The transfer of a heated towel rail is carried out during repairs or when remodeling a bathroom or a combined bathroom. In some houses, the pipe is part of the heating system, and then the transfer procedure will need to be agreed upon with the management company. In other cases, you do not need to obtain permits to carry out work.

Relocating a heated towel rail during repairs.

Standards and requirements for moving a heated towel rail

Requirements for the installation site and the equipment itself:

- The partition to which the heater is supposed to be moved should not be adjacent to the living rooms or living room.

- It is not recommended to move the heated towel rail over a long distance, since additional pipes reduce the water pressure.

- Steel or metal-plastic lines used for switching must withstand elevated temperatures and increased water pressure.

- The body of the heated towel rail should not have welded seams that could be destroyed by a sudden supply of water (water hammer).

When installing an electric heater, the power consumption is taken into account, which should not exceed the permissible load for the existing power circuit. If the equipment has increased power, then it will be necessary to organize a separate power supply branch equipped with protective elements. The socket body is selected according to the current strength in the circuit, which determines the degree of heating of the contacts and the dielectric core. If the selection is made incorrectly, the socket overheats and catches fire, accompanied by a short circuit.

Pipes should not be placed too far apart from each other.

Dismantling the old installation

When the preparatory work is completed, it makes sense to begin dismantling the old heated towel rail. This is done in several steps.

- First you need to outline the locations of future cuts. They must be made exclusively vertically, so it is recommended to place marks using a level.

- You will need to cut the pipes using a grinder. This must be done when approaching the dryer. We should not forget that the cut should be as smooth and correct as possible.

- You will need to carefully cut down the fastening elements, and then remove the cut device from the room so that it does not interfere.

- The frescoes will need to be sharpened. You should make an angle of 45° to ensure maximum comfortable entry of the perch.

- After this, the pipe will need to be coated with machine oil. Next, you will need to make a carving using a tool.

At this stage, the dismantling work will be successfully completed. If you plan to dismantle a serial Soviet-style water heated towel rail, then you will need to start from the method in which it is connected to the main line. The dryer can be attached by coupling or welding.

Who is the work coordinated with?

Before moving the heated towel rail, you need to decide on the principle of heating the water. If the design uses a spiral with electric heating, then coordination of the work is not required (the heater is not connected to the water lines). A power cable with an automatic fuse is laid to the installation site; safety regulations are observed during installation. If the heating device is connected to a hot water supply or heating pipe, then you need to obtain approval for the transfer from the management company.

List of documents required to obtain a permit:

- identification document of the applicant;

- certificate confirming ownership;

- a free-form application containing a list of works;

- technical passport of the apartment;

- conclusion of the expert commission confirming the possibility of redevelopment.

Apartment registration certificate.

The conclusion on the transfer of the riser is drawn up by employees of the housing inspection based on the apartment redevelopment project. In a number of localities in the Russian Federation, documents are issued by the management company based on the owner’s application. The legalized procedure for moving a water heated towel rail relieves the apartment owner of the risks associated with disruption of the normal operation of the heating or hot water supply system.

Agreement process

During this procedure, it is important to adhere to a special algorithm

Without redevelopment

If redevelopment is not needed during repairs, but there is a need to move the dryer, the owner contacts the management company and coordinates this issue. More often, assistance is offered during the transfer process, which everyone has the right to refuse.

Photo 1. Such an electric heated towel rail is completely autonomous; its transfer to another wall does not require approval from any authorities or additional investment.

For redevelopment

Redevelopment is approached wisely, taking into account the rules for carrying out such work. If the changes do not go beyond the law, they collect documents and submit them to the BTI, receiving approval for the transfer.

How to prepare for the transfer

To move the heater to another wall you will need:

- electric drill or hammer drill;

- drill or drills for working on concrete;

- spanners;

- building level;

- tape measure or pencil;

- equipment for installing water pipes (welding machine or installation for soldering polypropylene elements);

- materials for connecting and sealing highways;

- test device (in case of connecting an electrical device).

You will need a hammer drill for the job.

If you plan to install a heater with an electric coil, then a power outlet is located at the installation point. The cable is routed under finishing materials (for example, tiles); it is allowed to fasten the wires in plastic boxes located on top of the finishing walls. For switching, a cable of the VVG-Ng series is used, equipped with a grounding conductor. The cross-section of the conductors is selected according to the power of the heating device.

What is the procedure for replacing an old heated towel rail through the housing office?

How to choose a contractor?

If you decide to entrust all the work to professionals, then you need to seriously think about their choice - you should not trust the first one you come across. Here, naturally, the cost of services and the time of their provision play a big role.

However, we must not forget about the reputation of the company. Moreover, they must provide documentation that gives them the legal right to carry out such work. The main documents are the SRO certificate of approval and the contract. It is the SRO certificate that is important, since the license has been canceled since 01/01/2010.

General recommendations and rules

When installing a heated towel rail, the standards described in SNiP standards are taken into account:

- The upper crossbar of the heating device is located at a height reachable by the hand of an adult. It is recommended to place the heater sections at heights from 900 to 1700 mm (the value of the lower threshold depends on the configuration of the product).

- If a U-shaped element is being installed, then the lower elbow is located at a height of at least 1100 mm from the floor covering.

- When installing an M-shaped heater, the distance from the floor to the lower section should not be less than 900 mm.

- The metal body of the heat exchanger, made of steel, must withstand a pressure of at least 7.5 atm. The water pressure in the mains depends on the number of floors of the building and the distance from the house to the pumping station or boiler room. It should be taken into account that at night the pressure increases due to the reduced water consumption of residents.

- When choosing a towel dryer, take into account the size of the bathroom. Spaces with reduced dimensions require a heater with small dimensions (for example, models with a U- or S-shape configuration). The diameter of the heating element must correspond to the dimensions of the water supply lines.

- It is recommended to provide a gap between the lines and the wall in the range from 35 to 55 mm. The supply pipeline is installed at an inclination of 2-3°, ensuring automatic removal of air or steam plugs.

M-shaped heater.

Helpful hints

- The seamless steel model is recommended for installation in apartment buildings. This model will withstand increased liquid pressure in the pipeline, pressure surges, and changes in water flow speed.

- Brass appliances are installed in a house with an autonomous water supply.

- It is worth considering whether it is possible to mount the device on the border wall with the living room, or move the heated towel rail to another wall.

- When installing pipes in a riser, either threaded connections are used or welding work is performed.

- It is not advisable to use carvings in hard-to-reach places: behind decorative trim.

- It is necessary to slope the supply pipe towards the movement of hot water. This will ensure that there are no air traffic jams.

- A distance of 3.5-5.5 cm is maintained between the wall and the middle of the supply pipe.

If you do not want to seek the help of a specialist to move a heated towel rail in a water-type bathroom, then it is recommended to install an electric device. But then electricity bills will increase. The choice is yours.

Moving the dryer to another wall

Towel dryers are divided into categories according to the method of heating the surface:

- hot water flowing inside the line;

- using oil heated by a coil connected to the electrical network.

Water variety

Liquid heated towel rails are connected to water supply lines or heating lines. If the apartment has a centralized hot water supply, then it is recommended to embed the heater into the pipe break. When using a heating circuit, year-round use of the heated towel rail is not possible. It should also be taken into account that if an element is damaged in winter, the heating riser in the entire building must be turned off.

To install a water heater you must:

- Determine new equipment attachment points and mark the wall in accordance with the dimensions of the dryer.

- Turn off the water supply in the apartment or house. It is recommended to notify neighbors in advance about a temporary shutdown of water supply (for example, by placing a notice on the door to the entrance or in the elevator car).

- Cut the pipes using a grinding wheel or unscrew the mounting flanges (depending on the condition of the threaded connections).

- Unscrew the screws holding the brackets securing the heater to the wall. Holes in the tiles should be sealed with cement mortar or covered with decorative elements.

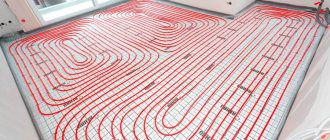

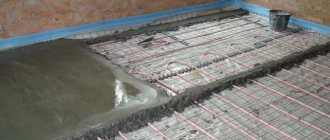

- Lay lines to the equipment installation site. If steel elements are used, the parts should be connected by resistance welding or special threaded couplings; the connection points are sealed with tow or synthetic tape. Plastic lines must be connected by soldering using a special device. Ball valves are provided in the fluid supply and discharge channels; there is a jumper (bypass) in front of the valves, which allows you to maintain water circulation when the towel dryer is turned off.

- Connect the heated towel rail unit with couplings; a special “American” type connector is used to connect the metal line to the plastic pipes. The coupling is screwed onto the thread on the heated towel rail and then soldered to the polypropylene lines.

- Install the mounting brackets that need to be fixed to the wall surface with dowels and screws. Use an electric drill or hammer drill to drill holes.

- Supply water to the mains and make sure there are no leaks. If drops of water are detected, the elements must be reconnected.

- Cover the water mains with a decorative box that provides inspection hatches (for example, for access to valves). If the room is being renovated, the pipes are embedded in the walls and covered with tiles.

Electric type heated towel rail

The electric heated towel rail is not connected to the water supply system, which simplifies the transfer procedure. Since the equipment is connected to a 220 V AC network, the installation point is located at a distance of at least 600 mm from faucets or shower heads. A socket with a waterproof housing, equipped with grounding contacts, is mounted on the wall. The power circuit is provided with an automatic fuse and RCD protection.

Electric heated towel rail.

Algorithm of actions when installing an electric heated towel rail:

- Remove the heater from its old location, seal the holes in the partition with decorative plugs or fill with tile grout.

- Mark the mounting points on the wall surface. It is recommended to install the heater at a distance of at least 950 mm from the floor surface and at a distance of 750 mm from the edges of furniture installed in the bathroom.

- Drill holes; For processing tiles, a special drill with a carbide tip is used.

- Install plastic dowels into the channels, and then fasten the heating equipment fastenings with screws.

- Connect the power and check the operation of the heater under different operating modes. It is not allowed to operate equipment with a leaking housing or with a faulty temperature controller.

Water type model

The mechanism for transferring a water heated towel rail is more complex. However, it is possible to do the job yourself.

Design features of the water model

A dryer of this type consists of elements:

- There is a Mayevsky valve on top of the device. Its purpose is to bleed air;

- there is a plug - a special plug;

- water is supplied through a supply system;

- The water is shut off using valves specially built into the device. If there are none, you need to install them yourself;

- fastening elements - brackets.

The operation of the dryer is carried out in some cases from the heating system, in other cases from the hot water supply. The second option is more preferable:

- The heating season is short. The heating operates for a maximum of 6 months.

- When a breakdown or leakage of the dryer is detected, you must immediately shut off the water supply to the coil. With running water it is quite possible to do this quickly. It will be difficult to do this with a heating system.

- Tap water contains fewer impurities than heating system fluid. In addition, the water in the heating system stagnates and becomes even more clogged.

Requirements for choosing a new model

The new heated towel rail model must meet the following requirements:

- The new model is selected according to the pressure level in the apartment’s water supply system.

- The model's dimensions vary in direct proportion to the size of the room. In the large bathroom there is a large heated towel rail.

- The model is selected taking into account the diameter of the outlet pipe. The indicator must correspond to the diameter of the inlet of the riser pipes.

- It is recommended to opt for a seamless model.

Procedure for transferring a water model

Tools and additional parts are prepared for work:

- fastening element - brackets;

- polypropylene pipes;

- welding machine;

- Bulgarian;

- a pipe cutter can be replaced with wire cutters;

- a set of keys;

- Ball Valves;

- prepare tools for cutting threads;

- FUM tape;

- fittings for connection.

Removing the old model

Dismantling does not begin until the water supply in the riser is shut off. The water drains completely. At this moment there should be a specialist from the housing department. He will answer whether it is possible to move the heated towel rail in the apartment to another wall.

- Trimming dryer pipes starts from the bottom. Then the top pipe is cut off. The remaining pieces remain of such length that they are enough to mount the new model.

- The work is done with an assistant. Otherwise, a falling dryer may cause a serious impact.

- The fasteners are removed from the old model after trimming. The device is taken out of the room.

You can team up with your neighbors to resolve the issue of replacing pipes in the riser. If this is not possible, then it is recommended to do this in your apartment. It is recommended to use polypropylene pipes with a cross-section of 25 mm.

Installation of the riser pipe to the installation site of the new device

Invite a specialist if the pipe laying distance is long. It is necessary to have knowledge of the correct laying of pipes and to comply with hydraulic calculations.

- The ends of the remaining pieces of pipes are cleaned of old paint.

- Threads are cut or welding work is carried out.

- A fitting (connecting element for propylene pipes) is threaded onto the resulting thread.

- The joints are treated with FUM tape and sealant.

- You can improve the service of a new heated towel rail using a special bypass jumper and ball valves. The latter may be needed to redirect the fluid flow to the jumper.

- Hot water is supplied to the water supply system. If there are no leaks, then the work is completed. System functionality has been confirmed.

- The dryer is mounted on the wall with brackets.

Safety precautions

When installing a dryer with an electric heater, it is necessary to ensure safe operation of the equipment:

- wiring is hidden in the wall or in boxes;

- contact connection points are protected by insulating materials;

- a protective shutdown device is provided in the power circuit;

- The socket is equipped with a grounding line to which the metal body of the heated towel rail is connected.

The socket must be protected.

The socket housing must meet IP4 or IP65 protection standards. The design does not allow dust and splashes of water to penetrate into the internal cavities, but if a jet of liquid enters, a short circuit occurs. It is recommended to place the outlet in an area inaccessible to water (for example, under the ceiling of a bathroom).

What are the approximate prices for labor to replace a heated towel rail?

After all the bureaucratic problems are completed, you can begin installing a new towel dryer. There are three ways to mount the unit :

- if the center distance and pipe diameters completely match, there is no need for alteration (the simplest method);

- the use of welding work in the absence of alignment and poor condition of pipes;

- use of threaded connections (the most common option).

At the moment, the approximate cost of replacing a heated towel rail is:

- installation on a ready-made pipe line without adjustment - 1,500 rubles;

- installation on a ready-made eyeliner with adjustment - 12,000 rubles;

- replacement of the unit with installation of a jumper and two taps up to size 3/4 – 15,500 rubles;

- moving the device with pipe connections without bypass – 14,000 rubles;

- moving the unit with pipe connections and installing a bypass – 19,000 rubles.

Otherwise, we can say that the cost of the work depends on the complexity of the entire structure.

To save your own money and save your nerves, if possible, you should resort to the services of companies that have an SRO certificate and take all the hassle of obtaining permission from the housing office. You can use another alternative option to avoid unnecessary problems - an electric towel dryer.

Welding of polypropylene pipes

We will connect the heated towel rail using polypropylene pipes. Why polypropylene? This is the best option.

The most common materials for supply pipes are steel, copper, and polypropylene:

- Steel pipes are heavy, susceptible to corrosion, and require a welding machine for installation.

- Copper ones do not rust, but are very expensive and are mounted by soldering.

- Polypropylene is not subject to corrosion, is cheap, and lightweight. Reinforcement with special fiber significantly increases their strength and resistance to high temperatures. The presence of a variety of fittings makes it easy to connect polypropylene to metal pipes. They are very easy to install. For this, there are special welding devices that you can master in just half an hour and easily make high-quality connections. In addition, these devices can be rented at most stores that sell plastic pipes and building materials. This service costs approximately 400 rubles per day.

You can read more about soldering and installation of polypropylene pipes here.

Connection options

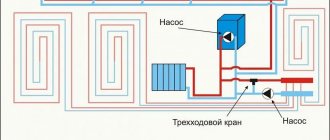

The principle of connecting a heated towel rail to a riser is the same for all models: water is supplied to one end, and its outflow (return) from the other. The connection option depends on the specific modification of the device:

- the hot coolant is connected at the top, the return – at the bottom;

- connection is made from below;

- hot water supply - from above, outlet - on the opposite side from below, diagonally;

- bottom center connection;

- four-point connection (for large dryers with horizontal pipes).

Methods for connecting heated towel rails to the hot water system.

Connection diagrams for heated towel rails to the heating riser:

Connection order:

Characteristics

A high-quality, correctly selected and placed heated towel rail can become a central element of the interior of any bathroom. The shelves of popular hardware stores are simply littered with various types of this plumbing component, and making a purchase on your own is quite difficult.

Before visiting the store, you need to carefully study the layout features of the bathroom and decide on the location and size of the structure.

Next, you need to familiarize yourself with what types of heated towel rails are:

- in small bathrooms, the use of M- and U-shaped models is more popular;

- The most common materials for manufacturing are plumbing brass, stainless steel and galvanized;

- You can make a heated towel rail stand out from the general background using a chrome-plated design.

Note! Large heated towel rails (like a ladder) do not tolerate high pressure well and are practically not used without a bypass. After 5–7 years, small models will begin to gradually lose their functional qualities due to exposure to alkaline deposits.

A modern new heated towel rail can completely replace a heating element, distributing heat indoors. You can always quickly dry linen and towels using it for its intended purpose.

To ensure the reliability and safety of equipment operation, replacing a heated towel rail must be accompanied by installing a bypass, which will allow air to be periodically released, getting rid of excess pressure in the system. Externally, this element looks like a special jumper with a tap that is mounted on a threaded connection.