Why should you be responsible when installing fence posts? Fence posts are the most important element, the support of the entire structure.

Pay attention to fences in the private sector - there are skewed structures, in some places the posts stick out and become warped.

In order for a fence to retain its geometry for many years, you need to know how to install fence posts correctly - what installation method to use in this or that case, understand why the posts stick out, warp and how to prevent this.

Is it necessary to concrete fence posts on the site?

To concrete or not - this is often one of the first questions when building fences. Not only the quality of operation of the fence structure, but also the financial costs, time and labor intensity of the process depend on the decision made. Is it necessary to concrete fence posts and when can you use other methods - we discuss the questions in the article

Installation technology

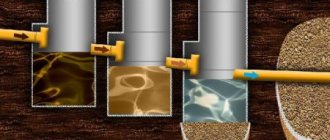

Butting is performed in the following sequence:

- The hole for the post is being prepared. The drilling depth is calculated as follows: at least 1/3 of the column height, but slightly below the soil freezing mark. For the Moscow region this is 1.3-1.6 m. The width of the recess should be 12 cm greater than the diameter of the support pipe. Using a shovel for this purpose will worsen the quality of work: a wide hole is difficult to compact well.

- For drainage, a cushion 10-15 cm high is formed at the bottom of the recess. Sand, crushed stone or expanded clay is used for this purpose. The material is compacted with a crowbar. This layer will remove moisture, preventing the accumulation of water.

- A support is installed on the drainage pad. If it is a hollow pipe, plugs are placed at its ends. The bottom plug is made wider than the diameter of the pipe to serve as an anchor.

- After this, filling the hole begins. To fill fence posts, crushed stone, gravel (or other stone) is poured in layers of 10-15 cm. Sand is added to each backfill to fill the voids between the fractions. Then the layer is watered and compacted using an electric vibrator. If you don’t have such equipment, you can make a tamper yourself from trimmed logs. The hole is filled with backfill with a slide so that water does not flow inside. This is where the bottling ends.

To guarantee strength, the last layer of crushed stone is filled with mortar, but this step is optional. It is also possible that the bedding does not reach the ground level by 15 cm. This gap is filled with concrete.

Butting can be done in other ways:

- A layer of concrete 30 cm high is poured into the bottom of the hole, then a post is inserted. The pouring mixture must be pierced with a metal rod to remove air bubbles - this gives the necessary shrinkage to the concrete. Then prepared stones are poured into the voids of the pit layer by layer, watered with water and compacted.

- In a hole at a level below the groundwater level, using a special drill or bayonet shovel with a narrow working blade, an expansion is made for the concrete heel. It increases the bearing capacity of the support and protects against the destructive effects of tangential forces when frozen soil thaws.

During butting, when installing the support, it is necessary to constantly monitor the position of the support - it should not deviate from the vertical. To do this, use a building level (or better yet, 2, placed mutually perpendicular). For convenience, the levels are attached to the support with tape. To ensure that the post does not change its position during installation, it is recommended to fix it with temporary spacers.

Correctly performed butting of supports is a guarantee of fencing durability.

A fence is an integral part of building structures, including houses, parks, and parking lots. The reliability of this structure directly depends on the support, on its stability, and on the installation method - concreting, screwing, etc. This also includes the butting of pillars with crushed stone.

What factors are taken into account when choosing an installation method?

In order for the fence to stand without distortion for many years, during its construction you need to install the supports correctly. They do this using various methods. The specific one is selected depending on the height and weight of the fence, mechanical influence from the outside, wind loads on the site and other factors.

The most important criterion influencing the choice or refusal of concreting pillars is the type of soil. The main soil characteristics that should always be taken into account include:

- strength and density of the earth;

- groundwater level;

- heaving of the soil.

Advantages and disadvantages of butting pillars

Butting is also called dry concreting. This method has been used for a long time, and it has not lost its relevance because it is simple and economical. Butting consists of the following: the part of the support located in the ground is sprinkled with crushed stone (fraction sizes - 20-40 mm) or other stone (expanded clay, gravel, broken brick, scrap concrete products). The backfill is spilled with water and carefully compacted to fill the voids in the hole.

Like any other method of installing poles, butting has disadvantages and advantages.

The main advantage of dry concreting is its versatility. With its help, wooden or concrete posts, plastic, asbestos, metal pipes or corners are installed. Butting is possible in any soil.

Thanks to the drainage cushion - an undeniable advantage of butting - there is no deformation of the soil near the column during freezing and thawing. There is no accumulation of moisture in voids, which is typical for heaving soils. Crushed stone or other material used for butting easily removes excess moisture, preventing the accumulation of water near the base of the support. Therefore, unlike concreting, butting fence posts is possible in clay soils.

In addition, the layer of stones creates a strong buffer zone, which absorbs the pressure of multidirectional heaving forces, preventing the support from being pushed out of the ground.

Compared to concreting, butting takes 3 times less time and is much cheaper. Backfilling of pillars can be done by one person.

Concreting or driving - depending on soil type

- Loam

. This is a mixture of sand and clay, with the latter component predominating in the composition. Clay does not allow water to pass through well, but is porous. Due to this, moisture can be absorbed during heavy rains. Loam is a fairly strong soil, but also plastic, especially when moistened. If you drive a fence post to an insufficient depth, then with a high weight it may sag over time. Driving is suitable for lightweight fences and when driving to a depth of 1.5 meters or more. Concreting – if the fence is high and heavy.

- Rocky soil and permafrost

. Very hard, durable and dense soils with high bearing capacity. When installing a fence in such areas, there is no need for concreting. But driving a pole into rocky and frozen ground will also not work. Therefore, installation of screw piles is suitable here. Dry concreting is also ideal - drilling a well and then filling the hole with a fence support with a sand-gravel mixture.

- Sandy soil

. It is a composition in which more than 50% is fine sand, with a fraction of up to 5 mm. It is movable, therefore, under lateral loads, simply hammering the support will cause a roll. Concreting makes it possible to increase resistance to lateral loads by increasing the area of contact with the ground. Therefore, in sandy areas this installation method is a prerequisite.

- Sandy loam

. This is a soil that is dominated by a mixture of sand and clay. It is quite loose and mobile. If you use the installation of fence posts without concreting, then during operation there is a high risk of displacement of the sandy loam, and as a result - loosening and tilting of the entire structure, up to its fall. In this case, concreting is recommended.

- Swampy soils and peat bogs

. Viscous and mobile soils. When installing a fence post by hammering, there is a significant risk that in the near future it will begin to wobble and tilt. Concreting can solve the problem. But here it is important to additionally waterproof the hole with a glass made of roofing felt or a piece of plastic pipe.

Required tools and materials

The technology is extremely simple, so the tools and materials needed are the simplest:

- shovel for digging a hole;

- tape measure and plumb line to check the verticality of the post;

- scrap or logs for tamping;

- bucket with water;

- gully sand.

You can fill the hole with crushed stone, gravel, or limestone.

Material for backfilling pillars

You need to approach the issue of choosing crushed stone more carefully. According to GOST, the minimum permissible stone size should be 5 mm, and the minimum permissible strength should be M200. In addition, you need to take into account the frost resistance of the material - at least F250.

The following breeds are used:

- Granite crushed stone – provides resistance to load-bearing loads.

- Limestone - obtained from sedimentary calcium rocks. Less durable, therefore it is used for backfilling only wooden poles.

- Gravel is obtained by sifting quarry soil. It is somewhat inferior in density to granite.

- Concrete crushed stone - made by recycling old concrete structures. This material is recommended for use on marshy soils and loams.

Brick fragments are often used. However, such a mixture obtained by hand is rarely homogeneous.

Heaving and its influence on the method of installing a fence post

Frost heaving of the soil occurs when moisture in the soil freezes and expands as a result.

Heaving forces act vertically on the lower part of the installed column - the heel or concrete foundation. It doesn’t matter whether you concrete the pillars for a corrugated fence or hammer them in. If you lay the support to the freezing level, with the maximum probability it will sag or fall after the first winter.

To prevent such a result, building codes give direct instructions - to lay a fence post with or without concreting exclusively below the soil freezing depth. The minimum value of the additional depth of the post is 20 cm. If you do not know where this line is located in the region where the fence is being built, then you can look at the average value in the standards SNiP SP 22.13330.2011 or its newer version - SNiP SP 22.13330.2016.

Examples of soil freezing level values in different regions are as follows:

- For Moscow and the Moscow region, the values are 1.2-1.44 m. Drive or pour concrete to a depth of 1.4 m.

- Rostov-on-Don - from 0.66 to 0.86 m. Hammer or concrete - from 1.06 m.

- St. Petersburg - from 0.98 to 1.28 m. Hammer or fill with concrete mixture to a depth of 1.18 m.

Butting

Like any work, butting requires work. The installation of pillars begins with the preparation of holes.

Digging holes

Before you begin preparing holes for installing support pillars, you need to make markings indicating the location of the supports.

In the place where the support will stand, you need to drill a hole. Its depth should be 200-300 mm below the soil freezing level.

To dig a hole, it makes sense to use a mechanical device, such as a mechanical drill. The use of a shovel will lead to the expansion of the hole and compaction of crushed stone will be difficult.

Installation of pillars

Installing fence supports for butting is practically no different from installing risers for concreting. That is, it is required to ensure that it is installed vertically. This can be achieved using two building levels. Before compacting the backfilled crushed stone, the installed riser is secured in place using temporary fasteners, which are removed after the fence support is secured in its place indicated in the diagram.

Can you do the budding yourself?

YesNot sure

Concreting fence posts and high groundwater levels

Groundwater is a factor invisible to the eye that can affect the reliability of operation of the building envelope. In most cases, the groundwater level is located quite deep. Still, there are many areas where water flows underground at a depth of less than 1.5 meters.

The impact of high groundwater levels on fence posts is obvious. Where the stand is installed, water gradually washes away the soil. The support begins to loosen. Over time, a distortion appears. The situation is aggravated by the presence of strong side winds falling on solid sections, like corrugated fences.

If the groundwater level is high, it is necessary to install a column below the groundwater level. It is allowed to use concreting and driving methods. The choice should be based on soil characteristics.

Concrete pillars are still better suited. Due to the foundation:

- the weight and area of contact with the soil increase;

- the durability and load-bearing capacity of supports increases;

- metal corrosion is prevented;

- the service life of the fence increases.

When filling a hole under a post with concrete, it is recommended to equip it with a waterproofing jacket. Roofing felt or any similar rolled waterproofing is suitable for this. Installing a fence post in a glass made of plastic water pipe is also widely used.

If the groundwater level is too high, it is necessary to make drainage to remove moisture from under the concrete foundation. To do this, a trench is dug at a short distance along the entire enclosing structure. Excess moisture from the ground will fall into it.

Other bottling methods

- Concrete 300 mm high is poured into the bottom of the prepared hole. The poured mixture needs to be compacted; for this operation it is permissible to use a reinforcing rod. After the post is installed and dropped vertically, crushed stone is poured into the hole. The backfill method is described above.

- In a pit for installation at a level below freezing of water, expansion is carried out using a special drill or a narrow bayonet shovel. It is required to increase the area of the supporting heel. It not only increases the bearing capacity of the support, but also counteracts the effects of forces generated when the soil melts.

When butting, it is necessary to constantly monitor the location of the support in space. It must be installed vertically. When the required location is achieved, the pole is secured using temporary spacers.

We must always remember that correctly performed butting is a guarantee of a long service life of the fence.

How to concrete support fence posts

Concreting is the most durable way to install fence supports. The method is especially recommended if a small-section metal pipe is chosen as a rack. Due to the concrete foundation, the contact area with the ground increases. The stand can withstand lateral loads much easier and does not loosen or sag.

Complete concreting of corrugated fence posts should be carried out in compliance with the following recommendations:

- The hole is drilled to the calculated depth. The characteristics of the soil, its level of freezing, and groundwater level are taken into account. For drilling, a hand or motor drill is better suited. This will allow you to get the exact diameter. Subsequently, concrete consumption is saved.

- The diameter of the hole for the fence post is selected taking into account the size of the support itself. It should be 2-2.5 more. If you have a metal round pipe with a diameter of 57 mm, then the size of the well should be from 114 mm to 142 mm. The smaller the pit, the less consumable material will be used for concreting installation. A larger foundation size strengthens the structure.

- A small layer of sand and crushed stone is laid out at the bottom of the pit. This cushion is needed to drain groundwater lower into the soil.

- Waterproofing is installed on the walls - a shirt made of roofing material or a glass from a piece of plastic pipe

- The pole is installed and aligned vertically. For fixation, a small layer of crushed stone is poured into the lower part of the hole. Next it is compacted.

- Concrete is being poured. It must be poured with a concrete mixture with grade strength M300. You can also use cement-sand mortar. Cement must be of a grade no lower than M400.

general description

Crushed stone is a bulk building material that is mined by crushing stones of different origins. This material can also be prepared using secondary raw materials in the form of concrete bases and metallurgical waste with further screening taking into account the resulting fractions.

Among the main indicators of building materials for butting fence posts, the following items can be noted:

- fraction - the minimum diameter of crushed stone or gravel, taking into account GOST 8267-93, must be at least 5 mm;

- manufacturing material - crushed stone - is made from river sediments, various types of rocks, secondary raw materials;

- flakiness - the characteristic is selected taking into account the proportions in the composition of the material of different shapes;

- strength - M1400 indicates the highest density, the lowest grade of crushed stone is M200.

Pattern for backfilling fence posts

When choosing a building material, you need to take into account the purity of the composition and additives that affect the technical performance of dry concreting.

Strength characteristics

Taking into account the strength grade, the following categories are distinguished:

- M1200 – M1400 – bulk composition of increased strength. Butting of the base of multi-storey buildings is carried out with a grade of at least M1200.

- M800 - M1200 - using this composition you can firmly concrete the load-bearing support of the fence.

- M600 - M800 is a medium-strength building material that is used for the construction of lightweight structures.

- M300 – M400 is a material of low strength. As a rule, this is crushed concrete or limestone. The building material is not used for backfilling the foundation of reinforced concrete structures.

- M200 is the minimum strength indicator.

Drawing for bottling

Granite occupies the first position in terms of its strength characteristics. After it there is crushed gravel, which is produced by crushing monolithic products. Limestone types of building materials, as well as recycled compositions, have the lowest reliability indicator.

Installation with and without butting

Frost resistance

Before hammering fence posts, it is necessary to consider such an indicator as frost resistance. This characteristic is marked with the letter F (translated from English Frost - cold):

- gravel is characterized by an index of F200 – F300;

- loose gravel is highly resistant to freezing and defrosting cycles, has an index of F300 - F400;

- limestone has little resistance to seasonal temperature changes, is marked F25 - F100;

- slag, taking into account the composition of recyclable materials, has frost resistance within the range of F75 - F200;

- Crushed stone from recycled materials has a frost resistance degree of F50.

Installing a fence support

Fence posts are backfilled with building materials with a frost resistance rating of at least F250.

Partial concreting of a fence post

The fence support under a corrugated board fence can be concreted partially or halfway. The method allows you to save money on the purchase of consumables. It is preferable when installing fencing on strong, stationary soils.

You can partially fill the hole with concrete as follows:

- By analogy with full concreting, work is carried out to dig a hole with the same characteristics.

- It is worth installing waterproofing on the walls - roofing felt or plastic pipe.

- At 40-50%, the hole must be filled with crushed stone and sand. The mixture is compacted, and as it does so it is moistened. Moisture allows the layer to be compressed better.

- Concrete is poured into the remaining space. The solution should be thick enough. It is worth adding crushed stone to the composition. After filling, it is necessary to displace the air. This is done using a metal rod.

Peculiarities

The difference between the described method and concreting is that the compacted layer is permeable to water, that is, a drainage layer is formed at the base of the fence support, which allows moisture to pass through it. This property is the main one when determining the method of installing racks in heaving soils.

During the onset of frost, the water in the ground freezes and begins to expand. After backfilling, the support layer does not contain any extraneous moisture, and therefore it does not expand.

Another difference is the plasticity of the base, made of crushed stone and sand. The buffer zone smoothes out the pressure of the lower layers of soil.

Why do you need to concrete the fence supports?

In order for the fence to last for many years, it is necessary not only to bury the support pillars, but to concrete them. The need to use concrete mortar is determined by the increased service life of the fence:

- poles reinforced with a concrete base will have long service life and good weather resistance characteristics.

- when concreting support pillars intended for fixing a fence made of universal corrugated sheets, it is created to protect against corrosion if the base is located directly in the ground.

- The disadvantage of using concrete is the incorrect dilution of the solution, which leads to cracking of the surface.

If the proportions of the composition based on sand, cement and water are observed, accurate calculations are made and the correct operating technology is selected, the operation of the structure will last up to 50 years.

Types of fence posts

They are selected based on whether the fence will be temporary or permanent and what kind of fabric will be used to fill the sections.

Popular types of supports:

Wooden

Recommended for lightweight fences made of picket fences, unedged or edged boards, and timber. Suitable for fences made of chain-link and PVC mesh. But even with proper treatment of wood against rotting and insects, its service life is limited.

Asbestos cement pipes

Less popular because they require careful installation. The pipe cavity is filled with concrete or left empty. Plugs are attached to the top, otherwise water that gets inside in winter will freeze and lead to the formation of cracks. Asbestos-cement pipes are used for fences made of concrete, welded or chain-link mesh.

Brick

For this type of support, you will need to competently draw up a masonry scheme and estimate the consumption of materials. For reliability, a metal pipe or a bunch of wire rods must be installed inside the trench, which will serve as reinforcement and strengthen the supports. Then cover them with bricks. Concreting of such fence posts should not be done spot-on, but rather poured together with a strip foundation. They are used for sectional fencing made of brick, stone, corrugated board, metal picket fences, and forged structures. Instructions for choosing materials, different masonry technologies, step-by-step installation of brick pillars.

Concrete

It can be delivered to the construction site in finished form or can be created at home. They look good in combination with spans made of concrete, stone, corrugated board, and forging. In the last two cases, to fasten the sectional material, even during the construction of the supports, it is necessary to fix special embedded parts. Concrete pillars must be installed on stable soils in warm weather so that they have time to shrink.

Choosing concrete correctly

The required grade of cement is M400 or M500, but not lower.

Buy products from well-known manufacturers. Check whether the storage conditions of the goods are met. Remember that the bags with the composition should not be hard.

A suitable proportion of the solution is where for 1 part of cement there are 3 parts of sand and 5 parts of crushed stone and water. The consistency should be like thick sour cream.

Metal

The basis is taken from profile pipes of round or rectangular cross-section. The average section is 60*60 mm with a wall thickness of 2–3 mm. These are optimal supports for both lightweight and massive fences. In the absence of an anti-corrosion coating, they require pre-treatment with protective solutions.

When installing temporary fencing at a dacha, poles made of wood or metal can be driven into the ground. Hammering is also suitable as the main method of fixing small-diameter supports under a chain-link fence or PVC mesh.

But in order for a massive decorative structure to last longer, it is still better to concrete the pillars.

Advantages and disadvantages

Butting has another name - dry concreting. This method has been used for a long time, and under some conditions is still used today. This technology is simple and cost-effective. This method of installing supports for fencing was used by ancient builders in the ancient world.

The essence of butting is as follows - part of the fence post is installed in a previously prepared hole, and crushed stone with a fractional size of 20-40 mm is filled in, it is sometimes mixed with gravel. The filled rock is filled with water and carefully compacted, thus eliminating the voids in the pit.

This method of installing fence posts has the following advantages:

- The advantage of dry concreting is its versatility. Using this method, risers for fences made of different materials are installed - wood, concrete, plastic, metal, etc. This method can be used in different soils.

- The presence of a drainage cushion, which is installed when installing the fence support, ensures that the soil does not vibrate during freezing and thawing.

- Crushed stone or other material removes excess moisture and prevents it from accumulating around the base of the support riser. It is this property that allows the use of butting fence posts in clay soils. A layer of crushed stone creates a buffer zone that absorbs forces directed in different directions, thereby preventing the fence post from bulging out of the ground.

- Compared to concreting, this installation method takes three times less time and is much cheaper. Buttoning fence posts can be done by one person.

Methods for fastening the canvas to the fence frame

Hooks as fasteners

Hooks are welded onto the posts, onto which the mesh is subsequently placed. After installation, the hooks are bent using a hammer. This method has many disadvantages: poor reliability, aesthetics, the mesh stretches and deforms, dangles and oxidizes in places of friction with the support hook. As a result, the mesh falls off and you have to tie the mesh with wire until such posts are completely replaced with normal ones. Although this is the cheapest and fastest way to secure a chain-link mesh or other, for example, welded mesh.

Installation on veins

The supports for the mesh are made with eyes for wooden or metal veins. It is better to make the eyes wide and long (10 by 25 cm), with 4-8 holes. The mesh on the vein is fixed with special staples or self-tapping screws through pieces of PVC-coated wire. This method of attaching the mesh is the most reliable, because in this case the mesh does not sag, tear or rust, so the fence turns out to be relatively rigid, evenly stretched and aesthetically pleasing.

How butting prevents supports from being pushed out

Thanks to a process such as bottling, the following effects can be achieved:

- drainage of the soil layer in contact with the base;

- water drainage;

- prevention of subsidence by compacting the soil at the bottom of the depression;

- reducing the impact of soil on the material during frosts.

The environment where part of the pillar is located underground has a stable, uniform density, which is why the supports do not warp even with seasonal changes in the soil.

Tricks and Tips

As in any work, when installing poles, it doesn’t hurt to know some of the nuances:

- To increase adhesion to concrete, a shallow longitudinal hole must be cut in the bottom of the pipe.

- 1 m long jibs or crosses made of reinforcing bars welded to the bottom of the post help to secure the post more firmly in the ground and concrete.

- To prevent precipitation from getting inside the support, the pipe is filled with a solution or the end is closed with a plug.

- The Stanly magnetic level, designed specifically for installing posts, will significantly simplify control operations and speed up the vertical alignment of the post.

- A string stretched over the top of the pipes to mark the contour does not get in the way underfoot and moves less, which makes installation easier. You can determine the position of the point for installing the stand using a plumb line attached to a string.

- Metal profiles must be very carefully cleaned of rust using a grinding machine and chemicals, and covered with a thin layer of primer and compatible paint.

Nuances of pouring supports, calculations and preparation

The concrete solution prevents loosening of the canvas, increases its load-bearing capacity and prevents corrosion of metal products. Before starting activities, it is worth deciding what seasonal impacts you want to eliminate.

Natural factors: influence on the choice of technology

The supporting element is located in the ground, so it is important to identify its changes at different times of the year:

- in the summer, the foundation is affected by the mass of the fence structure and soil resistance;

- in winter the soil expands. Depending on the depth of soil freezing, a pipe or wooden beam is pushed out;

- In spring, the soil structure changes - it thaws unevenly. A concrete pillar, unlike a dug or driven one, will not bulge or deform.

By studying weather influences, you can calculate the level of deepening of the trench.

Depth of pits for mounting supports

Whether it is justified to concrete or still hammer in the support pillars for a corrugated sheet fence, you have already decided. You should consider the depth of digging the ditch, which is determined by the height of the structure. Profile sheets 2.5 m high provide a standard pit depth of 1 m.

Distance between metal products

Installation of a fence made of corrugated sheets begins with marking the area:

- Pegs are hammered in the places of the pillars. Separate details should indicate the location of the gate and gate.

- the supports used to support wickets and gates must be stronger to avoid subsidence and bending of the structure.

- the distance between the products should be 1.5-2 m. Increasing the distance will lead to the structure warping under gusts of wind and compromising the integrity of the structure.

It is better to place the products at a shorter distance - this reduces the windage of the profile sheets.

Construction site preparation

To prepare the area where the corrugated sheet fence will be installed, you need to prepare the following materials:

- shovel;

- fittings;

- concrete mortar (crushed stone, cement, sand);

- level;

- wheelbarrow;

- plastic film.

Preparatory work for installing the fence begins with removing vegetation from the area. After that, using a garden drill or an ordinary shovel, holes are made in the ground with a depth of at least the soil freezing level - 1.5 m.