Interfloor staircases with a turn are used inside and outside buildings: in multi-level apartments, multi-storey private houses, in detached buildings, commercial and industrial buildings. They perform decorative and functional tasks in the interiors and exteriors of buildings.

Each similar metal staircase to the second floor must meet safety standards, SNiP and GOST. Design, production and installation should only be entrusted to trusted companies with extensive experience.

What are the main advantages of a turning staircase?

This design is ideal for small spaces where it is important to save more space.

In this case, the key feature is the possibility of installing additional steps if the opening width is about a meter. The staircase can be rotated in several ways - by 90° and 180°, and the latter design looks very “fragile” in appearance, but does not take up a lot of space.

Types of turning stairs:

- Curvilinear, used quite rarely due to the fact that you will not be able to feel the necessary stability under your feet, because when creating it you will have to strictly observe the width of the fitting end - it should be at least 10 cm;

- A curved staircase is considered the most economical type. Such designs, in turn, are divided into screw, quarter-turn and half-turn, differing in the angle of rotation. However, it is worth taking out spiral staircases, which are considered the most practical, especially if the counter is placed in the middle when arranging it. They are most often made of either wood or metal. Their key feature is the possibility of arrangement in a small area, but there is also a minus - metal stairs are not entirely convenient.

Briefly about the main thing

When the small area of the room does not allow installing a straight flight of stairs at the required angle, then a more compact design can be used. A staircase with winder steps will fit perfectly into any interior and perform the functions of a lift no worse than other structures. And most importantly, it will save space and provide a comfortable lifting angle.

But in order not to spoil the design of the room, you need to choose a decent model. After all, the same staircase can look completely different. This also applies to materials that will be involved in construction and design solutions. But the most important thing when choosing such a complex structure is competent calculations. They are either performed independently or entrusted with the work to specialists.

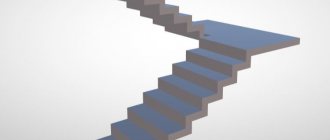

Parameters of a staircase with 180 degree winder steps

3d calculation of a staircase with a 90 degree turn

Rice. 1 General drawing of the stairs

- Y - opening height - usually determined by the height of the floors of your house

- X - length of the opening - depends on how much space you can allocate in your house for a staircase

- E - width of the stairs - depends on how much space you can allocate in your home for the stairs

- Z - thickness of steps - geometric parameter of the material (for example, boards) from which you plan to build the stairs

- F - step protrusion - the distance by which the upper step will hang over the lower one

- C - total steps - how many steps will it take for you to most comfortably move from floor to floor

- CP - turning steps - depends on your preferences and geometric characteristics of the staircase

- P - steps on the lower string - the number of steps before the turning ones depends on your preferences and the geometric characteristics of the house

Fig.2 Designation of steps

"Show risers: H" function

Fig.3 Execution of stairs with risers

You can build your staircase with or without risers. Calculating a staircase with 180° winder steps allows you to see what the structure will look like with both options.

Function “Upper step below the floor of the 2nd floor: SP”

Rice. 4 Execution of the staircase, with the top step below the floor of the 2nd floor

Depending on the relative placement of the structure and the floor of the upper floor:

- The upper plane of the top step is flush with the plane of the floor of the upper floor;

- The upper plane of the top step is lower than the plane of the floor of the upper floor by the height of the step.

The choice of one or another mutual placement may depend on: the thickness of the interfloor ceilings, the desired relationship between the number of steps and their height, the length of blanks for stringers and the length of the opening, the desired angle of inclination of the stairs, or simply the tastes and preferences of the owner of the house

Please note that in the figure in which the upper step is below the floor of the 2nd floor, the thickness of the interfloor ceiling is greater than in the figure in which the upper step is at the floor level of the 2nd floor. If the thickness of the ceiling is less than the height of the step, the stringer simply will not rest against the ceiling (therefore, when demonstrating the second option, this thickness had to be increased)

Function "Black and white drawing:"

Rice. 5 Black and white drawing of a staircase

It is advisable to use this function in two cases:

- If you are used to working with standard GOST drawings, and, accordingly, better perceive graphics without color content.

- If you are going to print the results of the calculator. Then you will spend less paint/toner and the visual perception of the drawings on paper will be better. And, of course, this function is used when printing on a black and white printer.

Function "Change lifting direction: LR"

Rice. 6 Type of stairs with different directions of ascent

A specific staircase, which is placed in a certain way in the house, can be approached from the side from two sides or only from one side - when the staircase is in contact with the wall. In the latter case, there are two options for placing the structure relative to the observer:

- Rise from left to right;

- Ascent from right to left.

This function allows you to visualize both of these options.

Calculation of a staircase with three turning flights

Making a wooden ladder: calculations and instructions for self-assembly

The main result of this calculator:

- Information needed to make bowstrings

- Information required for making steps

According to this information, the parts from which the structure is assembled are manufactured.

All other drawings show the final appearance of the structure: after joining the strings and steps to each other.

A special feature of this calculator is the implementation of two functions:

- Assessing the convenience of the stairs;

- Adjustment of staircase design.

Assessing the convenience of a staircase is carried out according to three criteria:

- Compliance of the design with the average stride length. According to this criterion, the sum of the step depth and the two heights should equal the average step length. The average human step length is 63 cm.

- Step depth. Comfortable step depth is from 28 cm. For a given opening length, the step depth can be adjusted by changing the protrusion.

- The angle of inclination of the stairs. The optimal angle of inclination of the stairs is from 30° to 40°. At tilt angles from 20° to 30° and from 40° to 45°, the comfort level of movement between floors is significantly reduced. Angles of inclination beyond the above limits can significantly affect the speed of movement between floors and the safety level of the stairs.

Based on the results of assessing a specific design, an indicator of the level of convenience is given for each of the criteria, and the staircase is assigned an overall level of convenience. The Three-Bay Staircase Calculator evaluates whether a staircase meets generally accepted criteria for convenience, but you should always remember that your staircase in your home should serve your purposes as efficiently as possible. And if, in accordance with these goals, you need to build the most non-standard staircase in the world - go for it. Any of them looks impressive and stylish: wooden, using metal, concrete or completely metal.

If there is a need to improve the design of the stairs, the calculator gives advice on how to do this:

- Reduce/increase the number of steps;

- Increase the protrusion of the steps (if the depth of the steps is insufficient for comfortable walking);

- Reduce/increase the length of the opening.

After adjusting the design, the normalized parameters will become closer to the ideal, but it is possible that such adjustments will have to be made several more times.

Instructions for the metal staircase calculator with a 90 degree rotation

Drawing of a staircase to the second floor in a private house

In order to calculate a metal staircase with a 90-degree turn using this calculator, you need to know the height of the floor, the size of the space that you can allocate for the staircase, the materials with which you are going to build it, and, of course, its purpose use. Before you start work, you need to carefully consider all the nuances: whether the staircase is adjacent to the wall, or in contact with elements of the interior of the house, and how this should affect the structure itself and the process of its construction. Perhaps, to choose the right option in terms of size and design, you will have to use a calculator to calculate and compare several. Before you start processing the material, make sure that the detail drawings correspond to the ladder that is suitable for you and your purposes. When building, attach the parts to each other, and the staircase itself to the house so that you can guarantee the reliability and strength of the structure for decades.

Stairs with metal strings presented on our website can be divided into categories according to four criteria that depend on each other:

1. Length dimensions

A. Maximum length - all steps are placed on one flight;

b. Average length - steps are placed on two flights;

2. Width dimensions

A. Maximum width - the steps are placed on two flights, the width dimension is regulated by changing the number of steps on the corresponding pair of strings;

b. Average width - the steps are placed on two parallel flights, the width dimension is equal to two widths of the stairs;

V. Minimum width - all steps are placed on one flight, the width dimension is equal to the width of the stairs;

3. Difficulty in manufacturing

A. Easy to manufacture - made from bowstrings and rectangular steps;

b. Medium complexity of manufacture - made from bowstrings, rectangular steps and platforms.

4. According to the type of strings and the fastening of steps to them, stairs are divided into two categories:

A. On supports - the string is a solid beam to which supports for the steps are attached;

b. With a zigzag bowstring - the bowstring consists of many mutually perpendicular parts located horizontally and vertically.

In each specific situation, the floor height is already specified. Based on your own preferences, you can choose the level of convenience: either the convenience criteria are met, or the staircase is flatter, or steeper, etc. Having this information, we can talk about the number of ascents (steps and platforms) in a particular situation .

Let's imagine that we have, for example, 13 climbs - steps and platforms. The design of a staircase is the shape of these rises (steps, landings) and how these 13 rises are placed relative to each other.

You can place all these 13 rises in one row along the length of the opening - “Metal staircase”, “Metal staircase with a zigzag string”. In this case, your stairs will have a maximum dimension in length, a minimum dimension in width and will not be difficult to manufacture. You can calculate a metal staircase to the second floor using a convenient and intuitive program.

You can place these 13 rises in 2 rows, rotated relative to each other by 90° (when viewed from above) - “Metal staircase with a 90° turn”, “Metal staircase with a 90° turn and a zigzag string” (for example, 4 steps per lower flight, platform and 8 steps on the upper flight). In these cases, your staircase will have an average dimension in length and an adjustable dimension in width. Calculating the steps of a metal staircase will help you correctly calculate the volume of material that will be needed to complete this work.

These 13 rises can be placed in 2 parallel (when viewed from above) rows placed next to each other - “Metal staircase with a 180° turn”, “Metal staircase with a 180° turn and a zigzag string” (for example, 4 steps on the lower flight, landing and 8 steps on the upper flight). In these cases, your staircase will have an average dimension in length and an average dimension in width.

Calculators for calculating metal stairs, which are presented on our website:

- Metal staircase - 1.a.-2.v.-3.a.-4.a.

- Metal ladder with a zigzag string - 1.a.-2.v.-3.a.-4.b.

- Metal staircase with a 90° turn - 1.b.-2.a.-3.b.-4.a.

- Metal ladder with a 90° turn and a zigzag string - 1.b.-2.a.-3.b.-4.b.

- Metal staircase with a 180° turn - 1.b.-2.b.-3.b.-4.a.

- Metal ladder with a 180° turn and a zigzag string - 1.b.-2.b.-3.b.-4.b.

This design is relevant in a situation where you want a staircase of two flights, but the amount of space in the place where it needs to be placed is limited.

general characteristics

This item is placed in openings that have a rectangular shape, close to square. For example, it could be a recess measuring 180x200 centimeters.

A 180º rotation can be implemented in various ways:

through the use of a small rectangular landing. It divides the entire structure into two parts, called marches. The platform is mounted in the stairwell and flight stairs extend up and down from it. This product is easy to install, but takes up a lot of space;

Use of the site

The use of winder steps of a staircase is the next way to turn. It saves space and makes the appearance more aesthetic;

Turning using winder elements

- the use of a semi-helical type of construction - it gives the staircase elegance. But, at the same time, such a product is difficult to manufacture and its price is quite high;

- combined options - there may be cases when both the platform and winder steps are used for turning.

Recently, modular staircases with a 180 turn have become quite a popular type of such structures. They consist of module elements. Thanks to this, they can be assembled easily and quickly like a children's construction set.

Modular product

The steps in the modules are made of pine using special technology. With its help, their service life is significantly increased. In addition, such parts are less subject to deformation.

180 degree rotation in modular designs is achieved using the same methods as described above. But most often a platform is used for this.

The advantage of such a product, in addition to ease of assembly, is ease of configuration. That is, the proposed planning solutions can be combined in different ways. This allows you to fit such a thing into any interior.

A modular staircase with a 180-degree rotation is assembled from metal elements. During assembly, they are inserted into each other and fixed in this position.

The design of modules allows you to create universal stairs. You can increase or decrease the height if necessary. You can also set different angles of inclination of the structure. Its value can range from 35 to 45 degrees.

There are various versions of such products available for sale. Depending on the specifications and brand of the manufacturer, a universal 180-degree staircase kit can have a very different cost. It can range from several tens to several hundred thousand rubles.

Manual calculation of staircase parameters

Despite the many nuances and pitfalls that are encountered in the work process, a wooden winder staircase can not only be built on its own, but also be designed without the involvement of specialists. This does not require any special knowledge; everything you need to know is written in our article.

Stair height

This parameter is the distance from the floor of the first floor to the floor of the second floor, that is, the thickness of the ceiling is also taken into account. Many people forget about this, rushing to calculate the structure for the walls of a living space.

When choosing a slope, the minimum distance to the ceiling is taken into account

The distance from the steps to the ceiling is calculated according to the person’s height; on average, this figure should not be lower than 190 cm, another 10 cm is added for ease of movement. Now this value can change upward, but not downward.

March length

The length of the future structure consists of several points:

- tilt angle;

- step width;

- number of steps;

- size of the landing.

And you should start by taking measurements of the space available for the stairs and subsequently adjust the project to the standards and norms.

Stair width

The basis of all calculations is the convenience and safety of movement; a person must walk without pressing against the railing due to tightness and without fear of putting his foot past the step.

Regarding the width of the stairs, there are several recommendations:

- the minimum size between handrails or other barriers is 80-90 cm, in which case only one person can move. It is not possible to drag furniture along such a structure;

- the optimal size for a staircase with winder steps is 100-125 cm. Two people can easily separate, moving towards each other;

- Comfortable movement zones are considered to be sizes from 125 m to 150 cm, when oncoming traffic is not obstructed in any way.

Tilt angle

Another parameter that is responsible for the ease of use of the staircase, and this has its own criteria: 1. If the structure is too steep, then more living space is saved. 2. If the structure is flat, then movement is more comfortable and safe.

The permissible slope angle of stairs for residential premises is in the range from 26 to 45 degrees. A steeper slope is considered hazardous and is used only for economic and industrial purposes.

Number of steps

This indicator cannot be certain and depends on the overall height of the structure and the height of the step. For example, if the floor height is 3 m, then dividing it by 15 cm - the average size of the riser - we get 20 steps.

It is also recommended to maintain an equal number of steps in two-flight structures, but in practice this is rarely the case, because other parameters have to be taken into account that go against the theory.

Stair pitch (step depth)

The most important rule to remember: the foot must be in full contact with the step, however, an error of several centimeters is allowed to clarify the dimensions of the structure.

- the minimum value is 100 mm, however, if you quickly ascend or descend such stairs, you can get injured;

- the most suitable dimensions are from 200 to 300 mm; the movement does not force you to strain and look every time where you put your foot.

If you need to increase the width of the steps, you can fix them with a slight offset, but not more than 40 mm, so as not to accidentally get caught when moving.

Stage No. 5 – detailed drawing and sketch

Before you start calculating a 180-degree rotating staircase, you need to create a design sketch. For a flight of stairs, the dimensions must be indicated on the sketch. Not only the design parameters, but also the room itself are applied to the paper. Be sure to mark the locations of windows, doors, etc. Some examples of drawings can be seen in the photos below.

Any consumer wants to have a comfortable and beautiful staircase. But in addition to these properties, the design must have reliability and high strength. Only in this case will the inhabitants be able to feel comfortable using it. We should not forget about the handrails, which act not only as a decorative element, but also as excellent protection against falls when walking up the stairs.

Design mistakes and expert advice (1 video)

Interesting staircase models (48 photos)

Types of wooden spiral staircases in a private house, made by hand (with photo)

Depending on the method of supporting the steps, do-it-yourself wooden spiral staircases can be divided into four types.

Among the spiral staircases, there are right and left ones. Right-handed staircases are most often built, since, according to research, most people place their right foot first on the step, both when ascending and descending. Therefore, the twisting of spiral staircases occurs counterclockwise.

Right and left spiral staircases, built with your own hands, are shown in these photos:

The steps of the spiral staircase are wedge-shaped and winder. One end of the step is narrow, the other, on the contrary, wide. There are certain building standards, according to which the narrow end of the step must be at least 100 mm wide, and the other must be no more than 400 mm wide (in practice, the wide part of the winder step is usually 410-500 mm).

A spiral staircase can be either main or auxiliary. In the first case, the tread must be at least 900 mm long, and the diameter of the opening in the ceiling must be at least 2000 mm. Such dimensions are necessary so that not only a staircase, but also a fence with a handrail can fit into the opening. To make a spiral staircase with your own hands, reducing the diameter of the opening is possible only by reducing the distance between the handrail and the edge of the opening. It is advisable to make it no more than 100 mm. But because of this, difficulties may arise when using the stairs, since the hand, when leaning on the handrail, will be constantly at risk of injury.

The length of the steps, which would be most convenient for walking, will be less than 1/2 of the diameter indicated in the plan. For example, let’s take as a basis the design of a staircase with a diameter of 2000 mm, then, dividing this value by 2, we should get a step with a length of 1000 mm. But it is necessary to take into account that a certain part of the tread will disappear on one side due to the central support, on the other side it will be “taken away” by the fence (railing posts). Therefore, the actual tread length will be only 800-900 mm.

To build a spiral staircase as the correct technology suggests, keep in mind that in this design all the steps are winders, and they are installed in a fan-shaped manner, that is, the treads located closer to the counter will hang over each other and turn about a third of the part step into an unused area. Thus, approximately 500-600 mm of tread can be actively used. Only one person can climb such a staircase; there won’t be enough room for two.

If you are building a spiral staircase in your house with your own hands and you know that it will not be used often (for example, a structure leading to an attic or basement), then the diameter of the opening can reach 1400 mm, and the length of the tread can be increased to 550-600 mm.

Before making a spiral staircase project, you need to find out the dimensions of the opening in the ceiling

This is important for determining the tread length. When calculating the number of steps, you should find out what the distance between floors is

The angle of twist of the stairs is no less important. Having walked a full circle along it, you can find yourself at the same point from which the movement began. This is not so important if the spiral staircase is located in the middle of the room, since the entrance to and exit from it can be oriented in any direction. It’s another matter if you plan to build a structure near a wall or in a corner, since in this case the direction of movement and the place of entry and exit matter. It is possible that the design of such a structure should be based on an angle other than 360°. Also, when constructing a staircase, it is necessary to take into account the distance to the ceiling if it is done in a house with an attic. This is necessary so that during operation of the structure you do not hit your head on the ceiling.

The next section of the article is devoted to how to calculate the dimensions of a spiral staircase.

Staircase with a 90 degree turn - how to make it yourself

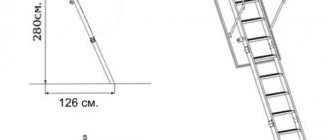

We will show how to make a winder staircase using an example of a design with the following parameters:

- the length of the staircase opening is 2294 mm;

- width - 930 mm;

- ceiling height - 2683 mm.

The corner staircase consists of two flights. There are 8 steps in a long flight, and the top one coincides with the landing of the second floor. There are 2 steps in the lower flight. And three winder steps, the angle of rotation of which is 30°. The wooden staircase project will look like this:

A wooden staircase with a turn is made on two stringers with dimensions of 50x300x3000 mm, one of which is mounted on the wall, and the other on a support post with dimensions of 100x100x2500 mm. It is also necessary to purchase steps measuring 900x300x40 mm, a turning platform 900x900x40 mm, from which the winder steps will be cut, and balusters.

A wooden staircase with winder steps, having this shape and parameters, is manufactured in several stages.

Making stringers

First, you should prepare a template, which is a right triangle, the legs of which are equal to the depth of the tread and the height of the riser. For convenience, the triangle should be secured to the guide rail, as in the photo. Using this template, mark the stringer and cut out the excess with a circular saw. It must be remembered that in the thinnest part the width of the stringer should not be less than 15 cm.

Next, you can begin installing the support pillar. First, you need to hollow out a groove in the post into which the stringer will be inserted.

In the corner we build an improvised support structure, which will expand the wall stringer and serve as the basis for the winder steps.

We secure the upper ends of the stringers with metal corners.

After the load-bearing elements are secured, the following should appear:

When installing stringers, it is important to monitor the level so that subsequently the steps lie strictly horizontal. The most common mistake made by inexperienced craftsmen is that parallelism to the floor is taken as horizontal.

But the floor may be uneven, so this parameter must be determined only using a level.

How to make winder steps

Winder steps are cut from a rectangular board 900x900x40 mm. For a staircase with a 90-degree turn, three steps will be enough. To make them, we divide the board into three parts with lines coming out of one corner. We adjust the cut steps to length.

Having decided which varnish to cover the stairs, apply at least 3 layers to the steps.

Installation of stairs with winder steps

To secure the winder steps, grooves are cut into the pillar, the height of which is slightly less than the thickness of the board. This way we will ensure reliable fixation of the steps on the inside of the stairs. And on the outside, we are modifying the supporting structure so that steps can be placed on it.

From the outside of the flight of stairs, the turning steps are screwed to the supporting frame using self-tapping screws. The inner ends of the steps are inserted into the cuts and, to strengthen the structure, are glued with PVA glue mixed with sawdust.

Next, we attach the straight steps using long self-tapping screws with recessed heads. The lower flight of stairs will be made on a bowstring to hide the protruding corner of the winder step.

We cut the end of the bowstring at a right angle to the floor so that the entrance pillar can be installed.

Installation of railings

Now you need to install the balusters. Sometimes they are attached from below through the steps using self-tapping screws, but this method is unreliable. It is better to use dowels - cylindrical wooden rods.

To do this, a hole is drilled in the steps, the diameter of which is slightly smaller than the cross-section of the dowel, and filled with glue

A similar hole is made in the balusters, and it is very important that it is exactly in the center. If the baluster has a rectangular shape, then the center is determined as the intersection of the diagonals of the rectangle

Try to drill the holes as accurately as possible so that they turn out strictly vertical, because the position of the balusters will depend on this.

A rope is stretched between the first and last pillars, along which the angle of inclination of the railing is marked on all balusters. Next, according to the applied marks, the tops of the racks are cut off. In this way we prepare the balusters for installing the handrail.

The handrail can be secured using simple self-tapping screws (hidden), and the attachment points can be hidden with putty.

The single-flight staircase with winder steps is ready. This is what we got.

With this manufacturing method, the load on the lower turning stage will act along the grain of the wood, which is undesirable, as it weakens the structure. In this case, it will be necessary to additionally strengthen the step with support, which is what we did.

Attaching support posts to the floor

Support pillars are vertically located load-bearing elements that form the basis of the frame of the lower part of the staircase. They provide support for the winder steps (landing) and the stringer (string).

There are no special requirements for the wood of the part - the main thing is that it is uniform, without cross-layers and large knots. Typically made from the same type of wood as the rest of the staircase.

In order for the future structure to be strong and reliable, the pillars must be firmly secured. This can be done using steel angles, studs, zip bolts, wood glue and other devices - there are a lot of options.

Finally, it is recommended to connect the columns with supporting stiffening beams.

Of course, by this time, all the technological holes and grooves for other elements of the staircase should already be made in the pillar structure.

- suitable fasteners;

- channel;

- welding machine;

- screwdriver

What materials can the assembly be made from?

At the moment, stairs of this type can be installed in cottages, made of:

- wood;

- metal

Both of these varieties are quite popular among owners of country houses. Wooden stairs are usually installed in buildings with a classic or “folk” interior. Such structures may have carved railings, be painted in different colors, etc.

Metal stairs, made of galvanized steel, are installed in houses decorated in any of the modern styles. Structures with forged railings, like wooden ones, are often installed in cottages with a classic design.

Step-by-step construction instructions

Finally, you can start making the staircase itself. The scheme described below is designed for a person who knows what it is to “weld metal”, but is not ready to do something complex, with an abundance of details.

So, a metal staircase is assembled both separately from the site and locally.

The second option is often preferable.

This scheme is standard, other options can be adjusted to it: with a ramp, with wooden steps, with stone, tiled ones. Naturally, the porch should be in harmony with the house, and the staircase should be a harmonious beginning of the structure. To do this, you need to carefully choose the design of the future structure, looking closely at other options for stairs for a porch in a country house or in a country house.

Calculation of stairs with a 90° turn

Calculation of stairs with a 90° turn

Please indicate the required dimensions in millimeters

Y – height from the floor level of the first floor to the floor level of the second floor

P – number of steps + platform

Calculation of stair comfort is calculated using a formula based on step length.

The length of a person’s step ranges from 60 to 66 cm, with an average of 63 cm.

A comfortable staircase corresponds to the formula: 2 step heights + step depth = 63±3 cm.

The depth of the steps of the stairs must correspond to shoe size 45 - no less than 28-30 cm.

The lack of depth can be compensated by the protrusion of the step.

The height of the step should be up to 20-25 cm.

The drawings show the general dimensions of the stairs, the markings of the top of the steps on the strings, the corners of the steps and the main dimensions of the steps themselves.

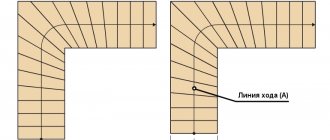

Method of proportions

Separately, there is a method of calculation by proportions, based on the fact that the space in the turning area should be evenly distributed.

Since these models differ in different width parameters along the length, you will need to select the center line as a guide, and the width of the tread is formed in relation to current standards.

For the design diagram, a horizontal projection of the future building is taken, through the marching bend of which a straight line is drawn. The boundaries of the last straight step are marked along the top and bottom of the segment, and then a mark is placed for the beginning of the turn.

Based on the size of the center line, determine the appropriate size of the tread, which is connected with a straight line to the reference point.

This method helps to highlight the boundaries of each step, which should be more massive than the main elements.