All apartment owners are prohibited from connecting water heated floors directly from a heated towel rail. Firstly, these actions relate to illegal redevelopment, and secondly, an unaccounted amount of thermal energy is consumed, for which all residents of the entrance/house pay.

However, there is a legal way to use a water heat exchanger in an apartment - installing a heat exchanger. According to existing standards SP, SNiP, water heated floors can be installed only in bathrooms of a combined type, toilets and bathrooms; wiring above living rooms is prohibited on all floors of an apartment building, except for the first lower level.

Types of connection

First, you need to decide which system to include the device in:

- Connecting a heated towel rail to the heating system. The traditional method and the only one where there are no hot water networks. Its disadvantage is that the heating system only works in the winter season. The advantage is that water circulation in the heating pipeline is forced and the heated towel rail will be hot throughout the heating season, acting as an additional battery.

- Connecting a water heated towel rail to the hot water supply system. Such systems are also subject to outages, but for a shorter period. In addition, the disadvantage of this method is that the unit will heat up only during the consumption of hot water, cooling down at night, even when connected directly to the riser. In small apartment buildings or private houses, this problem is even more acute.

The installation diagram and connection of the heated towel rail to the hot water riser in the bathroom looks like this:

As already noted, the optimal solution to many problems is the use of combined devices operating from the mains in the absence of hot water in the system.

After choosing a pipeline network for our device, the next question arises about how to include it in it:

- Direct insertion into the riser. If the bathroom was already equipped with a heated towel rail, then it is connected to the heating pipe in this way. By replacing it with a new one, you can, without further ado, use the same type of connection. You can also embed the new device directly into the hot water riser.

- Inclusion in the apartment pipeline. The advantage of this method is that when carrying out work it is not necessary to shut off the entire riser, but it is more suitable for a heating system. The above problem with the hot water pipeline will be further aggravated: the device will heat up only when washing dishes, taking a shower or bath.

With bypass jumper

Heated towel rails in old houses, as already mentioned, were a direct part of the heating pipe.

Such a connection creates problems in the event of an accident or repair and does not make it possible to turn off the device when it is not needed. Therefore, the most reasonable thing to do when installing a new device would be to insert a bypass jumper and shut-off valves parallel to it into the riser, to which it is connected. This useful addition to the pipeline should be included in the connection diagram.

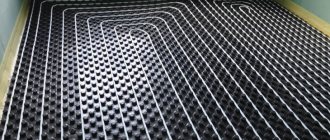

Laying heated floor pipes

The process of laying underfloor heating heating elements is quite simple. To install this system in a bathtub, products with a diameter of 16 or 20 mm are suitable. The circuit is laid in an open area; there is no need to install it under the bathtub.

The pipeline can be laid in any pattern: “snail” or “snake”. Since it is too small, the way it is placed will not affect the efficiency of the system.

For your information! Before you begin laying the floor contour, it is necessary to prepare a project indicating the length of the pipeline, diagram, pipe diameter and areas where the inlet and outlet valves will be located.

You need to start by dismantling the old finishing coating in the bathtub and cleaning the base on which the waterproofing and thermal insulation material will be laid. Foamed polyethylene (foiled penofol) is suitable for the substrate.

Since it has a small thickness, which will make the “pie” of the water floor smaller. This is especially important for the bathtub, because most often the height of the bathroom is lower than the ceilings in the entire apartment. It is better to install pipes from cross-linked polyethylene or metal-plastic.

The process of installing heated floors in the bathtub is the same as in any of the rooms of the apartment:

- Laying the circuit - this depends on the material of the pipe product; if it is polypropylene, then the connection is made with special fittings. When using metal-plastic, pipes should be laid out in such a way as to minimize the number of connections. When installing a copper product, it is necessary to use corners made of a similar material.

- Fastening pipes to the floor using clamps.

- Insertion into the system is carried out using couplings. Sharp turns of the contour should not be allowed.

- Reinforcement is the laying of reinforcing mesh, it helps to increase the strength of the structure.

- Gluing the perimeter with damper tape is necessary to prevent the concrete from cracking when drying.

- Pouring a concrete screed is best done according to the beacons. At the moment the concrete solution is applied to it, the system must be filled with cold water and there must be a pressure of 2 amps in it. It will take 2 to 4 weeks for the solution to harden, during which time the surface should be periodically moistened to prevent it from drying out.

Important! Before pouring the screed, it is imperative to check the device for functionality. Since, in case of problems or leaks, the concrete layer will have to be dismantled.

What to expect

We would like to immediately warn you that high-quality installation of heated floors from a towel dryer requires certain calculations, knowledge and skills, otherwise you will inevitably encounter the following problems:

Too hot towel dryer. A floor surface that is too hot can also become a problem if your appliance is working too hard. Sometimes it is not possible to reduce the temperature of the dryer, and then the whole installation does not make sense. In different buildings there may be problems with hot water, and if at the same time you have an underground structure, then it will make the surface not just cold, but icy

This point must also be taken into account during installation. The problem can be solved by installing a temperature control meter. If you do not work properly, you risk disrupting the normal supply and leaving both your own and your neighbors’ living space completely without hot water. Too much pressure in a set with an accidental kinking of pipes leads to a breakthrough of the entire structure, after which the illegal installation of the floor will be revealed and the results can be the most unpleasant. If you were planning to contact specialists, you will most likely receive a refusal, since, in general, companies do not want to get involved with criminal types of installation.

Warm floor from towel dryer

If you are not afraid of this kind of complexity, you can try installing a heated floor from a towel dryer yourself. There are several important connection types for this.

System check

The essence of testing is to check the line for leaks. To do this, the taps are opened, thereby releasing air from the pipes, and the circuit is filled with water. Crimping is carried out under increased pressure. If problems are found, they are eliminated and the process is repeated.

If the test was successful, then the screed can be poured. After the concrete surface has dried, you can begin laying the tiles.

For your information! Only after the screed has completely hardened, after 3 - 4 weeks, and the tile adhesive has dried, is it allowed to turn on the system for the first time. The temperature needs to be raised little by little over several days.

Device selection

All designs of these units are divided into three types:

- Mermen.

- Electrical.

- Combined.

When replacing an old device with a new one, it is most logical to use the water type. Electrical devices are used where there is neither a centralized heating system nor hot water supply, or as a backup during shutdowns.

If there is a heating network or hot water supply in the house, it is more reasonable, instead of backup ones, to use combined structures that do not take up additional space, and their installation differs little from the installation of water appliances.

The external design of water devices is quite diverse:

- 1st type: M‑, U‑, F‑shaped - traditional shapes.

- 2nd type: “ladders”, “snakes” and other types of original design of modern devices.

To include them in the existing system, the location of the installation pipes is also important:

- Lateral - usually used for type 1 devices;

- Bottom or top - more common among type 2 devices.

The choice of the appropriate option is determined by the availability of free space in the bathroom, the location of the piping system and the type of connection diagram. More details about which water heated towel rail is best to choose are in this article.

Pros and cons of underfloor heating from a heated towel rail

Heated floors in the bathroom are not expected to provide uniform heating of the air, like the same floors in other rooms of the apartment. Their main task is to make the floor surface more comfortable and drier, and so that splashes of water dry quickly. Otherwise, a microclimate will be created in the bath for fungal formations and mold.

Before you think about installing this heating structure in the bathroom, you should weigh the pros and cons.

Main advantages:

- The design does not take up space and is not visible, so it does not spoil the interior of the room;

- Stepping on a heated floor after taking water treatments is much more pleasant;

- The device is easy to install and safe;

- The maintenance process is simple;

- The system quickly pays for itself.

The disadvantages include the rather high cost of installation and the impossibility of laying some floor coverings on such a floor. But in the bathroom, mostly tiles are laid, and this is an ideal option for a heated floor.

In addition, in the event of an accident, the floor covering and concrete screed will have to be dismantled. In addition, it is worth saying that the quality of this coolant is not high, so scale and corrosion form inside the circuit.

Also, this device affects the heating of radiators in neighbors’ apartments, so it is recommended that they install a two-way valve.

Work principles

A towel dryer is a heating device that is intended for installation in residential areas and private buildings. In appearance, it strongly resembles an ordinary part of the design of external communications, however, its main purpose is hidden in the name itself - it is convenient to use such a device for drying towels and small laundry. Plus, sometimes the towel dryer acts as a compensating loop and acts as an additional source of heat in the bathroom.

All models of towel dryers are divided into 2 important categories: water and electric.

The first ones are connected to the main pipeline structure, or to the heating system and work thanks to the supply of hot water. In appearance they look like a curved pipe, which, for great aesthetics, is covered with a nickel-plated layer.

Electric towel dryers, therefore, are powered from an outlet and are convenient in that any area of the apartment where there is a power source nearby is suitable for installation. Such a device gives off a lot of heat, while consuming a small fraction of electrical energy, which is its main advantage.

Towel dryers come in a variety of options

Today on the market there is a large selection of good quality foreign models, among which you can usually choose the right one. And for our purposes, we need the most ergonomic device that will last a long time.

Very often, water models are used to install warm floors from a towel dryer, but sometimes preference is given to connecting electric ones. Everything is quite simple - the incoming hot water is passed under the floor covering using several additional turns of pipes. Electric heating is much thinner than the thinnest pipes, which in most cases complicates the task.

If you have already selected a towel dryer, then you need to be well prepared for future work.

Design Features

A water heated floor is a pipeline laid so that its bends are evenly distributed over the entire area of the room. If it is large, several segments (loops) are made, each of which is located on a certain part of the area. This allows you to maintain the temperature of the coolant - when passing through a short loop, it cools less. The number of loops depends on the size of the room. The more there are, the less thermal energy loss.

Heated floor loops are laid on the floor in different ways. It can be a snake, spiral, single or double options.

The more evenly the pipes are distributed, the better and more comfortable the heating will be. Each loop is connected to the water supply and drainage system, that is, to the direct and return water supply lines. At the same time, it is impossible to directly connect a heated floor to a heated towel rail; this will not allow you to regulate its temperature or turn off some loops if necessary.

As a rule, bends are made from the forward and reverse lines. Manifolds are connected to them, on which control valves are installed and loops are attached. Both the forward and return lines have their own collector.

For assembly, polyethylene tubes with a diameter of 22-25 mm are used. They are laid in a cement screed and covered with tiles. The result is the most efficient system, with virtually no loss of thermal energy. When pouring the screed, it is necessary to have fully assembled and connected loops, since the tubes must be under the operating pressure of the coolant at the moment the concrete is supplied.

Installation of a water heated floor is the most important procedure, since any repair of the system involves destroying the screed and replacing the tube. In terms of complexity, this procedure is significantly ahead of the initial assembly, therefore the work must be performed with the highest quality and care.

Temperature adjustment

The temperature is adjusted by changing the supply of coolant to the loops. You cannot run water directly - the room will become unbearably hot. The operating temperature of a heated floor is rarely higher than 35 °C (usually about 26 °C). Therefore, to adjust, cooled return flow is added to the hot forward flow.

For this purpose, a mixing unit is used, in which the coolant with the specified parameters is prepared. This method eliminates the cooling of the heated towel rail, since the extraction of hot water is insignificant.

The ready-made liquid enters the collector, but even here you can adjust the temperature by turning off some loops. This is done using control valves at each outlet of the manifold. When disconnecting the loop on the supply line, you must also close it on the return line.

For more precise control, use a temperature sensor and a thermostat that can automatically change the ratio of forward and reverse flows.

Setting the coolant temperature in this way is simple and convenient, but you will need to install a control unit - a special device that allows you to program the operation of the system and has a wide range of functions. Some models support control using a smartphone, where the owner can adjust the heating mode from another country or even part of the world.

Repair and service

If the installation of a water heated floor is carried out efficiently and without violations of technology, maintenance and repair are practically not required. However, any accidents are possible. That's why,

If there are signs of leakage or any loops stop working, it is necessary to shut off the system and identify the problem area.

Sometimes the cause of problems is the adjustment valve on the manifold. They change it and continue to operate the system. However, if the problem lies in the loops themselves, you will have to break the tie and change the tubes. This is a labor-intensive and expensive procedure, therefore, it is necessary to initially take all measures to eliminate such situations.

Dismantling the old device

You should start by disassembling the old heated towel rail. For this:

- Having agreed with the neighbors at the entrance and the management company, we shut off the heating riser and drain the water from it.

- If the old structure was welded to the riser pipes, cut it off with a grinder. In the case of a detachable connection, unscrew the fastening couplings.

- In rare cases when the installation dimensions of a new device coincide with the old ones, we can consider ourselves very lucky. Most often this is not the case and you have to cut the pipes even with a collapsible connection.

- The cutout in the riser must be higher in height than the distance between the inlet pipes of the new heated towel rail by the length of the pipes and couplings required for inserting the bypass.

- When cutting, we take into account not only the installation dimensions of the new device, but also the possibility of cutting threads on pipes.

- We remove the old device from the wall by cutting off its brackets with a grinder or a hacksaw.

Main materials of manufacture comparison of characteristics

Do-it-yourself - How to do it yourselfRepairing subfloors with your own handsHow to repair subfloors

The main materials for the manufacture of heated towel rails are stainless steel and brass; in budget options, galvanized steel is used for installation in apartment buildings. When choosing, the buyer often gives preference to the widely advertised stainless steel, which has an aesthetic appearance. To determine which metal is better, their main characteristics should be compared in terms of efficiency as materials for heat exchange devices.

If we consider stainless steel, it is almost three times cheaper than brass or copper, can withstand temperatures of more than 450º C, and is slightly susceptible to corrosion in water. Although stainless steel is corrosion-resistant and is not afraid of the effects of solutions of most acids and alkalis, if the alloy is made poorly (violation of technology, structural defects, reduced content of the main alloying additives of chromium), corrosion processes can occur in the structure. The material has high strength and durability, is harmless throughout the entire period of operation, but non-ferrous metals are used much less frequently as parts of plumbing fittings.

Copper-based brass alloys have thermal conductivity 4 times higher than stainless steel, which is the main advantage when using the material as a heat exchanger. Brass has high corrosion resistance (its surface is covered with a protective film of oxides, which serves as a barrier against the penetration of oxygen into the pure metal). Non-ferrous metals, unlike steels, are not subject to electrochemical corrosion; when used, the maximum temperature of the flowing coolant should not exceed 260º C.

Rice. 4 Types of heated towel rails – U-shaped, M-shaped and ladder

What is required for installation

Before starting any work, it would be a good idea to sketch out a wiring diagram or, in extreme cases, a small freehand sketch of the placement of the unit, choosing the most suitable option for connecting the device to the pipeline network.

The simplest diagrams for the correct connection of a heated towel rail with your own hands using universal ladder devices:

Tools

To replace or install a water heated towel rail, you will need a set of plumbing tools, the composition of which depends on the type of water pipes in the apartment. Considering that copper, polypropylene and other modern types of pipelines are still rare, we will describe the tools for standard ¾' steel pipes:

- Keys: gas No. 2 or No. 3; adjustable - “crocodile”; adjustable nut.

- Pipe cutter or hacksaw for metal.

- Threading dies ¾' with lever handle.

- Electric drill with hammer drill, drill bits for concrete.

- Angle grinder with cutting disc for metal - “grinder”.

- Fastening tools: hammer, screwdrivers, pliers.

- Marking tool: tape measure, level, pencil.

Materials

In addition to a set of tools for work, installation and consumables are also required:

- Turns, bends, couplings, bends and possibly other types of fittings.

- Shut-off valves, preferably ball valves.

- Plumbing linen tow or FUM mounting tape.

- Installation and fastening parts: brackets, screws, dowels, anchor bolts, etc.

Having prepared everything you need, you can start working.

It is best to carry out all work on the heating pipeline in the summer, when the system is turned off, there is no pressure in it and the water can be drained from the riser without any problems. But in this case, after finishing the work, it will be impossible to test its quality: you will have to wait until the start of the heating season.

Frequently asked questions

Installing a water floor powered by a heated towel rail is a rather complicated procedure. During the course of work, certain questions constantly arise. Some of them can be answered in advance to eliminate the possibility of errors or violations of the assembly technology.

What are the dangers of unauthorized installation of a heated towel rail?

It all depends on the location of the apartment. If after your apartment there are no more subscribers and no inconvenience will be caused to anyone, you can get by with only a small fine and the order will return everything to its original state. However, more serious consequences are also possible. In any case, installing a water-heated floor above the living quarters of neighbors below is strongly not recommended.

Is it worth installing a heated floor if the heated towel rail does not heat constantly and cools down at night?

In this case, it is not advisable to make a warm floor. Too much expense and effort will be required, and the result will be unstable and unable to provide the expected comfort.

Is it possible to get by with just one hinge in a typical bathroom?

It is possible if there is no need to install a heated floor under the bathroom itself. The room is small, intense heating is not needed here.

If brazed copper tubing is used instead of polyethylene, will this increase the strength and reliability of the system?

Yes, this will make the warm floor more durable and resistant to stress. However, the cost of material and labor will be quite high. This option is economically justified only if you need to make a small loop for a small room.

Is it possible, instead of a complex system of collectors and a mixing unit, to install a bypass and regulate the heating mode by changing the volume of water supplied to the heated floor?

No, nothing will come of this idea. Firstly, the water temperature will initially be too high and the room will be very hot. In addition, there will be difficulties with fine tuning - constant adjustment of the feed will be required.

How much more economical is a water heated floor than an electric one?

If electricity prices are low in the region, the difference in system maintenance costs is not too great. Especially when it comes to the bathroom and toilet, small rooms. However, if their area is large, and the cost of electricity is one of the highest in the country, using electric heated floors will become too expensive.

general information

With the adoption of SNiP 2.04.01‑85, in which the term “towel rail” appeared, the device soon came into general use.

Unaesthetically pleasing and, moreover, useless at the end of the heating season, iron structures painted with “silver” or nitro paint, nevertheless appealed to the taste of householders, and soon they began, by hook or by crook, to obtain and install nickel-plated, graceful, elegant and practical European units.

This topic has not lost its relevance even now: in the housing stock there are still many old buildings, where apartment owners, starting repairs or replacement of plumbing equipment, turn their attention to such useful and necessary devices for equipping a bathroom, which are quite within the capabilities of a home handyman. self-installation

How to connect heated towel rails with complex shapes

The main difference between the operation of a heated towel rail with a large number of elements and a simple one is its high hydraulic resistance, which leads to the fact that the volume of coolant passing through will be less and, accordingly, the device will not be sufficiently warmed up. In this case, you should reduce the diameter of the jumper, if present, or abandon the bypass altogether and remove all shut-off valves, connecting the heated towel rail in series to the riser pipeline.

If a highly branched heated towel rail is located at a large distance from the riser and you do not want to remove the bypass, you should choose the diameter of the supply pipes equal to or greater than the cross-section of the riser.

Rice. 19 Combined heated towel rails