work, the traction relay has failed.

There is a problem with the Rinnai wall-mounted boiler: at temperatures above 70 degrees, the boiler turns off and displays error 99. The boiler is well maintained and cleaned, the chimney is also clean. What can be wrong?

If, according to your description, the device is in exemplary condition and the chimney is free, then the reason for the error display is a malfunction of the vacuum relay, which indicates a lack of draft. Or the sensor in front of the burner indicates overheating and turns off the boiler due to lack of normal air flow.

The Rinnai boiler leaked after defrosting the water heating circuit. Maybe the reason is the heat exchanger? Or did something made of plastic “fly”?

After defrosting, the equipment is generally difficult to repair: the electronics fail, the sensors and capsules holding them are damaged, and the pump suffers. Everything needs to be examined and diagnosed.

The gas boiler has been operating for five years without any complaints. Recently we tried to raise the water temperature from 55 to 70 degrees, and the batteries became colder to the touch than they were. What's wrong with the device?

It’s hard to say in absentia, you have to see the system. Most likely, based on experience, the dirt filter is clogged, but there may be another reason. It looks like heat loss along the main line if the pipeline is not insulated enough.

Rinnai gas boilers, like a number of others, are prone to malfunctions. Therefore, manufacturers have provided a self-diagnosis system. If there is a problem, a code appears on the display indicating the cause. To help you get rid of the problem faster, we will provide all the errors of the Rinnai boiler, their explanation and solutions.

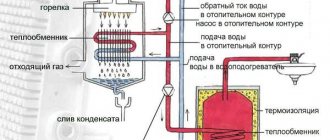

Boilers made in Japan "Rinnai" are closed type equipment. These are turbocharged units in which a fan operates to force the combustion products out. The coaxial chimney supplies combustion air and removes smoke.

The ignition unit is located in the center of the structure. The burner cuts the flame into three parts, so the heat exchanger heats up evenly. At the same time, the flame can be modulated in three modes. For example, in the summer you can turn on only one part, saving on fuel.

The product includes two copper heat exchangers: one works for heating, the other for hot water supply (DHW). A three-way valve switches heating from one system to another. Inside there is an 8.5 liter expansion tank.

A circulation pump is located at the bottom. Its rotor is dry, which contributes to long-term operation of the unit. It circulates coolant throughout the system. Remote or keyboard control. There is a display that shows the temperature and other indicators.

Product Description

According to consumer reviews, the following models are considered the most popular:

Wall-mounted gas boilers are considered the most economical in terms of resource consumption. They can be connected in a chain, providing heat and hot water in both small apartments and large houses. Rinnai power in space heating mode is 11.6-42 kW with an efficiency of 96%. The area of the serviced space is 30-120 m2, gas consumption is 0.3-1.15 m3/hour, hot water supply is 12 l/min. The volume of the expansion tank is 8.5 l. If it is necessary to operate on liquefied fuel, the injectors must be changed.

The Rinnai design includes a modulating fan-type burner with an automatic resource consumption function proportional to pressure. This feature is aimed at saving up to 20% and ensures a long service life of the heat exchanger and control system of the gas double-circuit boiler. As a result of complete combustion, a low level of toxic waste is observed, which prevents deposits of carbon deposits and soot on the injectors. The series includes models: RB-107, 167, 207, 257, 307, 367.

An improved version of wall-mounted gas double-circuit boilers from the manufacturer Rinnai. With increased functionality, the equipment makes less noise. The remote control is equipped with a color display, voice control mode, and weather-dependent sensors. When heating, you can reduce the power of the device by 20%. To achieve the optimal water temperature, an adjustment unit is used. Thanks to periodic heating, instantaneous supply of hot water is ensured. The Rinnai device operates at a minimum pressure of 2.5 l/min, and turns off at a pressure in the pipes of 1.5 l/min. The standard package includes a remote control, which, according to user reviews, simplifies the coordination of all systems.

Rinnai gas boilers with a closed combustion chamber have a power of 19-42 kW and heat an area of 190-420 m2. The efficiency is 90%, the volume of the expansion tank is 8 liters. The device is equipped with an ECO program (ecological mode). It has two additional sensors: control of frost protection and coolant temperature. The series includes models: RB-107, 167, 207, 257, 307, 367.

Rinnai gas boilers operate on main and liquefied fuel, subject to changing nozzles. The main advantage of this subgroup is its absolute environmental friendliness, which is due to the minimal release of toxic waste into the atmosphere. The automation unit is three-level; adjustment of the burner flame and heating of the coolant is determined depending on the season and climate. Error diagnostics are displayed on the monitor in text and digital code. Adjusting the fan operation prevents a lack of air for purging.

The power of a wall-mounted gas boiler is 12-42 kW, the heated area is 120-420 m2. The minimum consumption of hot water is 2.7 l/min, centralized resource – 1.1-4.2, liquefied – 1-3.5 m3/hour. The volume of the expansion tank is 8.5 l, the maximum coolant temperature is 85, DHW is 60 °C. A coaxial chimney is used to remove combustion products. Series models: RB-166, 206, 256, 306, 366.

Gas boilers produced by Rinnai are designed to serve premises from 100 to 400 m2. They are equipped with two heat exchangers, the first is made of copper, the second is fast-acting and produces up to 14 l/min. In the combustion chamber there is a smooth regulation of the fuel-air mixture, proportional to the volume of gas. This is achieved through a built-in turbocharged burner. Optimal functionality is independent of weather conditions. The release of toxic substances is minimized, which prevents the formation of soot and scale.

The boiler power is 18-42 kW with an efficiency of 90%. Minimum water flow – 2.7 l/min. Temperature range for heating – 40-80 °C, for hot water supply – 35-60 °C. The device has an electronically controlled pump. The microprocessor constantly analyzes sensor readings and sends information to operating nodes. Air intake is forced, from the street. The series includes models: RB-166, 206, 256, 306, 366.

Rules for safe operation

Any gas boiler is used to process fuel that is dangerous to the life and health of consumers in the event of its leak, the release of its disposal products and the leak of the coolant heated by it.

Boilers from the Japanese manufacturer Rinnai are known for their highest reliability and excellent performance. Basically, manufacturing defects are extremely rare on these devices and technical errors are associated with improper operation and late preventive inspection.

All work on repair and replacement of gas-using equipment should be carried out by specialists from the service department or gas distribution department. Otherwise, you may face a gas supply cutoff at best, or a threat to your health and life at worst.

Moreover, the cost of such devices, especially from well-known manufacturers, is not always budgetary, and the warranty is long. Intrusion into the system of gas boilers can be regarded as a violation of warranty immunity and, accordingly, you should not expect free repairs and replacement of individual elements from the service department.

But again, it is quite possible to fix some issues in boiler malfunctions yourself, or knowing them, you can determine what work to call a specialist for and ask how much the repair will cost.

Sources

- https://GradusPlus.com/kotly/gazovye/rinnai/

- https://tehnreshenya.ru/rinnay-oshibka-99-chto-delat/

- https://Kotly.VseInstrumenti.ru/rinnai/

- https://malivice.ru/oshibki-gazovogo-kotla-rinnai-kody-oshibok-sposoby-ustraneniya/

- https://teplofan.ru/oshibki-kotlov/kody-oshibok-rinnai

- https://sovet-ingenera.com/otoplenie/kotly/oshibki-gazovogo-kotla-rinnai.html