A grinder (angle grinder - angle grinder) can be found in the household much more often than a chainsaw or circular saw. In this regard, a logical question arises - is it possible to saw a tree with a grinder and how to do it correctly? There are several aspects that make woodworking non-standard, especially with regard to an angle grinder. Our article will give detailed explanations about whether it is possible to cut wood with a grinder, saw logs and vertically standing trunks, how and with what cutting devices this should be done.

What operations is the grinder intended for?

An angle grinder (grinder) is an almost universal tool for housekeeping.

Grinder models are classified according to power, engine speed and other parameters. Safety of operation and ease of use are ensured by end handles and side handles, a protective casing, a rotation regulator, a soft start system, an automatic brake, and other devices.

Household grinders are connected to an alternating current network of 220 volts, professional ones - to a three-phase network of 380 volts.

Any angle grinder is designed for the following operations:

- Cutting and grinding of hard materials;

- Polishing surfaces and sharpening cutting tools.

By hard materials we mean: metal, wood, concrete, brick, stone, ceramics, plastic and even tiles with glass (for the last two, special discs with diamond coating on the teeth are used). For safe and more convenient work, fastening devices for tables and workbenches are manufactured industrially for grinders. In this case, the angle grinder turns into a sawmill, sharpening machine, woodworking, grinding or cutting stationary tool.

How to cut plywood without chipping?

Plywood is several layers of wood veneer, connected to one another using an adhesive. If you do not follow the technology for cutting such material, the teeth of the cutting blade will tear off pieces of the top layer. The resulting defects are called chips.

You can cut plywood with any of the following tools:

- manual or electric jigsaw;

- circular saw;

- with a hacksaw.

Each of these tools is recommended for use under certain conditions.

Is it dangerous to work with an angle grinder?

Like any other power tool, an angle grinder poses a potential danger to people who do not comply with safety regulations and neglect personal protective equipment. When working with angle grinders of any class, you should remember that:

- Grinder discs have a very high rotation speed, sometimes more than 10,000 rpm;

- The protective cover around the drive does not completely cover it;

- When grinding, polishing, or cutting any hard material, fragments and abrasive particles fly off the disk, and the casing does not always protect against them;

- A powerful three-phase angle grinder is difficult to hold evenly in your hands, especially if the structure of the material is uneven. This remark especially applies to wood - resin, knots, and wire embedded in the trunk may be encountered in the path of the cutting blade during the sawing process.

Question to an expert

What to look for when choosing nozzles?

When choosing disk attachments for working with an angle grinder, you should pay attention to the physical condition and quality of manufacture of the devices: the attachments must be free of visual defects, and quality certificates must be attached to them.

For housework, the optimal option for an angle grinder is with a disk ⌀ 115 or ⌀ 125 mm; for a personal plot or professional use – from ⌀ 180 mm to ⌀ 230 mm. If this is not a production necessity, buy an angle grinder for a single-phase supply voltage of 220 volts.

Disc BISON multi-cut 125

Which comes first: felling or trimming?

Some trees do not need pruning, while others cannot be felled otherwise. Especially if gas pipelines or power line wires are located near the crown. As we have already said, the main purpose of pruning is to balance the tree, so it is not necessary to trim the branches on the side where you plan to collapse.

The height of the tree is no less important. If you cannot clear an area of the required length under the tree, the trunk needs to be shortened. Naturally, before this you will have to cut off all the lower tiers of branches, sometimes you even have to cut off the branches from the side of the blockage. What to do - sometimes the crown is intertwined in a very bizarre way.

When working in the garden and green spaces, neighboring trees often interfere. If this is not dead wood, it is not advisable to touch them. It is much better to cut the branches in sections, starting with the one furthest from the trunk that can be safely reached. Even if small fragments of branches get stuck in your own or neighboring crown, an assistant can easily pull them down and to the side.

We can definitely say that you should start felling only if:

- After treatment, the appearance of a tree clearly makes it clear that it will fall exactly the way you want it to.

- The height of the tree is 30–50% less than the length of the cleared area, similar to the width of the crown.

- There are other trees or stationary objects nearby to which guy ropes can be attached to guide the trunk when it falls.

What is the difficulty of using an angle grinder with wood?

The first thing that experts pay attention to is that the blade rotation speed of an angle grinder is much higher than that of a circular saw. Therefore, if you will be cutting not only metal and concrete, but also working with wood, buy an angle grinder with a disc rotation speed controller and soft start.

To cut a log, saw a tree with a grinder or fell a trunk, you need to work at medium speeds - at a high speed of rotation of the nozzle, any obstacle in the path of the cutting edge (wire, nails, resin, clamping the disk, incorrect angle of the disk, multidirectional wood fibers) can provoke a powerful a jerk of the tool, and you may simply not be able to hold the grinder in your hands. In addition, you can cut down a tree on your site using a grinder only by holding it horizontally, and this is a high risk of injury.

Before starting work, determine which side it will be more convenient for you to screw in the handle-holder of the grinder, and at what angle you should turn the protective casing in order to maximally protect your eyes and face from sawdust.

Pre-route the power cable along a safe route and not in the path of a falling tree.

Important! Under no circumstances should you cut a tree trunk or a lying log with a grinder without adjusting the rotation speed of the blade. Also, do not use metal discs, grinding or polishing attachments for this purpose. It is best to use a wood disc with large teeth.

Do it yourself or order it?

A custom cut will be smoother

High-quality sawing of chipboard is difficult to do manually due to the large size of the sheets. The dimensions of a standard slab are 2440x1200, and this is not the limit. However, if you work with chipboard or MDF quite often, it makes sense to get an expensive tool and work for your own pleasure. If you only need to cut a few sheets, you can go two ways:

Cut the slabs yourself using available hand tools;

Order cutting of chipboard in a specialized workshop.

What to choose is up to you, and we will consider each of these options.

Advantages of an angle grinder when working with wood

The engine of any angle grinder is not very powerful, and the necessary increase in power and speed occurs at the gearbox. The transmission mechanism makes it possible to process almost any solid material with high efficiency and a degree of safety.

Woodworking at home is not very diverse. This is work with boards, timber, slats, multi-layer plywood, chipboard or fiberboard, and sometimes cutting logs or sawing trees on the site. For standard construction and repair operations, a medium-power grinder (600-800 W) with a disk diameter of 115-125 mm is quite sufficient. But in order to cut wood with a grinder, you need a disk with a diameter of 180-230 mm and increased power of the tool - up to two or more kW.

In addition to wood blades, you can attach a chain saw to the grinder. This is an ideal solution for sawing logs or thick boards. With a chain attachment, the question of whether it is possible to saw a tree with a grinder automatically disappears - of course, it is possible, and the result will be the same as when working with a chainsaw. The only note is to choose an angle grinder with a gear rotation regulator and soft start.

In addition to wood blades, you can attach a chain saw to the grinder.

Thin tall trees

Such cases must be reported separately. The work of removing them is often complicated by the inability of the arborist to climb on them: the trunk can bend or even break under the weight of a person. Therefore, a bucket truck is often used to fell such plants. If it is not possible to use it: the terrain does not allow it, there are no entrances to the object, then the neighboring shoots are used. An additional rope is hung on them - a safety rope. In addition to all this, thin trees are sometimes felled entirely, at the root.

September 2013 Photo: Kaleria Lapshina

Flaws

The level of safety is perhaps the only criterion that makes you think about whether it is possible to cut a tree with an angle grinder without risk to yourself and others. The problem with the grinder is that the disc cannot stop if there is an obstacle on the way, since the grinder gearbox is not frictional. Even an incorrect cutting angle can be a problem - there is a risk of clamping or twisting of the disc, which means there is a danger of a sudden jerk of the tool.

Not a single model of an angle grinder has a physical or electrical stop, unlike the same circular saw (tension belt) or an electric circular saw (saw electric brake). This means that when the disk is buried in wood, the danger of its sudden stop when colliding with an obstacle or from a sharply increased load on the nozzle area increases.

Therefore, recommendations from professionals will be as follows:

- Do not work on wood with soldered discs;

- Do not cut wood with an attachment that is not suitable for the material;

- Select the disk or length of the chain saw bar so that the cutting tool matches the radius or cross-section of the workpiece (log, trunk, timber, etc.);

- Cut thick wood only with a disk with large and sparse teeth; the forward movement should be progressively slow, away from you.

Cut thick wood only with a disk with large and rare teeth

Important! Under no circumstances should you remove the guard to capture more of the wood's body—it's better to make several circular cuts. Wear safety glasses when handling wood.

When is the best time to do it?

Most of all, gardeners are interested in when is the best time to prune branches. In fact, it is very important to choose the right time, because the condition of the tree depends not only on the skill of the gardener.

It is believed that the best time for the procedure is when the frosts have already ended and the growing season has not yet begun, that is, the sap in the branches does not move very quickly. As a rule, pruning is carried out at the end of February or in the spring, at the beginning of March. In cold regions, the timing may shift due to prolonged frosts, and in some cases pruning can be done in the summer, in June, for example, in the case of sanitary work, when it is necessary to urgently save the tree. This has to be done when the plant is infected with powdery mildew.

Autumn pruning is also acceptable, when the entire harvest has already been harvested and the circulation of tree sap slows down. The best time for autumn pruning is late September and early October. Many gardeners note that it is after autumn pruning that trees begin to grow well.

But in May it is extremely dangerous to carry out the procedure, since in this month the tree is actively growing, the leaves are blooming, and if the weather permits, then abundant flowering begins. But when it comes to pruning, you need to focus not only on time, but also on tree species. As a rule, pome trees, such as apple or pear, are always pruned first, and only then do stone fruits. Weather also plays an important role in pruning. It is better to start processing trees when the sun is shining and the air temperature does not drop below minus five.

What attachments are recommended for working with wood?

The attachments for the angle grinder recommended by experts have already been listed, but here is a list of them again:

- Chain milling cutter or saw - the attachment is equipped with a device for rotating the cutting tool, which helps prevent the tool from pinching and jerking;

- A new product from tool developers is a chain saw blade. Recommended diameter – up to 230 mm;

- Ordinary disc for wood. The diameter, disc size and number of teeth are selected depending on the task at hand.

Grinding wheel

In addition to sawing and cutting, wood can be sanded and cleaned. For this purpose, emery and grinding discs are produced.

Instrument care

To ensure that the power tool is always in working order and in good working order, it is necessary to care for it and perform the following actions:

- Regularly sharpen and change removable working parts.

- The tool is stored in a protective container in a dry place - this will prevent rust from appearing on the elements.

- Regularly inspect the instrument to ensure its integrity.

- It is important to regularly lubricate the tool mechanisms with specialized oil.

- If necessary, seal the device with sealing paste.

- Cleaning internal cavities from dirt.

Wood carving is impossible without the use of hand tools; read about what you may need in your work in the article: “Basic tools for wood carving.”

Reminder when working on wood with an angle grinder

The main danger when working with an angle grinder is the sudden and unpredictable destruction of the disc when it encounters an obstacle or when the angle grinder is used incorrectly. Therefore, we recommend that you observe the following precautions and safety measures:

- Before work, check that the protective cover is securely fastened. When working, the casing should protect your face - turn it this way;

- Inspect attachments and discs for defects and wear;

- Install the side handle holder on the desired side. Turn on the angle grinder and check its operation at idle speed at different disk speeds;

- Inspect the material being processed and remember the location of large knots;

- When working, hold the tool with both hands, take a stable position;

- While sawing, inspect the blade for damage and watch the power cord;

- If the disk jams, turn off the grinder;

- When moving around the site, the wood saw must be turned off;

- Measure the diameter of the log - you should use it to choose the radius of the disk;

- Do not turn on the angle grinder with other people;

- Do not touch the blade or accessory immediately after it has stopped - the temperature of the cutting tool may be too high.

Important! Do not work with an angle grinder without a protective cover. When sawing, cutting or grinding, you do not need to exert much force on the tool. Do not point the grinder towards yourself - the movement of the cutting edge should be directed only away from you.

Why are they falling?

The first, and also the main, reason for the fall of trees, including tall ones, is a poor, weakened condition associated with diseases and any other damage to the trunk or root system. A healthy plant can withstand very serious loads, such as heavy winds, for example.

The second reason is the large windage. Tall trees grow in conditions of fierce competition with each other for a place in the Sun. They quickly stretch upward, and therefore their trunks are usually straight, without branches in the lower and middle parts. The crown is formed closer to the top and becomes the “sail” that “catches” the wind, causing the trunk to fall.

April 2014 Photo: Kaleria Lapshina

A clear example demonstrating greater windage is the Scots pine, widespread from China to the British Isles. In the European part of Russia it can be found everywhere. How can one not recall the paintings of I. I. Shishkin, especially his famous “Ship Grove”, which depicts tall, slender mast pines, with cone-shaped crowns crowning the very tops!

Another reason for the fall may be the root system. Common spruce, typical of the northern regions of Europe, has a shallow root system that does not securely hold the plant in the ground. Along with the trunk height of several tens of meters, this leads to poor wind resistance.

April 2014 Photo: Kaleria Lapshina

How to cut tiles without a tile cutter

When carrying out various construction work yourself, there is often a need to cut ceramic tiles at home. To do this, it is not at all necessary to have a professional tool - a tile cutter. Let’s make a reservation right away: We are not talking about constant work and large volumes, but about small batches or even one-piece products. In such cases, it makes no sense to buy an expensive tool; you can get by with improvised means.

️ ′′ How to properly cut wood with a grinder ′′ 100% WATCH TO THE END!

How to cut plywood - recommendations and instructions

How to cut plywood, given that its sheets have a minimum size of 12.2x12.2 cm. After all, during construction and repair work, fragments of smaller parameters and different shapes are needed, sometimes even curved. Cutting this material cannot be avoided as it has become a necessity in most cases.

Tips for cutting with a saw

How to cut plywood without chipping will become clear after familiarizing yourself with the basic recommendations regarding the work process:

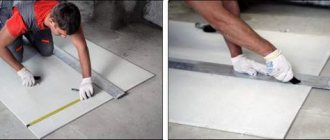

- The cutting of plywood sheets is carried out on the flooring with absolute support;

- It is necessary to adjust the depth of cut, which can affect the quality of the cut;

- When cutting longitudinally, a long, straight-shaped object is used as a guiding tool;

- Before making a cut, you should check the guide;

- It is recommended to cut at high speed, which should not be changed;

- When cutting with a circular saw, discs must be selected with the largest number of teeth;

- It is recommended to make a crosswise cut using adhesive tape.

Milling

How to cut 10mm thick plywood with a hand router, the following recommendations will tell you:

- The cutter is secured to the collet.

- The engine speed suitable for this operating process is set.

- The required milling depth is adjusted using a plunge limiter when working with plunge-cutters, or a specific value of the cutter overhang relative to the base is fixed - when working with edge cutters).

- A guide bearing or ring for working with edge cutters or other equipment is installed to help ensure the required path of the cutter.

The following basic safety measures are noted when using a router when cutting plywood sheets:

- Fastening the cutter and setting it up must be done with the power cord unplugged from the outlet.

- Operating a hand router requires careful attention and concentration. During milling, you need to stand firmly on your feet and firmly hold the router with your hands. It is not allowed to work while tired or distracted to avoid injury.

- The processing element must be firmly fixed, otherwise it may be torn out of place by the cutter and thrown with great force and speed.

- You need to be wary of possible impacts when the tool touches the material. To avoid impact, you need to hold the router firmly, pressing it securely to the base and move it with smooth movements. Clothing should be chosen to work without loose parts that could catch the tool.

- It is better to avoid inhaling fine dust that occurs during the milling process. It is sucked out with a vacuum cleaner. You can use a respirator.

Thus, it became clear how you can cut plywood and basic recommendations with the principles of work when cutting.

Sources:

https://eco-citi-lk.ru/interer/kak-rezat-plitku-bolgarkoj/ https://fixmaster74.ru/plitka/chem-mozhno-rezat-plitku-esli-net-plitkoreza.html https:/ /profanera.ru/montazh/chem-rezat-faneru-rekomendatsii-i-instruktazh.html

How to cut plywood without chipping with a hacksaw?

To do this, the material must be securely fastened to the workbench. It is also recommended to treat the site of the future cut along the entire length:

- with PVA glue using a brush 1–2 cm wide (cutting can begin after it has completely dried);

- with a sharp knife, making two parallel grooves.

To speed up the process, PVA can be replaced with electrical tape or masking tape.

When choosing the “two grooves” option, they are applied with a sharp knife, under a metal ruler, in three steps. The cut is made between parallel lines that prevent chipping. The load of the hacksaw blade should be on the plane of the plywood sheet.