If the family uses their own water supply, then they will need a caisson for the well. This is a structure that forms a special chamber in water and the adjacent wet soil, impervious to moisture. It helps protect against freezing and runoff. This is especially important for areas where there is no central water supply. Every home owner faces the task of preparing for the use of all systems. We recommend that you arrange everything correctly so that you don’t have to redo or repair it in the future.

Well caisson - what is it?

A caisson for arrangement is a waterproof tank made of metal or plastic.

Structures made from concrete rings are considered an obsolete option and are falling out of use. The reservoir can be square or rectangular in shape. Tank height: not less than 2 m, base area - not less than 1 sq. m.

Well caisson functions:

- Saving free space inside the house.

- Protection of the mouth from groundwater ingress.

- Protection of installed equipment from freezing in winter.

- Providing quick access to installed equipment.

- Silencing noise from a running pump.

produces caissons for wells under its own brand. This solution allows us to guarantee the quality of the tanks we install. And also reduce the price of equipment installation for customers.

Buden is interested: How to equip a water well after drilling - popular schemes.

Figure 1: Plastic caisson with equipment installed inside.

General information

Considering the caisson, what it is in construction, the structure can be defined as a hollow sealed chamber, mostly round in shape with a diameter of approximately 1 m, which is installed on top of the well pump.

Most often, the caisson is placed in a hole dug in a circle around the casing, with the casing's mouth located at a depth of 1-5 m. At the bottom of the device there is a hole for the well, at the top it is closed with a hatch for insulation. A ladder must be installed inside, which allows you to descend to the downhole equipment.

The ladder allows you to conveniently descend for installation, repair or routine maintenance of equipment Source eurolos.ru

Why a caisson is needed for a well is to protect the pumping station from bad weather conditions, seasonal temperature fluctuations, and the penetration of underground, waste and melt water.

Characteristics of a metal caisson

Metal caissons are made of steel 4-6 mm thick. Their design includes only one weld seam. The sealed container protects the mouth from dust, from groundwater, and from freezing. The metal structure can withstand strong soil pressure well. An insulated hatch is placed on the neck. Inside there are steps made in the form of brackets.

But the metal caisson has one serious drawback. The metal is destroyed by contact with groundwater and aggressive substances contained in the soil. An anti-corrosion coating can slow down this process, but not stop it completely.

To waterproof steel tanks, we coat their walls with bitumen varnish. It is possible to additionally cover the walls with waterproofing.

We will help you with choosing a caisson

Click on the button and order a call back from the Aqualux+ manager.

Order

Service life of a metal caisson: 25-30 years.

Figure 2: Metal caisson - schematic section.

Characteristics of galvanized caisson

Galvanizing improves the anti-corrosion properties of the metal. Unprotected steel easily reacts with oxygen contained in the soil. This process is called oxidation. Iron-oxygen compounds are unstable and easily destroyed. After their destruction, oxygen penetrates deeper, causing the oxidation of subsequent molecules. This is how metal corrosion occurs.

Zinc has a different mechanism of interaction with oxygen. As a result of oxidation, a protective film consisting of oxides is formed on the surface of zinc. The film prevents oxygen molecules from penetrating deeper into the metal. Also, the zinc layer provides additional protection against moisture.

Metal sheets 4 mm thick are subjected to galvanizing. Galvanized sheets are used for welding containers of various shapes. Galvanizing sheets, rather than finished products, ensures an even application of the protective layer.

Service life of a galvanized tank: 35-40 years.

Figure 3: Galvanized caisson with increased durability.

Characteristics of plastic caisson

Installing a plastic caisson is the best option for an artesian well. The plastic tank is not destroyed by water. A plastic tank will last 50-60 years. The service life of the tank coincides with the service life of the artesian well.

For the manufacture of caissons of the Aqualux Plast line, polypropylene is used. The tank design has 8 stiffening ribs. They increase the strength of the tank walls by bearing soil pressure. To increase the useful volume of the tank, we moved the stiffening ribs outward, to the outer surface of the walls.

The design of any model includes:

- Plastic tank.

- Sealed flange.

- Insulated hatch.

- Sealed hatch.

- Plastic ladder.

- Optional: locking eyes.

Reliable welds can withstand direct blows from a sledgehammer. There are hooks on the bottom of the tank for fixing in the ground. The temperature inside the plastic tank does not fall below +3C.

Prices for plastic caissons Aqualux Plast follow the link.

Figure 4: Construction of a plastic caisson.

Differences of rectangular round shape

Both metal and plastic tanks differ in shape. Often the shape depends on the volume of the tank. In the Aqualux lines, small-volume tanks are made cylindrical, and large-volume tanks are made rectangular.

Cylindrical options are easy to install. It is easier to dig a round pit than a pit with right angles. The absence of corners ensures uniform pressure on the walls of the tank. This reduces the likelihood of leaks. Due to the absence of corners, the usable volume increases.

Rectangular options are larger in volume. An adult can stand and walk freely inside the tank. Corner connections are made by welding. The corners are strong and reliable.

Shape options do not affect the properties of the surface and its service life. Shape is not the main indicator for choosing a caisson.

How to make a caisson without costs or helpers

Some varieties can be created without professional help and the purchase of expensive components. It’s worth trying to assemble a brick or concrete container; some specialists will even be able to weld a product from sheet iron. But at home, the quality is often worse than in production. How this is done is described below.

Warm brick option

This is one of the most budget-friendly and easiest ways to create protection for your water supply. To build it, you will need building materials of almost any quality left over from the construction of a house or other outbuildings. You will also need some concrete and sand.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Subsequence:

- a pit is dug taking into account all parameters;

- a concrete pad is poured;

- a wooden box is assembled to provide an even frame and protect against soil pressure;

- dilute the cement mortar in a ratio of 1:4;

- installation is in progress - it is important not to forget to insert the sleeves in certain places;

- so that the walls fit most tightly to the insulation, spacers are placed inside;

- a square steel sheet with the center on the side is often used as a cover;

- After complete drying, the inside of the container should be treated with waterproofing.

Warm method from concrete pouring

This method of obtaining a container for equipment and a well requires much more work, but it is also possible to do it yourself. It’s easier to do it if you turn on the concrete mixer or order the required amount of ready-made mortar. Mixing by hand is long and difficult.

Subsequence:

- dig a hole of a suitable size;

- compact the bottom, lay an insulating film, fill with the mixture;

- cut sheets of insulation according to the dimensions of the cube;

- Weld the mesh on the outside, put the formwork on the inside;

- to build the walls, you will need boards or panels tightly fitted to one another, which are fixed to the timber;

- pour concrete, preferably using a concrete mixer or machine;

- bayonet, tap or otherwise get rid of bubbles and unevenness in the mass;

- cover with cellophane so that everything dries without cracks;

- use a finished slab as a lid or fill it in a similar way;

- After all actions are completed and the surfaces have completely dried, everything needs to be treated with waterproofing.

Comparative table of caissons "Aqualux"

For comparison, we took models of the same volume, made from different materials:

| Option | Wall material | Wall thickness (mm) | Life time | Price, rub) |

| "Aqualux+ 1" | steel | 4 | up to 30 years old | 29 000 ₽ |

| "Aqualux Zinc 1" | Cink Steel | 4 | up to 40 years old | 31 800 ₽ |

| "Aqualux Plast 1" | plastic | 6 | from 50 years old | 42 000 ₽ |

You can see that metal tanks are cheaper than plastic ones. But their service life is shorter. Choose the type of caisson, taking into account the service life of the well and the budget for the work.

Disadvantages of a caisson made of concrete rings

We do not recommend using the option with reinforced concrete rings. There is one popular misconception associated with the installation of rings. It is believed that they are not destroyed by water, and the structure can last up to 100 years. But actually it is not.

Although concrete is indeed a durable material, it is not suitable for well improvement. The rings will gradually deteriorate after installation. But this is not the main drawback of the scheme.

The main problem is that the pipe insertion into the well cannot be made completely sealed. Water will constantly accumulate inside the lower ring.

Microcracks will form in the surface of the concrete, through which water will enter the well. Sooner or later it will penetrate the wellhead and mix with drinking water. This will lead to contamination of the source. Concrete rings are difficult to repair: leaks will occur with a certain frequency.

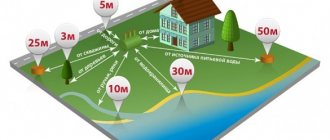

Buden is interested: The correct distance from the well to the house according to the standards.

Figure 5: What are you drinking? Groundwater inside the caisson entered the well.

Main types

Caissons for wells come in various geometric shapes, but cylindrical and round designs are the most popular. Sometimes you can find combined caissons; they have the shape of a rectangle at the bottom and a circle at the top.

Taking into account the material, the following protective systems are distinguished:

- plastic;

- iron;

- reinforced concrete.

In rare cases, brick is used for construction.

The materials used to make the caisson determine its performance. They all have their pros and cons.

Caissons come in different shapes, but mostly round ones are installed Source lider-skvajin.ru

Plastic

The most popular are plastic products. This material has excellent tightness, caissons made of plastic are easy to install, the surface is strong, durable, while it is absolutely not subject to corrosive processes and is inexpensive.

The structures are made from a solid cylinder or polymer sheet material 6-35 mm thick, taking into account GOST regulations; the material usually contains plasticized polyvinyl chloride, polyethylene, fiberglass, and polypropylene.

Main advantages:

- The material retains its characteristics for a long time, it is not exposed to rust and does not rot.

- The service life of plastic products is about 30 years (taking into account the wall thickness).

- The surface allows for excellent tightness and waterproofing.

This is what classic plastic caissons look like Source ytimg.com

- The low weight of the product facilitates the delivery and installation process. The medium-sized structure can be mounted without the use of special equipment.

- Plastic has excellent thermal insulation properties, due to which an additional insulating layer is not required in areas with moderate climatic conditions.

With all the described advantages, plastic structures are relatively inexpensive.

Flaws:

- Due to its low mass, during floods, a plastic product can rise from the ground. Therefore, a cement-sand cushion is poured into the base of the tank, this leads to an increase in the cost of the caisson.

- There is a possibility of surface deformation due to soil compression. This problem is partly solved by installing stiffeners.

Metal

The metal caisson for the well is not so popular. These products are characterized by high strength and maintainability. Taking into account GOST regulations, iron structures are made of steel with a thickness of 5-10 mm.

Insulation of the metal caisson is mandatory, but this can serve as part of the landscape design Source strojdvor.ru

Carrying out anti-corrosion, hydro- and thermal insulation work during installation is a mandatory requirement, in particular for products that are made of stainless steel.

Attention! The ideal shape is round, since this design has a minimum of connections.

Main advantages:

- Long service time. When all conditions of installation and further operation are met, iron structures last about 50 years, this can be compared with the service period of a directly dug well.

- Increased strength. Steel can better withstand pressure, unlike plastic products, this significantly reduces the possibility of cracks forming on the surface during soil heaving.

- Much easier to install, unlike reinforced concrete products.

- Good sealing. If there are no cracks in the joints, then the iron structure is guaranteed to be able to protect the installed equipment from the penetration of groundwater.

- Sustainable location. The relatively large weight does not allow the caisson to rise during floods.

But if the installation technology is not followed, the sealed metal caisson may float up Source domkesson.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Flaws:

- The main disadvantage of metal structures is their susceptibility to the development of corrosion processes. The need for waterproofing leads to additional costs.

- A factory-made iron caisson for a well (especially one made of stainless steel) is much more expensive, unlike plastic products.

- The relatively large mass, which prevents swelling, sometimes creates certain difficulties during installation. Most often, during installation it is necessary to use special equipment.

- Low thermal conductivity. To prevent freezing, iron structures must be insulated; this also increases the cost of the caisson.

Reinforced concrete

Considering what a caisson for wells is and the materials for its manufacture, it is necessary to note reinforced concrete structures, which are not very popular.

Concrete rings are difficult to install and impractical to operate Source beton-house.com

There are several options for these products:

- The structure is made by pouring concrete into the formwork with reinforcement in it. Filling wells come in any shape.

- During installation, reinforced concrete rings are laid on top of each other on a previously prepared foundation. The individual elements are connected using a waterproofing compound. When the caisson reaches the required height, a slab with a hatch is installed on top.

A caisson for a well made using the first method is characterized by high strength, but it also has many shortcomings. The main ones are low hygroscopicity and large mass, because of this the caisson can sink into the ground.

Attention! Due to the large number of shortcomings, reinforced concrete structures must strictly comply with the GOST 8020-90 regulations: in terms of water permeability, frost resistance, actual strength, corrosion protection, concrete layer thickness, steel grades for reinforcement.

When installing concrete rings you cannot do without special equipment Source ytimg.com

Main advantages:

- Long service time. If the technological process and subsequent operating conditions are observed, reinforced concrete caissons last up to 100 years.

- Increased strength. Even serious ground displacement will not damage the integrity of the product.

- Relatively inexpensive cost of manufactured reinforced concrete chambers.

- The large weight successfully prevents the structure from floating up during an increase in groundwater levels.

Flaws:

- The main disadvantage of reinforced concrete products is the connections between the installed caisson elements; this is the most vulnerable link.

- Poor waterproofing. Concrete surfaces are hygroscopic; water that gets inside over time destroys the walls of the rings and causes corrosion in the reinforcement frame.

- Very large weight often leads to subsidence of the well into the ground, which sometimes leads to disruption of the operation of downhole equipment. The significant mass also creates certain difficulties during transportation and installation.

- Poor thermal insulation. Concrete surfaces must be insulated.

If you install it yourself, there is a high risk of leaks Source provodoprovod.ru

What is well construction?

Construction is a set of works that are carried out to create a water supply system. This concept usually includes the installation of equipment and connection of a residential building to the water supply.

We construct wells according to ready-made diagrams drawn up by engineers. All kits available for installation are listed in the table:

| Option name | Model | Pump type | Cost, rub.) |

| "Economy+" | "Aqualux+ 1" | Waterstry 2-70 | 135 926 ₽ |

| "Standard+" | "Aqualux+ 1" | Aquario 75-75 | 139 420 ₽ |

| "Comfort" | "Aqualux Plast 1" | Aquario 75-75 | 161 320 ₽ |

| "Premium" | "Aqualux+ 1" | Grundfos 2-70 | 228 676 ₽ |

| "Premium+" | "Aqualux Plast 1" | Grundfos 2-70 | 250 576 ₽ |

| "Lux" | "Aqualux+ 1" | Grundfos 3-65 | 174 326 ₽ |

| "Lux+" | "Aqualux Plast 1" | Grundfos 3-65 | 196 226 ₽ |

A warranty is issued for the installed equipment. System maintenance must be carried out once every 6 months.

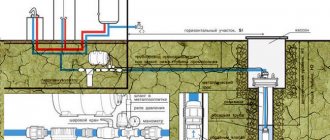

Caisson installation technology

Installation begins with digging a pit. You can dig a pit and a trench for water pipes manually. This does not require the use of an excavator. The width of the pit should be such that there is at least 15 cm between the walls and the ground. The depth of the pit should be 15 cm less than the height of the tank.

Figure 6: Pit preparation.

The base of the pit is leveled. The casing pipe is cut above the level of the bottom of the pit. A hole is cut in the bottom of the tank for installation on the well. After the caisson is lowered into the pit, the connection point is sealed and insulated. A sleeve is installed at the connection point. Sealed connections are provided for the entry of pipes and cables.

Figure 7: Lowering and anchoring the caisson.

When installing the plastic caisson, a concrete ring is mounted on the neck. It serves to anchor the tank and prevents the tank from moving or floating up. The mass of the ring compensates for the low weight of the tank. After connecting the equipment, the tank is closed with a hatch.

Figure 8: Installed caisson.

Video description

To see what errors can occur when installing a caisson, watch this video:

Also, the diameter of the installed casing tube must be 500 mm larger than the cross-section of the pressure pipe, the height of the caisson itself is at least 2400 cm, while the upper chamber must be above ground level, to prevent rainwater from entering it. For the same reason, the hatch must be sealed.

An installed caisson on the territory of a private house should not disturb residents Source strojdvor.ru

Is it possible to install a caisson yourself?

Proper installation of the caisson requires professional skills and knowledge. Installation errors will lead to displacement of the tank. After self-installation, there is a high risk of flooding the tank with groundwater.

Installing the tank is quite difficult. To install the container you will need a large set of tools and materials. Installing the tank will require the efforts of 2-3 strong men. To lift a metal tank and install it in a pit, you will need special equipment. Weight of metal containers: not less than 230 kg.

Professionals will install the equipment in a few hours. Installing the equipment yourself will take from several days to a week.

By ordering equipment installation from professionals, you will save time, effort and money. You will receive a guarantee for all elements of the water supply system. (If you install it yourself, the warranty may not apply.)

Order installation from professionals

Click on the button and order a call back from the Aqualux+ manager.

Order

Summarizing

Installing a caisson simultaneously solves many problems. The water supply at home immediately becomes safer; owners do not have to worry about being without water when frost sets in. At the dacha, this device can be used as a warehouse or cellar, equipping it with a reliable lock.

Now you can buy a durable, ready-made plastic or metal caisson, or make it yourself. The choice is up to you. The main thing is not to forget that without this equipment, normal operation of the well is simply impossible.

What equipment is inside

A pumping station is needed to lift water from depth. This is one of the key elements of the water supply system. A stable supply of water to the system depends on the operation of the pump. We install branded pumps, the quality of which is beyond doubt:

- Aquario.

- Waterstry.

- Grundfos.

The hydraulic tank is not needed to store a supply of water, although this is one of its functions. But the main function of the accumulator is to equalize the pressure in the system. Inside the hydraulic tank there are reserves of liquid and air. By equalizing pressure, the hydraulic tank reduces the number of pump starts, extending its service life.

The automation system controls the operation of the equipment. The kit includes a pressure switch, flow switch, dry running switch, frequency converter, pressure gauge and other devices. The automation system controls the flow pressure and protects devices from breakdowns.

How the camera works

The device is a sealed container. Previously, the design was used to operate water with water, then the scope of application increased. They learned how to install devices on a well to protect its head.

If you live permanently in a private house, regular operation of the well is required in different conditions and seasons, which makes its operation difficult.

At low temperatures, the liquid rising from depth freezes, which causes the pump to rupture.

Attention! The caisson guarantees equipment protection under negative environmental influences.

The head must have a temperature above zero for the well to operate continuously. For these purposes, a caisson is used.

A special sealed chamber is dug into the ground and fixed on top of the casing. If you insulate the structure, the well will maintain a high temperature. Hermetic properties do not allow drains and groundwater to penetrate inside, and serves as protection against moisture for sensitive devices.

It is convenient to install a pump in the caisson for pumping water. The device will be protected from groundwater, rodent attacks, and various insects.

If closed, access to the well head will be limited for unnecessary people and pets.

All elements intended for use of the well are easily placed inside the caisson:

1.cleaning and filtration systems, reverse osmosis system.

2. pumping device.

3.pipes with shut-off valves having any type of drive.

4. control unit for the pump, water supply system.

The container has a neck that closes with a hatch at the top.

The height of the tank is over two meters, since the length of the casing pipe inside the tank is one to two meters.

Products can be of different geometric shapes: circle or rectangle. The circular cross-section must be more than one meter in diameter so that a person can descend into the chamber.

Important! The main thing is to choose the right size of the chamber inside the well.

The caisson is insulated from the outside.

The bottom of the tank has a special hole for the entrance of the casing pipe. On the sides of the chamber there are additional holes for connecting electrical cables and water pipes. A service ladder is installed inside the structure; the most convenient option is a folding ladder.

Is it possible to do without a caisson:

1. you will have to equip the well so that it goes into a warm room, for example, a basement. Then the equipment will not freeze, but the noise from the devices will be heard into the house.

2. You will need to install a downhole adapter in the role of a compact adapter installed in the casing pipe. The cost of the structure is cheaper than a caisson, it is easy to install. The downhole adapter complicates inspection work and well repairs. In this case, all devices must be installed inside the house.