Welcome to our portal!

A fireplace is associated with warmth and comfort, and therefore is a desirable attribute of any private home. However, the main function of a fireplace is not to decorate the home, but to heat it. And this imposes a number of requirements on their arrangement, and the key is to install an effective smoke removal system.

A chimney for a fireplace is another topic in our issue. The focus is on compliance with building codes and safe operation, aesthetics and practicality. We will help you avoid the most common mistakes and give recommendations from stove and fireplace craftsmen.

What is it and what is it for?

A chimney is a system of pipe channels designed to discharge smoke and gases generated during fuel combustion into the atmosphere.

Basic requirements for chimneys:

- resistance to high temperatures (over 500⁰C);

- formation of sufficient traction force;

- complete tightness;

- resistance to moisture formed inside the system as a result of condensation;

- resistance to the effects of carbon and sulfuric acid formed inside the circuit as a result of the chemical reaction of water vapor and exhaust gases (soot);

- ensuring structural stability;

- compliance with fire safety standards.

Choosing material for constructing a chimney

Currently, most chimneys are built on the basis of a metal pipe made of stainless or galvanized steel. Occasionally, structures based on brickwork are found, mainly in old houses.

In new residential buildings, brick chimneys are just an imitation of masonry: they are based on the same metal pipe, simply lined with brick on the outside.

If owners want to get an authentic brick chimney, they need to choose a special type of material.

It is important! For contact with hot air, smoke and exhaust gases, you need a special refractory brick that can withstand temperatures up to 700 degrees.

In addition to metal, ceramic and glass chimneys are also used. Ceramics have a long service life - from 30 years and above, but the cost of such a design is several times higher. Glass chimneys are also an expensive option, usually found in designer fireplaces.

We recommend that you read: The use of an American tap in various types of pipelines

Most home or cottage owners prefer a stainless steel metal pipe when installing a fireplace. This material is more affordable, is resistant to corrosion and high temperatures, is lightweight and easy to install.

How the chimney works

Despite the fact that the structure of smoke channels made of different materials has its own characteristics, in general they represent a vertical, inclined or horizontal sealed shaft adjacent to the combustion chamber of a heat-generating unit (fireplace, stove or boiler).

The cross-section of the pipeline can be round, oval, rectangular and even polygonal. Height – at least 5 meters.

Each wiring diagram is individual and is selected depending on the specifics of the building and the fireplace model.

Placement methods

Assembly and connection of the smoke exhaust duct occurs after installation of the heating device. However, you need to select a location and calculate the cross-section and height of the chimney pipe before starting installation. Chimneys for fireplaces or stoves are placed in two ways:

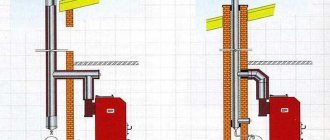

- Internal placement. This placement method involves installing and connecting a smoke exhaust duct inside a heated structure. In Russia, the chimney pipe of the stove was traditionally placed in the house, leading out to the street through the roof. Installing a channel inside allows you to protect it from freezing, as well as reduce heat loss occurring in the area passing along the street. In this case, the calculation is made on the fact that while the smoke moves through the pipe, it gradually cools, so that condensation does not form. The traditional internal placement method has one negative side: the pipe, especially the brick one, takes up a lot of space in the room. In addition, it increases the risk of fire.

Internal and external placement of the fireplace smoke exhaust duct - External placement. Installing a pipe outside a building allows you to increase the usable area of small rooms. In this case, chimneys for fireplaces are led through a wall located near the heating device directly to the street. This technology came to Russia from America and Europe; it became popular with the advent of effective thermal insulation materials used for channel insulation, and sandwich pipes that do not freeze even in the most severe frost. The disadvantage of external placement is that due to the large difference between the external and internal temperatures, a large amount of condensate forms in the chimney. To make a high-quality external smoke removal channel, it is necessary to perform a detailed calculation of the dew point and organize insulation. However, placing the pipe outside the building reduces the likelihood of fires and is considered safer.

Note! Calculation of the smoke exhaust duct of a heating device determines the recommended cross-section and height of the pipe, and calculates the required level of draft to maintain combustion. When calculating these parameters, the power of the device, the type of fuel used, location and climatic conditions in the construction region are taken into account. Chimneys for fireplaces are built on the basis of a design that takes into account all of the above factors, and the connection is made under the supervision of a professional craftsman.

Principle of operation

- The fuel placed in the firebox of a fireplace (stove, boiler) is ignited, as a result, the process of generating heat starts, and with it smoke (soot, ash and other aggressive chemical compounds harmful to human health).

- The temperature of the combustion products is about 500⁰C, which means they become lighter and rush up the shaft. The influx of cold air starts the process of natural convection, increasing the traction force and thereby displacing combustion products outside.

- Oxygen-rich air naturally supports fuel combustion.

Classification of chimney structures

Before installing a chimney pipe through a wall, you should consider the types of construction. By design, it can be single-walled or double-walled. The first option is made of sheet steel. It is inexpensive and suitable for installation in country houses and cottages. The disadvantage of the product is its short service life. For effective operation, the structure will have to be insulated.

Double-wall chimneys are sandwich systems that are recommended for installation in wooden houses. The chimney is multilayer and has low thermal conductivity, which is extremely important for highly flammable materials.

Depending on the material used to make the structure, there are:

- Brick . Often, their construction requires a foundation, and for proper laying, certain construction skills. This option is acceptable when building a fireplace in the house.

- Steel . Stainless steel material is cheap, but requires external thermal insulation. If this is not done, condensation will accumulate inside the pipes, which will affect the quality of traction. Moisture can also get into the firebox and extinguish the flame. It will be difficult to light the boiler again.

Steel chimney Source krovlyamoya.ru

- Asbestos-cement . Such products are heavy and fragile. A foundation is required for their installation. Under the influence of hot gases and moisture, such products deteriorate faster.

- Ceramic . Such a chimney can withstand temperatures of more than 100 degrees, but requires thermal insulation and careful operation. Installation of such pipes is difficult, and they are expensive.

- From sandwich pipes . The preferred option for building a chimney on the street. To produce the product, two pipes are taken, placed inside each other. There is a thermal insulation layer between them. The system is installed simply and quickly.

When choosing a material, not only its technical characteristics are taken into account, but also its decorative properties.

Traction force

The functioning of the chimney is based on the draft effect, due to which masses of gases move in the direction from the inlet of the pipe to the outlet due to the influx of fresh air from outside. Traction force is a variable quantity; it is influenced by weather conditions: wind direction and speed, outside air temperature, as well as the state of ventilation in the room (fresh air flow).

Signs of traction problems:

- difficulties in lighting a fireplace;

- low burning flame;

- smoke in the room.

To check the smoke shaft for the presence of natural draft, bring a lit candle or match to the firebox of a non-working fireplace:

- the tilt of the flame towards the smoke exhaust channel indicates the correct operation of the circuit;

- if the flame is level, there is no draft;

- the tilt of the flame towards the room warns of the backdraft effect.

It is impossible to operate the fireplace in the absence or reverse draft. Too much thrust leads to a decrease in thermal efficiency and unnecessary waste of fuel.

Causes of traction problems:

- incorrect configuration of the smoke channel;

- its insufficient height or incorrectly selected section;

- chimney blockage;

- lack of fresh air flow from the street.

Conditions for normal functioning of the chimney:

- maximum verticality of the contour;

- smoothness and tightness of walls;

- regular maintenance and cleaning of the smoke exhaust shaft;

- installing a deflector above the pipe;

- ensuring the flow of fresh air (the presence of a separate adjustable air duct from the street or setting window fittings to ventilation mode during operation of the fireplace);

- installation of equipment to provide forced draft.

Advantages and possible disadvantages

Before leading the pipe from the stove through the wall, you should consider the positive and negative aspects of the design. The following are its advantages:

- saving space indoors;

- the construction is not at the initial stage of construction of the building, but after its completion (this is the best option if it is necessary to reconstruct the house);

- ease of maintenance and repair;

- less construction work;

- ease of regulation of the chimney if necessary to change the draft force;

- high level of fire safety of the building and heating equipment;

Fire protection of a chimney Source krovlyaikrysha.ru

- there is no need to violate the integrity of the rafter system, there is no need to make holes in the ceiling or roof;

- optimal level of safety in terms of leakage of toxic gases.

However, this design also has disadvantages:

- requires mandatory thermal insulation;

- low efficiency (heat from them enters the atmosphere);

- at high altitudes, operation of the structure is difficult due to the large windage, so additional fastening is required;

- with a large number of bends, the rate of removal of combustion products decreases.

To prevent water from the slope from entering the chimney, it is necessary to install special ebbs. Sometimes the design can disrupt the exterior of the building.

Types and designs

Based on their location, chimneys are divided into external and internal.

- Placing a chimney inside a heated room and its outlet through the roof.

This method allows you to naturally increase draft, protect the chimney from freezing and reduce the heat loss coefficient. In addition, the absence of connection to an external wall makes it possible to install a fireplace in any part of the building, maintaining maximum verticality, and the gradual cooling of the air mass prevents the formation of condensation inside the circuit. However, the location of the chimney pipe inside the house, firstly, takes up useful space. Secondly, it does not always look aesthetically pleasing (except when it is made of brick). Thirdly, if there are errors in the arrangement of the smoke exhaust duct or improper care of it, the likelihood of fires increases.

- External placement of the chimney pipe.

The heating device is placed near one of the facade walls, and the pipe itself is carried out through this wall. This concept allows you to increase the usable area of your home, which is especially important for small house sizes. However, the pipeline circuit requires careful insulation, which still does not solve the problem of condensation formation in it, the cause of which is a significant difference in internal and external temperatures. The negative point is the inevitability of laying part of the pipeline in a horizontal position, which reduces draft and makes it difficult to clear the main path. The location of the chimney duct on the street significantly reduces the risk of fires and is therefore considered safer. In addition, it is easier to equip and repair.

According to the type of design, chimney circuits are divided into:

- radical, in which the chimney duct is arranged on a separate foundation and attached to the fireplace in a vertical position on the side.

- mounted ones, installed above the fireplace and being its natural extension.

- wall, when the chimney is placed directly in the internal or facade wall of a private house or goes outside through it.

For the construction of chimney shafts, a variety of materials are used that meet the following requirements:

- high coefficient of heat resistance and fire resistance;

- low thermal conductivity;

- inertness to aggressive chemical compounds formed from combustion products;

- resistance to water and corrosive processes.

The following types of materials meet the above conditions:

- Brick.

The material is available and traditionally used for the construction of stoves, fireplaces and chimneys. However, not every type of brick is used for this purpose, but only solid clay brick, which has gone through the pre-firing stage, due to which it is able to stably withstand high temperatures. If all construction technologies are followed and proper care is taken, a brick chimney will last more than 100 years.

Special requirements are also imposed on the cement mortar used to lay the bricks. It should be a mixture of sand, cement and lime in a ratio of 5:2:1. It is this solution that can provide a tight, airtight connection that is resistant to heat. Because the smoothness of the inner surface of the pipe is one of the primary requirements for the arrangement of the chimney duct; the laid mortar should not protrude inward from the seam joints. However, the surface of the brick itself has a certain roughness, which causes ash and soot to settle on the walls, leading over time to the appearance of congestion.

The significant weight of the structure requires the pouring of a separate deep foundation, which means that the construction of a brick chimney must be planned at the stage of preparing the house construction project.

- Ceramics.

Ideal for wood-burning and other solid fuel fireplaces. It withstands high temperatures (up to 1000⁰C) and the aggressive influence of chemical elements. Ceramics heats up quickly and cools down slowly, which allows you to significantly save energy resources when heating your home. The ideally smooth surface of the internal walls prevents combustion waste from accumulating inside. Service life – 30-50 years.

The variety of shaped elements allows you to implement almost any design solution. In addition, pipes alone are not enough; you will need a special assembly adhesive, with which the elements are assembled and sealed, as well as the construction of a heat-insulating circuit made of heat-resistant materials. Manufacturers suggest using specially designed lightweight aerated concrete blocks as a thermal insulation circuit, often additionally equipped with a thermal insulation layer.

Disadvantages include the heavy weight of the structure, which requires the installation of a separate foundation under the chimney, and the high cost of the structure. When using lightweight concrete blocks, there is no need for a traditional foundation; it can be completely replaced with a monolithic foundation made of a concrete pipe.

- Metal and steel.

Chimneys made of heat-resistant anti-corrosion steel are used only at combustion temperatures of no more than 400⁰C. They are much cheaper and lighter than their brick and ceramic counterparts, which eliminates the need to build a foundation site for them. Their service life ranges from 15-20 years.

Metal pipes are manufactured in factories in separate sections, from which the circuit of the desired configuration is then assembled. Depending on the type and rigidity of the metal, they can be self-supporting or require additional fixation to other supporting structures (walls, trusses, etc.), made of one type of metal or several (stainless steel inside, aluminum outside). The main advantage of steel chimney ducts is ease of installation and connection. In addition, they can be installed either independently or in combination with brickwork, performing the so-called lining.

Steel chimneys are classified into 2 groups: simple without thermal insulation and sandwich pipes, the design of which includes a heat-insulating layer. The coaxial design (“pipe in pipe” + thermal insulation) is the most popular.

- Glass.

Durable tempered glass is not the most practical solution for a chimney, and is most often used solely for decorative purposes. As advantages, it is worth noting the absolute inertness to the chemical effects of combustion products and the ideal evenness of the walls, which prevents the formation of soot build-ups inside the circuit. However, you have to wash visible areas quite often, since small deposits of soot still form, which negates the aesthetic appeal of such a chimney.

The complexity of assembly in terms of ensuring tight connections is one of the main disadvantages of this type of design. In addition, glass is prone to condensation accumulation and requires work on thermal insulation of the circuit. All this, combined with its high cost, makes glass not the most popular material for arranging chimney lines, assigning it the role of a decorative element only in a small area of the contour.

A number of technical documents allow the use of asbestos-cement pipes for the installation of chimneys. However, experts do not recommend using them for this purpose, because they are characterized by an insufficient level of resistance to high temperatures (no more than 300⁰C).

On an industrial scale, monolithic concrete is used, but for private households this method is considered too labor-intensive.

Prohibited for use:

- tree;

- silicate and hollow bricks;

- clay;

- galvanized sheet.

Waterproofing the passage

After completing the laying of the cap, you can install the umbrella and begin waterproofing the pipe passage through the roof.

Approximate diagram of chimney waterproofing

Waterproofing is a very important point in the design of a chimney, and the durability and efficiency of its operation depend on it.

The distance created between the pipe and the roof must be covered with an apron. Most often, roofing material is used for these purposes, which is fixed to a sealant.

On top of this layer of waterproofing is an “apron”, which is made from a wall profile or from a special waterproofing tape. It is also attached to the roofing material using sealant, and fixed to the pipe with a strip designed for this purpose.

"Apron" for the chimney pipe

Which fireplace is better

The choice of material for the smoke exhaust duct should be based on the technical characteristics of the fireplace and the fuel on which it will operate:

- for solid fuel fireplaces, pipes made of brick or ceramics are best suited;

- for gas models, priority can be given to coaxial steel pipes.

A few recommendations for choosing the type of structure:

- It is best to install the chimney inside the house, where operational loads on it are minimized. In addition, this solution will allow the heat coming from the chimney shaft to be generated into useful energy for heating the home. However, it should be understood that this is the most labor-intensive process and sometimes not feasible in the conditions of an already constructed building.

- Installation of a fireplace with a smoke circuit exiting to the street is possible at any stage of construction and even upon its completion.

- If the chimney shaft is located internally, it is best to allocate a place for it in the middle of the room or on one of the internal walls. This will keep more heat inside the room and reduce the likelihood of condensation forming inside the circuit.

- When choosing one of the facade walls, you should take care of careful insulation of the structure on the street side. To do this, either the brickwork is thickened or special fireproof materials are used.

- The cylinder is the most optimal shape of the chimney channel, providing maximum draft due to the movement of the flow in a spiral. A similar effect is typical for oval, square and rectangular shapes, but at a slower rate. In addition, soot will inevitably accumulate in the corners, which further impairs traction.

Brick chimney installation

A fireplace is not a simple heating system. The whole family gathers around a warm fireplace on winter evenings. It brings not only warmth to the house, but also joy, comfort and coziness from spending time together. Before starting work on building a chimney for a brick fireplace with your own hands, you should study the structure diagram, which consists of:

- From a mounted pipe. This part of the device is a structure for removing smoke with a valve for adjusting draft. It is laid out immediately behind the combustion system.

- Fluffs. It is the next part of the device in the form of an extension of the outer part of the chimney. Its length is about 30 centimeters. It makes the exit in the ceiling safe.

- Boner. This is part of the structure, located from the floor in the attic to the roof. In winter, it should be properly insulated.

- Otters (kryza, master flush). A device that protects the attic from moisture. It is a tetrahedral seal made of rubber or silicone.

- Shakey. The part of the chimney located above the roof and passing into the final head of the system.

The design consists of 5 elements.

If it turns out to be difficult to build a brick structure on your own, then you can always choose a simpler version of the fireplace chimney made of ceramics and other materials.

It is also possible to supplement the structure with a steel pipe in gas models. Interesting: wood-burning fireplaces for a country house.

Make it yourself or order it

At first glance, there is nothing complicated about installing a chimney with your own hands, however, this is not entirely true. First of all, it should be remembered that the structure must be absolutely safe, which means it must be durable, airtight and with good traction force. And this will require from the “stove-maker”, at a minimum, relevant knowledge and thoroughness, and, at a maximum, certain experience and skills.

On the other hand, entrusting such a responsible job to a builder whose professionalism and integrity you doubt is not the most reasonable decision. After all, poorly done work can subsequently result in a fire or carbon monoxide poisoning.

Therefore, preference should be given only to trusted construction companies or take on the work yourself.

But to independently implement the project, you will need to make every effort:

- study a number of building rules and technical information about the heating device;

- make the necessary calculations;

- carry out construction and installation systematically, often at length and with special care.

Stainless steel smoke exhaust structures

Chimneys for fireplaces of this type are stacked structures. The length and diameter of a stainless steel fireplace pipe can be very different. Such products are often produced complete with ceramic ones and placed inside steel ones.

Chimneys made from galvanized stainless steel have the following advantages:

- they can be installed without a foundation, since they are light in weight;

- assembly and installation of the structure is permitted after completion of construction;

- they are cheaper in cost than block and ceramic systems;

- If necessary, replacing individual elements will be easy.

The disadvantage of steel chimneys is the need for a design solution in the case of interior design, if such a structure is installed indoors.

Building regulations

The rules for installation and operation of chimneys are regulated by a number of building regulations:

- SNiP II 35/2.04.05-91/2.01.01-82;

- DBN V.2.5-20-2001 and NPB 252-98;

- GOST 9817-95, etc.

Key aspects:

- combining ventilation and chimney is not recommended;

- It is not allowed to connect the chimney circuit to other communications: electrical wiring, gas mains, etc.;

- a separate smoke exhaust duct must be installed for each gas equipment;

- when two fireplaces (not gas) are located on the same floor, it is allowed to connect them in one smoke exhaust shaft with its obligatory separation by a transverse wall at a height of 75 cm;

- the shaft is installed predominantly vertically (for gas equipment, verticality is required). The maximum permissible deviation coefficient is 30⁰, while the diameter of the slope must be equal to the cross-section of the main vertical contour. The number of pipe bends cannot be more than three, and the length of the horizontal areas must be within 1 meter, with a total of no more than 2 meters;

- the minimum pipe height is 5 meters from the grate to the extreme point;

- the optimal air flow speed is 15-20 m/s.

- to remove soot deposits at the base of the circuit, it is necessary to equip special “pockets” with a depth of at least 25 cm;

- Sagging of the pipeline circuit is not allowed; for this, all its parts must be hermetically joined together, and the pipeline itself is attached to the load-bearing elements of the building;

- To prevent precipitation from getting inside, the pipe is covered with an “umbrella” on top.

Requirements for the height of the chimney shaft:

- For a gable roof: at a distance from the ridge (parapet) of up to 1.5 m - from 50 cm; at a distance of 1.5-3 m - not lower than the height of the ridge; at a distance of more than 3 m - not lower than the edge of a line drawn at an angle of 10⁰ from the roof parapet to the horizon point.

- For flat roofs - more than 1.2 m.

- When leading a pipe through a wall - from 1-1.5 m from the ground.

Requirements for the room in which the fireplace is planned to be installed (SNiP 31-01-2003/31-106-2002/41-01-2003/42-01-2002/42-101-2003):

- Ceiling height - at least 2 m.

- Volume – at least 7.5 m³.

- Availability of a high-quality ventilation system.

Laying of the mounted pipe

It is necessary to decide what the cross-section of the chimney will be for a fireplace built from brick.

The smoke, rising upward, moves in a spiral. Therefore, it is customary to give preference to a round-shaped channel, but it is extremely difficult to lay it out of stone. You have to make a section in the form of a square, the size of which depends on the fireplace portal:

- Closed portal - approximately 15x25 cm Open portal - approximately 25x25 cm

It is necessary to start laying from the top, arranging the nozzle pipe.

It is very important to monitor the ligation of seams between rows, vertically and horizontally. The thickness of the seams should be 1-1.5 cm. One value should be maintained throughout the entire construction.

We make a fireplace from start to finish: stages of work in order:

It is necessary to continue laying the mounted pipe until 5-6 rows remain from the ceiling. To ensure that the smoke does not have any obstacles, it is recommended to plaster the inner surface with the mortar used for joints. It is better to lay the layer not thick, so as not to greatly reduce the diameter of the chimney for a brick fireplace.

If the mounted pipe is laid directly against the wall, it must be secured. To do this, pins are installed every 25-30 cm, one end of which is driven into the masonry, the other into the wall.

Having laid the last row of the chimney pipe, it is necessary to check the vertical and horizontal, it is time to begin the most important and difficult stage of construction - the construction of the fluff, the otter and the riser located between them.

Fire safety requirements for chimneys

The fireplace and its chimney are sources of increased danger. Therefore, compliance with fire safety measures is the main condition for their installation and operation.

- Areas of the floor, walls and ceilings in contact with the chimney are insulated with fireproof materials (metal, asbestos cement, plaster, basalt wool, etc.).

- The thickness of the insulating layer is at least 13 cm for sandwich chimneys and 25 cm for single-wall chimneys.

- A convection chamber with a thermal screen and ventilation vents is installed in the area between the cladding and the ceiling.

When operating fireplaces and chimneys, it is prohibited:

- Make kindling with flammable liquids and other flammable materials and substances.

- Use wood for kindling that exceeds the size of the combustion chamber.

- Use the chimney to dry clothes or shoes.Q = CA 2 g HT i − T e T i {\displaystyle Q=C\;A\;{\sqrt {2\;g\;H\;{\frac {T_ {i}-T_{e}}{T_{i}}}}}}

Block ceramic chimneys

The basis for the ventilation ducts in such a ceramic chimney are blocks made of lightweight concrete. A wide range of these products allows you to easily select the required parameters.

To connect the blocks, a vertical reinforcement process is used. A ceramic fireplace pipe is inserted inside them and thermal insulation made from non-combustible materials is placed.

The technology for carrying out installation work in this case depends on the features of the structure being installed and therefore the use of generally accepted rules will be inappropriate.

The advantages of this type of chimney for fireplaces include:

- quick installation and assembly;

- long service life;

- high efficiency;

- a wide selection of blocks to give the smoke exhaust channels the desired configuration;

- the ability to clean the smoke exhaust system through special openings. Their presence at the bottom of the structure also helps condensate to drain freely.

The disadvantages of a ceramic pipe for a fireplace chimney include:

- relatively low price;

- long delivery times, since such structures are in most cases produced abroad.

Even taking into account the shortcomings, ceramic fireplace pipes are considered the undisputed leaders among similar products.

Making and installing a chimney with your own hands

Having decided to make a chimney with your own hands, first of all you should:

- decide on the material from which the structure will be made;

- make a drawing and diagram of the future structure;

- calculate the dimensions.

There is no universal construction scheme for a smoke exhaust structure; it will be individual for each chimney, because depends on a number of factors:

- features of the room where the fireplace is planned to be installed, and the structure as a whole;

- type of heating device;

- type of fuel used;

- the selected building material (its thermal expansion coefficient).

Regardless of the above aspects, work must be carried out in mandatory compliance with building codes, fire safety requirements and recommendations of heating equipment manufacturers.

What materials are best to make it from?

Initially, the choice of material is based on the type of fireplace used and only then on aesthetics and the personal preferences of the owner.

- A brick chimney is recommended for use only with solid fuel equipment.

- The symbiosis of brick and gas fireplace is not the best solution, because... The temperature of processed combustion products in gas appliances is quite low. This leads to the formation of a large amount of condensate, which, entering into a chemical bond with combustion products, destroys the brick structure. The same applies to liquid fuel, pyrolysis (gas generator) or pellet (automated solid fuel) fireplaces.

If brickwork is a prerequisite for you, you should line the chimney duct, i.e. install a single-layer stainless steel pipe inside, which is resistant to acidic environments. The advantage of a metal liner is that it can be inserted into the chimney even after construction work is completed or during the reconstruction of an old mine. In this case, there must be a distance between the wall and the steel liner.

On a note! Lining is also an excellent solution in cases where the channel is not straight or has non-standard dimensions.

- When choosing an iron chimney, you should take into account their fire resistance coefficient when working with different types of fuel. So for coal fireplaces it is better to use AISI 310/309 steel with an operating temperature of up to 1000⁰C, for wood fireplaces - AISI 430/439 (up to 900⁰C), for gas fireplaces - AISI 321 (up to 700⁰C).

Drawing and diagrams

Diagram of a metal sandwich chimney:

Drawing of a traditional brick chimney shaft:

Diagram of a brick chimney with a steel/ceramic liner:

Size calculation

When carrying out design calculations, the required cross-section and height of the pipes are determined. This takes into account:

- fireplace power;

- fuel type;

- its location;

- climatic features of the region.

When the result obtained is lower than the height of the house, it is adjusted upward, taking into account regulatory standards for height (at least 5 meters) and the required level of elevation above the roof.

In addition, you should adhere to the following recommendations:

- the diameter of the smoke exhaust duct must be equal to the diameter of the fireplace outlet pipe;

- the diameter of the chimney shaft when two units are simultaneously connected to it is calculated for each separately and summed up;

- when rounding into a turn, the radius of this rounding should not exceed the cross-section of the main contour.

To determine the necessary parameters, knowing the power of the heating unit, you can use the table:

To maintain optimal heat transfer and circuit safety, the thickness of the pipeline walls is of no small importance. Depending on the type of material, the following minimum values are established:

- for a brick structure - 12 cm;

- for concrete – 6 cm;

- for steel pipes – from 1 mm.

Fireplace through attic and roof

In order to pass a chimney for a fireplace built by yourself through the ceiling as safely as possible, you need to lay out the fluff. The thickness of its walls should be equal to at least one brick placed in length. In this case, the expansion is done in stages, moving by ¼ with each row.

Sometimes, instead of the classic tub of the thickened part, a concrete box is used, filled with pebbles, sand or expanded clay and installed around the chimney pipe. This option is easier to implement:

- First, the wooden formwork is arranged so that it rises 7-10 cm above the ceiling; it must be secured more securely and make sure there are no cracks. The inside of the boards is covered with a solution of sand and clay so that the formwork can be easily dismantled after the concrete mixture has hardened. Next, reinforcement is done by rigidly connecting the rods and brick masonry with each other A solution consisting of a high grade of cement, sand and the selected filler is prepared, thoroughly mixed and poured, completely hiding the reinforcing rods. After drying, the formwork is dismantled. The surfaces must be smooth so that it is possible to cover the fluff with masonry without any problems.

In order to maximally protect the structure of the ceiling, which should not touch the chimneys for stoves and fireplaces, it is necessary to make a steel edging around the perimeter of the hole, and put glass wool impregnated with clay mortar into the resulting gap. It is also recommended to lay the insulation to the sides, removing up to 20-30 cm.

Watch the video, the chimney through the roof slab:

After the formation of the fluff, the installation of the riser continues.

In this part, the size of the chimney for the fireplace is made similar to the mounted pipe, only plastering with clay mortar is carried out simultaneously from the inside and outside. During the heating season, the attic temperature is set to low. To eliminate the big difference inside and outside the chimney, it is recommended to wrap the riser with non-flammable insulation.

The most difficult stage of the instructions on how to build a chimney for a fireplace has been completed.

Having reached the roof, it is necessary to proceed to the next stage - arranging the otter. The pipe is expanded, as when laying fluff, but only slightly. In this case, it is necessary to install a galvanized metal casing around the perimeter with a small protrusion on the roof, which is covered with soft waterproofing and roofing.

Installation features

- Installation is done from bottom to top.

- The assembly of a modular pipeline is carried out by inserting one pipe into another; the joints are additionally treated with fire-resistant sealant and fixed with clamps.

- The pipeline is attached to the supporting structure with special brackets every 2 meters, avoiding deflections and constrictions.

- Connecting seams should not be placed in the areas of floors and roofing pie. In addition, the so-called “fire cutting” of 150 or 300 mm is performed here for pipes with and without insulation, respectively.

- If the roof is classified as flammable, a spark arrester made of metal mesh with 5x5 mm holes is mounted on the pipe.

- The walls around the fireplace shaft must be lined with fire-resistant material (clinker, tiles or iron sheets).

- When the circuit is drained horizontally through the wall, inspection and cleaning modules are installed in them.

- To prevent precipitation and debris from getting inside, weather vanes and deflectors are installed on top of the pipe.

Another, somewhat simplified version of the chimney

Another option for laying a chimney could be a simple straight design. It is suitable for those who have no experience in performing this type of construction.

- The entire chimney, from the stove to the head, is laid out in an even column with a channel inside, and all the elements necessary for it are made using formwork, cement mortar and reinforcement with a metal rod with a thickness of four to seven millimeters.

- In the area where the fluff should begin, formwork of the required size and shape is arranged.

- A metal rod or mesh is secured to the pipe.

- The formwork is coated with a thin layer of clay mortar. It is needed so that the formwork boards can be easily removed from the hardened concrete solution.

- Then the concrete solution is placed into the formwork and left until it hardens completely.

- After the cement has hardened, the formwork is removed and all concrete parts, if necessary, are leveled to give them a neat appearance.

In this way, the complexities of masonry configurations can be circumvented. Of course, this work will take much longer, but it is impossible to make a mistake. The main thing is to arrange the formwork correctly, neatly and evenly.

Frequent errors and problems during installation

- Defect in the chimney structure.

Excessive slope, a large number of bends and their incorrect radius, the presence of horizontal areas and exceeding their permissible length weaken the traction in the circuit and contribute to the formation of soot build-ups in it.

In the case of a complex-contour brick chimney, it is quite difficult to correct the situation; sometimes the problem is solved by lining or installing forced-type smoke exhaust equipment (smoke exhauster). If this is not possible, the structure will have to be disassembled and rebuilt.

The open-type modular steel structure can be easily disassembled, which means that remodeling it will not be difficult.

- Low shaft height.

When the pipe height is less than 5 meters, the traction force is significantly reduced. When a ventilation and smoke exhaust pipe is located in one module and the height of the latter is insufficient, the risk of gases being drawn back into the ventilation increases.

The error is corrected by increasing the chimney pipe to the required level.

- Cross section too small or large.

Not only does it reduce traction, but it can also disrupt the tightness of the circuit as a whole.

The draft is corrected by installing a weather vane or turboprop on the chimney head, protecting the circuit from blowing and the effect of reverse draft in windy weather. However, in calm weather they will be useless.

- Unsuitable material and construction defects.

The material must comply with technical operating parameters, and installation must be carried out in strict accordance with regulations.

Neglecting these issues may result in the coating melting or burning out and, as a result, a fire.

Height of pipe above ridge

The chimney pipe should rise above the roof ridge by half a meter if it is located one and a half meters from it horizontally.

The relative position of the pipe and the roof ridge

If it is located lower along the slope, it is raised level with the ridge or lower no more than 10 degrees at an angle to the ridge. These parameters must be strictly observed, as they ensure the safe operation of the heating structure and have been tested by many years of experience.

Maintenance and cleaning

Preventive maintenance and cleaning of the chimney duct is carried out at least 2 times a year, before the onset of the heating season and at its end. The inspection must be carried out by representatives of regulatory organizations, and they also issue a conclusion on the suitability or unsuitability of the chimney circuit for operation. If you have the appropriate knowledge and skills, the home owner can also periodically inspect it. In this case, the channel is checked for:

- presence of traction;

- integrity of partitions;

- circuit tightness;

- presence of blockages.

If the thickness of ash deposits is more than 2 mm, cleaning is carried out. To do this, use a special ball weight, a brush and a stiff brush with an extended folding handle or on a steel cable. Starting cleaning from the top and gradually unfolding the handle, they move into the depths of the shaft. The fireplace insert is first closed to prevent soot from penetrating into the room, the furniture is covered, and the windows and doors are closed.

Cleaning can also be done using chemicals. When burned, the so-called “miracle logs” release chemical compounds that are harmless to humans, under the influence of which the soot lags behind the walls.

Once every ten years, a major overhaul of brick structures is carried out, replacing the mortar in the seams.

It is prohibited to burn off soot and use chlorine-containing cleaning products.

Preparing for assembly

Before installing a stove in a country house with a pipe exiting through the wall, you need to prepare. Work requires special clothing and gloves. If you will be cutting metal products, it is advisable to wear safety glasses.

Selection of tools and materials

To complete the work, the following tools are required:

- drill, equipment for cutting material;

- heat-resistant sealant;

- riveter;

- clamps, dowels, corners;

- foil construction tape;

- screwdrivers;

- level, plumb;

- knife;

- ladder;

- When working with concrete walls, you will need a hammer drill.

Components for installing a chimney Source vse-postroim-sami.ru

The materials you will need are a steel pipe, with which the horizontal fragment is connected to the boiler. You also need a tee for connecting pipes, an elbow (with its help the structure is directed upward), and a support console. Brackets and dowels are used to mount products on the wall. The connection of several pipes is carried out using clamps. You also need thermal insulation material and a protective cap.

See also: Catalog of companies that specialize in the installation of fireplaces, stoves and utility networks.

Choosing a location

The house has central and side walls. The second is located on the side of the slopes and under the roof overhangs. Liquid gets onto this part when it rains (if the drainage system is not fixed). There is a small roof overhang above the central walls, so the risk of liquid entering from the roof is minimal.

It is better to mount the smoke exhaust structure on the front wall. Here it is taken into account that there should be no windows or balconies on it along the line of the chimney. If you have to install a pipe through an overhang, then high-quality fire protection is installed.

Choosing a location for the chimney outlet through the wall Source stroychik.ru

Calculation of chimney height

Since it is possible to correctly bring a chimney through a wall to the street in a wooden house only if technical requirements are met, the first parameter that is taken into account is the height of the structure. It depends on the number of floors of the house. If the height of the building does not exceed 5 m, then the minimum parameter for the height of the structure is 5 m. If this value is neglected, the structure in the house will smoke in the house, the draft will deteriorate, and the performance of the heating device will decrease.

If the pipe is too long, fuel consumption will increase. When the height of a building exceeds 10 m, the main reference point is its ridge: it should be 0.5 m below the chimney. This characteristic is affected by the cross-section of the pipes and the power of the heating equipment.

Chimney height Source vosaduly.ru

Pipe diameter calculation

The internal diameter of the structure must correspond to the dimensions of the pipe. Any narrowing of the internal volume of the pipe affects the formation of draft. The presented value is affected by the power of the equipment: the higher it is, the larger the internal diameter. You need to follow standard building rules:

| power, kWt | Internal section, cm | Minimum diameter, cm |

| up to 3.5 | 14×14 | 15,8 |

| 3,5-5,2 | 14×20 | 18,9 |

| 5,2-7 | 14×27 | 21,9 |

If we take into account all the technological features of installation, the structure will last for decades without significant problems.

Expert advice

A few tips from experienced stove makers:

- You should not place chimneys in corners and places where walls intersect, so as not to weaken their strength.

- Before laying a brick smoke duct, you should prepare a row (layer-by-layer) layout for its installation.

- The otter and fluff masonry, which is an integral part of the brick structure, can be reinforced with metal rods or plates.

- You cannot smooth out the internal roughness of a brick pipe with clay. This causes condensation and dampening of the brick.

Brick pipe repair

To put the pipe in order, you can go in two ways: restore the masonry or perform lining - treat the channel inside with special means.

Reconstruction of masonry

In case of minor damage to the chimney masonry, they act quite predictably - instead of destroyed bricks, they install whole ones. To do this, the crumbled elements are carefully cleaned of the solution and removed. The empty cell is scraped out, after which a new element is placed in place of the taken brick, using a fresh mixture of clay and sand.

In case of minor damage to the masonry, it is restored by replacing individual bricks with new ones

Sometimes a situation arises when cracks appear in the pipe, through which moisture seeps in during heavy rains. In these cases, the outer surface of the pipe above the roof is primed and then plastered.

When the bricks in the masonry are damaged by more than 20%, partial repair of the chimney is out of the question. The smoke channel with severely damaged elements is completely dismantled to create a new masonry.

Video: one way to repair a brick chimney

Brickwork

Lining is an excellent way out of the situation if the problem is the loss of smoothness and strength by the chimney walls. To complete this task you need a mixture of Masan or Mordax. These compositions simplify the restoration of the chimney’s functionality and do not reduce its cross-section at all.

It will take only a few hours to complete the lining. The operation consists of the following steps:

- The area near the chimney is covered with film so that drops of a special composition do not stain the roofing material.

- Taking a brush with metal bristles, peel off fragments of bricks and soot from the inner walls of the channel.

Before lining, the brick channel is cleaned, achieving a smooth surface. - The channel, which has become completely clean, is wiped with a generously dampened rag.

- Using a special brush and winch, a special composition is applied to the inner walls. The mortar mixture should spread over the surface as the brush moves.

Masan lining mixture is used for repairing chimneys, as it is fire resistant - When the applied composition dries, the internal walls of the chimney are treated a second, and then a third time.

You may need several different brushes during the lining process. This is explained by the fact that the cross-section of the chimney in certain areas may not be the same. In general, the size of the brush should correspond to the parameters of the smoke channel.

If you comply with the requirements for the masonry process in a house or bathhouse, you can create a safe and durable chimney. A self-made structure can look no worse than the structures of real masters. If you have learned how to build chimneys with your own hands, then you can also make repairs of any complexity without outside help.

Errors in chimney installation

Since it is not always possible to correctly install a stove in a house and route the pipe through the wall, you should consider the most common installation mistakes in order to avoid them. Incorrect robot design is possible in the following cases:

- Insufficient amount of insulation at the junction of elements. In this case, the pipe will overheat.

- The presence of joints where they pass through a wall or roof overhang. Such installation increases the risk of fire in a capital structure.

Video description

You can see the chimney outlet through the wall in a bathhouse in this video:

- the upper part of the structure is located slightly above the roof ridge so that the smoke is blown away by the wind;

- there should be no other communications or wires near the box through which the pipe is inserted;

- Regardless of the material of the chimney, its horizontal part is inserted into the wall at a right angle.

Before making a chimney through a wall in a wooden house, you should treat it with an antiseptic and a liquid that increases its resistance to fire.

The danger of a cold chimney

An air lock often forms in a cold chimney - this is a layer of cold air located inside the channel. It is because of this plug that the flue gases cannot escape. As a result, the gases will flow back into the room, and the heating device will not turn on or simply will not melt.

Ilya ManaevTechnical specialist at Schiedel

It is important to know! If, when lighting a fireplace/stove, smoke comes into the room or the gas boiler does not turn on, then it means that the heating device does not have enough draft. This usually happens when the chimney is cold. To correct the situation, you need to warm up the smoke channel. Crumple up some paper and burn it in the firebox or chimney. Due to this, the internal channel of the chimney will warm up and the necessary draft will appear.

Another disadvantage of a cold chimney is the unstable operation of the heating-chimney connection. Thrust changes may occur, which will lead to significant excess fuel consumption. And also, a chimney running along the facade will produce more condensation than a pipe located indoors.

Advantages and disadvantages of installing a steel chimney along the facade and indoors

The answer to the question why most people choose a steel chimney is simple:

Let's move on to the pros and cons of installing a chimney system outside and inside the building.

Ilya Manaev

Helpful information! Steel chimney systems are assembled without the use of sealants. All elements have socket connections. The DS parts are inserted into one another and crimped with a clamp. This guarantees tightness and high reliability of the system. Sealing compounds can only be used to connect the chimney and the heating device.

Advantages of installing a chimney on the facade:

- saving space indoors;

- DS cleaning takes place outdoors (no moisture or dirt);

- it is easier to install the chimney to the facade;

- there is no need to violate the integrity of the roof and ceilings.

Disadvantages of a chimney on the facade:

- if the heating device operates irregularly, an air lock may form in the internal chimney channel;

- a pipe running along the facade can reduce the aesthetic component of the building;

- Ice may form if proper condensate drainage is not organized;

- Single-wall chimneys cannot be used; only double-walled insulated steel chimneys are recommended.

Advantages of installing a chimney inside a building:

- optimal traction is created;

- the service life of the chimney is extended when compared with outdoor placement;

- no negative impact of wind loads and precipitation;

- the risk of damage to the chimney by third-party factors is minimized.

Disadvantages of a chimney indoors:

- during installation it is necessary to violate the integrity of the roof and ceilings;

- when the chimney is located in residential premises, cleaning and drainage of condensate is difficult;

- it is difficult to fix the DS to the mounting surface;

- the chimney may not fit into the design of the room.

Fire safety rules

The distance from the brick wall to the chimney is 130 mm. If the structure is wooden, then this parameter increases to 260 mm. When pipes pass in close proximity to rafters or through flammable materials, these places must be insulated.

Fire protection of a chimney Source petropech.ru

When using solid fuel equipment, the chimney is equipped with a mesh metal spark arrester, regardless of the material from which the building is constructed. The cell size does not exceed 5*5 mm. In addition, there are other rules:

- the chimney head must be positioned correctly relative to the roof;

- to reduce moisture condensation, the temperature at the outlet of the structure should be 15°C higher than the dew point temperature (60°C);

- if the chimney height is less than 5 m, then the installation of an electrically driven smoke exhaust is required.

The outer wall is separated from the structure by an asbestos-cement sheet or basalt overlay.

Video description

This video clearly shows an example of violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically. When insulating main walls with foam plastic or mineral wool, long dowels are used to secure the chimney.

- There is no ebb on the side roof slope. In this case, precipitation can get on the insulation and impair its functions.

- Insufficient overall vertical height. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Briefly about the main thing...

Chimneys can be single- or double-walled. Based on the material of manufacture, metal, brick structures and structures made of sandwich pipes are distinguished. The last option is optimal for private houses. When installing a chimney, the rules for its placement in the room are observed. Its functionality, as well as the presence of draft in the heating equipment, depends on the correct determination of the diameter and height of the structure.

The installation technology through a wooden and brick wall is the same, but there are some nuances: wood is more susceptible to ignition and requires maximum protection. During installation, you must comply with fire regulations, and also take into account possible errors.

Ratings 0

Internal section of the chimney

Fireplace chimney.

There is nothing better than the usual cylindrical shape for constructing a chimney. Considering the uneven upward movement of combustion products, which move in a circle along the axis of the chimney, a cylinder seems to be the most acceptable shape, which is capable of providing the strongest draft. In a rectangular pipe, turbulence will form at the corner parts, which will prevent the normal level of draft. However, it is noted that a rectangular pipe can be successfully used with thermal devices that do not require high draft.

These fireplaces and stoves include options that heat rooms with wood. If, for example, the cross-section of the chimney is rectangular and the smoke circulation in it is properly arranged, then this will allow maintaining the temperature to which the heating device was heated. In comparison with pipes with a round cross-section, this looks ideal, since all the heat will evaporate from a cylindrical chimney quite quickly. New generation fireplaces are increasingly equipped with cylindrical chimneys. They operate using a fast heating system - when the system heats up to the set temperature, the boiler will automatically turn off and go into standby mode, thus saving energy.

Video description

How to pass a pipe through a wooden base is shown in this video:

- Making a hole for the box. At this stage, the diameter of the product is taken into account, as well as the space for the insulating material (basalt wool inserts).

- Pipe installation. An asbestos sheet is laid between its walls and the box. The element is displayed strictly at a right angle. Any deviation will impair the operation of the boiler.

- Attaching a protective screen outdoors. This is a steel plate fixed to the outside of the wall. It protects the wood from overheating and reduces the risk of fire.

Pipe protection with insulating material Source petropech.ru

- Tee installation. A vessel for collecting condensate is attached to its lower part.

- Installation of support. It is screwed to the wall or rests on the ground. Its task is to maintain the vertical part of the structure.

- Chimney connection. Condensation should not get into internal joints. Every meter the structure is fixed to the wall with brackets. During fastening, a building level is used to maintain the strictly vertical position of the pipe. The last clamp is installed under the roof.

Lastly, a protective fungus is put on the pipe.

Service life of the external chimney

The service life of the structure depends on the material of its manufacture and correct installation. When used correctly, ceramic pipes will perform their function for up to 40 years. A brick chimney can be used for more than 50 years. Stainless steel will have to be replaced after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A high-quality sandwich system will last up to 20 years. Structures last longer if heating equipment runs on gas or pellets.